#chemical facilities

Text

Little P.Eng. Engineering for Piping Stress Analysis Using AutoPIPE across Canada and USA

Piping systems are the lifelines of industrial plants, carrying fluids and gases to various components and ensuring the smooth operation of critical processes. However, the design and analysis of piping systems require meticulous attention to detail to prevent catastrophic failures that can lead to safety hazards and costly downtime. In Canada and the USA, engineers and professionals turn to tools like AutoPIPE for piping stress analysis, and Little P.Eng. Engineering has emerged as a trusted name in providing expert services for this critical task.

Little P.Eng. Engineering for Piping Stress Analysis Using AutoPIPE across Canada and USA

The Significance of Piping Stress Analysis

Piping systems in industrial plants, refineries, power plants, and chemical facilities are subjected to a wide range of stresses during their operational lifespan. These stresses can result from various sources, including temperature fluctuations, pressure changes, seismic activity, and the weight of the piping itself. Piping stress analysis is the process of evaluating and predicting how these stresses affect the integrity and safety of the piping system.

Here are some key reasons why piping stress analysis is of paramount importance:

Safety: Ensuring the safety of personnel and assets is the primary concern in any industrial setting. Piping failures can lead to leaks, ruptures, and even explosions, posing a significant risk to human lives and the environment.

Compliance: Regulatory bodies in Canada and the USA have strict standards and codes governing the design and operation of piping systems. Compliance with these standards is mandatory to avoid legal issues and penalties.

Reliability: Reliable piping systems are essential for continuous production and minimal downtime. Stress analysis helps identify potential weaknesses and areas of concern, allowing for proactive maintenance and improvements.

Cost Savings: Early detection of piping issues through stress analysis can prevent costly repairs, replacements, and unplanned shutdowns.

AutoPIPE: A Powerful Piping Stress Analysis Tool

AutoPIPE is a state-of-the-art software solution designed for the analysis and design of piping systems. Developed by Bentley Systems, it offers a comprehensive set of tools and features for performing piping stress analysis with precision and efficiency. AutoPIPE is widely used in the engineering and construction industry across Canada and the USA due to its versatility and reliability.

Key capabilities of AutoPIPE include:

Stress Analysis: AutoPIPE can calculate stresses, displacements, and forces within piping systems under various load conditions, including thermal expansion, pressure, and external loads. It considers complex interactions between different components and materials.

Code Compliance: The software is equipped with a vast library of international piping codes and standards, ensuring that the analysis results align with industry regulations in Canada and the USA. Engineers can easily select the appropriate code for their projects.

Advanced Modeling: AutoPIPE allows for the creation of detailed 3D models of piping systems, including components such as elbows, tees, and flanges. This level of detail is crucial for accurate analysis.

Material Database: Users can access a comprehensive material database, which includes a wide range of materials commonly used in piping systems. This simplifies the process of specifying material properties.

Post-Processing and Reporting: AutoPIPE generates detailed reports and graphical representations of analysis results, making it easier for engineers to communicate findings and make informed decisions.

Little P.Eng. Engineering: Your Trusted Partner

While AutoPIPE is a powerful tool for piping stress analysis, it requires expertise and experience to harness its full potential effectively. This is where Little P.Eng. Engineering steps in as a trusted partner for clients across Canada and the USA. With a team of highly skilled and certified engineers, Little P.Eng. Engineering offers a range of services that complement and enhance the capabilities of AutoPIPE.

Let's explore the key aspects that make Little P.Eng. Engineering a reliable choice for piping stress analysis:

Expertise: The engineers at Little P.Eng. Engineering have years of experience in the field of piping stress analysis. They possess in-depth knowledge of industry codes and standards, ensuring that all analyses are compliant and accurate.

Customized Solutions: Every project is unique, and Little P.Eng. Engineering tailors its services to meet the specific needs of clients. Whether it's a complex refinery system or a simple water distribution network, the team can handle it all.

Seamless Integration: Little P.Eng. Engineering seamlessly integrates AutoPIPE into its workflow, ensuring that clients receive the full benefits of this powerful software. The combination of software and expert analysis enhances the quality and reliability of results.

Cost-Effective Solutions: By detecting and addressing potential issues early in the design phase, Little P.Eng. Engineering helps clients avoid costly rework and repairs during construction or operation. This proactive approach results in significant cost savings.

Timely Delivery: In the fast-paced world of engineering and construction, timing is critical. Little P.Eng. Engineering is known for its commitment to meeting deadlines and delivering results on schedule, helping clients stay on track with their projects.

Case Studies: Little P.Eng. Engineering in Action

To better understand the real-world impact of Little P.Eng. Engineering's services using AutoPIPE, let's examine a couple of case studies from projects conducted in both Canada and the USA:

Case Study 1: Canadian Refinery Expansion

A major refinery in Canada was planning a significant expansion project to increase its production capacity. Little P.Eng. Engineering was contracted to perform a comprehensive piping stress analysis using AutoPIPE. The project involved intricate piping networks, including high-temperature lines, complex fittings, and multiple load scenarios.

The engineers at Little P.Eng. Engineering utilized AutoPIPE's advanced modeling capabilities to create a detailed 3D representation of the refinery's piping system. They then conducted a thorough stress analysis, considering factors such as thermal expansion, pressure variations, and seismic loads.

The analysis identified critical areas where piping stresses exceeded acceptable limits, allowing for proactive design modifications. By addressing these issues early in the project, costly delays and potential safety risks were avoided. The refinery expansion project was completed on schedule, and the client praised Little P.Eng. Engineering for its expertise and contribution to the project's success.

Case Study 2: USA Power Plant Retrofit

In the USA, a power plant undergoing a retrofit faced the challenge of integrating new piping systems into the existing infrastructure. The client turned to Little P.Eng. Engineering for its expertise in piping stress analysis using AutoPIPE.

Little P.Eng. Engineering's team began by conducting a site assessment and a thorough review of the plant's existing piping systems. They then used AutoPIPE to model the proposed modifications and analyze the stress implications. The analysis revealed potential conflicts with existing structures and equipment that could lead to operational issues and safety concerns.

Working closely with the client, Little P.Eng. Engineering provided recommendations for design changes and rerouting of piping to mitigate stress-related problems. The collaborative approach ensured that the retrofit project progressed smoothly, with minimal disruptions to plant operations.

Conclusion

Piping stress analysis is a critical component of ensuring the safety, reliability, and compliance of industrial piping systems in Canada and the USA. AutoPIPE, a powerful software solution, plays a pivotal role in this process by providing advanced analytical capabilities. However, to maximize the benefits of AutoPIPE, the expertise of professionals like Little P.Eng. Engineering is indispensable.

Little P.Eng. Engineering's commitment to excellence, combined with their extensive experience and seamless integration of AutoPIPE, makes them the go-to partner for clients seeking top-notch piping stress analysis services. Through case studies, we have seen how their expertise has contributed to the success of projects in both Canada and the USA, saving clients time and money while ensuring the integrity of their piping systems.

As industries in Canada and the USA continue to evolve and expand, the demand for reliable piping stress analysis services remains high. Little P.Eng. Engineering stands ready to meet this demand, providing innovative solutions that contribute to the growth and success of various industries across North America. With a dedication to safety, compliance, and cost-effective solutions, they are a driving force behind the reliability and efficiency of piping systems in the region.

