#made in uk

Text

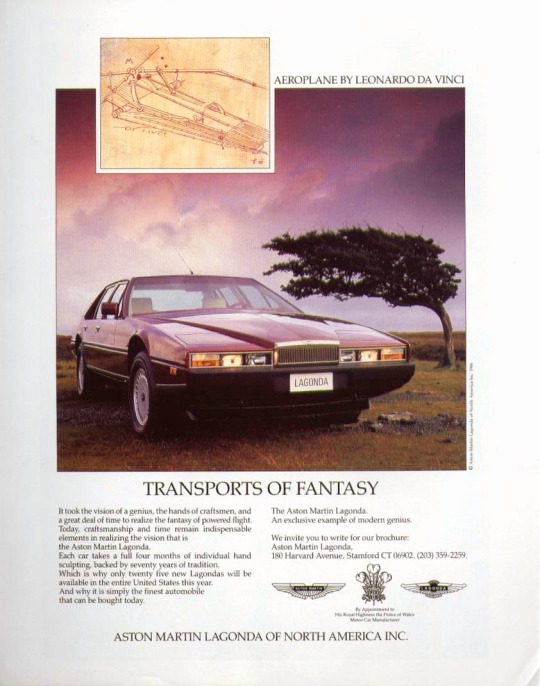

🇬🇧 Embark on a journey through the illustrious lineage of the Aston Martin Lagonda, spanning from 1976 to 1990, a testament to automotive luxury and innovation!

👑 Founded in 1913, Aston Martin has become synonymous with luxury, English elegance, and high-performance automobiles. In the early 1970s, it continued to push the boundaries of automotive design and engineering.

🚘 The Aston Martin Lagonda lineup of the late 1970s and 1980s exemplified the pinnacle of luxury automobiles, featuring sleek and sophisticated designs that set new standards for elegance and refinement.

🛞 Beneath their refined exteriors, the Lagonda boasted powerful V8 engines, delivering exhilarating performance and effortless cruising. Their spacious and sumptuously appointed interiors were outfitted with the latest amenities, including plush leather upholstery and polished wood trim.

💡 The Lagonda was known for its innovative use of electronic systems, including digital dashboard displays, onboard computers, and advanced climate control systems, setting new benchmarks for automotive technology and innovation.

💔 Despite critical acclaim and a loyal following, production of the Aston Martin Lagonda ultimately ceased in 1990. One of the key factors contributing to the discontinuation of the Lagonda series was the high cost of production and limited demand in the luxury car market.

#brits and yanks on wheels#transatlantic torque#retro cars#vehicle#cars#old cars#brands#companies#automobile#american cars#aston martin#aston martin lagonda#lagonda#old car#cool cars#classic cars#car#english cars#made in uk#made in england#luxury car#luxury cars#luxurycars#luxury#innovation#innovative#innovators#electronic#electronics#v8 engine

59 notes

·

View notes

Text

Fall in love with Jess, we have 💚

83 notes

·

View notes

Text

ASTON MARTIN Vantage 2024 🇬🇧

#vantage#aston martin#aston martin vantage#2024#made in uk#made in england#yellow#car#luxury car#supercar#fast car

21 notes

·

View notes

Text

8 notes

·

View notes

Photo

9 notes

·

View notes

Text

#made in uk#central cee#vibes#d block europe#dripcheck#lifestyle#londonstyle#london#nike tech fleece#singer#trapstar#air force#rapper

73 notes

·

View notes

Text

Garmology podcast: The way of Cabourn - With Nigel Cabourn (S05/E22 #122)

It’s been a long time coming, but this week finally sees iconic British designer Nigel Cabourn guest Garmology for a wide-ranging and openhearted chat about why he really got into fashion design, his inspirations and heroes, the ups and downs of life and business, his love of travelling, meeting people and collecting vintage garments, the collection that never happened, and being taught fitness…

View On WordPress

3 notes

·

View notes

Text

Mould Design in Plastic Injection Moulding

Injection Moulding is an extremely versatile procedure. It can be utilised for virtually any product. Injection moulding is the industry standard for manufacturing components for products.

There are some limitation needs to consider. Here are the rules to follow when designing your product to make sure quality and durability:

Wall Thickness

Keeping your walls thin will ensure a faster cooling rate and less materials used. Lower cooling rate and less material used will result in a shorter cycle time. This allows you more parts in a shorter amount of time, for less production cost

To strengthen parts, ribs are more effective than thicker walls. Adding ribs at right angles to a wall will add considerably to its overall strength. It is a common mistake to thicken the walls of a design to achieve this effect when ribs are a cheaper and more effective option.

Ribs should be about half the main wall thickness. There can be some leniency here, but not too much or the ribs will be completely ineffective. Half is the generally accepted standard and is more than enough to increase a wall’s strength.

Coherence

Try to make your design uniform throughout. That is, wall thickness, rib thickness and corner radii, for instance, should all be the same values. This will help the part to cool uniformly.

