#like specifically 3d model wise not even printing wise

Text

I know no one gaf but I love how no matter when we see them, the Forbidden Five are always in the same positions.

#the 3rd one is a blood moon vision btw .#thats why we can actually see their unprinted black heads in the 3rd one lol#and why theyre posed so ... gayly.#so dramatic and for WHAT#stupid little f#ninjago#ninjago dragons rising#raine's rambles#ninjago spoilers#forbidden five#also i noticed this earlier. hoodface and the smaller bucket face are the same models lol. idk why they didnt like . detail them out .#like specifically 3d model wise not even printing wise#why no bandage face ...#like the guy w the tiny scythe thing ? wheres THEIR face bucket !!!

71 notes

·

View notes

Text

Draftsight professional review

DRAFTSIGHT PROFESSIONAL REVIEW HOW TO

DRAFTSIGHT PROFESSIONAL REVIEW PDF

DRAFTSIGHT PROFESSIONAL REVIEW UPDATE

DRAFTSIGHT PROFESSIONAL REVIEW FULL

Binary and ASCII DXF files can be created through the program.The interface can be adjusted and customized to one’s desire.

DRAFTSIGHT PROFESSIONAL REVIEW HOW TO

Yes, Solidworks is designed specifically for 3D solids, yes, so is Inventor, but AutoCAD works just as well as long as you understand and know how to use the program.The positives that come with Draftsight are especially noteworthy: I was one of maybe 10 people using AutoCAD there, and I still did well enough to be proud of. I went on to the national conference and placed 32nd out of about 60 competitors, each the best in their state (and also puerto rico, navajo nation, etc. Everybody, including the other two competitors, said that my design was far superior. The design was a complex 3D shape involving sweeps, chamfers, extrusions, lofts, etc. Sure the program plays a part but it's definitely more about skill than what program you use.įor example, last year at the state SkillsUSA conference I won the technical drafting competition using AutoCAD against two other people using Inventor. Once you learn the program it more than holds its own against Solidworks or Inventor. That way you get to create drawings faster, but also maintain the utility of 3D cad.ĪutoCAD is most definitely not a solely 2D software. And then use 3D sketches, weldments, and parametric equations to build out templates. I would definitely see if you can standardize design principles. This cut drawing time from 8-10 hours down to maybe 30 minutes.

DRAFTSIGHT PROFESSIONAL REVIEW UPDATE

Some of the more complex templates also include assemblies with hardware that updates based on the equations, and driven parts that update with the frame. So my workflow is to pack and go the template drawing to the project folder, open the frame part file, change the numbers in the equations to match what was sold, and then update the drawing the match the customer information etc. For example, my job mostly consists of modeling aluminum frames, and I’ve created a template using equations to drive the frame spacing and type. If the docks follow repeatable design standards, such as x beams every so many feet, y amounts of floats spaced regularly, then you could create a template that could be reused for multiple projects. However, I think if your optimized your workflow and automated some of your modeling processes you could significantly reduce modeling time. To answer your main question, no, solidworks isn’t good for designing in 2D. It sounds like your workflow is a little rough for solidworks. Just trying to improve efficiency is all + not sure if Autocad would be better career wise if that was a pursuit. The other half of this is everyone around me only knows of AutoCad - I'm wondering about maybe trying to get into Cad as a job outside family. There's a course on lynda that I could do (for draftsight) and see how far it takes me.

DRAFTSIGHT PROFESSIONAL REVIEW PDF

However, if we want to get that into parts - I make the whole thing in 3D - individual parts - make drawings for each part - compile that into a binder.ġ) Is solidworks even meant for 2D at all? If not thats fine just need to know if I'm pounding a round peg through a square hole.Ģ) Would Autocad be better suited for all of it? Getting a PDF -> doing a 2D sketch and then making a bunch of parts to send for fabrication - having a 3d view for selling the product.ģ) would Draftsight work just fine for the 2D and thus worth learning? What I currently do is nothing fancy but it seems like Solidworks isn't great for 2d drawing (however, I have nothing to compare it to). Do a sheet with multiple layers and then split that into individual sheets? frustrating.įor instance - my work flow is we get a plan with a footprint and a general footprint of a float - then from that foot print I gotta lay out timbers (which is much faster in 2D). Trying to a sketch pattern and then edit that pattern after? owch. So I've been doing 2D in solidworks and it sure doesn't seem like its very good for that. So naturally my ol' man wants to do just 2D.

DRAFTSIGHT PROFESSIONAL REVIEW FULL

However, 3D takes me a bit of time to do a full giant piece. He was sold on Solidworks - and if I want to make a full 3d rendition of a marina - it works awesome - make parts from those 3D pieces (just long boxes with holes) - awesome, great, love it, perfect. I do a bit of Cad for my father doing Dock design. Kinda rambly, apologies if it makes zero sense just ignore if so haha.

0 notes

Text

<h1>Choose Insurance Firm For Home & Materials Insurance Coverage Quote</h1>

Parts like genuine water spurting system can create exceptional results when it is used to make pool and fountains. The office complex version brings the designer's style to life by creating various illumination configuration, detailed structure facade. Ifferent from conceptual models, version manufacturers take complicated products like metal, concrete, etc to make the working models. Making architectural designs is a reliable method to aid the architect connect. This indicates that architectural imagination will remain to make use of building versions. The results and the applications of building models maintain enhancing as well as innovating.

" Inch. Style" is a team composed of several young developers, utilizing different design elements.

Team Within Layout is a set of professional with a dedication to fulfill customers needs on home production.

The Financial institution books the right to bill such Qualified Consumer a quantity equivalent for the Offers granted.

The Council additionally prompts traders to refrain from making questionable quotes yet ought to offer their solutions seriously and also honestly to maintain their own track records.

Control damage from managing using physical defenses as well as ideal handling techniques for building designs.

The Council also consulted the Hong Kong Institute of Surveyors on points to note for consumers preparing for house renovation. Residence renovation, be it a total overhaul or simply partial design, mostly sustains a considerable quantity of cash. Nevertheless, customers generally 裝修報價 do not have much experience in reviewing the work called for and the quotation. In instance they are not careful enough as well as ignore the information on the quotation, it would quickly generate conflicts, and the most awful of even uncompleted jobs.

Family Definition Print, Instant Download, Residence Style, New Home Gift, Living Space Style

Following in the footsteps of Mahatma Gandhi and also Nelson Mandela, Daw Aung San Suu Kyi stands as a beaming icon as well as worldwide ideas for calm resistance to harsh repression. Extra especially, she symbolises Burma's struggle for freedom. She has spent virtually one quarter of her life in detention in the root cause of liberty as well as autonomous adjustment.

Additionally, rolled right into thick sheets, you can additionally cut clay and also plasticize to make wall surfaces for large presentation designs. It is simple to utilize without the demand for unique equipment during the manufacturing as well as installation process of the model. And also it is just one of the structure model-making products to make the framework and also the framework of the buildings. Actually, it is just one of the hardest version structure materials among all other 3D published plastics. On the one hand, presentation models requires long lasting, steady and also fade-resistant products. To pick appropriate materials, the engineers require to consider specific design standards to identify the most effective materials.

Exactly How Expensive Is A Wise Home Restoration?

Each piece is handcrafted to guarantee you are obtaining the high quality you should have at a budget-friendly price. It will likewise offer you a foot in the door to the market through our one-month teaching fellowship program, which 95% of the moment results in full time employment. The Diploma in Interior Design consists of both the Certification in Interior Design Residentialand the Certificate in Interior decoration Commercial programs.

裝修報價 "/>

0 notes

Text

Mediums - Master List of Comic Making Digital Programs and Apps

While you can make some form of comic with just about any art software if you try, choosing quality art software that is geared toward the unique needs of comic-making can make your life easier. There are programs across every operating system and price range (even free!), and community resources like video tutorials and brush packs for many of them.

Things good comic-making programs and apps have in common:

Ability to handle large files at print resolutions (300dpi) in case you ever want to print your comics.

Layer functionality for keeping your art, panels, and text separate and editable.

Connectivity with pressure-sensitive tablet hardware to emulate the drawing experience.

Compatibility with your operating system (not every program works on every computer or tablet!)

An active userbase invested in making tutorials. While you can go it alone, the more popular a program is, the more resources you have from the community when you get stuck.

Here's our current list of recommended comic-making programs!

Clip Studio Paint/EX

Price: $50 (Paint) /$219 (EX), monthly subscriptions from $2.09-$14.99/month

Platform: Windows, macOS, iPad, iPhone, Galaxy, Android, Chromebook

Clip Studio's software is specifically made with comics in mind, and comes with built-in word bubble, paneling, 3D modelling, rulers, and many helpful tools. Clip Studio has frequent sales and is very actively engaged in the comic-making community, integrating a lot of new features like Webtoon scrolling formatting and timelapse recording in their recent version.