Pipe Stress Analysis Program AutoPIPE: Unlocking Its Capabilities

Piping systems are the arteries of industrial plants and facilities, ensuring the smooth flow of fluids and gases critical to various processes. The integrity and reliability of these systems are paramount, as any failure can lead to catastrophic consequences, including safety hazards and costly downtime. To safeguard these systems, engineers and professionals across the globe rely on advanced pipe stress analysis programs like AutoPIPE. In this comprehensive article, we will delve deep into the capabilities of AutoPIPE, covering static and dynamic analysis, a range of international codes and standards, and additional features that make it an indispensable tool in the world of piping engineering.

Introduction to AutoPIPE

AutoPIPE, developed by Bentley Systems, is a state-of-the-art software solution designed for the analysis and design of piping systems. Its versatility, accuracy, and compliance with industry standards have made it a trusted choice among engineers and organizations worldwide. AutoPIPE empowers engineers to assess the behavior of piping systems under various conditions, ensuring they meet safety standards, code requirements, and operational needs.

Static Analysis with AutoPIPE

Linear Analysis

Linear analysis is the foundation of pipe stress analysis, and AutoPIPE excels in this fundamental aspect. It performs linear static analysis to calculate stresses, strains, and deflections in piping systems under a variety of loads, including gravity, temperature, pressure, static earthquake, wind, and snow. Let's delve into each of these static loadings:

Gravity: AutoPIPE accounts for the weight of the piping system and its components, ensuring that stress due to gravity is properly considered.

Temperature: Temperature changes can cause significant stress in piping systems due to thermal expansion or contraction. AutoPIPE accurately predicts these effects.

Pressure: Pressure variations within the system, such as startup and shutdown, are analyzed to assess their impact on pipe stress.

Static Earthquake: In regions prone to seismic activity, the software performs seismic analysis according to the relevant seismic code, assessing the system's response to ground motion.

Wind and Snow: AutoPIPE evaluates the stresses induced by wind loads and the weight of accumulated snow, crucial in structures exposed to harsh environmental conditions.

Non-Linear Analysis

While linear analysis covers a wide range of scenarios, there are instances where non-linear behavior must be considered. AutoPIPE supports non-linear analysis, enabling engineers to assess situations such as plastic deformation, large deflections, and material non-linearities. This capability is particularly valuable in extreme loading conditions or when dealing with materials with nonlinear stress-strain behavior.

Dynamic Analysis with AutoPIPE

In addition to static analysis, AutoPIPE offers advanced capabilities for dynamic analysis, crucial for assessing the behavior of piping systems under time-varying loads. Here are some of the dynamic analysis features provided by AutoPIPE:

Modal Analysis

Modal analysis helps identify the natural frequencies and mode shapes of the piping system. This information is crucial for understanding the system's dynamic behavior and resonance frequencies.

Response Spectra Analysis

For seismic events and seismic anchor movement, AutoPIPE can perform response spectra analysis. This method assesses the system's response to ground motion, allowing engineers to design piping systems that can withstand seismic forces.

Time History Analysis

In scenarios involving fast-acting loads like slugs, fast-acting valves, or hammers, AutoPIPE conducts time history analysis. This analysis method considers the time-dependent nature of the loads to predict the system's response accurately.

Harmonic Analysis

Vibrations caused by oscillating loads can lead to fatigue and structural issues. AutoPIPE can conduct harmonic analysis to evaluate the effects of these vibrations on the piping system, helping engineers make necessary design modifications.

International Codes and Standards

AutoPIPE supports a wide range of international piping codes and standards, ensuring that analyses are conducted in compliance with industry regulations. Here is a list of some of the prominent codes and standards that AutoPIPE accommodates:

ASME B31.1: Power Piping

ASME B31.3: Process Piping

ASME B31.4: Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids

ASME B31.8: Gas Transmission and Distribution Piping Systems

ASME B31.12: Hydrogen Piping and Pipelines

EN 13480: European Standard for Metallic Industrial Piping

CSA-Z662: Canadian Standard for Oil and Gas Pipeline Systems

ISO14692: International Standard for Petroleum and Natural Gas Industries - Glass Reinforced Plastics (GRP) Piping

DNV F101: Design of Offshore Steel Structures, General (LRFD Method)

European Piping Codes: Including Sweden SPC, Norway TBKS 6, Russian SNIP, France SNCT & RCC-M, and United Kingdom BS 806

Additional Code Features

AutoPIPE offers a range of additional features to enhance compliance with codes and standards. Some of these features include:

ASME B31J Flexibilities

This feature allows engineers to assess the flexibility factors of piping components, ensuring that they meet the requirements of ASME B31J, a code used for evaluating the flexibility and stress intensification factors of pipe fittings.

Code Case N755 for HDPE

AutoPIPE incorporates Code Case N755, enabling engineers to perform stress analysis on High-Density Polyethylene (HDPE) piping systems as per ASME B31.3 and B31.1.

Basic Static Loading and Analysis

AutoPIPE handles a variety of basic static loading scenarios:

Gravity

It considers the weight of the piping and its components.

Temperature

AutoPIPE accurately predicts the effects of thermal expansion or contraction due to temperature changes.

Pressure

Pressure variations within the system are analyzed to assess their impact on pipe stress.

Static Earthquake

For regions prone to seismic activity, the software conducts seismic analysis according to the relevant seismic code.

Wind

AutoPIPE evaluates the stresses induced by wind loads, ensuring compliance with design requirements.

Snow

It accounts for the weight of accumulated snow, particularly important for structures in snowy regions.

Dynamic Loads

AutoPIPE's capabilities extend to dynamic loads, enabling engineers to assess complex scenarios:

Modal Analysis

This feature helps identify natural frequencies and mode shapes, providing critical insights into dynamic behavior.

Response Spectra for Seismic Events and Seismic Anchor Movement

AutoPIPE performs response spectra analysis, assessing the system's response to ground motion during seismic events.

Time History Analysis for Fast Acting Loads

Fast-acting loads, such as slugs and fast-acting valves, are accurately analyzed using time history analysis.

Harmonic Analysis of Vibrations

Vibrations caused by oscillating loads are evaluated through harmonic analysis to prevent fatigue and structural issues.

Buried Piping

For buried piping systems, AutoPIPE offers specialized features:

Soil Stiffness Calculator

Engineers can calculate soil stiffness to assess the interaction between buried pipes and the surrounding soil.

Soil Overburden Loads

The software considers the weight of soil overburden when analyzing buried piping.

Seismic Wave

AutoPIPE accounts for seismic waves that can affect buried piping systems.

Building Settlement

Settlement of nearby structures can impact buried piping, and AutoPIPE incorporates this consideration.

Upheaval Buckling

To prevent upheaval buckling in buried piping, AutoPIPE provides the necessary tools for analysis and design.

Offshore

AutoPIPE addresses the unique challenges of offshore piping systems:

Buoyancy

The software evaluates buoyancy forces, a critical factor in offshore piping design.

