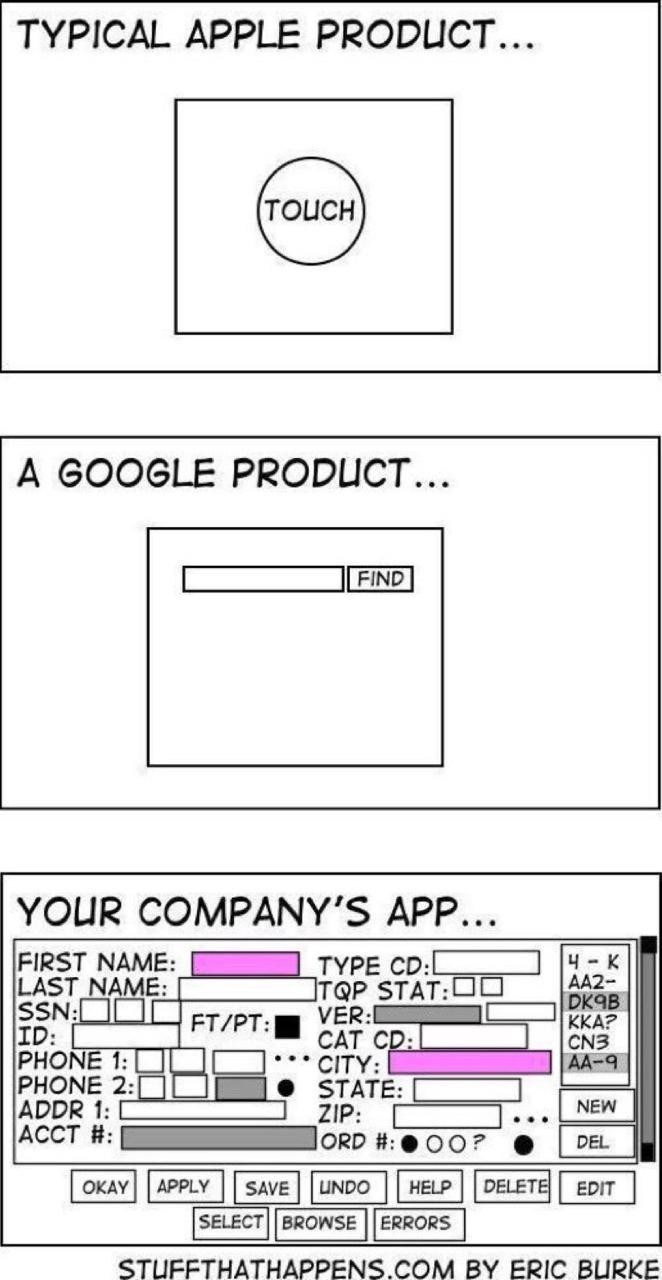

#aerospace vs electrical engineering

Text

in case u needed help distinguishing them

#sth#miles tails prower#renegade au#au stuff#the normal one is nicknamed bowie#miserable one is nicknamed amp#get it#bowie (similar to boeing)#amp (electrical)#aerospace vs electrical engineering#ok#bowie wears the silly science nerd joke shirts#useless#bye#luc arte

220 notes

·

View notes

Text

What are the Uses of Aluminium Coil? Let’s Explore Their Endless Applications

Aluminium is an exceptional metal known for its low density and lightweight properties. Aluminium coils exhibit various metal attributes, including excellent ductility, rust resistance, and corrosion resistance compared to other metals. These versatile coils find numerous applications both in industrial settings and daily life. While many may be aware of the versatility of aluminium coils, let’s delve into their specific use cases.

Versatile Aluminium Coil Characteristics

Non-Corrosive -Aluminium boasts exceptional corrosion resistance, even in harsh industrial environments. Its natural oxide layer protects against many corrosive substances, ensuring durability

Machinability and Casting: -Aluminium’s lower melting point than steel makes it more malleable and easier to cast into various shapes and moulds, streamlining production processes and reducing costs

Lightweight yet Durable: — Aluminium is lightweight yet robust with its low density. It’s a preferred choice in aerospace construction. Additionally, its recyclability contributes to sustainability

Non-Magnetic and Non-Sparking- Aluminium is non-magnetic due to its crystalline structure and quickly forms an oxide layer upon scratching, preventing sparking.

Excellent Thermal and Electrical Conductivity — Free electrons in aluminium’s structure make it an effective electrical and thermal conductor, ensuring efficient heat dissipation

Soft and Ductile: — Aluminium’s malleability and ductility allow for easy shaping, enabling engineers to create innovative designs, like micro channel coils, for improved heat transfer

Non-Toxic- Aluminium poses no harm to human health upon exposure

Malleable and Ductile: — Aluminium’s high elasticity allows for wire production

Aluminium Coil Specifications

Dimensions:-Aluminium coils come in various sizes, with inner diameters typically at 508 mm, 406 mm, or 610 mm. The recoiler machine’s capacity determines the outer diameter, and the thickness varies from 0.2 to 8mm, with most coils falling between 0.2mm and 2mm

Weight Calculation: The weight of an aluminium coil can be estimated using the <b>formula: Weight = (Coil Diameter/2 * π — Inner Diameter/2 * π)* Coil Width*Density of Aluminium.

Considerations When Choosing Aluminium Coils

Supplier History Select suppliers with a proven track record and an established online presence for reliability and credibility

Machining Compatibility : Ensure that the chosen aluminium coil is compatible with machining processes and welding if required.

Price vs. Value : Balance cost and value by considering the intended use and grade of aluminium

Formability : Evaluate the formability of the aluminium coil, considering the desired metal-forming processes

Supplier Reliability :Choose suppliers with ample stock to avoid interruptions in supply.

End-Use Applications : Align the coil grade with the specific requirements of the intended applications.

Price : Seek competitive pricing that reflects the material’s quality and value without compromising essential characteristics.

