#ai fm

Text

Ashton Irwin on Ai FM

3 notes

·

View notes

Text

merry christmas! ♡

(character ai) (aisekai) (sakura fm)

(character ai) (aisekai) (sakura fm)

(character ai) (aisekai) (sakura fm)

(character ai) (aisekai) (sakura fm)

hope everyone had a great christmas! thank you for all the support.

#leon kennedy#re4 remake#c ai#character ai#resident evil#leon x reader#re2 leon#aisekai#sakura fm#death island leon

48 notes

·

View notes

Text

Crumbs: the episode. You'd think it was crumb-y but it's really a joy to see so many little glimpses of new side boys and you'd think it'd make a mess of the bed but Ai and Nhai did that instead. @absolutebl SO MANY CRUMBS.

#ai long nhai#ailongnhai#thai bl#thaibl#thai bl drama#thai bl serise#bl series#bl drama#thai drama#thai series#asian lgbtq dramas#asianlgbtqdramas#asian lgbtq drama#intha x song#nine x fm#fm x nine#song x intha#ton x chon#chon x ton#i love them all so much#side couples!

107 notes

·

View notes

Photo

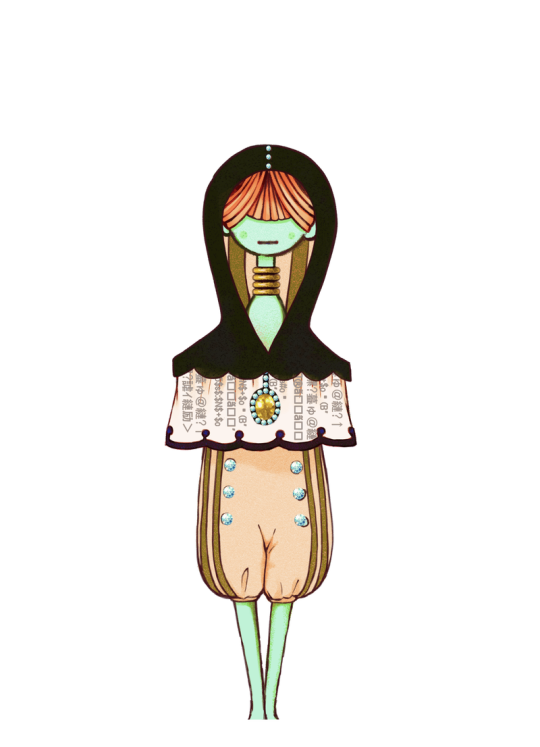

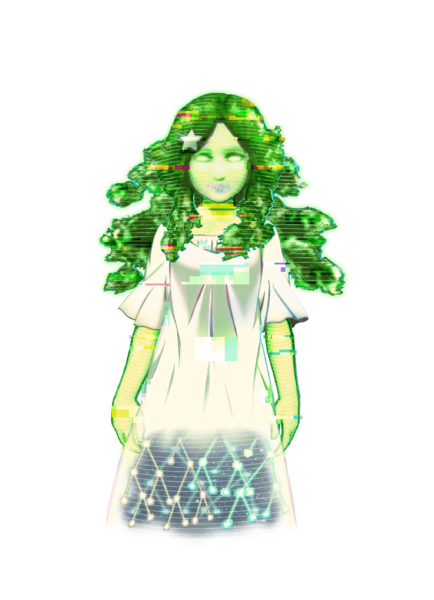

Magia Record Rumor and Uwasa Transparents Part 1

Requested by @squidink18

[ Source ] [ Source ]

[ Source ] [ Source ]

[ Source ] [ Source ]

[ Source ] [ Source ]

[ Source ] [ Source ]

#Puella Magi Madoka Magica#PMMM#Madoka Magica#Magia Record#Rumors#Uwasas#Rumor Spreader#Rumor of FM Kamihama#Rumor of the Memory Creator#Uwasa of the Anonymous AI#Uwasa of the Saint of Kamihama#Uwasa of the Eternal Sakura#Uwasa of the Wind Evangelist#Uwasa of the Chelation Land Ferris Wheel#Uwasa of the Commoner's Horse#Uwasa of the Friendship Ending Staircase#Transparents#PNG

39 notes

·

View notes

Text

Some AI Generated photos of Abel

#AI#ai generated#the weeknd#abel tesfaye#xo#xotwod#abel xo#the weeknd xo#explore#aesthetic#archive#photography#inspo#music#hip hop#rap#r&b#after hours#dawn fm#starboy#trilogy#kissland#house of balloons#my dear melancoly

134 notes

·

View notes

Text

'Vibing up, time to kick back'

Good for you king, thank you for sharing such wisdom

#i love Ashton irwin#and I love this AI FM#like a lot#5sos#ashton irwin#anotheryoutubefanpage#luke hemmings#calum hood#michael clifford#five seconds of summer

7 notes

·

View notes

Text

My feelings on the no-plot-whatsoever Ai Long Nhai

No. Seriously. This show has NO PLOT, and I couldn't love it more.