Beginning Tutorials:

VAMPBYTE's Intro to Clip Studio

Procreate

Price: $10

Platform: iPad only

Procreate is a raster graphics editor app for digital painting. It is iPad-only and specifically tooled for touch response and the iPad pencil, which it is integrated very smoothly with to emulate the feel of physical drawing. Also allows integrated export of process videos. The larger your canvas, and/or the higher the DPI, the fewer layers you'll have to work with, presumably to keep things manageable processing-wise.

Beginning Tutorials:

James Julier's App Guide to Procreate (video)

Paint Tool SAI

Price: $50 after free trial

Platform: Windows

SAI (or Easy Paint Tool SAI) is a lightweight painting software, with very smooth painting functionality. As of SAI2, the program now has some shape and text tool functionality, though it is still limited when it comes to tools for assembling art into a comic page format.

Beginning Tutorials:

Anastasia Purtova's Beginner's Guide to Paint Tool SAI

Krita

Price: Free

Platform: Windows, macOS, Linux, Android and Chrome OS

Krita is a free and open-source raster and vector graphics editor designed primarily for digital painting and 2D animation. It has good gesture/hotkey commands to make switching tools quick and easy.

Beginning Tutorials:

Sara Tepe's Introduction to Krita (video)

MediBang Paint

Price: Free

Platform: Windows, macOS, iPad, iPhone, Android

MediBang is a free digital painting and manga creation software. The smartphone and tablet versions are particularly optimized for mobile devices, and auto cloud backup are nice. Particularly nice for comic creators are the comic page file types, which inlcude include page margins and guidelines, and the edge pen which lets you create adjustable speech bubbles.

Beginning Tutorials:

Winged Canvas How To Use MediBangPaint Pro (video)

Adobe Photoshop

Price: $10/month

Platform: Windows, macOS, iPad

Adobe Photoshop is the oldest and most established art program out there, and the PSD file format it uses is a standard that most other art programs also try to align to. Many brushes and resources have been developed for it over the years. It is very multi-purpose and used across many artistic disciplines, so while it can do almost everything the above programs can do, it isn't specifically made with comic artists in mind. It's also the only option that has a recurring subscription fee, which can be a hard hit unless you're getting the software through work or school.

Beginning Tutorials:

Justin Oshido's Adobe Photoshop CC Beginners Tutorial (video)

290 notes

·

View notes

Text

6 Tough Lessons Learned From Freelancing For 6 Years 💸💜

Here is a list of 6 tough lessons learned from freelancing for 6 years. These are some of the lessons that I had to learn the hard way. Don’t be dumb like I was! Learn from my freelancing mistakes.

💜 6 Lessons Learned from Freelancing

So… I have to let you in on a little secret.

This is probably a shock to no one, but I didn’t exactly hit the ground running when I first started freelancing. When I first started, I had to take several L’s in my beginning stages, and it was tough. Unfortunately, I had to learn it the hard way – through trial by fire.

I sucked at freelancing for a WHILE. There were so many mistakes made that I’m surprised that I stuck with it.. or made any money at all. I got serious about freelancing when I was too broke to move out from a toxic relationship… (story on how I went from broke to $1000 a week here) but for a good while, my freelance side hustle was a flop at BEST.

If you’re a beginner, learn from my mistakes.

Learn from my lessons learned from freelancing. Don’t be stupid like I was! You don’t have to learn the hard way to become a success. Here are 6 tough lessons I’ve learned from 6 years of freelancing.

“A smart man makes a mistake, learns from it, and never makes that mistake again. But a wise man finds a smart man and learns from him how to avoid the mistake altogether.”

Roy H. Williams

Related Article: Advice For Freelance Beginners

💜Lesson #1 – As a freelancer, you are now your own business, NOT an employee

And don’t let anyone treat you as such.

The first lessons learned from freelancing is this. Hear me loud and clear: You’re the boss who is running things now.

Of course, you will have clients to please, and you should go above and beyond on your services for them.

Also, make sure you are open-minded about the categories that require collaboration. Sometimes clients will have specific restrictions, times, and other requests or suggestions. But this my dear, is a business transaction first and foremost.

Be Your Own Boss

You are the one who dictates your schedule, your pay, and your limitations (more on that later.) The on who decides your working conditions is YOU. They are not hiring you as an employee and you are not at their beg and call.

“At the end of the day, I’m the biggest boss. I’m self-made.”

– Rick Ross

Last but not least, as a business, make sure you set yourself up for success. Be sure to check out: How to Set Goals for Your Freelancing Business as well.

💜Freelance Lesson #2 – Some work isn’t worth the money

The next tough lesson learned from freelancing is this:

Do not work with problematic people.

The word “NO” will become your biggest ally when your freelance career gets going. Trust me, some work is not worth the money.

Sometimes, this will take some trial and error before you get the hang of it, but I realized that the clients that I REFUSED define me just as much as the clients I took on.

Freelance Client Red Flags

If you see any of these red flags, consider turning down this client:

Client is nit-picking constantly and unreasonably

Your client is trying to lower your rate

They are unprofessional, dismissive

Client goes long periods of time without responding to you or paying you

The client is overly critical, hot headed, or just plain mean

Client and you just don’t mesh well

They withhold payment from you or they are a hassle to collect payment from

You feel uncomfortable IN ANY WAY talking to this client.

Avoid Stressful Clients Like the Plague

If you feel like this client is going to be trouble in any way… DON’T DO IT.

I have gained so much peace of of mind by firing and rejecting problematic customers. Time is money, so don’t spend valuable time on stress.

Choose to work with people who you have a good rapport, who are polite, and who has mutual respect with you. Having “no client” is actually 100 times better than having a bad one.

“When two people talk with mutual respect and listen with a real interest in understanding another point of view, when they try to put themselves in the place of another, to get inside their skin, they change the world, even if it is only by a minute amount, because they are establishing equality between two human beings.”

– Theodore Zeldin

💜Lesson #3 -SERIOUSLY- The ability to say no is a BLESSING

Another serious lesson learned from freelancing was this: I am not going to be able to be everything to everybody.

This is why you have a unique specialty and skillset. Both you and your client will have a better experience if you are able to set boundaries from the beginning.

Back Away From The Money!

I know it sounds crazy to turn down the money, but like I’ve said before, some money just isn’t worth it. Some jobs will cost you more in the long run than they are worth. Let me give you an example.

When I first was starting out as a graphic designer, even though I had narrowed a specialty, people asked me for all kinds of things. These requests ranged from 3D modeling, video editing, and logo designs, even though I was more of a print designer.

One of my biggest mistakes

One of my biggest mistakes was taking on a video editing project. I had very little experience with video, but I had built a relationship with a client and I didn’t want to turn down an opportunity when I desperately needed the money.

My lack of experience should have been my first clue not to take it. The second clue should have been that this was a rush project, and I would be burning myself out to get this thing done. I needed a miracle, but all I had was elbow grease and a stubborn will.

I sleeplessly worked on the project for 12 hours, and it looked like crap. Stupid decisions were made- I was an idiot because had only billed the client for 4 hours. I ended up wasting time, money, and effort on a project that was not meant for me. Not to mention… with such a terrible video, I never heard from that client again—not even for graphic work.

Make sure you draw lines in the sand when possible. If a project isn’t right for you, send your client elsewhere. Manage your client’s expectations as well as your own. Don’t take on any work that you are not qualified for. Trust me.

💜 Freelance Lesson #4 – “That’ll cost you extra.”

I highly recommend that you become acquainted with “That’ll cost you extra.”

From the creators of “No”.

This phrase should be within an arm’s reach for when your client requests anything “beyond”.

Anything that is an emergency will cost you extra. Rush? That’ll cost you extra. Can we just add another… EXTRA. Make sure you have the proper upcharges in mind for any additions that may happen. Don’t be afraid to speak up for yourself and your business.

If you have a client that respects your time and you as a business, they will have no problems paying a fee if it is truly necessary. If not.. not to be rude, but it’s not your problem.

Tough Lesson Learned From Freelancing: Don’t Let It Slide

Trust me, do not think you are being nice by letting something slide once or twice for free. You will be hurting yourself in the long run, because that client will take advantage of your kindness. This will add extra stress to your job and could cause you to resent your clients.

I would also recommend that newbies check out this article for more tips: Freelancing Tips For Beginners: What I Learned My First Year

💜Lesson #5 – A good third of your time will be spent outside of your craft

Like we’ve discussed earlier, as a freelancer you are now the holder of your very own business.

