#Tooling

Photo

A recently completed scabbard commission for the Albion Laird.

3K notes

·

View notes

Text

tooling work I've ever done. So much more to do, but it's progress. I definitely want to do more!

151 notes

·

View notes

Text

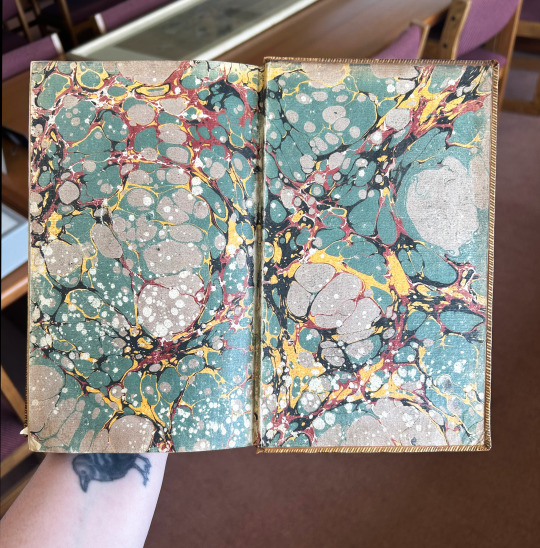

Marbled Monday

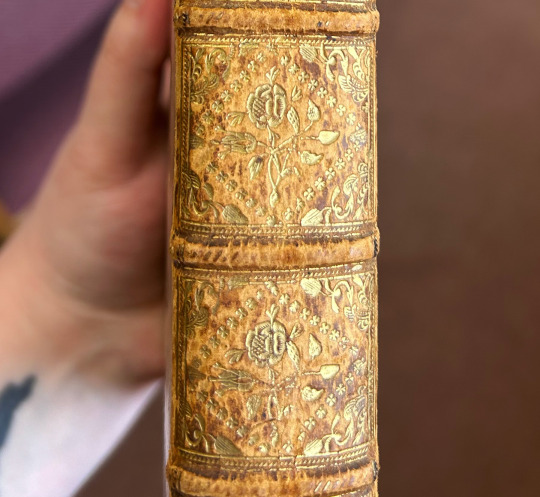

This Marbled Monday we're sharing volume 5 from a ten volume set of The Plays of William Shakespeare with the Corrections and Illustrations of Various Commentators to Which Are Added Notes by Samuel Johnson and George Steevens with an Appendix. This edition was published in 1773. Volume 5 contains the plays King John, King Richard II, King Henry IV Part I and Part II.

The marbling is (I think) a Turkish pattern with black, yellow, red, and grey on a blue-green field. There is some really nice tooling around the inner edges of the binding as well as on the spine. It was really difficult to get a good image of the spine because the leather is so mottled and the gold is so delicate, but in the last picture shown here you can see the beautiful roses and designs stamped on it.

View more Marbled Monday posts.

-- Alice, Special Collections Department Manager

#Marbled Monday#Shakespeare#The Plays of William Shakespeare#marbled paper#marbling#Turkish marbling#Turkish pattern#gold stamping#tooling

55 notes

·

View notes

Photo

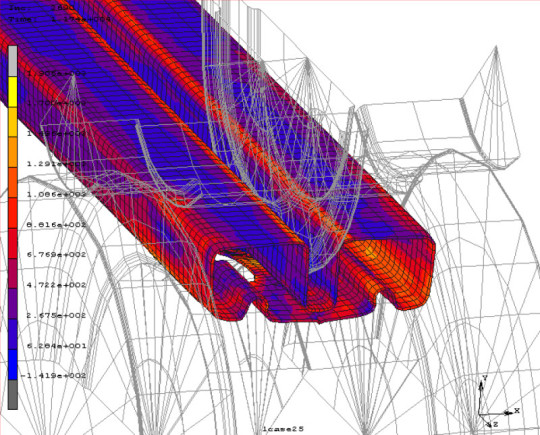

Roll Form Tooling Design & Manufacturing | Metform

54 notes

·

View notes

Text

Impossible !

Brilliant Mercury Leatherworks Boots

33 notes

·

View notes

Text

COWPUNK, a minimalist wallet that I made for myself from leftover leather from my workshop.

If you want one with your own design, message me.

It easily fits 8-10 cards, vehicle registration documents, banknotes, etc.