No plot.

None.

Nothing.

I love it.

73 notes

·

View notes

Text

what's this ?

Oh !

#half life vr but the ai is self aware#half life#the freemans mind#gorgeous freeman#hl au#hlvrai au#fm au#gf au#multiversal mishap au#MM au#multiversal mishap#gordonverse#these r my portrayal's of them btw so pls don't say shit about Gorgeous..#they aren't the only four.#perhaps.#i cannot tell more#i hate drawing the hev suit#height difference gets me pulling my hair#made this yesterday that i entirely forgot to ever post anywhere

12 notes

·

View notes

Text

happy valentine's day! ❤︎

shrug on the jacket he brought just for you. laugh at the icy-white frozen breaths escaping you. admire the light-up signs staining him neon. inhale the perfumed cotton candy and watch him go at it again. everything else is background noise in the world so unmistakably leon’s.

(c ai) (artheart) (sakura)

just five more minutes. tangle yourself in him. sink deeper into the bed, down the doughy cloud. enjoy his soft embrace and know he could never let you go. shape the cloud and know that mornings with leon kennedy are whatever you want them to be.

(c ai) (artheart) (sakura)

#leon kennedy#leon x reader#c ai#character ai#re4 remake#resident evil#re4#sakura fm#re2r leon#re2 remake#valentines day

16 notes

·

View notes

Text

BL FANDOM BLOG: A LOVE FOR BOYS LOVE

SIDE DISH EDITION (aka: SIDE COUPLE)

Series: AI LONG NHAI From: THAILAND

Year: 2022

I will call this the drive by. On this week's AI LONG NHAI.

FM (NATTANON TONGSAENG aka FLUKE) seemingly in one or two sentences hit on and hired Nine (THANATHORN KHUANKAEW aka JOM) to be his tutor. Then gave a "bro hug" before quickly excusing himself.

Will you be my tutor? I like you, can I pursue you? Thanks, see ya later.

13 notes

·

View notes

Text

Unleashing Agility: A Comprehensive Exploration of Flexible Manufacturing Systems

In the realm of modern manufacturing, the term “Flexible Manufacturing Systems” has become a cornerstone, revolutionizing the way industries approach production. This comprehensive guide delves into the intricacies of Flexible Manufacturing Systems, shedding light on its core principles, applications, and the transformative impact it imparts on the manufacturing landscape.

Understanding Flexible Manufacturing Systems

1. Defining Flexible Manufacturing Systems

Flexible Manufacturing Systems (FMS) represent a sophisticated approach to manufacturing that integrates computer-controlled machines, automation, and advanced technologies. FMS enables the seamless adaptation of production processes to accommodate varying product specifications, thereby enhancing efficiency and responsiveness.

2. The Core Components of FMS

At its essence, a Flexible Manufacturing System comprises interconnected machines, robots, and computer systems working in tandem. These components communicate and adapt in real time to produce diverse product types without the need for extensive reprogramming or reconfiguration.

3. Adaptive Automation

FMS embodies adaptive automation, where machines and processes autonomously adjust to changing production requirements. This adaptability allows manufacturers to efficiently handle fluctuating demand, frequent product changes, and dynamic market conditions.

4. Integration of Technologies

FMS seamlessly integrates various technologies, including Computer Numerical Control (CNC) machines, robotics, sensors, and Artificial Intelligence (AI). This convergence facilitates synchronized operation, data exchange, and decision-making, creating a cohesive and responsive manufacturing environment.

5. Real-Time Monitoring and Control

An integral aspect of FMS is real-time monitoring and control. Sensors and monitoring devices gather data on machine performance, product quality, and overall system efficiency. This data is analyzed to make informed decisions, optimize processes, and address potential issues promptly.

Benefits of Flexible Manufacturing Systems

1. Increased Production Flexibility

FMS empowers manufacturers to swiftly adapt to changes in product demand, design modifications, or new product introductions. The ability to reconfigure manufacturing processes without extensive downtime enhances overall production flexibility.

2. Reduced Setup Time

Traditional manufacturing setups often involve prolonged changeover times when transitioning between different products. FMS significantly reduces setup times by automating the reconfiguration process, allowing for quicker and more efficient changeovers.

3. Enhanced Efficiency and Productivity

The integration of automated systems and intelligent technologies in FMS leads to enhanced efficiency and productivity. The continuous flow of information and real-time decision-making optimize production processes, minimize idle time, and maximize throughput.

4. Improved Quality Control

FMS incorporates quality control measures at various stages of production. Automated inspection systems and sensors monitor product quality, ensuring consistency and compliance with predefined standards. This proactive approach minimizes defects and enhances overall product quality.

5. Cost Reduction

While the initial investment in FMS can be substantial, the long-term benefits often outweigh the costs. Reduced setup times, increased efficiency, and minimized waste contribute to cost savings over the life cycle of the system.