Wave Loading

AutoPIPE accounts for wave-induced loads on offshore structures.

Nuclear

In nuclear applications, AutoPIPE ensures compliance with stringent requirements:

ASME III Class 1, 2, and 3

It supports ASME III codes for nuclear piping, including Class 1 (NB), Class 2 (NC), and Class 3 (ND).

ASME Fatigue Analysis

AutoPIPE provides tools for ASME fatigue analysis, crucial for nuclear piping integrity.

QA Program and Compliance

The software's QA program has been in place since 1989 and complies with class 1, 2, 3, plus ASME NQA-1, NB, NC, ND codes, and ISO 9001.

Flange Design and Analysis

AutoPIPE supports flange design and analysis, ensuring that flanged connections meet the required standards and safety margins. It covers:

ANSI

ASME VIII Div 1 and 2

ASME III Appendix XI

Additional Loadings

AutoPIPE accommodates various additional loadings to provide a comprehensive analysis:

Hydrotest

It assesses stresses during hydrostatic testing, which is crucial to verify the integrity of the piping system.

Force Spectrum

The software can handle force spectra analysis, particularly relevant in systems subjected to varying loads.

Thermal Bowing

AutoPIPE predicts thermal bowing, helping engineers address potential issues due to temperature differentials.

Thermal Transient Analysis

In cases where temperature changes occur over time, thermal transient analysis is conducted to ensure accurate stress predictions.

Additional Features

AutoPIPE includes several additional features that streamline the pipe stress analysis process:

Spring Hanger Analysis

Engineers can analyze spring hanger supports, crucial for managing pipe movement and vibration.

Automatic Support Optimizer

AutoPIPE offers an automatic support optimizer to help engineers identify optimal support locations, minimizing stress and ensuring system integrity.

Creation of Digital, Customizable Stress Isometrics

The software allows for the creation of digital stress isometrics, aiding in communication and documentation of analysis results.

Interoperability

AutoPIPE seamlessly integrates with other engineering software and platforms:

Structural with STAAD and SACS

It can interface with structural analysis software like STAAD and SACS for comprehensive structural-piping interaction analysis.

Import from 3D CAD

AutoPIPE supports importing from various 3D CAD platforms, including OpenPlant, AutoPLANT, PlantSpace, SP3D, Plant 3D, PDS, PDMS, and Revit, simplifying the modeling process.

Nozzle Loads to AutoPIPE Vessel

For vessels connected to piping systems, AutoPIPE can calculate and transfer nozzle loads to AutoPIPE Vessel for vessel analysis.

Importing Time History FRC File

Time history data can be imported into AutoPIPE from external sources to perform dynamic analysis accurately.

Conclusion

AutoPIPE is a comprehensive and versatile pipe stress analysis program that caters to the diverse needs of engineers and organizations across the globe. With its robust static and dynamic analysis capabilities, support for a multitude of international codes and standards, and additional features that streamline the analysis process, AutoPIPE has established itself as an indispensable tool in the field of piping engineering. As industries continue to evolve and face new challenges, AutoPIPE remains at the forefront, empowering engineers to design, analyze, and optimize piping systems with confidence, ensuring the safety, reliability, and efficiency of critical infrastructure.

The listing below indicates a few of Meena Development’s most commonly served industries.

Steel and Metals Industry

Energy and Power Generation Industry

Water and Wastewater Industry

Oil & Gas Industry

Chemicals and Plastics Industry

Pulp & Paper Industry

Facility Services

Residential Buildings Sector

Hospitality and Hotel Sector

Commercial Buildings Sectors

Sports and Stadia Buildings Sector

Education Buildings Sector

Government Buildings Sector

Hospitals Engineering Services

Biotech / Pharmaceutical – Engineering Services

Food & Beverage – Engineering Services

Tags:

Canada

USA

Little P.Eng. Engineering

Compliance

Safety

3D modeling

Piping stress analysis

Thermal expansion

Regulatory standards

AutoPIPE

Retrofit

Material properties

Infrastructure

Industrial piping

Reliability

Cost savings

Refinery

Power plant

Chemical facilities

Seismic analysis

Engineering codes

Expertise

Proactive maintenance

Site assessment

Design modifications

Analytical capabilities

Project success

Compliance with industry regulations

Risk mitigation

Timely delivery

Pipe Stress Analysis Services

Engineering Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Canada#USA#Little P.Eng. Engineering#Compliance#Safety#3D modeling#Piping stress analysis#Thermal expansion#Regulatory standards#AutoPIPE#Retrofit#Material properties#Infrastructure#Industrial piping#Reliability#Cost savings#Refinery#Power plant#Chemical facilities#Seismic analysis#Engineering codes#Expertise#Proactive maintenance#Site assessment#Design modifications#Analytical capabilities#Project success#Compliance with industry regulations#Risk mitigation#Timely delivery

0 notes

Text

Exclude completely the possibility of the use of chemical weapons.

The Chemical Weapons Convention’s aim is “to exclude completely the possibility of the use of chemical weapons”. It does so by ensuring that all existing stockpiles of chemical weapons are destroyed, and by putting in place a framework – made up of a set of binding obligations on States Parties and a verification regime run by the Technical Secretariat – to ensure that chemical weapons do not re-emerge.

Chemical weapons may re-emerge in a number of ways: through state-sponsored programmes, through the actions of terrorist or other criminal groups, or through lone individuals. Chemical weapons may be produced by repurposing existing chemical facilities or they may be made on a smaller scale in purpose-built laboratories or even domestic settings. The OPCW works in a variety of ways to prevent these scenarios from happening.

#OPCW#stockpiles of chemical weapons#Chemical weapons convention#chemical facilities#terrorist or other criminal groups

0 notes

Text

La sad deve mettersi a limonare duro sul palco per fare scandalo mi disp

#Sanremo#sanremo 2024#molto facile fare gli alternativi. almeno Achille Lauro e rosa chemical i baci gay li facevano

18 notes

·

View notes

Text

i wanna do etching again so baddddd i also wanna do risograph but that's more feasible even though i cant print it myself

#i wish could go back to nyc so i can use my school's facilities#i love breathing in chemicals#and touching chemicals.#and cranking the aquatint box so hard i wreck my elbows#and coming out with a shitty print at the end of it

2 notes

·

View notes

Note

🖊🖊🖊🖊 for diana ofc

a fun little fact about diana is that she wears her watch with the face on the inside of her wrist

while working for umbrella (well, undercover for the rival company, that is), diana's employment was never common knowledge to the public – because why would a pharmaceutical company need a herpetologist? instead, she simply held a position as a researcher at raccoon university, and would occasionally do lectures, but for the most part she would just take the cable car underground to the nest

when diana collaborated with the connections through h.c.f. in the early 2000s, they named one of the d-type bioweapons after her

diana saw a lot of her younger self in sherry when they first met due to the similarities in their situations with their parents, and the way she behaved around both herself and albert. despite her dislike of children, she couldn't help but feel for her and even came to enjoy when she would stay over on occasion (i'd love if my brain would let me finish the rewrite of their first meeting because i touch on all of this in there and diana's thought process ough)