#cowpunk#leather#custom#handmade#carving#tooling#oldschool#oldstyle#wallet#crafted#handcrafted#kustom#skull#ftw

6 notes

·

View notes

Text

Brief thoughts on Barry King vs Craftool stamps

Still acclimating to the new Barry King stamps. There is definitely a learning curve, since I’ve got eleven years of experience with the Craftool (Tandy) versions and I can use those to a high degree of precision, so it’s not an instant “Wow Yay These tools are Such an Improvement!” For all that the BK stamps are higher quality, they’re not what I’m used to, which means every tiny difference is throwing me off my game.

The BK stamps have sharper edges, for one, that are prone to catching on the leather and messing up my cutlines (and making me feel like a FUCKING AMATEUR again), and less lateral curvature, which means it’s more prone to showing the stamp marks as individual hits rather than a smooth, continuous line. It’s also a lot harder to walk the BK stamps than the Craftool stamps, for reasons I’ll get into when I talk about tool geometry.

(They’re just less forgiving overall -- the drawback to precise tools, I suppose, is that they require you to be precise.)

That said, I’m already better with them today than I was yesterday, so I’m resisting the urge to go at them with sandpaper, until I get some more practice and figure out what I actually want to change, vs what I just need to get used to.

Anyway, my takeaway from this experience is that Craftools are genuinely more beginning-friendly -- the same features that make them cheaper (because they are about 1/5 the price of BK tools) also make them easier to work with, and require less precision and control. You’ll run up against their limits eventually, when you’re doing tiny, complicated carving and they simply don’t come in the shapes you need, but they will take you very far. If anyone tries to tell you that you need the expensive stamps in order to get quality results, tell them to get good.

(Detail of the Wonder Woman bombshell bracers, done entirely with Tandy tools. For scale, those larger stars are about the size of my pinky nail.)

10 notes

·

View notes

Text

iOS Home Depot

Qué ricos los chocolates Lint, ¿verdad?

Pues no, amigos, Lint es una herramienta más que podemos usar en nuestros desarrollos. Y precisamente de herramientas útiles nos va a hablar este mes la grandísima Sofía Swidarowicz, de los Swidarowicz de toda la vida.

Después de triunfar con esta charla en Buenos Aires y Barcelona, tenemos el honor de recibirla en Madrid y no os la podéis perder. Conocimiento del bueno directo a vuestro cerebelo.

Sólo hay una norma para venir: trae tus propias herramientas para compartirlas con la comunidad y... ¡Así aprendemos más!

¿Nos vemos… o ke ase?

Donde y cuando:

Proximo miercoles 15/03/23 a partir de las 19h en el local Puerta de la Innovación, C. de Toledo, 110 · Madrid

Puedes registrarte en el siguiente link a MeetUp:

4 notes

·

View notes

Text

Some examples of sculpting and tooling of leather that I have done

#finnleycraftsportfolio#finnleyleather#finnleycrafts#leatherwork#tooling#leather tooling#leather carving#leather sculpting#hand made#crafts

3 notes

·

View notes

Text

Mould Design in Plastic Injection Moulding

Injection Moulding is an extremely versatile procedure. It can be utilised for virtually any product. Injection moulding is the industry standard for manufacturing components for products.

There are some limitation needs to consider. Here are the rules to follow when designing your product to make sure quality and durability:

Wall Thickness

Keeping your walls thin will ensure a faster cooling rate and less materials used. Lower cooling rate and less material used will result in a shorter cycle time. This allows you more parts in a shorter amount of time, for less production cost

To strengthen parts, ribs are more effective than thicker walls. Adding ribs at right angles to a wall will add considerably to its overall strength. It is a common mistake to thicken the walls of a design to achieve this effect when ribs are a cheaper and more effective option.

Ribs should be about half the main wall thickness. There can be some leniency here, but not too much or the ribs will be completely ineffective. Half is the generally accepted standard and is more than enough to increase a wall’s strength.

Coherence

Try to make your design uniform throughout. That is, wall thickness, rib thickness and corner radii, for instance, should all be the same values. This will help the part to cool uniformly.

Corners & Edges

Corners could be an issue in a mould and will not come out flush. It is difficult to form plastic into a flawless corner. The outcome will look amateurish and messy, not to mention the power of the components can be compromised.

Corners and edges should be rounded wherever possible. Sharp edges do not always come out perfectly when the part is ejected from the mould.