Aluminium coils offer many applications across industries due to their remarkable properties and adaptability, making them a valuable material choice

Applications of Aluminium Coil

Building and Construction

Aluminium coil is a versatile material widely used in many building and construction applications. Its lightweight yet robust properties make it an ideal choice for various purposes, including roofing materials, window frames, facade panels and more. Its outstanding durability ensures suitability for indoor and outdoor projects, with resistance to adverse weather conditions such as sunlight, rain, snow and high temperatures, guaranteeing longevity and preventing rust or wear concerns

Electrical and Electronics

They are used in the electrical and electronics sector. It’s malleable nature, lightweight design and resistance to corrosion make it an excellent choice for various purposes, including household appliances, electronic components, switchgear housing, motor insulation and transformers. Its exceptional heat conductivity contributes to efficient cooling systems, while its adoption in consumer electronics, like mobile devices and televisions, allows for more compact and streamlined designs. The aluminium coil protects against external electromagnetic interference, enhancing its usability in this field

Consumer Goods

Aluminium coils are pivotal in producing everyday consumer items, including packaging materials, kitchen tools, and playthings. The inherent corrosion resistance properties of aluminium render it the preferred option for packaging perishable foods. Manufacturers harness aluminium coils to fabricate containers, bottles and foil packaging, capitalising on its inherent shaping flexibility for crafting household items and kitchen utensils.

Industrial Utilisation

Aluminium coils find vast applications in industry, functioning as sheet metal for diverse industrial apparatus such as air conditioning and ventilation systems, containers and storage tanks. Their malleability makes them particularly suitable for shaping intricate components, obviating the need for welding or joining processes.

Transportation

These coils have gained a reputation in transportation because of their lightweight characteristics and corrosion resistance. These attributes render them highly suitable for the fabrication of vehicles, augmenting structural integrity with minimal weight increment. They also effectively mitigate noise levels and provide protection against environmental factors, encompassing rain, snow, wind and debris. These coils are frequently used in constructing trailer body liners due to their durability and adaptability, rendering them the material of choice for transportation-related purposes

Different Uses and Applications of Aluminium Foil by Marudhar Industries

Marudhar Industries offers a diverse array of applications for aluminium foil. Their versatile products are applied in various industries, such as food packaging, pharmaceuticals, insulation, etc. Aluminium foil from Marudhar Industries is a dependable solution for preserving food freshness, ensuring pharmaceutical product integrity and providing efficient insulation.

Our range of foil products caters to a broad spectrum of needs, demonstrating the adaptability and utility of aluminium foil in different sectors. Now You Much About What are the Uses of Aluminium Coil? Let’s Explore Their Endless Applications

0 notes

Text

Monel 400, k500 Strips, Sheets & plates Supplier & Exporter in india

Monel alloys, a circle of relatives of nickel-copper alloys, have earned a popularity for exquisite electricity, corrosion resistance, and high-temperature performance. They are the workhorses of diverse industries, locating programs in tough environments like marine engineering, chemical processing, and oil and fuel. This weblog explores Monel K500 and Monel 400 strips, sheets, and plates, highlighting distinguished suppliers in India and their numerous programs.

Understanding Monel Alloys: 400 vs. K500

There are two number one Monel grades relevant to strips, sheets, and plates:

Monel 400 (UNS N04400): This widely used grade offers brilliant corrosion resistance, excellent formability, and high power. It's the pass-to choice for a massive array of programs.

Monel K500 (UNS N05500): This precipitation-hardening grade boasts even higher energy than Monel 400, accomplished through warmness treatment. It's perfect for packages requiring extremely good power and wear resistance.

Both Monel four hundred and K500 are to be had in diverse forms, along with:

Strips: Thin, elongated sections with a rectangular go-section, suitable for forming and bending applications.

Sheets: Flat, square shapes with a rather uniform thickness, used for fabrication and cladding.

Plates: Thicker and larger flat sections as compared to sheets, best for high-pressure vessels and structural components.

Applications of Monel Alloy Strips, Sheets and Plates

The unique properties of Monel alloys lead them to a favored choice throughout several industries in India. Here are a few distinguished programs:

Chemical Processing: Monel's remarkable resistance to diverse chemical compounds like hydrochloric acid and sulfuric acid makes it ideal for tanks, vessels, piping structures, and warmth exchangers.

Marine Engineering: Seawater's corrosive nature isn't any suit for Monel. Ships' hulls, desalination flowers, offshore oil rigs, and heat exchangers all take advantage of Monel's homes.

Oil and Gas Industry: Piping systems, wellheads, and processing gadgets handling harsh chemical compounds and high temperatures rely on Monel's power and corrosion resistance.

Power Generation: Heat exchangers, condensers, and other additives uncovered to excessive temperatures and corrosive environments find Monel to be a dependable answer.

Aerospace: Specific Monel grades are utilized in a few aerospace programs because of their strength and excessive-temperature overall performance.

Finding Reliable Suppliers: Monel Alloy Products Supplier and Exporter in India

When sourcing Monel alloy strips, sheets, and plates in India, partnering with a truthful dealer is important. Here are some key issues:

Product Quality: Ensure the dealer adheres to identified standards like ASTM or ASME, guaranteeing the material's overall performance and reliability.

Product Availability: Choose a provider supplying a variety of sizes, thicknesses, and grades of Monel products to cater to your unique task needs.

Experience and Expertise: Partnering with a supplier with experience in Monel alloys guarantees they can provide technical steering and assist all through the selection and alertness technique.

Competitive Pricing: Compare prices across unique suppliers to secure the pleasant cost for your undertaking.

Jay Steel Corporation: Your Partner in Monel Alloy Solutions

At Jay Steel Corporation, we're a prominent producer, supplier, and exporter of Monel alloy merchandise in India. We are committed to presenting fantastic Monel 400 and K500 strips, sheets, and plates that meet stringent international requirements. Our giant inventory guarantees we have the proper length, thickness, and grade for your undertaking necessities.

In addition to Monel alloys, we provide a complete range of nickel alloys, along with:

Inconel Alloy Plates: These nickel-chromium alloys offer top notch excessive-temperature overall performance for traumatic programs.

Hastelloy Alloys: These high-performance alloys are perfect for environments with severe temperatures and harsh chemical substances.

We apprehend the significance of patron pride and provide super technical assistance to help you choose the maximum appropriate nickel alloy to your project. Whether you require Monel 400 strips for a chemical processing software or Monel K500 plates for a high-pressure vessel, Jay Steel Corporation is your one-stop store for all your Monel alloy wishes in India.

Contact us these days to speak about your project requirements and experience the Jay Steel Corporation distinction!

0 notes

Text

Nickel Alloy 200 vs 201 Fasteners: Which One Do You Need?

In the realm of fasteners, the selection between Nickel Alloy 200 and Nickel Alloy 201 pivotal. Each alloy boasts unique properties and characteristics that cater to distinct industrial necessities. Whether you are on the lookout for electricity, corrosion resistance, or ease of fabrication, understanding the disparities between those two alloys is paramount. This complete guide ambitions to elucidate the disparities among Nickel Alloy 200 and 201 fasteners, helping you in making an informed choice tailor-made in your precise desires.