#asks.#denerims#oc: diana#thank youuu emily!! ilysm 💖💖#i think for the diana asks some things are going to be like things i have probably mentioned before but just like a lil more in depth...#you know how i am. or like things i've deleted since posting them. it's fine. i'm normal about her!! but many lil tidbits in my brain i can#share about her too. just not sure if i have enough rn for the couple of asks i got with lots of pens lmaooo head empty and i've talked#about her SO much that there's not much that's not around here somewhere on my blog in previous ask games oopsies or on her page#also ngl i'm forever mad that in the 3 remake they made nest 2. because the university lab was where the vaccine research for the#t-virus was done when things went to shit and they named that daylight. and then for the creating weapons to combat the b.o.w.s and also#test the bioweapons against one another was done at the r&d centre... i'm fine i'm okay it's okay. capcom can i pleaseeee have an outbreak#remake!!! i miss her!!!! but yeah that's weird cause nest 2 didn't exist originally and the nest was a lot bigger?? it's fine.#anyways she just did her typical like Legal research with herpetology and virology there as a front but then she'd take the cable car#underground to the nest because my rules. if travel to the nest was available by cable cars from the waste facility / treatment plant /#arklay labs / rpd sewers & training facility then i can add another one beneath the university :) ALSO in outbreak they travelled to the#actual nest from the hospital and not nest 2 :) so yes. underground system for employees to access all facilities basically 💅🏼#i originally had her work at the chemical plant as her front but then i went no that would make no sense for her background and like both#of the birkins were already there so it would just be too much going on there and needed to split them up#OH also. sorry omg i talk so much but you know me <3 the part about her working at the university. i literally had this mentioned in that#fic where she went over to the s.t.a.r.s. office and um things happened but i cut that off early cause i liked it ending where it did

8 notes

·

View notes

Text

putting grocery store gelatin in the million dollar instrument to either be really funny or make a very important point

#half the papers on this subject use bizarre chemicals nobody in the entire department uses#the other half uses tissue from organisms#(and puts it in heavy water)#we need something to reference to make sure we're running the experiment right#since the head of the nmr facility sure doesn't know#so. jello time.#for the collagen#(we are not a biochemistry department we don't just have collagen)#if it doesn't match the collagen paper it'll just be a funny story#but if it does it'll be very useful#(it doesn't have to be a pure reagent since we're just trying to do preliminary method validation)#aka: Have We Set The Delays Right On This Thing???

5 notes

·

View notes

Text

Examining lunar soil for moon-based construction - Technology Org

New Post has been published on https://thedigitalinsider.com/examining-lunar-soil-for-moon-based-construction-technology-org/

Examining lunar soil for moon-based construction - Technology Org

Most people are familiar with the iconic photograph of astronaut Buzz Aldrin’s boot print on the moon’s surface. But what, exactly, is in the soil that holds the imprint of that famously “small step for man”?

Sample of a lunar soil simulant in Steven Jacobsen’s laboratory. Illustration by Shane Collins

The answer to this question is more than a fleeting curiosity — it’s essential knowledge for NASA’s Artemis program, which aims to build a permanent base on the moon. While researchers understand the general makeup of the lunar soil, Northwestern University mineralogist Steven Jacobsen has received funding from NASA’s Marshall Space Flight Center to unravel the mystery of the dubious dust further.

Because the cost of bringing traditional building materials from Earth is incredibly high, NASA has partnered with robotics and artificial intelligence company ICON Technology Inc. to explore new methods for building a lunar outpost using the moon’s own resources. But before ICON can build structures with the moon’s soil, the team must first understand the soil’s exact composition, which can change drastically from one sample to the next.

To characterize these samples, Jacobsen is working closely with his former student Katie Koube, now a materials scientist at ICON, to analyze various samples using Northwestern’s facilities. Their end goal is to create a library of potential sample compositions, which will be used to optimize parameters for the building process.

“Off-world construction comes with many challenges,” said Jacobsen, the project’s principal investigator. “The moon’s soil is not like that on Earth. On the moon, soil is formed from meteoroid impacts that have crushed the surface. So, the moon is essentially coated in a thick layer of pulverized flour. The types of minerals and glass found in lunar soil depend on many factors. The material can vary widely within even a small area.”

Jacobsen is a professor of Earth and planetary sciences at Northwestern’s Weinberg College of Arts and Sciences. He also is a faculty affiliate with the Paula M. Trienens Institute for Sustainability and Energy and the Center for Engineering Sustainability and Resilience. Members of the project also include Laura Gardner and Tirzah Abbott, who are Ph.D. candidates in Jacobsen’s lab.

The dangers of dust

With plans to travel back and forth to the moon more regularly, NASA first needs a reliable landing pad. Otherwise, every time a lunar lander makes contact with the moon’s surface, it will kick up destructive dust that could gum up equipment and damage the surrounding habitat.

“Each particle of dust on the moon is jagged and angular,” Koube said. “When you think of grains of sand on Earth, they are rounded because weathering removes all those rough edges. Without weathering, the particles remain bumpy and sharp. So, if a rocket lands directly on the moon’s surface, it stirs up abrasive dust that basically sandblasts the whole area.”

In November 2022, NASA selected ICON for a $57.2 million grant to develop lunar construction technology. The contract builds upon previous NASA and Department of Defense funding for ICON’s Project Olympus to research and develop space-based construction systems to support planned exploration of the moon and beyond. ICON’s Olympus system is intended to be a multipurpose construction system primarily using local lunar and Martian resources as building materials to further the efforts of NASA as well as commercial organizations to establish a sustained lunar presence. ICON is already using its advanced 3D-printing technology to build homes on Earth. By putting multipurpose in situ resource utilization (ISRU)-based lunar construction systems on the moon, the team aims to use lunar resources as the building blocks for construction.

“It’s not feasible to send traditional Earth-based construction equipment and materials to the moon,” Jacobsen said. “The payload would be too heavy. So, this plan is a lot more practical. Just as the first bricks on Earth were made out of terrestrial soil, the first bricks on the moon will be made out of lunar soil.”

Simulated soil samples

After ICON received NASA’s funding, Koube, who graduated with a dual degree from Northwestern’s materials science and Earth and planetary sciences programs in 2014, contacted Jacobsen to lead sample analysis. The pair assembled a team that works with NASA’s Marshall Space Flight Center in Huntsville, Alabama, under the Space Technology Mission Directorate’s Moon to Mars Planetary Autonomous Construction Technologies (MMPACT) project.

At Northwestern, analysis is already underway. Gardner and Abbott currently are using various microscopy techniques to analyze eight lunar simulants — faux moon soil that is designed to mimic the real thing — and synthetic plagioclase, a brittle, greyish-white mineral that is a major constituent of moon rock. Then, the team will compare the lunar simulants to actual samples collected from the Apollo missions.

“Of course, we know from Apollo missions what’s in lunar dirt — and that it’s very heterogenous (or variable),” Jacobsen said. “Our job is to anticipate the likely variability in lunar soil and come up with a way to measure it on the fly, onboard the 3D printer.”

So far, the researchers have noticed vast differences among the lunar simulants. In some minerals, the team has detected hydrogen — a component of water, which is not abundant in minerals on the moon. They also are on the lookout for mineral impurities in the simulants that are not expected on the lunar surface. The team can then focus on materials and chemical variations that the construction processes are more likely to encounter.

