#work safety

Text

'Stop it first'

Royal Society for the Prevention of Accidents work safety poster (c. 1950). Artwork by Blake.

#vintage poster#1950s#Royal Society for the Prevention of Accidents#work safety#safety#button#stop button#spanner#wrench#british

218 notes

·

View notes

Text

6 notes

·

View notes

Text

"Will you be here tomorrow?" (1998)

youtube

Highlights from a very silly (and gory) work safety video.

2 notes

·

View notes

Text

2022 SAFETY AND HEALTHY

Steel hasp lockout.

Allows up to six workers to lock out a single point.

2 notes

·

View notes

Video

youtube

anyway, back to my comfort media

#gore#i mean stuntmen recreate industrial accidents and deaths complete with fake blood#i'm still learning how to tag / warn properly sorry#mst3k#rifftrax#mike nelson#kevin murphy#bill corbett#video#short#shake hands with danger#1980#work safety#this has become something i watch or at least listen to daily

6 notes

·

View notes

Text

Saw a post about helping people that used the analogy of "if you see someone fall off a cruiseship and theres a life preserver ring on the wall next to you do you walk away or do you throw them the life preserver? Of course you throw them the life preserver." And i dont want to add to or tag the post with any sort of correction because its literally not the point at all but i am desperate to say that the first thing they teach you when you work on a cruise ship is that if someone falls overboard you Do Not Look Away

If theres a life preserver nearby but you have to turn your back to get it, tough luck. If theres someone nearby who can't hear you but you could run and get them, absolutely not. You see someone go overboard you point at them and never ever let them out of your sight because looking away even once could mean losing them forever, so you just have to trust that someone will hear you scream for help but you cant for any reason look away

And maybe that adds to the life preserver metaphor somehow but mostly i just need you to know if you spot someone in the water you point at them and you watch them close and you scream for help

#water safety tips with grinchwrapsupreme#what could the metaphor be#um#if you see someone struggling and they are seconds from 'drowning' make sure theyre not going to go under before working on a rescue plan?#idk#point and stare and scream babes thats the key

35K notes

·

View notes

Text

Industrial Safety Market by Type, Offering (Hardware, Software), End User (Oil & Gas, Energy & Power, Chemicals), and Geography—Global Forecasts to 2030

1 note

·

View note

Text

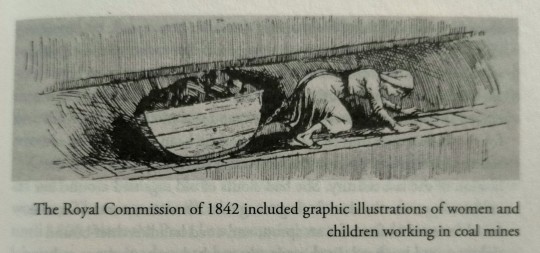

The terrible work and conditions for women and children working underground came to public notice after an accident at Huskar Colliery near Barnsley in 1838, when 26 children (11 girls) were drowned while working. An inquiry reporting on the conditions made the point that women stripped naked to the waist to work in the heat of the mines and wore trousers for the heavy work. This was as shocking to the elite as the danger of the job.

"Normal Women: 900 Years of Making History" - Philippa Gregory

#book quotes#normal women#philippa gregory#nonfiction#work safety#working conditions#underground mining#public notice#workplace accidents#huskar colliery#barnsley#30s#1830s#40s#1840s#19th century#drowning#death#child death#royal commission#coal mining#dangerous jobs

0 notes

Photo

‘Meals at work: lead poisoning! Protect yourself from accidents!’

Hungarian work safety poster warning about accidental lead contamination at work, featuring an illustration of a man reaching for his sandwich lying on top of a storage compartment filled with lead pieces (c. 1940).

#vintage poster#1940s#hungary#hungarian#work safety#lead poisoning#lead contamination#work#food safety#sandwich#lead#health#food#food poisoning

133 notes

·

View notes

Text

Is a Safety Recognition Program Right for You?