6. Adaptability to Market Changes

In today’s dynamic market landscape, FMS positions manufacturers to swiftly respond to market changes, customer preferences, and emerging trends. The adaptability of FMS ensures that production remains aligned with market demands, fostering competitiveness.

7. Resource Optimization:

FMS optimizes the use of resources by automating repetitive tasks, minimizing human intervention, and utilizing machinery more effectively. This resource optimization results in improved utilization of labor, reduced energy consumption, and better overall resource management.

8. Customization and Personalization

The flexibility inherent in FMS allows manufacturers to easily customize and personalize products. Whether accommodating unique customer requests or adapting to niche market demands, FMS enables the efficient production of customized products.

Core Components and Technologies in Flexible Manufacturing Systems

1. Computer Numerical Control (CNC) Machines

CNC machines are a foundational component of FMS, providing precision and programmability in manufacturing processes. These machines are capable of executing complex machining operations with high accuracy.

2. Robotics and Automation

FMS relies heavily on robotics and automation to streamline production. Robots handle tasks such as material handling, assembly, and even complex manufacturing processes, contributing to increased efficiency and consistency.

3. Sensors and IoT Connectivity

Sensors play a crucial role in FMS by collecting real-time data on machine performance, environmental conditions, and product quality. The Internet of Things (IoT) connectivity enables seamless communication between machines and systems.

4. Artificial Intelligence (AI) and Machine Learning

AI and machine learning algorithms are integrated into FMS for data analysis, predictive maintenance, and decision-making. These technologies enhance the system’s ability to adapt to changing conditions and optimize processes.

5. Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM)

CAD and CAM software facilitate the design and programming of products within FMS. These tools enable efficient product development, simulation, and the generation of instructions for manufacturing processes.

Applications of Flexible Manufacturing Systems

1. Automotive Manufacturing

FMS has found extensive applications in the automotive industry, where the ability to adapt quickly to design changes and produce multiple models on the same production line is paramount.

2. Aerospace Industry

In aerospace manufacturing, where precision and flexibility are critical, FMS enables the efficient production of complex components and the adaptation to varying specifications.

3. Electronics Manufacturing

The electronics industry benefits from FMS by rapidly adapting to changes in product design, accommodating diverse product configurations, and optimizing production efficiency.

4. Consumer Goods Production

FMS is employed in the production of consumer goods, allowing manufacturers to respond swiftly to market trends, customize products, and efficiently produce a variety of goods.

5. Medical Device Manufacturing

In the highly regulated and rapidly evolving field of medical device manufacturing, FMS ensures the production of high-quality, customized devices while meeting stringent regulatory requirements.

6. Custom and Low-Volume Production

FMS is particularly advantageous in industries requiring custom or low-volume production runs, allowing for efficient production without the need for extensive retooling.

7. Textile and Apparel Industry

The textile and apparel sector leverages FMS for flexible and efficient manufacturing of clothing and textiles, adapting to changing fashion trends and consumer preferences.

8. Food and Beverage Production

Challenges and Considerations in Implementation

1. Initial Investment and ROI Considerations

The implementation of FMS often involves a significant upfront investment. Manufacturers must carefully assess the return on investment over the system’s lifespan to justify the initial costs.

2. Integration with Existing Systems

Integrating FMS with existing manufacturing systems and technologies can be complex. Compatibility issues and the need for seamless integration require careful planning and execution.

3. Workforce Training and Skill Development

The adoption of FMS necessitates a skilled workforce capable of operating, maintaining, and troubleshooting advanced technologies. Investing in workforce training and skill development is crucial for successful implementation.

4. System Downtime During Implementation

The transition to FMS may require downtime for installation, testing, and training. Manufacturers must carefully plan for minimizing disruptions to ongoing production during the implementation phase.

5. Cybersecurity Concerns

With increased connectivity and reliance on digital technologies, FMS introduces cybersecurity considerations. Safeguarding sensitive data, intellectual property, and the overall system from cyber threats is paramount.

6. Scalability and Future Expansion

Manufacturers should consider the scalability of FMS to accommodate future expansion and changes in production volume. The system’s ability to adapt to evolving business needs is crucial for long-term success.

7. Maintenance and Reliability

Ensuring the reliability of FMS is essential for maintaining continuous production. Implementing proactive maintenance schedules and monitoring systems contributes to the system’s overall reliability.

8. Regulatory Compliance

Industries subject to regulatory requirements must ensure that FMS adheres to relevant standards and compliance measures. This is particularly crucial in sectors such as aerospace, automotive, and medical manufacturing.

Conclusion

Flexible Manufacturing Systems represent a paradigm shift in the manufacturing landscape, offering unparalleled agility, efficiency, and adaptability. As industries evolve to meet the demands of a dynamic market, FMS emerges as a strategic asset, enabling manufacturers to navigate complexities, respond to changes swiftly, and optimize production processes. Embracing the core principles of FMS, understanding its applications, and addressing associated challenges position manufacturers to thrive in the era of advanced manufacturing, where flexibility is not just an option but a strategic imperative.

0 notes