No scoop is the same

After determining variability in realistic samples, the researchers will probe how the composition of dirt can affect the melting process used in robotic construction. Once on the moon, ICON’s multi-purpose ISRU-based lunar construction systems will scoop up lunar soil and melt it for printing. After printing, the melted dirt will harden and cool into a ceramic material.

“On Earth, you can gather clay and fire it in a kiln to make ceramics,” Jacobsen said. “But the properties of lunar soil are such that it needs to be melted first. Different minerals in lunar dirt melt at different rates, so the 3D-printing process is very sensitive to changes in mineralogy.”

And, of course, no sample is the same. One scoop of lunar dirt might have a different melting point than the next scoop. The 3D-printing technology needs to be nimble enough to know how to handle these subtle differences. That’s where Jacobsen’s sample library comes into play. By enabling the 3D printer to be prepared for all potential compositions, it can perform diagnostics of each scoop and then adjust its laser parameters for heating and cooling.

“Without understanding the characteristics of the soil, it’s difficult to understand the variability of the final printed materials,” Jacobsen said. “Using the library that we create from simulants — cross-checked against the lunar soil — the printer will know how to process each piece to produce the best ceramic. That detailed library of information will play a part in making the imagined outpost a reality.”

Source: Northwestern University

You can offer your link to a page which is relevant to the topic of this post.

#2022#3d#Analysis#Angular#Artemis Program#artificial#Artificial Intelligence#Arts#Astronomy news#Building#ceramics#change#chemical#college#Composition#construction#cooling#course#curiosity#defense#diagnostics#dust#earth#energy#engineering#equipment#Facilities#Faculty#flight#focus

0 notes

Text

Government Concerned About Chemical Facility Security: Urgent Renewal Needed

The government's Chemical Facility Anti-Terrorism Standards program has expired, leaving chemical facilities and national security at risk. Urgent action from Congress is needed to address the gaps and prevent terrorists from gaining access to dangerous chemicals.

#headline horizon#news#latest news#chemical facility security#Department of Homeland Security#renewal

0 notes

Text

0 notes

Text

Control the International Transfers of Chemicals!

The States Parties to the Convention also have obligations when they export or import scheduled chemicals. There are two basic elements to the Convention’s regime concerning international transfers of chemicals: monitoring transfers between States Parties, and restrictions on trade with non-States Parties.

In brief, Schedule 1 and 2 chemicals may only be transferred between States Parties to the Convention. Schedule 3 chemicals may only be transferred to non-States Parties if the recipient provides an end-use certificate and pledges not to transfer them onward. All transfers of scheduled chemicals must be declared to the OPCW Technical Secretariat.

#international transfers of chemicals#chemical elements#chemical compounds#chemical facilities#chemical equipments#opcw

0 notes

Text

Things Biden and the Democrats did, this week #13

April 5-12 2024

President Biden announced the cancellation of a student loan debt for a further 277,000 Americans. This brings the number of a Americans who had their debt canceled by the Biden administration through different means since the Supreme Court struck down Biden's first place in 2023 to 4.3 million and a total of $153 billion of debt canceled so far. Most of these borrowers were a part of the President's SAVE Plan, a debt repayment program with 8 million enrollees, over 4 million of whom don't have to make monthly repayments and are still on the path to debt forgiveness.

President Biden announced a plan that would cancel student loan debt for 4 million borrowers and bring debt relief to 30 million Americans The plan takes steps like making automatic debt forgiveness through the public service forgiveness so qualified borrowers who don't know to apply will have their debts forgiven. The plan will wipe out the interest on the debt of 23 million Americans. President Biden touted how the plan will help black and Latino borrowers the most who carry the heavily debt burdens. The plan is expected to go into effect this fall ahead of the election.

President Biden and Vice-President Harris announced the closing of the so-called gun show loophole. For years people selling guns outside of traditional stores, such as at gun shows and in the 21st century over the internet have not been required to preform a background check to see if buyers are legally allowed to own a fire arm. Now all sellers of guns, even over the internet, are required to be licensed and preform a background check. This is the largest single expansion of the background check system since its creation.

The EPA published the first ever regulations on PFAS, known as forever chemicals, in drinking water. The new rules would reduce PFAS exposure for 100 million people according to the EPA. The Biden Administration announced along side the EPA regulations it would make available $1 billion dollars for state and local water treatment to help test for and filter out PFAS in line with the new rule. This marks the first time since 1996 that the EPA has passed a drinking water rule for new contaminants.

The Department of Commerce announced a deal with microchip giant TSMC to bring billions in investment and manufacturing to Arizona. The US makes only about 10% of the world's microchips and none of the most advanced chips. Under the CHIPS and Science Act the Biden Administration hopes to expand America's high-tech manufacturing so that 20% of advanced chips are made in America. TSMC makes about 90% of the world's advanced chips. The deal which sees a $6.6 billion dollar grant from the US government in exchange for $65 billion worth of investment by TSMC in 3 high tech manufacturing facilities in Arizona, the first of which will open next year. This represents the single largest foreign investment in Arizona's history and will bring thousands of new jobs to the state and boost America's microchip manufacturing.

The EPA finalized rules strengthening clean air standards around chemical plants. The new rule will lower the risk of cancer in communities near chemical plants by 96% and eliminate 6,200 tons of toxic air pollution each year. The rules target two dangerous cancer causing chemicals, ethylene oxide and chloroprene, the rule will reduce emissions of these chemicals by 80%.

the Department of the Interior announced it had beaten the Biden Administration goals when it comes to new clean energy projects. The Department has now permitted more than 25 gigawatts of clean energy projects on public lands, surpass the Administrations goal for 2025 already. These solar, wind, and hydro projects will power 12 million American homes with totally green power. Currently 10 gigawatts of clean energy are currently being generated on public lands, powering more than 5 million homes across the West.

The Department of Transportation announced $830 million to support local communities in becoming more climate resilient. The money will go to 80 projects across 37 states, DC, and the US Virgin Islands The projects will help local Infrastructure better stand up to extreme weather causes by climate change.

The Senate confirmed Susan Bazis, Robert White, and Ann Marie McIff Allen to lifetime federal judgeships in Nebraska, Michigan, and Utah respectively. This brings the total number of judges appointed by President Biden to 193

#Thanks Biden#Joe Biden#student loans#student loan debt#debt forgiveness#gun control#forever chemicals#PFAS#climate change#green energy

3K notes

·

View notes

Text

The Klamath River’s salmon population has declined due to myriad factors, but the biggest culprit is believed to be a series of dams built along the river from 1918 to 1962, cutting off fish migration routes.

Now, after decades of Indigenous advocacy, four of the structures are being demolished as part of the largest dam removal project in United States history. In November, crews finished removing the first of the four dams as part of a push to restore 644 kilometres (400 miles) of fish habitat.

“Dam removal is the largest single step that we can take to restore the Klamath River ecosystem,” [Barry McCovey, a member of the Yurok Tribe and director of tribal fisheries,] told Al Jazeera. “We’re going to see benefits to the ecosystem and then, in turn, to the fishery for decades and decades to come.” ...