This leads us to the next lesson learned from freelancing.

You will need to make sure that you stay on top of your day to day tasks. These tasks will include keeping track of your income and expenses, planning out your taxes, dealing with your client’s Human Resources Department or Payroll company, and countless other things.

Client communication will also take quite a bit of your time. You will need to make sure you are landing clients, communicating on project status, and keeping up work quotes and invoices. You will also have to stay on top of who has paid you and who hasn’t.

Lesson Learned From Freelancing: Bill for Admin Work

Make sure that you pad this business minutia into your pricing structure, so that you are still getting paid for this time.

Although this sounds stressful, it’s still worth it. The financial freedom that freelancing has allowed me has been invaluable. In addition, getting to make money doing a job that I love really overruled the minutia of business.

Adulting will sneak in through the cracks in all forms, so just make sure to stay on top of it.

💜Freelance Lesson #6 – Be Honest and Own Up to Problems

The final lesson is an important one, and it ties into some things that we’ve already discussed. Make sure you are honest with yourself and your clients.

This goes along with setting boundaries, being able to say no, refusing work that are outside of your scope, and knowing your worth. Be truthful, upfront, and forthcoming, and you will be successful at freelancing.

Not only will you manage realistic expectations for you clients, but you are prioritizing your own wellbeing. Never, ever over-promise and under-deliver.

When Problems Arise

Sometimes, the issue is a miscommunication, or sometimes it’s more serious. Bring things to your client’s attention as soon as it’s a roadblock for you.

The worst time to tell them is when a project is due tomorrow. Work together on these issues to make sure both you and your client is happy. Hey, customers are human too who f up just like the rest of us.

The good ones tend to be understanding as long as you are reasonable!

“I’m not perfect; I make mistakes all the time. All I can do is to try my best to learn from my mistakes, take responsibility for them, and do a better job tomorrow.”

– Lana

💜What It All Boils Down To:

When I first started freelancing, I was kind of a pushover. I let things slide, let people try to control me, and let them walk all over me.

Not anymore.

Throughout my career, I’ve learned to create boundaries and draw lines in the sand like I never have before in my life.

I learned how to speak up for myself and be an advocate for myself and my business, all while gaining respect from my clients and looking stunning in the process.

That is what being a boss is all about.

“Really, every day is the perfect day to boss up. Every day that you wake up is a perfect day to boss up. It’s all about continuing to put one foot in front of the next. That’s what it’s about. Whatever you think you’re going through, just put one foot in front of the next.”

– Rick Ross

Are you a newbie at freelancing? Check out The Ultimate Freelance Guide for Beginners

1 note

·

View note

Note

That Allister cosplay is outstanding!! How did you make the mask and the gym symbol+endorsements? I'm planning on doing an Allister cosplay in the future myself

Thank you so much, and happy to answer! I took lots of pictures through the process so I’ll answer this in two parts.

“How did you make the gym symbol/ endorsements?”

So the first thing I did is take a TON of screenshots I have almost 300 screenshots of reference images of allister and the gym league trainers and the pokejobs logos and so on to get good references for all the logos I needed.Once I was done taking all the screenshots I spent hours tracing them to the best of my ability to create these images: (Not all of these were the final versions which were modified right before printing, apologies)Gym Logo - QUAY/ Gym Logo

XXA - Sponsor (This is the logo for MC Insurance, Allisters Sponsor)

291 - Number

ASTSA - Name (This is the new pokemon language for Onion, Allister’s japanese name)

The square with the diamond - This I nicknamed the “NIKE” cause its the logo for the spotswear company in game

Galar league logo - Galar League logo (this is the logo thats the red and blue pokeball with white marks, and “galar league written underneath it)

And then I put together this ref sheet to make sure the logos looked good together color wise, and some of the colors were still altered later but it all looked pretty good

And then once the logos were all set, I printed them onto heat transfer vinyl and let me explain why I did that specifically. The fabric I used was polyester, which is the kind of fabric that sports jerseys are made of. I did that because the gym’s uniforms are based on soccer jersey’s so it felt fitting!IT WAS A HUGE PAIN I DONT RECOMMEND ITbut now because of the fact that it was polyester paint wouldnt’ work on that fabric because of how stretchy it is and the fact it doesn’t absorb moisture easily. So we printed it onto heat transfer vinyl with my cheap ink printer and then I ironed them onto my clothes! I made sure they were placed correctly by first taping them to my clothes and making a note of the location before ironing it, and then once I was happy with a placement I’d carefully iron it on. This vinyl seems kinda cheap and like the ink might come off with too much water so watch out if you choose to use it. There are also printable iron on paper for other types of fabric as well and are cheaper iirc!

Same goes for the dots, thos were all cut using a CNC/ off brand cricut (just a bunch of circles all at once) and I placed them by hand using painters tape and trimmed as needed to make the designs:

Hopefully that was helpful!

“How did you make the mask?”

So this ones a little more complicated to answer because its not complicated but its not something everyone can do.

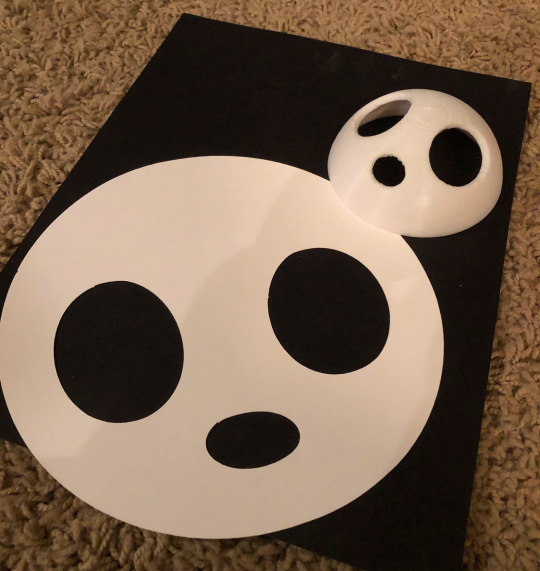

So we started on this one before the game came out, and before I’d gotten to Allisters battle in the game but we had enough reference material to figure out the general look of Allister’s mask, so we made a 3D model of it that we planned to 3D print (my bf has a 3D printer and a CNC and helped me a TON for this project) and did a test print of a tiny mask to start to make sure we were happy with the 3D model (here is the tiny mask in my tiny hand, we affectionally nicknamed it “mini mask”)

Now after we had the 3D model we had another issue of how big does it need to be? I have a round head on my own so I didn’t need to modify the shape of the mask thankfully (one time my fat head came in handy!) But we needed to figure out how big to make the mask to make sure it “fit” correctly.

So we tried cutting out a circle with paper in a few sizes until we thought we found a good size for my face (which for me was a little over 7 inches)

went and bought a styrofoam dome from the craft store in that size to make an EVA foam dome and then checked if that fit my face (later this worked fantastic as a way to transport the mask as a protective shell around it) I don’t have a picture of this EVA foam dome but all it was used for was putting it on my face and making sure it went over my chin and such. Once we had that we were ready to start printing the final mask.

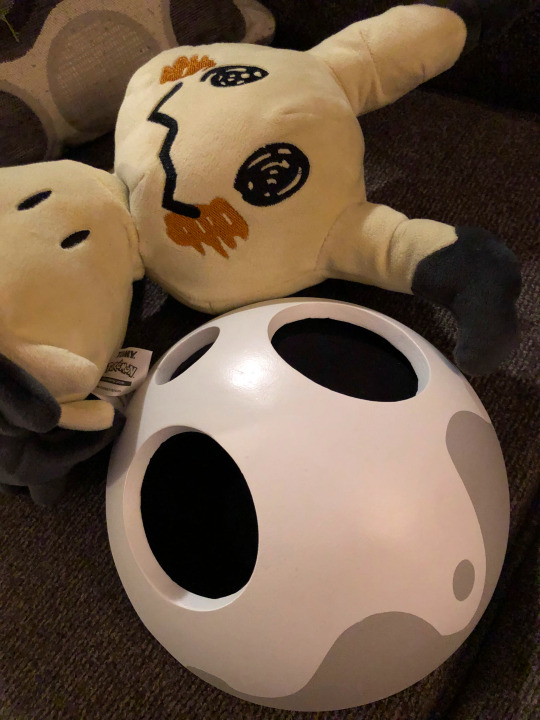

Once the 3D model was scaled for the final mask, it was too big for my bf’s printer to print all in one go so we split it into 4 pieces. Each piece took about 9 hours to print, and a few of the prints failed and had to be redone, so after a few days of printing it looked something like this:

for those who don’t know much about 3D printing all those beams are the supports that lets the printer print raised surfaces like that and have to all be removed. So after about 2 hours of pulling plastic with pliers it looked more like this:

so we left small gaps in the edges of the mask so that we could put metal pins between each piece to help hold it together so we cut our metal pins and assembled the mask and it was starting to come together!