Nickel Alloy 200 Fasteners: Unparalleled Corrosion Resistance

Nickel Alloy 200, a commercially pure wrought nickel, is famed for its great resistance to various corrosive environments. Its resistance spans from fairly decreasing to neutral and even alkaline solutions, making it a preferred desire in chemical processing and marine applications. The inherent homes of Nickel Alloy 200 render it pretty immune to corrosion via caustic alkalis. This robust resistance extends to distilled and herbal waters, rendering it perfect for marine device and desalination vegetation. Additionally, Nickel Alloy 200 fasteners exhibit wonderful resistance to mineral acids which includes hydrochloric and sulfuric acid, further amplifying their application in various commercial settings.

Nickel Alloy 200 Fasteners Manufacturers, Nickel Alloy 200 Fasteners supplier, Nickel Alloy 201 Fasteners Dealer and ,Nickel Alloy 200 Fasteners stockists recognize the paramount significance of sourcing Nickel Alloy 200 fasteners from reputable assets. Ensuring advanced first-rate uncooked substances and adherence to international great requirements is vital to ensuring the efficacy and toughness of fasteners in disturbing environments. Whether procured from a relied on producer or provider, Nickel Alloy 200 fasteners offer extraordinary corrosion resistance, making them integral throughout various industries.

Nickel Alloy 201 Fasteners: Enhanced Ductility and Fabricability

In assessment to its counterpart, Nickel Alloy 201 well-known shows more advantageous ductility and fabricability, owing to its decreased carbon content. This function makes Nickel Alloy 201 fasteners fantastically acceptable for applications requiring great forming and welding. Industries reliant on problematic designs and complicated fabrication tactics regularly want Nickel Alloy 201 for its ease of manipulation without compromising structural integrity. Additionally, Nickel Alloy 201 demonstrates commendable resistance to a myriad of corrosive environments, albeit slightly not as good as Nickel Alloy 200.

Fasteners made from Nickel Alloy 201 discover sizable application in industries necessitating stringent fabrication requirements. From problematic additives in aerospace engineering to intricate structures in chemical processing flowers, the flexibility of Nickel Alloy 201 fasteners is unrivaled. Nickel Alloy 200 Fasteners Manufacturers and Nickel Alloy 201 Fasteners exporters prioritize sourcing Nickel Alloy 201 from dependable suppliers to ensure adherence to considered necessary specs and standards, thereby making certain greatest overall performance in various programs.

Choosing the Right Alloy: Factors to Consider

When thinking of between Nickel Alloy 200 and 201 fasteners, several elements warrant consideration. The precise requirements of your software, ranging from environmental situations to mechanical properties, dictate the optimum desire of alloy.

Corrosion Resistance:

Nickel Alloy 200: Unparalleled resistance to a big selection of corrosive environments, together with alkaline answers and mineral acids.

Nickel Alloy 201: Demonstrates commendable corrosion resistance, albeit slightly not as good as Nickel Alloy 200.

Fabricability:

Nickel Alloy 200: Exhibits slight fabricability, suitable for applications requiring minimal forming and welding.

Nickel Alloy 201: Enhanced ductility and fabricability make it best for difficult fabrication techniques and good sized forming.

Mechanical Properties:

Nickel Alloy 200: Boasts first-rate mechanical residences, rendering it appropriate for excessive-pressure programs.

Nickel Alloy 201: Retains commendable mechanical properties even as supplying more advantageous ductility, catering to applications necessitating good sized fabrication.

Application Specifics:

Nickel Alloy 200: Preferred in environments requiring advanced corrosion resistance, together with chemical processing and marine applications.

Nickel Alloy 201: Ideal for packages necessitating elaborate fabrication strategies and substantial farming without compromising structural integrity.

Conclusion

In the end, the choice among Nickel Alloy 200 and 201 fasteners hinges at the unique requirements of your application. While Nickel Alloy 200 gives unprecedented corrosion resistance, Nickel Alloy 201 excels in fabricability and ductility. Understanding the nuances among these alloys empowers you to make a knowledgeable selection tailored to your business needs. Whether you prioritize corrosion resistance, ease of fabrication, or mechanical properties, selecting the proper alloy is paramount to making sure top-rated performance and toughness.

For advanced satisfactory Nickel Alloy 200 and 201 fasteners synthetic in accordance with worldwide fine requirements, appearance no further than Bhagyalaxmi Industrial. As a good producer, supplier, stockist, provider, and exporter of a variety of ferrous and non-ferrous metals, Bhagyalaxmi Industrial guarantees unparalleled high-quality and patron pride. Contact Bhagyalaxmi Industrial nowadays to procure top rate fasteners on the maximum reasonable costs, tailor-made in your unique requirements.

#Nickel Alloy 200 Fasteners Manufacturer#Nickel Alloy 200 Fasteners Supplier#Nickel Alloy 200 Fasteners Stockist#Nickel Alloy 201 Fasteners Exporter#Nickel Alloy 201 Fasteners Dealer

0 notes

Text

Guide to Choosing the Right Nickel Alloy Sheet: Nickel 200 vs. Nickel 201

The guide to selecting the right nickel alloy sheet involves understanding the nuances between Nickel 200 and Nickel 201. These two alloys, while seemingly similar, have distinct properties that cater to different applications. Manufacturers and industries often face dilemmas when choosing between Nickel 200 and Nickel 201 sheets for their specific needs. This guide aims to demystify these alloys, highlighting their differences, applications, and key considerations to help you make an informed decision.

Nickel Alloy Sheet: Understanding Nickel 200 vs. Nickel 201

Nickel 200 Sheet:

Nickel 200, a commercially pure nickel alloy, showcases exceptional resistance to various corrosive environments. It’s known for its superior mechanical properties and excellent thermal and electrical conductivity. The high nickel content in Nickel 200 (at least 99.6%) renders it highly resistant to corrosive chemicals, alkaline solutions, and caustic substances. Its low electrical resistivity makes it ideal for applications demanding good electrical conductivity.

Nickel 200 sheets find applications in diverse industries such as:

Chemical Processing:

Nickel 200 and Nickel 201 sheets are vital in chemical processing, where they resist corrosive substances in vessels and piping systems, ensuring plant integrity at high temperatures and pressures. Their durability and resistance make them essential for handling acids, alkalis, and aggressive chemicals.