In today's fast-paced work environment, ensuring the safety of employees is more critical than ever. A key strategy in promoting workplace safety is the implementation of a safety recognition program. Such programs are designed to reward and acknowledge employees and teams for their contributions to maintaining and enhancing safety standards. But is a safety recognition program the right choice for your organization? Let's delve into the benefits and considerations to help you decide.

The Essence of Safety Recognition Programs

A safety recognition program is a structured approach to promoting work safety by recognizing and rewarding individuals or groups who consistently adhere to safety protocols and contribute to a safer workplace. These programs aim to foster a culture of safety awareness, where the focus shifts from merely complying with regulations to actively engaging in safety practices.

Benefits of Implementing a Safety Recognition Program

Enhanced Safety Awareness

One of the primary benefits of a safety recognition program is the heightened safety awareness it instills among employees. By celebrating safety achievements, employees become more mindful of their actions and their impact on workplace safety.

Increased Employee Engagement

Safety recognition programs can significantly boost employee morale and engagement. When employees feel appreciated for their safety efforts, they are more likely to take ownership of their roles in maintaining a safe work environment.

Reduction in Workplace Accidents

Organizations that implement safety recognition programs often see a tangible reduction in accidents and incidents. Recognizing safe behaviors encourages their repetition, leading to a decrease in risky practices and an overall safer workplace.

Positive Organizational Culture

A culture that values safety attracts and retains top talent. A safety recognition program signals to current and prospective employees that their well-being is a priority, contributing to a positive organizational culture.

Considerations for Implementing a Safety Recognition Program

Tailoring to Your Workplace

For a safety recognition program to be effective, it must be tailored to the specific needs and dynamics of your workplace. Consider the unique risks and safety challenges your employees face and design your program accordingly.

Ensuring Fairness and Transparency

The criteria for recognition should be clear, measurable, and achievable for all employees. This transparency ensures that the program is perceived as fair and motivates widespread participation.

Continuous Improvement

Safety recognition programs should evolve based on feedback and changing workplace needs. Regular assessment and adjustment of the program can help maintain its relevance and effectiveness.

Integration with Existing Safety Efforts

For maximum impact, a safety recognition program should complement, not replace, existing safety training and protocols. It's another tool in your safety toolkit, not a standalone solution.

Call to Action

If you're committed to enhancing work safety and fostering a culture of safety awareness within your organization, a safety recognition program might be just what you need. By acknowledging and rewarding safe behaviors, you not only protect your most valuable asset—your employees—but also contribute to the creation of a positive and productive work environment. Contact us now!

0 notes

Text

The Right Way to Weld Aluminium

Aluminium welding can be exciting, especially for first-time hobbyists. However, safe aluminium welding is better for a number of reasons. Not only will abiding by best practices reduce the chances of accidents, but it can also improve the results you get.

Learning how to weld aluminium properly and safely can be done in a few ways. The first is through experience. The second is through getting the right information. The third is combining both.

Experienced welders understand best practices, safety precautions, and crucial information. Doing so allows them to finish any welding project in a timely manner without compromising the quality of the results.

To that end, here is what you need to know to weld aluminium the right way.

Background Details On Aluminium Welding

Welding aluminium is not all fun and games. It presents incredible potential from both a hobby and commercial standpoint. However, no one should go into it without having a basic level of understanding.

After all, you are dealing with a high-voltage machine that bonds materials together using high heat.

The first thing to note is the sheer ubiquity of aluminium welding. It’s done in every corner of the globe for a virtually endless number of reasons. From car manufacturers to aeronautic engineers, the practice is everywhere.

Aluminium welding also comes in many different forms in terms of machinery, techniques, and scope. Someone building a framework for their vehicle will likely be using similar methods as those welding buildings together.

From there, we come to the point of issues that can crop up when welding aluminium. Inexperience will certainly play a role in this. However, not having some relevant information can be even more damaging.

Aside from best practices that are worth sticking with, some of the worst mistakes that occur when welding stem from ignorance. This often leads to a lack of preparation, which can affect your safety and the quality of the results.