A ‘watershed moment’

Four years later, [after a catastrophic fish die-off in 2002,] in 2006, the licence for the hydroelectric dams expired. That created an opportunity, according to Mark Bransom, CEO of the Klamath River Renewal Corporation (KRRC), a nonprofit founded to oversee the dam removals.

Standards for protecting fisheries had increased since the initial license was issued, and the utility company responsible for the dams faced a choice. It could either upgrade the dams at an economic loss or enter into a settlement agreement that would allow it to operate the dams until they could be demolished.

“A big driver was the economics — knowing that they would have to modify these facilities to bring them up to modern environmental standards,” Bransom explained. “And the economics just didn’t pencil out.”

The utility company chose the settlement. In 2016, the KRRC was created to work with the state governments of California and Oregon to demolish the dams.

Final approval for the deal came in 2022, in what Bransom remembers as a “watershed moment”.

Regulators at the Federal Energy Regulatory Commission (FERC) voted unanimously to tear down the dams, citing the benefit to the environment as well as to Indigenous tribes...

Tears of joy

Destruction of the first dam — the smallest, known as Copco 2 — began in June, with heavy machinery like excavators tearing down its concrete walls.

[Amy Cordalis, a Yurok Tribe member, fisherwoman and lawyer for the tribe,] was present for the start of the destruction. Bransom had invited her and fellow KRRC board members to visit the bend in the Klamath River where Copco 2 was being removed. She remembers taking his hand as they walked along a gravel ridge towards the water, a vein of blue nestled amid rolling hills.

“And then, there it was,” Cordalis said. “Or there it wasn’t. The dam was gone.”

For the first time in a century, water flowed freely through that area of the river. Cordalis felt like she was seeing her homelands restored.

Tears of joy began to roll down her cheeks. “I just cried so hard because it was so beautiful.”

The experience was also “profound” for Bransom. “It really was literally a jolt of energy that flowed through us,” he said, calling the visit “perhaps one of the most touching, most moving moments in my entire life”.

Demolition on Copco 2 was completed in November, with work starting on the other three dams. The entire project is scheduled to wrap in late 2024.

[A resilient river]

But experts like McCovey say major hurdles remain to restoring the river’s historic salmon population.

Climate change is warming the water. Wildfires and flash floods are contaminating the river with debris. And tiny particles from rubber vehicle tires are washing off roadways and into waterways, where their chemicals can kill fish within hours.

McCovey, however, is optimistic that the dam demolitions will help the river become more resilient.

“Dam removal is one of the best things we can do to help the Klamath basin be ready to handle climate change,” McCovey explained. He added that the river’s uninterrupted flow will also help flush out sediment and improve water quality.

The removal project is not the solution to all the river’s woes, but McCovey believes it’s a start — a step towards rebuilding the reciprocal relationship between the waterway and the Indigenous people who rely on it.

“We do a little bit of work, and then we start to see more salmon, and then maybe we get to eat more salmon, and that starts to help our people heal a little bit,” McCovey said. “And once we start healing, then we’re in a place where we can start to help the ecosystem a little bit more.”"

-via Al Jazeera, December 4, 2023

#indigenous#river#riverine#ecosystem#ecosystem restoration#klamath#klamath river#oregon#california#yurok#fishing#fisheries#nature is healing#literally this time lol#united states#dam removal#climate change#conservation#sustainability#salmon#salmon run#water quality#good news#hope#rewilding#ecology#environment

5K notes

·

View notes

Text

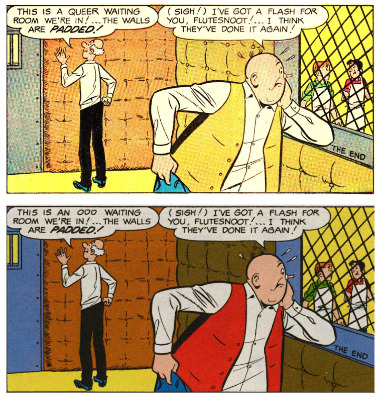

Padded room

"Queer" is out.

#Archie Comics#Archie Andrews#Jughead#Mr. Weatherbee#Prof Flutesnoot#word usage#Precisely why Jughead and Archie wander past I don't know#Chemical lab#All some kind of misunderstanding#Subterfuge#Psychiatric facility#padded room#Harry Lucey#1967#okay but why are they put there together?

0 notes

Text

Ominous smoke plume in the distance. I’m sure it’s fine.

1 note

·

View note

Text

Needs & Wants - Sex Pollen Trope Pt. 1

Bucky Barnes x Reader

Summary: When you're both exposed to an unknown chemical in the field, things go from bad to worse.

Warnings: prelude to obvious smut, talk of masturbation, talk of unprotected sex, profanity, use of y/n, MINORS DNI, 18+!!!

Feel free to comment and let me know if this requires more warnings.

Word Count: 2.8k

Author's Note: Just messing around on here and seeing where I end up. I want to write an absolutely filthy part 2 but if this doesn't get anywhere I may scrap it lmao.

Every. Damn. Time. Something goes sideways every damn time. You want to blame Fury for making the two of you partners to begin with. What the hell did he see between the two of you that made him think missions would ever end in anything other than the two of you butting heads? You sigh deeply and rub your temples with the pads of your left thumb and middle finger, squeezing your eyes shut as you will yourself not to kick Bucky clear across the lab. You know what Fury saw between the two of you, and as much as you hate to admit it, when you’re in absolute life-or-death situations, you and Bucky work together better than any other partner you’ve ever had in the field. Even Nat.

Dropping your hand from your face and opening your eyes, your gaze lands on Bucky. He stands at one of the lab benchtops in the center of the room, his eyes narrowing as he examines an array of monitor screens before him. You can make out an organized table of data along with a few charts on the monitor to his left, but that’s not what draws your attention. The second monitor, the one right in front of him, displays a few words that have you on edge.

Confirmed nitric oxide stimulant capabilities. New formula contains increased quantity of aqueous extract of dried tuberous roots of C. borivilianum.

Shit. This can’t be what you think it is, but with your medical background and your old medical microbiology classes from before joining SHIELD and the Avengers, you know that there’s a very slim chance that you’re misinterpreting what you’re reading. You step forward now, gently pushing Bucky’s arm to move him away from the monitors so you can get a better look at the data. He begins snapping pictures and immediately sending them back to the team. You can feel his eyes on you as you study the graphs and tables. He’s not used to you being this quiet, he knows something’s up.

“What are we looking at?” He finally speaks up, his gaze drawn to the colorful graph displayed on one of the monitors.

“I don’t know.” You lie straight through your teeth, reaching for the keyboard that controls the monitors. You press the right-facing arrow key and the page that said something about nitric oxide disappears, quickly replaced being replaced by a row of video clips, each one titled with a trial number and date. It looks like HYDRA was running trials in this experiment for months.