Food Processing:

These nickel alloy sheets are crucial in food processing equipment, ensuring food safety by withstanding rigorous cleaning procedures and maintaining hygiene in heat exchangers and storage tanks. Their non-reactive nature with food products meets strict industry standards.

Aerospace:

In aerospace, Nickel 200 and Nickel 201 find use in manufacturing components like turbine blades and exhaust systems, enduring high temperatures and corrosive environments, ensuring reliability and safety in flight.

Marine Engineering:

Nickel alloy sheets are integral in marine engineering, offering excellent resistance to saltwater corrosion for ship components, offshore platforms, valves, and piping systems, ensuring longevity and reliability in maritime environments.

Electronics:

In the electronics industry, these sheets play a crucial role in manufacturing electronic connectors, battery casings, and sensor components due to their excellent electrical conductivity, magnetic properties, and corrosion resistance, ensuring stable performance in various devices.

The superior resistance to alkalis and acids makes Nickel 200 sheets a preferred choice in industries where corrosion resistance is paramount.

Nickel 201 Sheet:

Nickel 201, an alloy closely related to Nickel 200, possesses similar characteristics with slight alterations in chemical composition. With a slightly lower carbon content, Nickel 201 exhibits improved ductility and thermal conductivity. This modification enhances its suitability for applications involving extensive temperature variations while retaining exceptional resistance to corrosive environments.

Nickel 201 sheets are commonly used in:

Electronic Components:

Nickel 200 and Nickel 201 sheets are utilized in electronic connectors, battery casings, and sensor components due to their excellent electrical conductivity and resistance to corrosion, ensuring stable performance in various electronic devices.

Handling and Storage of Sodium Hydroxide:

In applications involving sodium hydroxide, these nickel alloy sheets provide excellent resistance to corrosion, making them suitable for handling and storing this caustic substance without degradation, ensuring safety and longevity of equipment.

Manufacturing of Vessels and Reactors:

Nickel alloy sheets are crucial in the manufacturing of vessels and reactors due to their resistance to corrosive environments, ensuring the integrity and durability of equipment used in chemical and industrial processes.

Pharmaceutical Equipment:

These sheets are employed in pharmaceutical equipment for their corrosion resistance, ensuring hygienic and safe processing environments, meeting stringent quality standards in pharmaceutical manufacturing.

Synthetic Fibers Production:

In synthetic fibers production, nickel alloy sheets are utilized for their resistance to corrosive chemicals and high temperatures, ensuring the durability and reliability of equipment involved in the manufacturing process.

The reduced carbon content in Nickel 201 makes it advantageous for applications where stringent dimensional control is required without compromising on corrosion resistance.

Key Differences and Considerations:

Chemical Composition: Nickel 200 is virtually unalloyed, whereas Nickel 201 has a reduced carbon content, enhancing its ductility.

Corrosion Resistance: Both alloys exhibit outstanding resistance to various corrosive substances, with Nickel 200 slightly edging out Nickel 201 in resisting caustic substances.

Temperature Resistance: Nickel 201, with its superior thermal conductivity due to reduced carbon, may be preferable in applications involving temperature variations.

Applications: Understanding the specific requirements of your industry or project is crucial in determining which alloy best suits your needs. Consider factors like environmental conditions, temperature variations, and chemical exposure.

Choosing the Right Nickel Alloy Sheet:

When deliberating between Nickel 200 and Nickel 201 sheets, it's imperative to consult with a reputable sheet manufacturer specializing in nickel alloys. Anand Steel stands as a leading importer and exporter of stainless steel shims, strips, coils, foils, round bars, and specializes in nickel alloys. Their expertise and commitment to quality ensure they cater to diverse industry needs.

With their extensive experience and unwavering commitment to customer satisfaction, Anand Steel offers a wide range of products, including sheets, plates, coils, foils, and round bars. Whether your industry requires corrosion-resistant materials or solutions for varied temperature conditions, Anand Steel's comprehensive product range and expertise make them a reliable supplier.

In conclusion, the choice between Nickel 200 and Nickel 201 sheets depends on the specific demands of your application. Consulting experts like Anand Steel ensures you receive guidance tailored to your industry's needs, ensuring optimal performance and longevity in your operations. For quality stainless steel solutions and specialized nickel alloy sheets, Anand Steel stands ready to assist.

Contact Anand Steel today for reliable and high-quality stainless steel and nickel alloy solutions tailored to your industry requirements.

0 notes

Text

Alloy vs Aluminum: A Comprehensive Comparison of Strength and Durability

Choosing the right material is vital in shaping the overall strength and durability of a product, especially in manufacturing industries and for engineering applications. When it comes to the topic- “Alloy vs Aluminum”, you should know that both materials have different advantages and characteristics.

Alloy vs Aluminum- Let’s Compare Their Strength And Durability-

Alloy-

It combines two or more metals or metals with one or more non-metal elements. Alloying metal is to improve certain properties such as strength, durability, corrosion resistance and more. Alloys can be customized with specific characteristics for a specific application by mixing different metals.

Strength- Alloys are highly recognized for their superior strength compared to pure metals. For example, Aluminum Alloy is stronger than aluminum. It concludes that the incorporation of different metals in an alloy improves its structural integrity and makes it more durable, stress-resistance and heavy-loads resistant.

Durability- Alloys also excel in this category. When we combine different metals in an alloy, it boosts its resistance to wear, fatigue and deformation. Additionally, it makes alloys more appropriate for applications where durability is highly required such as the aerospace, automotive, and construction industries. Alloys are also corrosion resistant which enables them to survive ruthless environments.

Aluminum-

Aluminum is a lightweight and extremely abundant metal. With an Atomic number of 13, it is a silvery-white, soft, non-magnetic, and pliable metal. Aluminum features outstanding properties, including low density, corrosion resistance and electrical conductivity.

Strength- Pure aluminum is less strong compared to alloys. It is not an alloy, but it can be combined with different other elements to shape an aluminum alloy which is versatile to be involved in different applications across industries like automotive, aerospace, construction, and consumer products. Aluminum alloys can be designed to give excellent strength while keeping the advantageous properties of the metal.

Durability- Aluminum ensures good durability in terms of corrosion resistance. Its natural oxide layer acts as a defensive barrier against oxidation and other environmental factors. Pure aluminum is more prone to deformation and fatigue. This is why it is good to prefer aluminum alloys over pure aluminum where higher durability and strength are required.