So from here we melted some plasitc onto the seams (plastic welding!) with a wood burner and - wow that looks gross

but trust me its better than gaps in the mask. so after a bit of sanding here we entered the rounds of priming it with spraypaint primer and sanding it for like an hour and doing that again, occasionally using bondo putty to try and even out those seams and those rounds tended to look like allister just murdered a village:

but you can see compared to the previous image that the mask is a lot smoother! This was the final round of sanding and you can tell that most of the layer lines from the printer have been sanded down! You can almost not see the seams anymore! (though now they’re also very red but they’re very smooth in comparison to the beginning trust me…I sat there sanding for many hours for this)

But after this all that needed to be done with a final priming in grey, and then painted it gray!

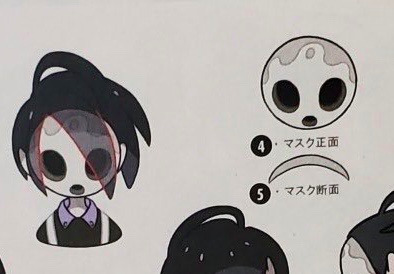

While the paint was drying, we prepared some masking in the design of allisters mask which if you don’t know what the full mask looks like I wanna reference this from the collectors guidebook (which I just now got my hands on today but saw these on twitter)

So we cut out a sticker sheet in that design and placed it down with some painters tape to keep that part of the mask gray and then it was painted white, and that was the painting done!

For the black in the eyes, I got a scrap of black fabric for cheap at joann’s that I picked up and pulled and it was a very soft polyester/spandex material that you’d use for pantyhose so i’m sure you could also cut up some of those for a similar effect. But when stretched you can see out of them.

So we made small rings the same shape as the inside of the mask behind the eyes, glued the fabric using super glue to that ring (and the mouth as well) and viola:

and then the final step was to get that mask on my face, and basically we had some rings on the left and right sides of the inside of the mask that I attatched some elastic too, and then needed to glue a third strap over the top of my head. and sewed it all in place and put some craft foam along the forehead and chin inside the mask for some cushioning and it was done!

I really hope that was helpful and I tried to make sure I took lots of photos along the way so I hope they were helpful. If you have other questions feel free to ask! Sorry for the novel but just wanted to be as detailed as I could be!

Thank you for your nice words and best of luck!! Allister is a detailed boy but he’s very fun!

#my cosplay#allister cosplay#allister#gym leader allister#cosplay help#cosplay reference#allister reference#galar#swsh cosplay#cosplay description#ask#answered#long post#if theres other tags I should add let me know#anon

101 notes

·

View notes

Photo

Fox’s Blaster (Super Smash Bros Ultimate)

This is my first finished prop and I am incredibly proud of it. It is not my first prop because I’ve started a few in the past and just never got around to finishing them either for complications, not enough skill, or just boredom; but it is the first prop I’ve completed. I intend to finish all those other, but I just wanted to ride the motivation for this one and it certainly paid off.

For anyone interested in how I made it, please continue reading.

(Tried to edit which messed up my post so most of the pictures are unreadable. Trying to fix, but connection is shoty. Check out someones reblog to see all)

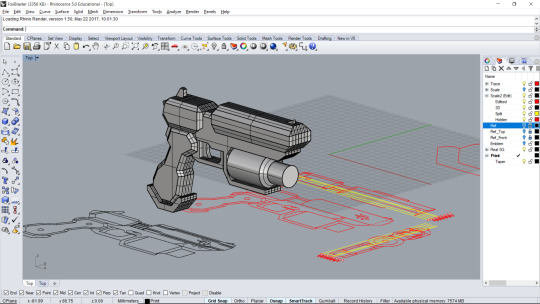

Step 1: References and Drafting

First I needed to get some reference images for the blaster. Thankfully, Smash Bros has a convenient in-game camera mode so I was able to zoom in and take screenshots of the blaster in any frame of gameplay.

I briefly considered making the blaster able to open up like in the second image above, but I had no idea how to do that and figured it’d take too long to figure it out, let alone actually make a prop capable of that. So, I decided on a single piece prop with nothing moving. Better to keep things simple when you’re starting out.

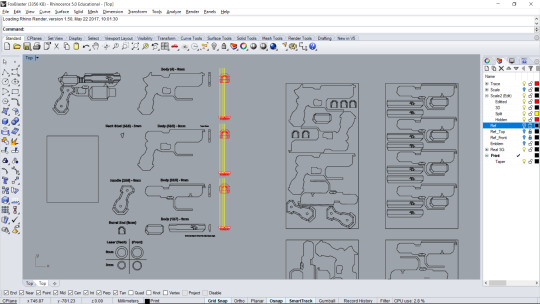

Now I had to draft outlines for it. I use Rhino 3D for all of my drafting, whether 2D or 3D.

I imported my reference images and traced them as best I could. Unfortunately, since there’s no option to turn off perspective in Smash, some dimensions were a bit off, but hardly an issue.

Before I went any further, I needed to make sure I had the right scaling, so I made a mock-up. Since I needed the handle to fit my hand, I made it out of layers of PVC foam board and just used cardboard for the rest of the gun.The sizing was actually perfect by coincidence, but I needed to determine the best thickness. I tried out a few thicknesses for the handle with different numbers of layers and found 5 layers of 6mm foam board was perfect.

Next I made a 3D model to make sure all my dimensions looked right when put together.

Step 2: Materials

Before I did anything to start making the physical prop, I had to plan out all my materials and cuts. I did some adjustments to my traces so that a length wise cross section would fit into several pieces of equal size. Below, to the left of the yellow lines, are one of each kind of cross section I need. There are 7 total layers. The largest pieces are within layers 2-6, comprising the main body of the blaster and part of the handle, as well as support for the laser-sight barrel. After those are the two outer layers for the handle which will have some beveling, and then layers 1 & 7 include a few smaller pieces to add bulk to the two bulging sections at the top of the gun.

The section to the right of the yellow lines are for planning out how many cuts to fit into each board of material (For some reason I doubled a few layers on the right sheet, not sure why).

Materials (everything in the finished product):

6mm PVC foam board (celtec)

1″ PVC pipe

1.5″ PVC pipe

PVC cement

Spray paint

Acrylic paint

Tools and disposable materials:

X-acto knife

Straight-edge of some kind

Sand paper, both fine and course versions

Blue painter’s tape

Brown paper

PVC pipe cutter (any kind of saw will also work)

Thumbtack (or something with a fine point)

Large piece of cardboard (painting surface; can use whatever you don’t mind being spray painted)

I spent some time debating what I wanted the blaster to be primarily made out of. I had worked with PVC foam board before and I knew it was high quality and would provide a good weight to the prop. I also considered EVA foam which I’d just heard about at the time, or just plain cardboard. PVC foam board was the best choice, though I does take a few passes with an X-acto knife to cute through 6mm, but if you’re patient it’s worth it.

Step 3: Cut and Assemble

Now comes the tedious part.

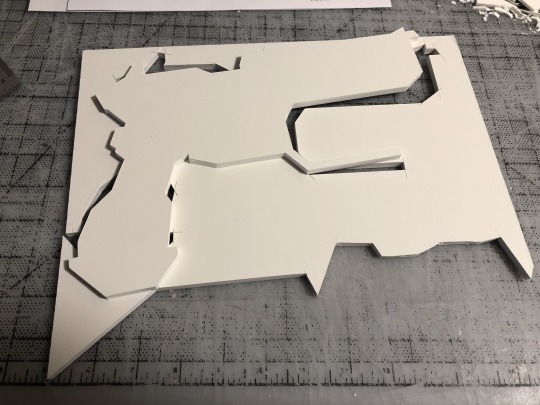

Since I had digital plans I printed out full-scale outlines of each part. I then taped the sheets down on the PVC boards and used a thumbtack to poke the corners of the outlines and leave small impressions in the board. Then with a straight-edge I used my X-acto to connect the dots and cut out each piece.

Below is layer 5, i.e. the middle most piece of the blaster.

The PVC board is pretty dense, which adds to it’s quality, but like I said I had to run through each line several times before cute when all the way through. Do not rush this part. I may have been a bit too anal about it, but I did not want any mistakes at all.