“Bullshit. Why won’t you tell me what it is?” Bucky asks. His tone is sharp, impatient. He isn’t used to being the one who doesn’t know what’s going on, and it’s bothering him. He gnaws on the inside of his cheek and waits in silence for you to say something, to say anything. You hover the cursor over the first video clip, dated three months ago from today, Trial #1. Everything in you is screaming not to watch it, not to click on it and confirm your suspicions, but you’re here for a reason. You have an easy job here today: break into the HYDRA facility, collect samples and any data that goes along with what they’ve been working on for the past few months, and then destroy the facility on your way out. Sam and Torres planned it out so perfectly, making sure it would be vacant for the next 13 hours so you and Bucky could slip in and get the job done under the radar. They planned it for two months, doing recon and coming up with contingency plan after contingency plan. You need to confirm your suspicions and get as much evidence as possible before blowing the place to bits.

You glance over your shoulder at Bucky, and his blue eyes meet yours with a hint of concern. He hates when you’re quiet like this, he hates those rare moments in the field when he can’t read your mind. What the hell are you thinking? What aren’t you telling him? He knows you well enough to know that you’re nervous about whatever you’re seeing here.

You click the video link and a slightly grainy image of a padded square room fills the screen. The floor and walls are gray and there isn’t any furniture in the room, only what looks to be a set of shackles on the back wall. A shiver runs down your spine and you pull your phone out, typing up a message to Bruce Banner while you wait for something to happen on screen.

You: A chemical compound that stimulates NO and uses aqueous extract of C. borivilianum…is it going to be what I think it is?

As your message sends, Bucky reaches around you, his chest brushing against your back, and he uses the mouse to fast forward the video until people are appearing on screen. You watch as presumably a HYDRA agent shoves a woman into the room, obviously an unwilling participant in the experiment. She doesn’t fight much as she’s placed in the shackles on the wall, but it’s obvious that she’s weak and likely drugged. The HYDRA agent briefly steps out of view of the camera, before returning with a second captive, a man this time. He’s large, muscular, and has a dark look in his eye. You feel Bucky stiffen up behind you, realizing at the same time as you that this man is a super soldier. Your phone vibrates in your hand and you steal a look at the response from Banner.

Banner: Yes.

Fuck. The next two minutes of the video are pure horror, even though nothing particularly horrific happens before you slam your hand down on the spacebar, pausing the clip abruptly. You both watched on as a cloudy vapor was pumped into the room through vents, and then watched on as the super soldier became more and more restless, sweaty, and crazed. As soon as the female captive began whimpering and pulling against her shackles, with her eyes trained on the super soldier a few feet to her left, you couldn’t let the video play any longer.

“Tell me what it is.” Bucky says evenly from behind you. You swallow hard and reach into one of the pockets of your tactical pants, pulling out a device similar to a USB and plugging it into the computer before you. As all of the data and video clips begin to transmit through the device, back to Sam and Torres, you turn around and face your partner.

“HYDRA hasn’t been able to recreate the super soldier serum. They haven’t made any progress at all since Zemo killed Dr. Nagel.” You say slowly, choosing your tone and words carefully. You don’t want to say too much and leave Bucky as terrified as you are right now, but you also know you can’t keep this from him. Not when you need him to understand how fucking careful you’re both going to have to be from now until the end of this mission.

“I know that. What are we here for, y/n?” His tone is growing more and more impatient, his jaw ticking as he stares down at you. God, he can’t ever just shut up and listen. You put your hand on his chest, shoving him a few steps back and walking across the lab, to the glass refrigerator in the far corner. It’s full of vials of a clear liquid, each sealed at the top and marked with a label full of scientific terms.

“They got desperate, and turned to even more barbaric methods of creating super soldiers. They started experimenting with chemical compounds that induce a primal need in those exposed.” You explain carefully. You pause now, turning to look back at Bucky once more. You see realization spread across his face and he quickly comes to understand what you’re saying. It’s a fucking sex pollen.

Static crackles in your in-ear briefly before Sam’s voice reaches you both.

“Banner and Stark just finished reviewing some of the data you shared. This is not something that either of you want to be exposed to.” Sam advises, and you can hear Torres in the background typing away on a keyboard.

“Yeah, no shit.” You mutter, retrieving a pair of nitrile gloves from a box on the benchtop nearby and setting up the small lockbox that you brought for samples. You open it to reveal a padded interior, with enough room for three vials. The rest will have to be destroyed.

“Just grab the samples, rig the place to blow, and get the hell out of there. I don’t want you in there any longer than you have to be.” Sam’s orders spur Bucky into action, and he starts setting up explosives around the corners of the lab while you get ready to retrieve the samples from the fridge. If only you’d known that HYDRA was one step ahead.

It happened so fast that you didn’t even have time to try to protect yourself. The moment that you pulled open the small door to the fridge full of samples, that same cloudy vapor you saw in the video clip began to rush in from every air vent in the lab.

“Shit.” You mumble, reaching into the fridge and grabbing three vials. You quickly place them into the lockbox and seal it, knowing that you’ll definitely need samples to test now that you’ve both been exposed.

“Sam, we’ve got a problem.” Bucky is as calm as ever, though his voice comes out slightly annoyed. Of course he’d sound annoyed in this moment. He’s been exposed to a sex pollen alongside the partner that he can only get along with when they’re staring death right in the face. He heaves a weighty sigh before stalking over to you and snatching the lockbox from the benchtop. He quickly slides his backpack off, shoving it inside, and then heading for the exit, without checking to see if you’re on his heels or not. You strip off your gloves and bound after him. The gravity of the situation hasn’t hit either of you yet, but oh, it will soon enough.

--

Bucky weaves his motorcycle in and out of traffic almost recklessly, with your arms clutched around his abdomen. It’s only been fifteen minutes since you were both exposed but you swear that you’re starting to feel the effects. Your cheeks are hot and flushed under your helmet, your hands are shaking as adrenaline courses through your veins, and your heart is racing. If you hadn’t been on the back of a motorcycle with Bucky so many times in the past, you would’ve chalked your symptoms up to this experience, but it’s definitely not that.

“Loosen up, are you trying to do the Heimlich on me or something?” Bucky spits out, his voice playing in your helmet. You do as he says, loosening your hold and taking a deep breath in. You don’t say anything in response, which furthers the tension between you both. It’s been fifteen minutes of stressful silence and Bucky’s losing his damn mind. He wants you to give him shit like you usually would when a mission goes sideways. He wants you to lash out, tell him to stop driving like an ass, he wants you to say anything so he knows you’re okay. He can’t fucking stand the silence.

He guides the bike down the long dirt road to the safe house you stayed in last night, and you hop off before he’s even put the kickstand down. He watches as you rush up the steps of the small cobblestone house, yanking off your helmet in one swift movement before you key the code into the door and force it open. You’re feeling the effects of the chemical pulsing through your veins, you’re feeling it and you’re trying to keep it from him.

--

“It’s a very complex compound. A nitric oxide stimulant, utilizing both natural and man-made components. It’s basically a super soldier version of Viagra and ecstasy all in one.” Bruce says, addressing both you and Bucky through the video call. Concern and stress are etched into his soft features as he stands in the lab of the Avengers compound, his arms crossed and glasses sliding down the bridge of his nose. “You’re going to have to look out for the negative effects, which from the video clips of their experiments, are extremely strong. Take the side effects of ecstasy and multiply their intensity by a hundred.”