The Final Thought-

“Alloy vs Aluminum”- The choice between alloy and aluminum is completely based on the specific requirements of the application. However, finding a reliable supplier is also important. Make sure you find the best manufacturer and supplier. This is where we step in. We can assist you to get the right supplier. Visit www.pipingmaterial.ae for more information.

Resource: https://pipingmaterialuae.wordpress.com/2023/06/27/alloy-vs-aluminum-a-comprehensive-comparison-of-strength-and-durability/

0 notes

Text

What is The Highest Paying Engineering Specialization?

Engineering is a discipline that students consistently praise. Students from all around the country work hard to get into B. Tech colleges near me in order to pursue engineering since it ensures the greatest possible future for them. Engineering is “the discipline of science and technology concerned with the design, construction, and usage of engines, machines, and structures,” according to Wikipedia. This stream is for those who are fascinated by machines or structures and have a strong grasp of physics and mathematics. Engineering is the process of learning how to apply science and technology to numerous parts of daily life in order to lead it smoothly.

The majority of innovations come from engineering. Engineering is the course for those with a desire to make a difference in the world. This discipline has been practiced since people started looking toward science to lead a comfortable life. Engineering has a broad scope and application. It can range in size from a single cell to an entire spacecraft. Engineering paved the way for the current way of living. B. Tech in Greater Noida colleges offer a wide range of opportunities for tech students to lead a career worthy of appreciation.

It goes without saying that Greater Noida is one of the most popular cities to get started for your B. Tech program. The reach of Top 10 B. Tech colleges in Greater Noida is narrowing by the day. Students are drawn to these colleges mostly because of their academic excellence, reputation and numerous placement opportunities.

Engineering Pay scale

Engineering is a field with numerous specializations, each with its own pay-scale based on demand. The demand for most specializations varies. However, some branches of engineering have consistent demand. In the engineering field, experience is extremely significant in defining a person’s pay scale. It also depends on a person’s title or position inside an organization or agency. For a good start in career, it is important for all engineering students to find best B. Tech Colleges near me to further their studies.

A table is provided below that will assist readers in better understanding the engineering pay scale.

Branch of Engineering - Average Annual Salary

Computer Science and Engineering - 5.5 to 37 LPA

Aerospace engineering - 6 to 25 LPA

Chemical Engineering - 7 to 22 LPA

Electronics and Communication Engineering - 4.5 to 14 LPA

Civil Engineering - 3.5 to 10 LPA

Electric Engineering - 2.7 to 9 LPA

Big Data Engineering - 4 to 15 LPA

Petroleum Engineering - 5 to 41 LPA

Nuclear Engineering - 5 to 14 LPA

Metallurgical Engineering - 4 to 8 LPA

Which engineer earns the most money?

Statistics and study are required to answer a query like this. A consistent style reflecting the popularity of software engineering has been discovered based on the same. This conclusion also provides a complete record of the students’ placement and overall impressions of the courses offered by top 10 B. Tech Colleges in Greater Noida.

The supply and demand factor accounts for the high pay scale of software engineers. To create an app, one needs a skilled software engineer, and new apps are released virtually every day. It’s no surprise that software engineers are in such high demand in today’s job environment. Without the focused hard work of these engineers, life would grind to a halt.

5 Ways to Pick an Engineering Specialization

Interest: A student’s interest in a certain engineering discipline is the first and most crucial factor that motivates him or her to pursue it.

Return on Investment (ROI) is an important aspect to consider while deciding which engineering branch to pursue. In terms of monetary value vs cost, the branch you choose must provide adequate and satisfying returns. You can reach to B. Tech institutes near me to make an inquiry about the specialization that is best suited to your skills, career preferences and academic background.

Career Growth: A student should always choose an engineering branch that allows for rapid worldwide career advancement.

Synchronization with current events: As previously said, engineering is a field that is driven by market need. As a result, accurate synchronization with current times is critical for the branch a student chooses. Outdated branches will limit not only studying but also job advancement.

Pay scale: The pay scale that a person will receive shortly is the most significant element to mind while picking a particular branch. It is always best to choose a degree that will ensure a solid future.

B. Tech in Greater Noida: KCC Institute of Technology and Management

KCCITM is undoubtedly the place to study B. Tech in Greater Noida. KCC Stands out as one of the best private engineering colleges in Greater Noida in terms of infrastructures, hi-tech labs, Quality Education, Experienced Staff, Fee Structure and more. It stands out in its approach to assist and equip the students for their overall development, giving them a strong foundation for a successful career. The institute offers B. Tech engineering program in civil engineering, mechanical engineering, computer engineering, electrical engineering and more. It is approved by AICTE and affiliated to APKTU which means it will further add value of your degree and help bag jobs after you complete the program. The institute has received many awards and appreciations in the past for selfless dedication toward improving the technical skills base of India.

Source: https://bestbtechcollegeingreaternoida.wordpress.com/2022/06/06/what-is-the-highest-paying-engineering-specialization/

0 notes

Text

OKAY! This is going to be an extreeeemely long post with my various WandaVision theories! SPOILERS ahead for episodes 1-5, so tread carefully if you haven’t seen them yet! Also, buckle in for a lot of reading haha...

- Agnes is Agatha Harkness

This theory is pretty widely accepted but in case you haven’t heard it yet/need a reminder of what the theory is: Agatha Harkness is a witch in the comic books. She is an agent of Mephisto (basically the devil in the MCU, a sorcerer who is super powerful & does trades/grants wishes but in a monkey’s paw kind of way) and also acts as Wanda’s mentor when she is training. She is there to help Wanda realize her full potential. Reasons for this theory being accepted are:

1. Agnes = AGatha HarkNESs

Pretty self explanatory, this one.

2. One piece of evidence everyone likes to point to is that Agnes is ALWAYS wearing a brooch, much like Agatha.

In a similar vein, Agnes dresses up like a witch in the Halloween episode (which we get tonight!!). The third comic-y reason is that she says her anniversary with Ralph (whom we NEVER see) is June 2nd, which is the start of the Salem Witch Trials. Agatha Harkness was one of the witches at Salem.

3. She (especially in episode 5) keeps showing up at the exact right time to help Wanda however she needs it. Examples include her showing up to welcome Wanda to the neighborhood and plan the dinner with Vision, bringing her along to the neighborhood planning committee, helping Wanda with the boys (showing up when they’re crying, the doghouse). She is always there, basically acting as a guide for Wanda in the town.