Best Practices and Key Information

There are some key details regarding aluminium welding that you simply must know. The same goes for certain practices that every expert welder adheres to. For the former, let’s take a look at the following:

Oxidation - Coats the surface of the aluminium immediately after it has been exposed to open air.

Porousness - Bubbles can form during the welding process and compromise the structural integrity of the project.

Thickness - Thicker or thinner aluminium objects vary in density, weight, and size.

Impurities - Grime, dirt, oil, grease, and others that can interfere with the welding process.

Thermal conductivity - Aluminium can disperse heat quite easily.

Hot cracking - Too much heat in one spot can lead to cracks.

Having all of those details in your head before you start welding can be the difference between failure and success. Too many who go into this practice for the first time don’t really think about such things.

They get a welding machine, and some metals, and start making sparks fly. Then they seem surprised that their dirty aluminium sheet didn’t bond properly with the rusty aluminium pole.

Preparations are always worth doing, especially with tasks as delicate as welding. It needs precision and control, along with knowledge and patience. While experience will eventually allow you to gain all of this as you keep welding, a good start would still be preferable.

Now that the key details have been covered, it’s time to move on to the best practices for aluminium welding:

Protective clothes like overalls, gloves, and boots are critical equipment for any welder. Wear them and keep wearing them until you’re done welding.

The smallest flaws can lead to catastrophic results when welding. Paying attention to the smallest details is needed.

No welding project can be rushed. You can only get faster with time. The actual process itself will still involve patience.

Exposing your materials and equipment to the elements via poor storage is highly ill-advised. Keep them clean and dry.

Conclusion

Those are everything you need to know about welding safely. For the most part, as long as you do your homework ahead of time, you should be fine. You just really need to prepare ahead of time by learning what to watch out for and what you should be doing for the best results.

Need high quality fully custom aluminium products and services? Contact us at Custom Aluminium.

0 notes

Text

One time I showed up for a job interview at a worksite and was wearing steel-toed boots that were green. Only ones I had. When the guy was asking if I had proper footwear I assured him I did and pointed to my boots. He said in such a disappointed tone "oh...I thought those were...fashion boots". Anyway, didn't get the job lol

#memes#nick cage#nicolas cage#work safety#safety first#health and safety#construction site#construction work#safety gear

1 note

·

View note

Text

(source)

having Complicated Feelings (concern, a small but nonzero amount of recognition of the self through the other, admiration, sexual desire,) about this one, lads

#something cw#diy CW#do not try this at home#do not try this anywhere#do not try this while travelling#like#whoever did this is absolutely unhinged#and is uncomfortably cavalier about (read: totally unconcerned with) electrical safety#but like - it works#and it's kinda hot#to me

7K notes

·

View notes

Text

Join the comprehensive International Chemical Safety Cards Training in India in 2023. Enhance your knowledge and skills in chemical safety management. Learn essential safety measures, risk assessment techniques, and emergency protocols. Register now for a transformative training experience.

0 notes

Text

The musical episode.

[First] Prev <–-> Next

#poorly drawn mdzs#mdzs#jin guangyao#nie mingjue#Remember jin guangyao: If you do any treachery you will face the wrath of five horses.#When are the horses going to come into play? You'll see.#s2.ep8 had beautiful music... I listened to it on loop while drawing!#Good music to chill out to before you fly into a rage.#This episode really cements how JGY's mind works - It is a matter of long-term outcomes at the sake of nearly everything else.#Morals do not matter to him if the outcome is more favourable.#and at the center of it all - he has learned that the only person he can truly trust is himself.#In turn - the only person his actions benefit are himself.#He will do anything and everything it takes to reach a position of power - not just for the power. But because it means safety.#Because it was something he was denied and the idea of not having control in his life again is unforgivable.#'Happiness' isn't a goal. We are looking at someone still stuck at the bottom of Maslow's hierarchy of needs.#Everything and everyone is a piece in a game. Bonds and friendships are assets. People are dispensable.#He wants to climb for the sake of climbing. He wants praise and recognition because he feels it is deserved. It's all so hollow.#We could go deeper into his psyche on this.#But these are also tags under a comic in which 'evil penis music' is the punchline.

4K notes

·

View notes