“So, sweating, hypertension and tachycardia, jaw pain…” Your voice trails off as you list off the side effects of ecstasy that you know from your previous pharmacology classes. Bruce nods slowly.

“Basically, you’ll feel like you’re having a heart attack, unless you’re able to relieve yourselves.” He summarizes.

“What do you mean relieve yourselves?” Bucky questions. He’s seated on the couch next to you, his brow is furrowed and a sheen of sweat is becoming apparent along the side of his neck. You try not to look at him for too long, already feeling yourself longing for touch and physical contact of any kind.

“If you’re able to achieve a postcoital state, you should have temporary relief of your symptoms. You might have to achieve that state more than once, until the chemical is out of your system.” You can almost hear the wheels turning in Bucky’s head as he works out what postcoital means. You have to reach an orgasm to feel any relief, but bless Banner for trying to put it in a more professional way.

“Have you tested the half-life of the chemical yet?” You ponder, wanting to know exactly how long you’ll both be suffering through this. You wipe a bead of sweat from your brow with the back of your hand.

“Yeah, it seems like it can last anywhere from eight to ten hours in a non-super soldier, but it was designed specifically to work in conjunction with the serum, so it lasts eight to twelve hours in a super soldier.” Bruce’s words are starting to jumble together in your head, adding to the slightly throbbing headache that’s forming behind your eyes. You squeeze them shut and rub your temples just like you did in the lab earlier, zoning out as Tony and Bruce both start discussing the pharmacokinetics behind the compound currently wrecking your body.

“What are our options here?” Bucky asks quietly, directing his question to you alone. You turn to look at him and see his cheeks flushed like yours now, his pupils dilated a minute amount, and his hands clasped together over his knees. There’s no hiding that it’s affecting you both now.

“I don’t know. The only thing I can think to do is lock ourselves in different rooms and try to ride it out.” You say, rubbing your aching thighs through your tactical pants with the palms of your hands. Your bones are starting to hurt in a deep, consuming way, and all you want to do is give yourself a few doses of propofol to knock yourself out for the next eight hours. It’s going to be hell trying to get through this without having sex, especially if pain is setting in only an hour after the initial exposure.

“Okay, so we do that. We each lock ourselves in a bedroom and fight it.” Bucky sounds sure and resolved, like he has total faith that your only plan available will work out fine. All it took to bring out his optimistic side was being doused with a sex pollen and stuck in a safe house.

“I want to monitor both of your vitals through the night.” Bruce calls out, gaining your attention again.

“No.” You and Bucky both speak firmly at the same time, quick to reject the idea. You don’t need a medical record showing how aroused you end up being tonight, you don’t need Bruce or any of the SHIELD lab staff watching your heart rate increase as you touch yourself, watching your blood pressure spike as you near your climax alone. Bucky is thinking the same thing, shit, his heart rate is probably already through the roof as it is, just from sitting next to you. He tries to focus on whatever else you, Bruce, and Tony are discussing but his jaw is clenched in pain and he’s fighting the urge to rip off his tactical suit right there. It feels like it’s fucking ninety degrees inside. The only thing he catches in the last bit of the conversation is from Tony.

“There’s a chance you won’t find any relief in an orgasm alone, Y/n. Bucky will, because his body won’t know the difference between finishing himself off vs. finishing inside of a fertile woman, but this compound is meant to make your reproductive system go into overdrive. You won’t feel relief until your body thinks it has a chance of reproducing, until semen is introduced into your system.”

“Fuck.” You inhale sharply, doubling over in pain both at Tony’s unfortunate conclusion and at the cramping sensation you’ve suddenly felt deep in your stomach. Fucking hell.

Next Part

#bucky barnes smut#bucky barnes x you#bucky barnes x reader#bucky barnes fic#sex pollen#the winter soldier#winter soldier#mcu#bucky barnes#bucky barnes fanfiction#marvel

3K notes

·

View notes

Text

Transforming Wood Waste for Sustainable Manufacturing - Technology Org

New Post has been published on https://thedigitalinsider.com/transforming-wood-waste-for-sustainable-manufacturing-technology-org/

Transforming Wood Waste for Sustainable Manufacturing - Technology Org

Lignin, a complex organic polymer, is one of the main components of wood, providing structural support and rigidity to make trees strong enough to withstand the elements. When transforming wood into paper, lignin is a key ingredient that must be removed and often becomes waste.

Marcus Foston (left) and collaborators are exploring how to use lignin, a common waste product of paper pulping, as a source of renewable alteratives to petroleum-derived chemicals. Image credit: Jerry Naunheim Jr./Washington University

Marcus Foston, an associate professor of energy, environmental and chemical engineering in the McKelvey School of Engineering at Washington University in St. Louis, is exploring how to add value to lignin by breaking it down into small molecules that are structurally similar to oxygenated hydrocarbons. These renewable chemicals are key components in many industrial processes and products, but they are traditionally sourced from nonrenewable petroleum.

Foston’s study of lignin disassembly, done in collaboration with Sai Venkatesh Pingali, a neutron scattering scientist at Oak Ridge National Laboratory (ONRL), was published Jan. 17 in the journal Sustainable Chemistry & Engineering.

“Lignin’s structure actually looks a lot like what we get from petroleum,” said Foston, who is also director of WashU’s Synthetic Biology Manufacturing of Advanced Materials Research Center (SMARC). “In current manufacturing processes, we spend time making petroleum look like the elements of lignin. Instead, I’m using a catalyst to break lignin down more easily and in such a way that it produces specific chemicals. Once we can produce chemical from lignin in a form we want, then we can make more efficient use of lignin, which is an abundant byproduct of pulping wood into paper.”

With collaborators at ORNL, Foston used neutron scattering to study how lignin interacts with solvents and catalysts during its disassembly under reaction conditions, including high temperature and pressure. ORNL’s advanced facilities allowed researchers to observe the reaction process in real time to improve their catalyst and further streamline reaction systems for lignin depolymerization. This direct, molecular-level view is critical, Foston said, to figure out how the catalyst and lignin behave in solution and to ensure the lignin doesn’t recondense into a polymer with bonds scientists can’t easily break.

“In this study, we’re specifically thinking about how we can take the large amount of lignin that gets produced during biofuel or paper production and use it to make renewable chemicals that replace some of the chemicals we currently get from petroleum,” Foston said. “More broadly, the same depolymerization principles we’re exploring with lignin could be used in other applications. For example, the same lessons from this study apply to plastic waste scenarios, where one approach is to deconstruct plastic waste into small molecules that could be used to make plastic or other useful products.”

“Ultimately, we want to take a bunch of chemicals that are coming from petroleum and figure out how we can make those renewably,” Foston added. “Everything we’re learning about lignin will apply to other spaces as well.”

Source: Washington University in St. Louis

You can offer your link to a page which is relevant to the topic of this post.

#advanced materials#amp#applications#approach#Biology#catalyst#catalysts#chemical#Chemical engineering#chemicals#chemistry#Collaboration#energy#engineering#Environmental#Facilities#form#Fundamental physics news#high temperature#how#how to#hydrocarbons#it#learning#Link#Manufacturing#materials#molecules#neutron#Oak Ridge National Laboratory

1 note

·

View note