3. She knows that this is a fake world and that Wanda has some control over what happens. This is most clearly evidenced in episode 5 when she says “Do you want me to run that again?” She also doesn’t notice/care that Wanda has magic, which anyone else in the town would. Also - anyone else notice how she overacts constantly? (In a good way - I love Kathryn Hahn)

Which brings me to theory two:

Agnes/Agatha Harkness is the one in control, not Wanda - or at the very least, is using her power to try to influence Wanda’s actions.

1. Agatha is an agent of Mephisto. I think that she is acting on his orders to make this town and Wanda’s life in it the way that it is. Multiple reasons for this, but the main one for me is episode 5 (On A Very Special Episode), she clearly has control over/intimate knowledge of what’s happening inside the WandaVis household. How else would she know to show up when the twins are crying, or when they bring in a new dog? Other sketch things:

2. The boys only ever age up (or attempt to age up) when Agnes is there. I think that she is the one who is making them do that. If she can control every single person in town’s actions and speech, who’s to say she can’t control and manipulate the magic twins’ powers as well?

3. She clearly* killed Sparky, likely in order to try to help Wanda realize how powerful she really is and bring in the idea that she can bring people back to life. It may even be possible that Agnes wants to bring back a specific person but can’t without Wanda’s powers. *To me, it’s clear, because when she walked into the kitchen, Sparky almost killed himself with the electricity but didn’t, and then of course she “found him” in her azaleas.

4. Norm never specifies who “she” is that’s in his head.

MOVING ON TO THEORY THREE:

SWORD and (Acting) Director Hayward are sketchy as fuck, and likely are doing some evil shit and trying to pin it on Wanda.

I don’t mean this to say that SWORD is the organization that put the town in the hex, or is the one that is controlling everything that's happening, but I think it's very clear that there's something going on behind the scenes that they don't want us to know. There are lots of different ways that you can see this, but some of the ones that are most important are as follows:

1. SWORD is clearly developing weapons which Monica highlights when she says, “it also says observation and response on that door not creation.” This is apparently against the mission of SWORD itself, which does not lead to a super trustworthy organization.

2. Director Hayward is clearly trying to place blame on Wanda for things she either didn’t do or didn’t control. The clearest example of this is when he is giving his speech in Episode 5 after Monica comes back, and Jimmy Woo was speaking. Hayward keeps interrupting to explain how Wanda is evil - she joined Hydra (as Jimmy says, it’s more complicated than that), she purposefully hurt people in Lagos (it was an accident), she fought against the Avengers (before gaining their trust and joining them). (Also, side note, I love Jimmy Woo and how kind he is. We need more Jimmy Woo in the MCU).

3. The video that he shares of Wanda breaking into SWORD...not a single. person. in the SWORD lobby turns, notices, or reacts at all to Wanda walking in, violently throwing open doors, and basically stealing a corpse. I don’t know about you, but if I worked in a secure and secretive government facility, and a rogue Avenger that’s been gone for 5 years just suddenly appeared and was using her powers to break down doors and steal a secret project, I’d probably at LEAST turn and look.

3a. I’m honestly not even sure that that’s Wanda vs. a body double, like, there’s a reason that the only power they showed was her opening a door, breaking glass, and gently coming down into the room - all things that can be easily faked. You’re telling me that SWORD, in all their advanced tech, space travel, science, money, you’re telling me that the best visuals they have are 1. barely in color 2. blurry and 3. don’t show close-ups of her face? I think that it wasn’t Wanda who took Vision’s body, and I think the footage was fabricated.

4. CLEARLY - SWORD has been experimenting on Vision. Whether to revive him, recreate his technology, whatever, it is explicitly stated that that is against his living will and the Sokovia Accords. IF (and I think it’s a big if...) Wanda did violently break in to steal his body, it would likely be to protect him and make sure he is being honored, not make him into a weapon.

NEXT THEORY!

VISION IS ALIVE - and no, Wanda is not just puppeteering his corpse (this is one of the worst theories I’ve heard about WandaVision and I hate it and if I never hear it again it’ll be too soon)

1. I have several reasons to think this. First, if he weren’t alive, why would we have so many scenes of just Vision, or scenes where Vision is figuring out that something is wrong?

2. In the trailers, we see Vision leaving the boundaries of the hex (to be fair, I haven’t watched any of the new trailers, because I don’t want any spoilers) - BUT - how could he do that if he weren’t his own being?

3. I genuinely do not think that Marvel is going to make us watch Vision die again. Not a third time.

How is he alive? I think that there’s obviously an extreme amount of Mind Stone energy within Wanda, and I’m sure that there’s a world in which she could transfer some of that energy to Vision and help bring him back. Not entirely sure of the methodology to be fair, but I just have a feeling in my heart.

OKAY ON TO RANDOM THEORIES THAT I BELIEVE BUT HAVE NO EVIDENCE FOR:

1. Monica came out of the Hex with powers - my only reasoning being that her brain scan and her blood draws were both inconclusive/blank.

2. Wanda isn’t lying when she says she doesn’t know how this started or what’s happening. I think she has more control than most people in town, but I think that’s more that she is a little tuned in to the frequencies of the town than that she started it all. But I really think that Agnes is in control.

3. OH PIETRO - He’s the Evan Peters Quicksilver instead of ATJ (rip) because Agnes had to search through the multiverse for him - she can’t bring people back to life (Wanda can though...ATJ i’m holding out hope...). So anyway, she just searched through the universes and found the closest thing to Pietro that she could.

4. Aerospace engineer that Monica knows might be Reed Richards aka Mr. Fantastic. (The Fantastic 4 and the X-Men have a long history with Agatha Harkness, so it would make sense to bring those characters in now that Disney is able to)

5. Dottie is also a witch - she’s not identified on the magnet board with the other townspeople, she’s in control of some things.

6. Hayward might be Mephisto in disguise, who knows.

7. Magneto is going to come back at the end of the series i have no real reason to believe this

8. I don’t trust the post man.

OKAY THAT’S ALL I have to go back to work and this is way too long please send me all your theories :)

#wandavision#wandavision theory#wandavision theories#wandavision season 1#wandavision season one#wandavision spoilers#wandavis#wanda maximoff#agnes#agatha harkness#dottie#vision#timmy and tommy#monica rambeau#jimmy woo#sword#director tyler hayward#wandavision episode 2#wandavision episode 3#wandavision episode 4#wandavision episode 5#i have to post this before episode 6 comes out tonight bc i feel like we're going to get some ANSWERS#manifesting a 55 minute long episode#marvel#marvel cinematic universe#marvel multiverse#mcu multiverse#marvel theories#marvel theory#i'm too obsessed with this show lmao

18 notes

·

View notes

Text

Five Things You Should Do In Engineering Physics | engineering physics

Engineering physics, also called science of engineering, is a branch of mathematics that focuses on studying the combined areas of science, engineering, mathematics and the arts. Engineering physics, also known as the science of science engineering or science of engineering technology, studies all aspects of human activities that involve the use of electricity, steam, mechanical power, and heat in their processes.