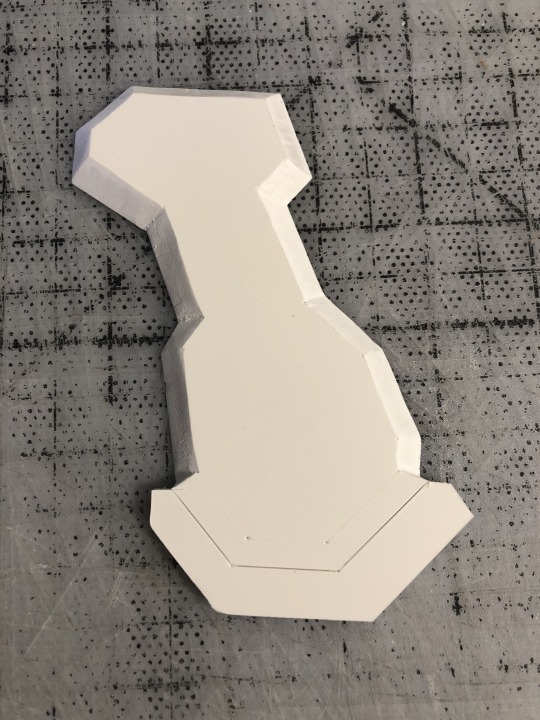

Some pieces required beveling. I do not have any kind of table saw or other tool made specifically for beveling so I did it all by hand with my X-acto knife. This requires even more patience than the last part. Once you cut too much, you can get it back on and look the same. I recommend listening to some music or have a show play in the background, just be careful with the knife and always cut away from yourself.

Once all the board and pipes where cut I cemented everything together. You can see the other parts which have beveling. Again, takes a long time, especially when it’s circular.

What I found is despite my best efforts, not all the parts where exactly aligned and flush with those next to it. this part was 0.5mm too high here. This one was 1mm too thick there. I spent a lot of time sanding everything down so the edges were all aligned. I didn’t get everything perfecting flush due to my limited tools, but I was happy with it. This actually killed two birds with one stone because I would have needed to sand it down anyway so the paint would hold onto it better.

Step 4: Painting

Now for the fun part.

The base of the blaster is black so I can paint the whole thing a black coat, but for the grey on parts like the outer handle I’ll have to tape sections off to protect the black.

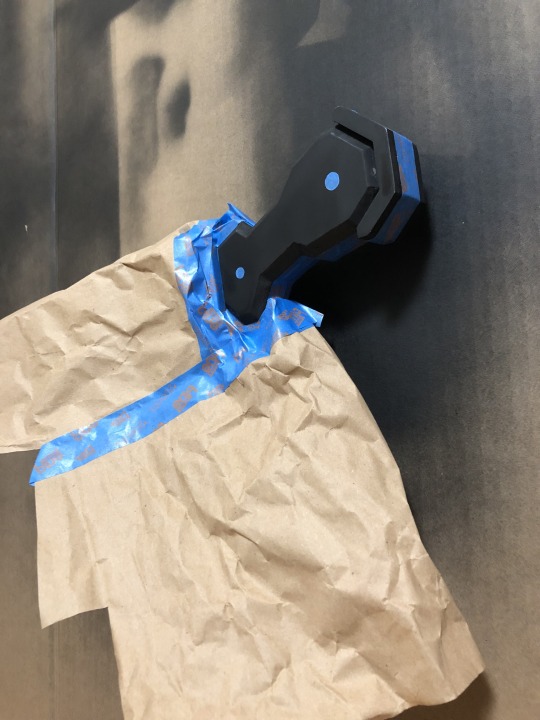

As you can see, the only thing I taped off from the black coat was the Star Fox emblem on both sides of the barrel. Since it’s small with lots of curves and made of tape, I had to be delicate with cutting it.

But I think it worked out. Just a little tap residue to wipe off.

The grey was fun because of how I had to weave tape between all the joints and crevices. As you can see, used brown paper and taped that on, rather than cover the whole thing in a layer of tape. Just tape along the edge of the paper and attach.

Lastly, the finer details, i.e. anything orange or blue. I did all these details by hand, again using painter’s tape to make sure my lines were exact. Don’t forget to sand whenever you put on a new layer of paint. I forget to sand for the orange on the picture below the first time and the acrylic ended up peeling off. Sand so the paint can grip onto something rather than a smooth surface.

And voila!

Pretty damn close to Nintendo’s replica (below), don’t you think?

From start to finish, this took me about 2 months in my down time. 1 month drafting and obsessing over how every detail needed to be replicated perfectly, and 1 month of actually building it. I should have paid a little more attention to the spray painting, though. I’ve never spray painted before I had trouble figuring out the right distance to hold the can, and some of the grey paint found it’s way under some edges of the tape, but not a big deal. And maybe some time spent to texture the handle.

Overall, I absolutely love it! It’s got a great weight to it, feels wonderful in my hand. I don’t think I’ll ever cosplay as Fox, but this has been a wonderful use of my down time rather than just web-surfing and video games all the time. I built something with my hands. There’s nothing quite like it.

If you enjoyed this, consider supporting me on Patreon at https://www.patreon.com/erikchamber

#star fox#fox's blaster#smash bros#super smash bros ultimate#ssbu#smash bros ultimate#gotta blast#cosplay#prop#cosplay prop#sci-fi#pvc foam#first cosplay#blaster#nintendo#fox mccloud#spam b

65 notes

·

View notes

Text

Factors That Should Matter When Buying A 3D Printer

New Post has been published on http://www.webshophost.xyz/2021/01/14/factors-that-should-matter-when-buying-a-3d-printer/

Factors That Should Matter When Buying A 3D Printer

3D printers create three dimensional objects that vary from parts models, tools and toys and many others from digital 3D files. The printing technology has been embraced in the various sectors and industries and for this reason the machines have become relatively popular and affordable. You can choose a small 3D printer for your home needs or bigger, more sophisticated models for commercial 3D printing or for industrial production purposes.

But considering that the market has become populated with the printers now, it is wise that you take all important factors into consideration so that you end up with a machine that meets your printing objectives. Below are some of the most important elements to think about when getting a printer for your three dimensional printing needs.

1. The printing technology

Not all printers use same printing technology. PJP or Plastic Jet Printing is the most popular printing technology and it involves creating the objects by layering a plastic material successively until the object is completely made. These layers are created by modeling software and formed by extruding plastic material in continuous length via a heated nozzle; the material hardens immediately after the extrusion. Think about the technology your printer uses and select accordingly.

2. The printing materials

When choosing a 3D printer, think about what materials, spools or filaments it is compatible with. There are various types of materials and truth is some machines use specific materials. The most major options you have include nylon, wood, resin, high impact polystyrene filament, stainless steel and resin. Check out the pros and cons of each of these materials and then ensure that your machine will actually accommodate the materials you are interested in for your type of 3D productions.

3. The printing attributes

Your requirements should guide you into the perfect printer in terms of performance attributes. When comparing the machines and the printer models in terms of attribute, think about print area or the build volume, printing speed, layer resolution and extruders. No one machine is completely similar to the next so make sure that you are buying one whose printing attributes actually meets with your specific requirements.

4. The machine features

The printers continue to become more and more sophisticated, most come with very interesting features designed to make the printing process easier and enjoyable. Some features that should matter when selecting a printer for your 3d needs include display and LCD, connectivity, assembling and additional features like camera, automatic material recognition and combined abilities, meaning you can use your one printer for copying, printing, faxing and even scanning. If you care about how your printer looks, then it would also be wise to consider the aesthetics.

5. The printing software

Most come with own 3D printing softwares, so you are able to rotate, scale and even resize the model as desired. The software also makes it possible to choose different printing settings like fill type and the layer thickness. You can however also consider modeling software to breathe life into your creation.

3d printer

0 notes

Text

Wise Motor For Industrial Machines: Keeping It Simple

Technology throughout factories has always been developing. From equipment like an overhead workstation crane system aiding improve efficiency and the factory workers jobs quicker to A 3D MODEL printing cutting the cost of the manufacturing course of action, new-technology has generally already been beneficial to factories. And nowadays, there is a different development which might help to make processing even more useful – Detectors.

Sensors have been making their way in to manufacturing facilities regarding some time now. These kinds of small, high-tech devices present manufacturers a new new strategy to see exactly how their very own capability is running in addition to reporting any issues in current. Integrating verhead free standing factory crane into manufacturing equipment and systems lets manufacturers foresee likely breakdowns and make repairs in advance of unscheduled downtime wreaks chaos on the business.

Quite a few manufacturers are looking to upgrade their own facilities that include these precious devices, nonetheless it doesn’t come cheap. Fresh equipment can cost tens of thousands and thousands of bucks and the particular sensors in new systems can drive the purchase price up even higher.