Add a slight angle to the sides of your mould to allow easy release. A one- or two-degree angle should be applied to the mould on the face perpendicular to the parting line. This will allow for easy removal of the part from the mould.

Ribs

These are structural factors for your component, utilised for general stability control. Ribs are thin wall protrusions which extend vertically from a plane or wall. Adding ribs instead of thicker walls will provide greater structural support.

Bosses

These are empty, cylindrical protrusions. These are normally integrated in a style for accepting screws or other mating parts of your style. Making sure these are secured by attaching them a wall. Putting in ribs will means the bosses will stay straight as well as accommodate the part it was made for without an issue.

External Undercuts

A depression or protrusion in the exterior of the mould – the cavity half – could create issues if trying to divide parts from the mould. Adjust the parting line to lodge this.

Internal Undercuts and Overcuts

Related to external undercuts, these depressions or protrusions are within the mould – on the centre half. Adjust the parting line to lodge this.

Protrusions on the part that will snag on the mould core or cavity when it is opened can make it impossible to remove from the mould.

Threads

When your mould has a thread, always position it vertical to the parting column. This will make sure that the delicate thread isn’t damaged. It’s better, preferably, to not comprise a thread at all in the design. Making your design simple will lower the odd of something going wrong.

Injection mouldingdesign makes a superior product. The myriad possibilities far outdo the limitations. Designing for an excellent injection moulded part is the core of the design process. These restrictions are the guidelines for making a flexible end product.

Colour use

Where possible, use lighter colours for your moulds. The mould is already cool when the molten material is being injected. As such it begins the setting process immediately and will sometime leave setting patterns. Using lighter colours will help y.to hide these patterns.

Injection mouldingis the industry standard for creating lasting, quality parts. To be able to take advantage of this technology your design must meet its minimum requirements. Small considerations are all it takes and the result is a successful product that will meet all of your quality needs.

If you would like to find out more or have any questions please do not hesitate to get in touch, contact details can be found below:

Email: [email protected] or [email protected]

Tel: 01455 558825

Mob: 07754 857071

Our Socials can also be found below:

LinkedIn: https://www.linkedin.com/company/dudley-associates-ltd/

Instagram: https://www.instagram.com/dudleyassociates

Twitter: Dudley Associates (@DALPlastics) / Twitter

Facebook: https://www.facebook.com/DudleyAsssociates

#plastic injection molding#plastic injection moulding#injectionmoulders#injection moulding#injectionmouldtooling#injection mould toolmaking#toolmaking#tool making#toolmakers#tooling#rapid prototyping#productdevelopment#product design#productdesign#made in uk#made in britain

2 notes

·

View notes

Text

Presenting my latest build, for a sword made by the late Jody Samson, and commissioned by a very special client of mine. I absolutely loved this build, both for the sword, and the client.

685 notes

·

View notes

Text

I still need to get used to working with this but I like it so far! Seeding is still the hardest part of tooling though...

135 notes

·

View notes

Text

114K notes

·

View notes

Text

just to hide outside your door 🐍🍎

#my art#good omens#good omens 2#crowley#anthony j crowley#aziracrow#fan art#artists on tumblr#digital art#illustration#paint tool sai#good omens fanart#good omens season 2#gomens#portfolio

105K notes

·

View notes

Text

#writers#writers on tumblr#writing#writing prompt#writer#my writing#daily writing prompt#daily writing#writing tool#story#write it

48K notes

·

View notes

Text

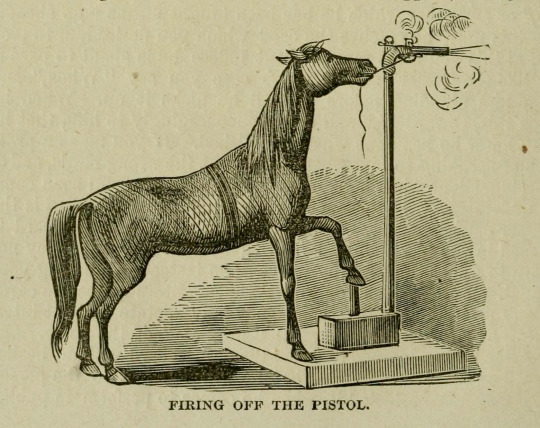

Item: apparatus allowing a horse to fire a gun

25K notes

·

View notes