Some common areas covered by engineering physics include power generation, fluid dynamics, energy, thermodynamics, optics, biomedical research, software, and aerospace engineering. The study of engineering physics includes the application of mathematics to solve physical and biological problems and engineering applications. The application of physics in human activities is a significant part of engineering physics and includes the development of advanced tools for research in human physiology, engineering ergonomics, environmental design, materials science and mechanical design.

Science of science engineering is the scientific study of nature in its most simple form. It is concerned with the study of natural phenomena with the aim of applying that knowledge to human activity. This branch of science has made significant advances in the fields of aerospace, aeronautics, biomedical research, computer science and other applications in human and environmental science. Scientists in this field work in a wide variety of organizations and conduct research at both theoretical and applied levels. They use different methods to study nature and apply it to engineering fields.

This branch of science is primarily concerned with the study and description of physical systems. Engineering physics provides the scientific foundation that can be used to analyze engineering and science processes and applications. The study of physical systems often involves the study of physical laws, which are applied in specific situations. The principles of physics apply to all fields of science and engineering and can be applied to solve certain types of scientific problems.

Engineering Physics is an integral part of the engineering field, in which it is considered as the link between theory and practical research. The research that engineering physics carries out in its studies are called 'science of science' in that they apply the principles of science to solve specific issues that arise within an engineering system. Engineers and scientists use physics to study the behavior of physical systems in all areas of engineering from transportation and aerospace to power generation.

Engineers who work in the field of engineering physics often make contributions in their own way to research and development. These contributions can help advance the progress of a technology and help the field of engineering.

Engineering Physics School of Engineering – engineering physics | engineering physics

Abstract word cloud for Engineering physics with related tags. | engineering physics

Amazon | engineering physics

Physics Vs Engineering Which Is Best For You? – engineering physics | engineering physics

Buy A Textbook of Engineering Physics (Old Edition) Book Online at – engineering physics | engineering physics

Engineering Physics degrees – engineering physics | engineering physics

The post Five Things You Should Do In Engineering Physics | engineering physics appeared first on Academic Degree.

from WordPress https://degreeneat.com/five-things-you-should-do-in-engineering-physics-engineering-physics/

1 note

·

View note

Text

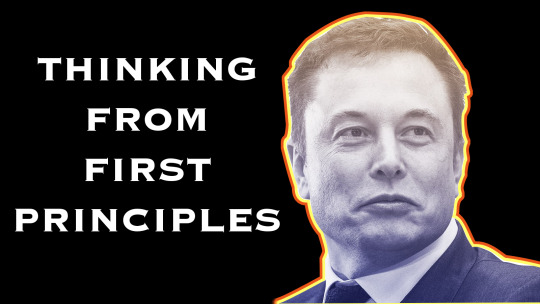

Problem Solving from First Principle!

On one side tech entrepreneur like Jack Ma advocating for 9-9-6 work culture & other side people fight for 40 hours equality!

But, there are some global leaders like Narendra Modi, Warren Buffett, Marissa Mayer, Elon Musk who work more than 100+ hours to accomplish their goals.

In this diverse argument, At the age of 46, Elon Musk has innovated and built four revolutionary multibillion-dollar companies in completely different fields — Paypal (Financial Services), Tesla Motors (Automotive) and SpaceX (Aerospace), Boring (Transportation).

How these people achieve so much within a short span of time??

How did he able to manage all these things ??

What is the secret behind there success??

.

.

.

The answer is simple:

Read, Read & More Read!!!

No doubt Reading plays an important role in unlocking your inner creative genius and becoming the best at what you do — but there’s more to this —

Reading new things continuously over a period of time. (power of compounding) will change the way you think!!

Learning is the single best investment of our time that we can make. Or as Benjamin Franklin said, “An investment in knowledge pays the best interest.”

Thinking from the First Principle gives many Out of box & innovative solutions to hard problems.

Your brain encourages you to think in analogies, as this is the most efficient and safest way of thinking. So how do you break this programming, take a step back and start thinking in basic principles?

First Principle: The Building Blocks of True Knowledge!!

First-principles thinking is one of the best ways to reverse-engineer complicated problems. the idea is to break down complicated problems into basic elements and then reassemble them from the ground up.

It’s one of the best ways to learn to think for yourself, unlock your creative potential, and move from linear to non-linear results.

When Elon Musk’s started development of the TESLA electric car, many experts felt that electric vehicles could not be popular because of battery costs.

The $600/kW is the market price, The battery has always been so expensive. Which increased in 2/3rd of production cost.

Why it's $600/kW ??

“That’s just the way they will always be because that’s the way they have been in the past”.

However, Elon Musk does not agree!! He needs to understand the root cause of the Problem, He applied First-principles methodology!!

What are the material constituents of the batteries?

What is the spot market value of the material constituents?

When he dig dipper into the ground, basic things like cobalt, nickel, aluminum, carbon, and some polymers for separation, and steel can enough to produce a battery pack;

Next, If we bought that on a London Metal Exchange, what would each of these things cost?

Oh, god, it’s … $80 per kilowatt-hour.

So, clearly, you just need to think of clever ways to take those materials and combine them into the shape of a battery cell, and you can have batteries that are much, much cheaper than anyone realizes.

youtube

Through these “basic facts”, Elon Musk and the team will further analyze and experiment each part of the raw materials and re-engineer each work process.

Finally, he and the team will optimize the original parts and add a comprehensive improvement of the production method, which significantly reduces the Cost-of electric vehicles.

Musk used first principles thinking not only for making inexpensive battery packs for his Tesla cars but also for building cheaper rockets for his other space exploration company SpaceX.

The result of such thinking was astonishing!!