Nonetheless presently, there could be a new better option.

A good group of technical engineers from Saarland University will be developing ‘smart’ electric car systems the fact that will function without the need regarding added sensors. Not simply is going to they function, but these brand-new motors will likewise in essence be transformed into some sort of sensor itself. A new motor unit with the capacity to help monitor itself together along with the overall effectiveness involving the equipment is a new truly impressive leap frontward for manufacturing technology.

Another enormous benefit of these kind of ‘smart’ motors is their particular ability to communicate together with get in touch with some other motors upon the store floor. This will effectively function the same function as stand-alone monitors connected through typically the Industrial World wide web of Factors services. Equipment to unit communication is essential for some sort of smart facility to work appropriately. If there is some sort of problem with a particular piece of equipment, prior to any individual has the chance to intervene, this motor of which has an issue could call to another piece of equipment to help pick right up it has the slack.

Furthermore, updating musical legacy tools could become much simpler with this particular brand-new ‘smart’ motor. Instead of having to outfit a great older equipment with some sort of host connected with sensors and hoping that they can all get the job done and will attach for you to the cloud or perhaps storage space you wish to post the data to, a single electric motor might be the only thing that wants to be enhanced. This specific could be a driving force to obtain more manufacturers about board with the professional revolution that’s happening all around us. Numerous manufacturers don’t own the means to upgrade all of their gear on one time, yet changing out old electronic generators is much even more controlable.

The way info is gathered from the motor will be by thoroughly overseeing the accurate supply of the permanent magnetic field strength in this electric motor. The researchers file the way the magnetic field alterations in the event the motor swivels. Through this information, the scientists can infer how the motor is jogging. For now, the researchers are looking at several methodologies to decide which often methods are best suited to accumulate information from the motor.

No word yet on when that technology will be readily available in order to consumers, but suppliers are waiting in uncertainty. The experience would be invaluable and the capability to reduce the quantity of sensors lessens the chance of failures even though also making it substantially more manageable for companies to update their machines and devices. The technological innovation is remarkable and typically the implications could be far-reaching. We are excited to help see how these types of power generators will perform if suppliers are willing to adapt to this incredible technologies. Recall, in case your organization uses devices, you should use business chillers to avoid overheating and faltering, or maybe worse causing personal injury at work. Make sure you invest in safety tools such as this mainly because well as innovative time-saving devices as described in this posting.

#overhead workstation crane#overhead bridge crane#overhead workstation bridge crane#overhead factory crane

0 notes

Text

<h1>Job Deco Tile</h1>

Parts like genuine water spurting system can create exceptional results when it is used to make pool and fountains. The office complex version brings the designer's style to life by creating various illumination configuration, detailed structure facade. Ifferent from conceptual models, version manufacturers take complicated products like metal, concrete, etc to make the working models. Making architectural designs is a reliable method to aid the architect connect. This indicates that architectural imagination will remain to make use of building versions. The results and the applications of building models maintain enhancing as well as innovating.

" Inch. Style" is a team composed of several young developers, utilizing different design elements.

Team Within Layout is a set of professional with a dedication to fulfill customers needs on home production.

The Financial institution books the right to bill such Qualified Consumer a quantity equivalent for the Offers granted.

The Council additionally prompts traders to refrain from making questionable quotes yet ought to offer their solutions seriously and also honestly to maintain their own track records.

Control damage from managing using physical defenses as well as ideal handling techniques for building designs.

The Council also consulted the Hong Kong Institute of Surveyors on points to note for consumers preparing for house renovation. Residence renovation, be it a total overhaul or simply partial design, mostly sustains a considerable quantity of cash. Nevertheless, customers generally 裝修報價 do not have much experience in reviewing the work called for and the quotation. In instance they are not careful enough as well as ignore the information on the quotation, it would quickly generate conflicts, and the most awful of even uncompleted jobs.

Family Definition Print, Instant Download, Residence Style, New Home Gift, Living Space Style

Following in the footsteps of Mahatma Gandhi and also Nelson Mandela, Daw Aung San Suu Kyi stands as a beaming icon as well as worldwide ideas for calm resistance to harsh repression. Extra especially, she symbolises Burma's struggle for freedom. She has spent virtually one quarter of her life in detention in the root cause of liberty as well as autonomous adjustment.

Additionally, rolled right into thick sheets, you can additionally cut clay and also plasticize to make wall surfaces for large presentation designs. It is simple to utilize without the demand for unique equipment during the manufacturing as well as installation process of the model. And also it is just one of the structure model-making products to make the framework and also the framework of the buildings. Actually, it is just one of the hardest version structure materials among all other 3D published plastics. On the one hand, presentation models requires long lasting, steady and also fade-resistant products. To pick appropriate materials, the engineers require to consider specific design standards to identify the most effective materials.

Exactly How Expensive Is A Wise Home Restoration?

Each piece is handcrafted to guarantee you are obtaining the high quality you should have at a budget-friendly price. It will likewise offer you a foot in the door to the market through our one-month teaching fellowship program, which 95% of the moment results in full time employment. The Diploma in Interior Design consists of both the Certification in Interior Design Residentialand the Certificate in Interior decoration Commercial programs.

裝修報價 "/>

1 note

·

View note

Text

Wise Motor For Industrial Machines: Keeping It Simple

https://mfgtalkradio.com/smart-motor-for-industrial-machinery-keeping-it-simple/ throughout factories has always been recently developing. From equipment like an overhead free standing workstation crane aiding improve efficiency and the factory individuals jobs better to A 3D MODEL printing cutting the cost of the manufacturing course of action, new technology has often recently been good to production facilities. And today, there is a new development which might produce developing even more useful – Receptors.

Sensors include been making their means in to manufacturing facilities with regard to some time now. All these small, high-tech devices offer manufacturers a good new way to see exactly how their particular service is running together with confirming any issues around current. Integrating sensors into making equipment and equipment let us manufacturers foresee potential malfunctions and make fixes in advance of unscheduled downtime gives vent chaos on their business.

A lot of manufacturers would like to upgrade his or her facilities to feature these precious sensors, but it really doesn’t are available cheap. Brand-new equipment can cost tens of hundreds and hundreds of bucks and often the sensors in new systems can drive the purchase price right up even higher.

Nonetheless now, there could be a new better choice.

The workforce of planners from Saarland University are developing ‘smart’ electric motor methods that will will function with no need regarding added sensors. Not simply is going to they function, but these fresh motors will in addition fundamentally be transformed into the sensor itself. Some sort of engine with the ability to monitor alone together with the overall effectiveness associated with the equipment is a new truly modern leap ahead for manufacturing technology.

An additional enormous benefit of these types of ‘smart’ motors is their very own ability to work together together with contact other motors about the shop floor. This will basically provide the same function as stand-alone devices connected through typically the Industrial Internet of Factors services. Unit to appliance communication is critical for some sort of smart facility to work appropriately. If there is the problem with a particular part of equipment, in advance of everyone has the chance to help intervene, this motor that has an issue may call to one more tool to help pick way up the slack.

Furthermore, updating older devices could become much simpler with this particular fresh ‘smart’ motor. Alternatively of required to outfit a great older equipment with a host regarding sensors and hoping they will all do the job and will hook up in order to the cloud or even web server you wish to publish the data to be able to, a good single electric motor might be the only thing that desires to be enhanced. This specific could be a traveling force to get more companies upon board with the manufacturing revolution that’s happening all around us. Quite a few manufacturers don’t have got typically the means to update all of their equipment at one time, nevertheless transitioning out old electrical motor is much even more workable.

The way files is gathered from the engine will be by simply thoroughly overseeing the specific submission of the permanent magnet field strength in the particular engine. The researchers file how a magnetic field alterations in the event the motor goes around. Coming from this data, the analysts can infer how the motor is running. With regard to now, the analysts will be using various methodologies to identify which methods are very best suited to collect records from the motor.

Not sure yet on when that technology will be offered to be able to consumers, but producers will be waiting in incertidumbre. The experience would get invaluable and the power to reduce the quantity of sensors lessens the particular chance of failures even though also making it significantly more workable for makers to up grade their machinery and gear. The technological innovation is outstanding and the implications could be far-reaching. We are excited to help see how all these engines will perform in case manufacturers are willing to adopt this specific incredible technological innovation. Bear in mind, if the business uses machines, it is important to use commercial chillers to avoid overheating and faltering, or perhaps worse causing injury on the job. Make sure an individual invest in safety devices such as this such as well as innovative time-saving devices as described in the following paragraphs.