Corners & Edges

Corners could be an issue in a mould and will not come out flush. It is difficult to form plastic into a flawless corner. The outcome will look amateurish and messy, not to mention the power of the components can be compromised.

Corners and edges should be rounded wherever possible. Sharp edges do not always come out perfectly when the part is ejected from the mould.

Add a slight angle to the sides of your mould to allow easy release. A one- or two-degree angle should be applied to the mould on the face perpendicular to the parting line. This will allow for easy removal of the part from the mould.

Ribs

These are structural factors for your component, utilised for general stability control. Ribs are thin wall protrusions which extend vertically from a plane or wall. Adding ribs instead of thicker walls will provide greater structural support.

Bosses

These are empty, cylindrical protrusions. These are normally integrated in a style for accepting screws or other mating parts of your style. Making sure these are secured by attaching them a wall. Putting in ribs will means the bosses will stay straight as well as accommodate the part it was made for without an issue.

External Undercuts

A depression or protrusion in the exterior of the mould – the cavity half – could create issues if trying to divide parts from the mould. Adjust the parting line to lodge this.

Internal Undercuts and Overcuts

Related to external undercuts, these depressions or protrusions are within the mould – on the centre half. Adjust the parting line to lodge this.

Protrusions on the part that will snag on the mould core or cavity when it is opened can make it impossible to remove from the mould.

Threads

When your mould has a thread, always position it vertical to the parting column. This will make sure that the delicate thread isn’t damaged. It’s better, preferably, to not comprise a thread at all in the design. Making your design simple will lower the odd of something going wrong.

Injection mouldingdesign makes a superior product. The myriad possibilities far outdo the limitations. Designing for an excellent injection moulded part is the core of the design process. These restrictions are the guidelines for making a flexible end product.

Colour use

Where possible, use lighter colours for your moulds. The mould is already cool when the molten material is being injected. As such it begins the setting process immediately and will sometime leave setting patterns. Using lighter colours will help y.to hide these patterns.

Injection mouldingis the industry standard for creating lasting, quality parts. To be able to take advantage of this technology your design must meet its minimum requirements. Small considerations are all it takes and the result is a successful product that will meet all of your quality needs.

If you would like to find out more or have any questions please do not hesitate to get in touch, contact details can be found below:

Email: [email protected] or [email protected]

Tel: 01455 558825

Mob: 07754 857071

Our Socials can also be found below:

LinkedIn: https://www.linkedin.com/company/dudley-associates-ltd/

Instagram: https://www.instagram.com/dudleyassociates

Twitter: Dudley Associates (@DALPlastics) / Twitter

Facebook: https://www.facebook.com/DudleyAsssociates

#plastic injection molding#plastic injection moulding#injectionmoulders#injection moulding#injectionmouldtooling#injection mould toolmaking#toolmaking#tool making#toolmakers#tooling#rapid prototyping#productdevelopment#product design#productdesign#made in uk#made in britain

2 notes

·

View notes

Text

1 note

·

View note

Text

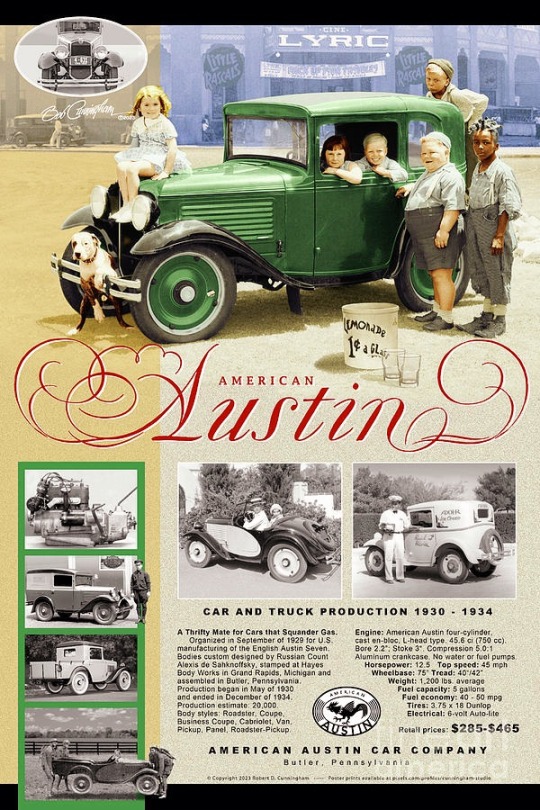

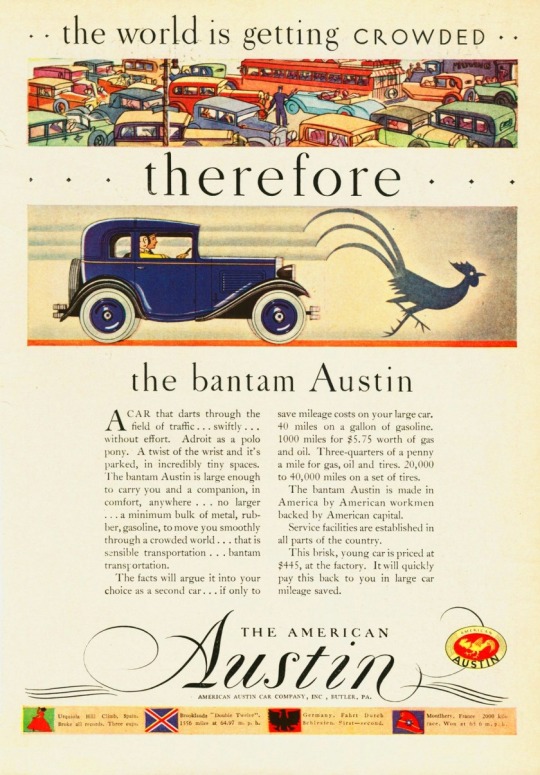

🇺🇲🤝🇬🇧 Embark on a captivating journey through the history of the American Austin Car Company, a pioneering force in the automotive industry that left an enduring legacy on American roads!

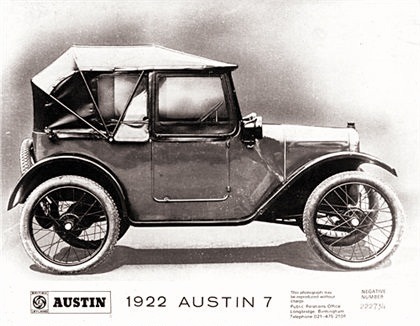

🔍 Founded on February 23, 1929, in Delaware, the American Austin Car Company Inc. aimed to revolutionize urban mobility during the Great Depression by producing affordable, fuel-efficient vehicles tailored to American drivers' needs. Licensed from the renowned British Austin Motor Company, the company drew inspiration from European compact cars to create its own unique models.

👑 The parent company, Austin Motor Company Limited, established by Herbert Austin in Longbridge in 1905, experienced significant growth during World War I, fulfilling government contracts and expanding its workforce. Despite its illustrious British roots, the American Austin Car Company faced challenges in marketing tiny Austin cars in the US market.

💡 In 1930, the company introduced its first model, the American Austin, featuring a compact design and economical performance that quickly appealed to urban commuters. With its diminutive wheelbase of only 75 inches and track width of 40 inches, the American Austin stood out as one of the smallest production cars in the USA, gaining popularity for its efficiency and agility.

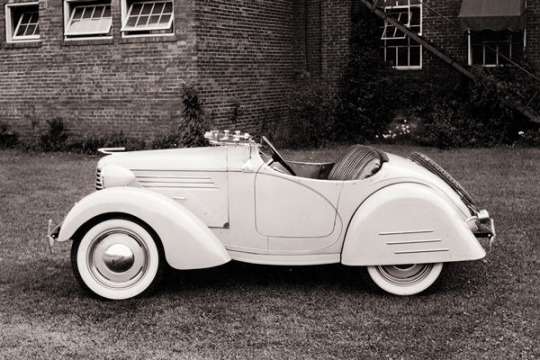

⚙️ The American Austin Car Company's innovative approach to automotive design paved the way for iconic models like the American Austin Coupe and Roadster, renowned for their streamlined silhouettes and nimble handling. Despite initial success, the company faced challenges during the Great Depression, leading to a decline in sales and eventual suspension of production in 1932.

📉 Despite attempts to diversify production, including the introduction of small-scale pickup trucks in 1934, the company struggled to regain momentum. By 1935, the American Austin Car Company was liquidated, with its assets acquired by Evans Operations, Inc. The formation of the American Bantam Car Company in 1936 marked the end of an era for the American Austin brand.

#brits and yanks on wheels#retro cars#transatlantic torque#vehicle#cars#old cars#brands#companies#automobile#american cars#british automotive#american auto#automotive#auto#british cars#made in uk#made in america#made in england#made in usa#austin motor company#austin#american austin motor company#great depression#1920s#1930s#history#old car#retro#vintage#industry

13 notes

·

View notes

Video

Charlotte is classic for a reason 🌹

#edge o beyond#luxury lingerie#british lingerie#made in uk#rose embroidery#embroidery#basque#merry widow#illusion tulle

97 notes

·

View notes

Text

ASTON MARTIN DBS 770 Ultimate Volante 🇬🇧

#aston martin#dbs 770 ultimate volante#made in uk#made in england#red#Aston Martin dbs 770 ultimate volante

17 notes

·

View notes

Text

Lorenzo Berni shot "The Eurydice collection" campaign anticipation for Patrick McDowell featured on Forbes ahead of Ahead Of AW24 London Fashion Week.

#lorenzoberni#lorenzo berni journal#patrickmcdowell#patrick mcdowell#silk#silk blouse#silk dress#model#fashion campaign#ad campaign#campaign#beauty#londonphotographer#london#london production#lorenzo berni photography#intimate#closer#closet#gold#golden hair#sustainability#luxury#luxurydress#British designer#designer#british#made in UK

1 note

·

View note

Photo

6 notes

·

View notes