#overhead workstation crane#overhead bridge crane#overhead workstation bridge crane#overhead factory crane

0 notes

Text

Wise Motor For Industrial Systems: Keeping It Simple

Technology inside factories has always already been developing. From equipment such as an overhead factory crane supporting improve efficiency and making the factory employees jobs better to A 3D MODEL printing cutting the expenses of the manufacturing method, new-technology has often recently been best for plants. And now, there is a innovative development which might help make developing even more productive – Receptors.

Sensors possess been making their technique in to manufacturing facilities intended for some time now. These kind of small, high-tech devices offer manufacturers a new way to see exactly how their center is running in addition to revealing any issues in current. Integrating sensors in to making equipment and machines let us manufacturers foresee likely equipment failures and make vehicle repairs in advance of unscheduled downtime gives vent disorder prove business.

A lot of manufacturers would like to upgrade their very own facilities to incorporate these useful monitors, however it doesn’t occur cheap. New equipment can cost tens of thousands of dollars and the particular sensors in brand-new machinery can drive the retail price upward even higher.

But now, there could be a new better choice.

A new crew of designers from Saarland University are developing ‘smart’ electric motor unit techniques that will function without the need intended for additional sensors. But not only can they function, require different motors will furthermore basically be transformed into a good sensor itself. A new car with the power in order to monitor itself coupled along with the overall efficiency involving the equipment is the truly modern leap frontward for manufacturing technology.

One other enormous benefit of these kind of ‘smart’ motors is their very own ability to socialize and communicate with some other motors about the purchase floor. This will effectively assist typically the same function as stand-alone sensors connected through the Industrial Internet of Factors services. Device to machine communication is important for a new smart facility to work adequately. If there is the problem with a particular item of equipment, prior to anybody has the chance to intervene, the motor that will has an issue can certainly call to an additional tool to help pick up their slack.

Furthermore, changing musical legacy tools could end up being much simpler with this fresh ‘smart’ motor. As a substitute of required to outfit an older device with some sort of host regarding sensors and even hoping they all do the job and will hook up to help the cloud or maybe machine you wish to transfer the data to be able to, some sort of single electric motor could be the only thing that desires to be improved. This could be a driving force to obtain more companies on board with the professional revolution that’s happening everywhere. Numerous manufacturers don’t possess typically the means to upgrade all of their tools from one time, but changing out old electrical motors is much extra feasible.

The way data is gathered from the electric motor will be by thoroughly monitoring the specific syndication of the magnetic field strength in the particular motor. The researchers record what sort of magnetic field changes as soon as the motor rotates. Through this data, the analysts can infer how the motor is operating. Regarding now, verhead free standing shop crane system will be looking at diverse methodologies to identify which methods are most beneficial suited to collect records from the motor.

Not sure yet on when that technology will be accessible to be able to consumers, but companies happen to be waiting in suspense. The insights would get invaluable and the capability to reduce the variety of sensors cuts down often the chance of failures although also making it substantially more controllable for companies to enhance their machinery and gear. The technological innovation is outstanding and the particular implications could be far-reaching. We are excited for you to see how these power generators will perform and when companies are willing to adapt to this kind of incredible technology. Keep in mind, if the business enterprise uses equipment, it is important to use commercial chillers avoiding overheating and inability, as well as worse causing personal injury in the workplace. Make sure you invest in safety devices such as this just as well as innovative time-saving devices as described in this posting.

#overhead workstation crane#overhead bridge crane#overhead workstation bridge crane#overhead factory crane

0 notes

Text

Wise Motor For Industrial Machines: Keeping It Simple

Technology around factories has always recently been developing. From equipment as an overhead factory crane assisting improve efficiency and the factory personnel jobs simpler to A 3D MODEL printing cutting the expenses of the manufacturing process, new technology has usually been recently good for plants. And nowadays, there is a brand-new development which might make developing even more efficient – Devices.

Sensors possess been making their means in to manufacturing facilities with regard to some time now. These types of small, high-tech devices offer manufacturers a good new strategy to see exactly how their very own ability is running together with confirming any issues around real-time. Integrating sensors into developing equipment and equipment permits manufacturers foresee likely malfunction and make maintenance ahead of unscheduled downtime gives vent havoc on the business.

Quite a few manufacturers need to upgrade their own facilities to include these important devices, nonetheless it doesn’t arrive cheap. Brand-new equipment can easily cost tens of tons of money and typically the sensors in innovative systems can drive the purchase price up even higher.

Nevertheless nowadays, there could be the better option.

A staff of engineers from Saarland University are developing ‘smart’ electric electric motor techniques that will function with no need regarding extra sensors. verhead free standing factory crane will they function, require fresh motors will likewise in essence be transformed into a new sensor itself. Some sort of motor unit with the capability to monitor themselves along along with the overall efficiency associated with the equipment is a good truly progressive leap forward for manufacturing technological innovation.

An additional enormous benefit of these ‘smart’ motors is their own ability to interact plus talk to various other motors in the purchase floor. That will in essence function typically the same function as stand-alone receptors connected through typically the Industrial Online of Points services. Machine to device communication is essential for the smart facility to function effectively. If there is a new issue with a particular piece of equipment, ahead of everyone has the chance to be able to intervene, the particular motor that has an issue can easily call to another unit to help pick way up their slack.

Furthermore, upgrading legacy of music devices could get much simpler with this kind of fresh ‘smart’ motor. As a substitute of the need to outfit the older appliance with a new host connected with sensors and hoping which they all get the job done and will join to be able to the cloud or perhaps web server you wish to transfer the data in order to, a new single electric motor could be the only thing that wants to be new. This kind of could be a driving force to get more manufacturers with board with the business revolution that’s happening everywhere. Many manufacturers don’t include typically the means to update all of their equipment at one time, nevertheless switching out old electric powered motors is much whole lot more controllable.

The way data is gathered from the motor unit will be simply by meticulously supervising the specific distribution of the magnets field strength in this engine. The researchers record how the magnetic field adjustments if the motor swivels. Via this information, the scientists can infer how the motor is jogging. Intended for now, the research workers will be using various methodologies to identify which will methods are best suited to accumulate information from the motor.

No word yet on when this specific technology will be obtainable to be able to consumers, but manufacturers can be waiting in uncertainty. The experience would get invaluable and the ability to reduce the amount of sensors lessens typically the chance of failures when also making it much more workable for suppliers to upgrade their equipment and equipment. The engineering is outstanding and often the implications could be far-reaching. We are excited for you to see how these types of motors will perform and if makers are willing to embrace that incredible technologies. Remember, should your company uses machinery, it is very important use professional chillers to stop overheating and disaster, or perhaps worse causing harm in the workplace. Make sure a person invest in safety gear such as this as well as innovative time-saving devices as described in this posting.

#overhead workstation crane#overhead bridge crane#overhead workstation bridge crane#overhead factory crane

0 notes

Text

Wise Motor For Industrial Equipment: Keeping It Simple

Technology in factories has always been developing. From equipment like an overhead shop crane system encouraging improve efficiency and the factory personnel jobs easier to A 3D MODEL printing cutting the expense of the manufacturing process, new-technology has always also been good for factories. And now, there is a different development which might create producing even more effective – Sensors.

Sensors own been making their way straight into manufacturing facilities with regard to some time now. verhead free standing shop crane system of small, high-tech devices present manufacturers a new approach to see exactly how their own ability is running plus confirming any issues throughout real-time. Integrating sensors in developing equipment and devices let us manufacturers foresee possible equipment failures and make vehicle repairs just before unscheduled downtime wreaks chaos on their business.

Several manufacturers would like to upgrade their facilities to include these precious receptors, nonetheless it doesn’t appear cheap. New equipment can easily cost tens of hundreds and hundreds of bucks and the sensors in brand-new devices can drive the value way up even higher.

Although nowadays, there could be some sort of better solution.

A good staff of designers from Saarland University can be developing ‘smart’ electric car systems that will will function with no need regarding added sensors. But not only will they function, but these innovative motors will likewise fundamentally be transformed into a good sensor itself. The motor unit with the power to monitor themselves alongside with the overall performance of the equipment is a new truly impressive leap onward for manufacturing technology.

An additional enormous benefit of these kind of ‘smart’ motors is his or her ability to communicate in addition to talk to additional motors upon the purchase floor. This particular will basically work often the same function as stand-alone monitors connected through the Industrial Online of Issues services. Machine to device communication is vital for some sort of smart facility to function adequately. If there is a good issue with a particular part of equipment, just before anyone has the chance to be able to intervene, the motor the fact that has an issue can call to one other machine to help pick up it is slack.

Furthermore, replacing heritage gear could turn out to be much simpler with this specific different ‘smart’ motor. Rather of the need to outfit a good older device with a host connected with sensors plus hoping that they all function and will join to the cloud or even machine you wish to publish the data in order to, a new single electric motor will be the only thing that wants to be new. This particular could be a driving a car force to get additional suppliers on board with the business revolution that’s happening everywhere. Numerous manufacturers don’t include the means to enhance all of their gear at one time, although switching out old electronic motors is much extra workable.

The way files is gathered from often the engine will be simply by thoroughly tracking the accurate supply of the magnet field strength in often the car. The researchers file how a magnetic field adjustments once the motor goes around. Via this info, the researchers can infer how this motor is running. To get now, the analysts will be using several methodologies to identify which will methods are best suited to accumulate data from the motor.

Not sure yet on when this technology will be accessible to help consumers, but manufacturers can be waiting in repos. The information would get invaluable and the capability to reduce the amount of sensors lessens the chance of failures while also making it very much more controlable for makers to up grade their equipment and products. The technologies is amazing and the implications could be far-reaching. We are excited in order to see how these types of engines will perform of course, if makers are willing to take hold of this incredible technological innovation. Keep in mind, should your organization uses equipment, it is very important use professional chillers in order to avoid overheating and inability, or even worse causing damage at work. Make sure an individual invest in safety devices such as this as well as innovative time-saving devices as described in this article.

#overhead workstation crane#overhead bridge crane#overhead workstation bridge crane#overhead factory crane

0 notes

Text

Mele PCG03 Plus review unit was sent to me courtesy of Mele, so many thanks and especially to Isaac, for the kindness and support!

This review unit was sent to me courtesy of Mele, so many thanks and especially to Isaac, for the kindness and support!

Mele has been around since 2004, and have a nice range of Android, Windows and other Media TV boxes/Mini PCs and Streamers.

The PCG03 Plus, or “StarCloud”, is the newest iteration of Mini PC by Mele. It is a second generation to the previous PCG03, with some updated hardware.

What’s in the box?

PCG03 Plus, or “StarCloud” is Mele’s first Cherry Trail based Mini-PC/Intel Kodi box.

So what do we get? The Mini-PC, a power adapter, multiple power plug adapters, a Quick guide, and… that’s it!. No HDMI cable included. Mele did everything it could to walk the delicate balance between an all out Mini PC system (which ideally would include said HDMI cable, and maybe a Air mouse, or even a wireless mouse/keyboard combo), and a bone basic PC box.. well, actually it is pretty much a bone basic box.

Looks

PCG03 Plus does show an elegant facade. constructed inside a box that’s half Matte and half reflective, with “Intel Atom” sticker, printed name logo on top, and model name in front. Inside, there is a fully working Windows 10 PC.

It runs off a brand new 14 nm Intel Atom based chipset, just like the latest crop of Mini PCs (same as Tronsmart’s Ara X5/Plus). The pre-installed operating system is Microsoft Windows 10 Home, and it runs quite smoothly as long as you don’t burden it with too much crap.

The system arrives completely clean. Kodi had to be installed from scratch.

No remote, mouse, or any other control device is included with the package. As mentioned before, it’s meant for keeping the cost down. However, you can use various windows-android remote control programs that rely on a server part installed on the device, and a client part installed on your smartphone or tablet. Those use WiFi or Bluetooth communication in order to allow mouse/keyboard interaction with the device.

Specifications

CPU Intel Atom x5-Z8300 “Bay Trail” quad core processor @ 1.44 GHz (Burst up to: 1.84 GHz) GPU Intel HD Gen8 graphics Memory / Storage 2 GB DDR3L / 32 GB eMMC Wireless Connectivity 802.11 b/g/n Wi-Fi, Bluetooth 4.0 OS Windows 10 Home (activated) Video Output HDMI 1.4, and VGA Audio Output HDMI, 3.5mm earphone jack Power DC 12V/1A Peripheral Interface

1 x RJ-45 Ethernet Port (10/100Mbps)

2 x USB 2.0 Ports

1 x USB 3.0 Host Port

1 x SD/SDHC Card Reader (Up to 512 GB)

1 x HDMI 1.4 Port

1 x VGA Port

1 x 3.5 mm headphone jack

1 x Kensington security lock

Packing Included

Mele PCG03 Plus

DC Power Adapter

Four (4) plug adapters (GS,UK,SAA,UL)

Quick Guide

Dimensions / Weight 150 mm * 120 mm * 40 mm / 360 grams

Benchmarks and Testing

All benchmarks have been repeated 3 times and results have been averaged to give a more accurate reading:

Novabench

Novabench offers a marinade of tests ranging between CPU and memory to GPU abilities.The rating PCG03 Plus gets is lower than that of the cheaper Tronsmart Ara X5 (especially in regard to RAM speed), but I suspect this is due to usage of slower RAM chips or memory controller.

PC Mark 8

PC Mark 8 Basic tests go for 20-45 minutes in GPU-accelerated or standard mode and they test regular office tasks as well as memory and video performance. Again, the performance is similar but slower than that of the Tronsmart Ara X5 which is based on the same CPU.

3D Mark

3D Mark does what the name says – it tests a device’s ability to handle 3d animation and simulation. As the PCG03 Plus is based on the same GPU as the one in the Tronsmart Ara X5 the similar performance is to be expected.

Video Playback testing (Using KODI)

Resolution Video Format Local Playback Network (Wi-Fi/LAN) Playback 720p (1280*720) AVC ([email protected]) Playing correctly Playing correctly 1080P (1920*1080) AVC (High@L4) Playing correctly Playing correctly 4K/UHD (4096*2304) AVC ([email protected]) Playing correctly Playing correctly (mixed results) 2160P (3840*2160) HEVC (H.265) Playing correctly Playing correctly 4K TS HEVC files HEVC (H.265) 10Bit Artifacts & stutter Artifacts & stutter

System arrived with a clean installation of Windows 10. Tests were conducted after installing Kodi 16 RC1 from Kodi website, and later repeated with the (more) standard Kodi 15.2.

The issue mentioned before makes the box unpredictable. Video playback may stop after 10-30 minutes and seem to pause forever (no audio or video, but subtitles keep running. The only way to resume is to manually stop playback, wait a while till Kodi returns to the playlist, and resume playback. Again and again.

Local (SD card) Playback: Most of the files played correctly locally.

Local Network Playback: As can be seen on both tables, the results are mixed. Performance is inconsistent on wireless connection, 10 bit TS files do not play correctly and push the CPU cores to their max (100%). Most of the playback issues in the tests (aside from the TS files) came due to bandwidth bottleneck, as videos encoded in higher than 30 mb/s begun stuttering when their cache ran out too fast. In any case, it is recommended to use a wired connection when available.

Issues and bugs

The first and most disturbing issue I noticed with PCG03 Plus was that in many videos (not all), after 10-25 minutes of playback, the video and audio would stop as if “pause” was pressed, but pressing pause and play again would make no difference (although subtitles, if any were present continue to roll as usual). Only stopping the video playback completely and resuming it would continue proper video/audio playback. This happened both in Kodi 16 RC1 and Kodi 15.2, and been reported to the manufacturer for repair.

In the games Asphalt 8 Airborne and World of Tanks Blitz, Arrows (Minix A2 Lite air mouse directional buttons, or unified remote control keyboard arrows) do not respond.

TS files (10 Bit) do not play correctly. Artifacts and stutter abound.

Device goes to sleep when screen (TV) is turned off, unless Kodi is left on. When turning back on, can be accessed only by clicking the power button first to wake it up.

WiFi disconnects when PC goes to sleep. Takes a while to reconnect when awoken.

Flickering noticed in 4K video.

Network performance

Network performance has been tested using Speedtest.net Internet speed measuring website, in WiFi and in Wired mode. My Internet connection is 200 Mbit Symmetric Fibre connection. Performance is average-low for WiFi (only N standard is supported), but quite good for Wired connection:

WiFi 2.4GHz

Wired over power lines

Gaming performance

Two games were tested:

Asphalt 8 Airborne – Run mostly fine, but control via arrows just would not work. I had to switch to mouse control which is quite uncomfortable. Performance-wise, The game run smoothly in a window, but less so in full screen (FullHD resolution).

World of Tanks Blitz – Aside from not responding to arrow movements (it did acknowledge that the directional ASDW keys were pressed, but did not move the tank), the game run quite smoothly.. as much as that helps if you cannot play the game.

In conclusion, unless you play mouse only (or mostly) games, you’ll find this PC problematic. However, I did not try a physical keyboard, only a wireless Air Mouse/Keyboard Minix A2 Lite, and a android based remote client-server combo. It may work properly with a wired USB keyboard.

PCG03 Plus Conclusions