The Basic: Analogy vs Axioms

“I think it is important to reason from first principles rather than by analogy.” — Elon Musk

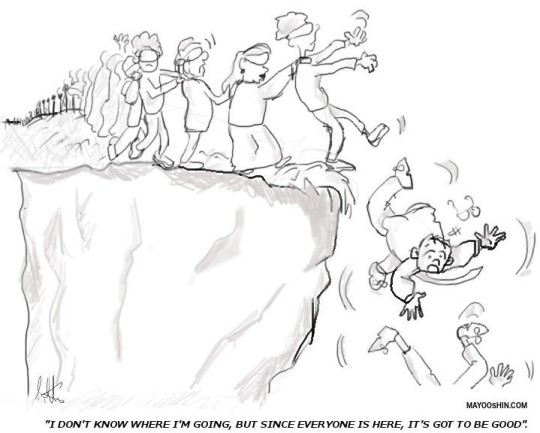

Your brain encourages you to think in analogies, as this is the most efficient and safest way of thinking. So how do you break this programming, take a step back and start thinking in first principles?

In our day to day life, we tend to use what is known as Comparison Thinking, this is when we do what comes naturally and normally to us and reason through analogy.

What this means is that we make decisions and judgment calls based on what we’ve seen, heard or done from our experiences or from others.

Knowing the outcome due to past experiences, we either repeat or iterate slightly to suit the current situation.

This is an easy mode of thinking, and for the most part effective, but also offers no innovation or large changes.

Thinking from First Principles.

In this, you take a problem and break it down into its fundamental parts and truths, until you get to the bare bones as it were. Once you’ve eliminated everything down to its constituent parts then you start reasoning up from there.

This is a harder mode of thinking, but does offer better results, is far more effective and creates recognizable change.

Analogy thinking: Cook vs Chef ??

He compares people and how they behave to cooks and chefs. With a chef, he means a person who invents their own recipe, while a cook is someone who follows an already existing recipe.

Some people usually behave like cooks and follow recipes from a cookbook, while others prefer to come up with their own.

A cook takes some ingredients and goes through a series of steps to come up with a standard dish. On the other hand, a chef might use those same ingredients, but mix them up in new and original ways and come up with a new dish. For both of these guys, the ingredients were the first principles, but the way they used them was different.

🔸Iteration: doing the same things again.

🔸Innovation: doing new things.

🔸Disruption: doing new things that make old things obsolete.

Examples of First Principles in ActionSpaceX:

Problem: Elon musk childhood dream is to send the First Rocket to Mars.🚀

Reasoning from analogy: Build Vs Hire? As a startup, It's difficult to understand the new rocket technology & build from scratch. so purchase the unused rocket from existing companies/Govt agencies like NASA/ISRO but the cost of purchasing a rocket was astronomical — up to $65 million.

Reasoning from first principles: let’s look at the first principles. What is a rocket made of?

Aerospace-grade aluminum alloys, plus some titanium, copper, carbon fiber.

Then I asked, what is the value of those materials on the commodity market?

It turned out that the materials cost of a rocket was around two percent of the typical price.

Within a few years, SpaceX had cut the price of launching a rocket by nearly

10x while still making a profit. Musk used first principles thinking to break the situation down to the fundamentals, bypass the high prices of the aerospace industry, and create a more effective solution.

Minimal Product Design:

Problem: Create a login system for a web/mobile app.

Reasoning from analogy: Most apps require a user to provide a username, email address and password, with the password confirmed twice!!

That seems to be the best practice, so I’ll do the same.

Reasoning from first principles: What’s the least information I need to collect from the user to make the app functional?

The app creates a page for each user that is their online identity hub.

I want their full name to be displayed at the top of the page, so I need to collect that. I won’t display a username anywhere in the app, so Do I really need that?

But if two users have the same name, how will I create a unique URL slug for each?

I guess I could add a randomized number to the slug, and do a check before saving that ensures the number is unique.

I’ll then need to collect the user’s email in-case they forget their password.

I probably don’t need to verify their password twice, since the app will allow them to easily reset it as long as they have access to their email account.

Artists thinking:

Problem: Even after 500 years, we are unable to produce one more world-class painting like Mona-lisa??

Reasoning from analogy: This generation artist learns drawing & painting. Mostly they expertise in one specific area. they unable to visualize depth & authenticity of the image. (not a polymath).

Reasoning from first principles:

It’s hard to talk about the First principle thinking without mentioning the impressive genius of Leonardo da Vinci.

Before writes in the world famous Mona Lisa, he knows the art, anatomy, engineer, science, biology, optics & experimenter which makes him a renaissance!! With all these basics principle, da Vinci will draw the picture of the millennium.

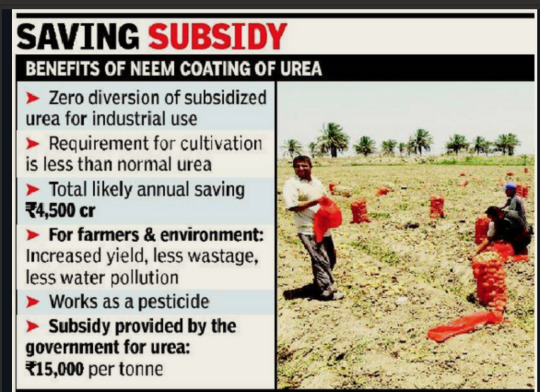

Neem Coated Urea

Problem: The urea was subsidized for agriculture use but it was being diverted to non-agricultural purposes, chemical factories.This lead to a shortage of urea to the farmer.

How to solve this ??

How it reaches to the Farmers or beneficiaries??

Reasoning from analogy: Think to avoid the middlemen & directly distribute to the farmers. But It's a challenging job to distribute proper fertilizers, seeds to the 110 million farmers across India. Either we need to

* Produce excess adequate amount of the Urea.

* Create a task force which monitors the distributions on various level.

Reasoning from first principles:

The GoI has mandated neem coating of urea while producing it in the Factories!! Expect Agriculture, coated urea is not good for any other commercial usage.

Why ??

🔸Urea is highly subsidized in India for agricultural usage.

However, people were using the subsidized urea for other industrial applications due to its high nitrogen content.

Hence Neem coating was adopted to prevent usage of Urea for any other application than farming as Neem coating doesn’t affect agriculture but does so for industrial usage.

🔸Urea is very volatile in nature. If it is applied directly on the crops,

it is released very rapidly. This results in high usage of urea by farmers on the crop thereby hampering the quality crop and soil.

Neem coating slow downs the release of urea to crops. Also, Neem is an excellent ingredient for farming which improves plant and soil quality.

What Are You?

Who we are ??

How This Universe Created??

How can something appear without nothing??

The best way to understand the Universe, Physics laws, Human evolution, Culture, Consumer behavior or predict the future is to deduce that from the First Principle.

Reasoning from the first principle allows gives a structured framework for thinking & gives a solution to the above-mentioned complex problem!

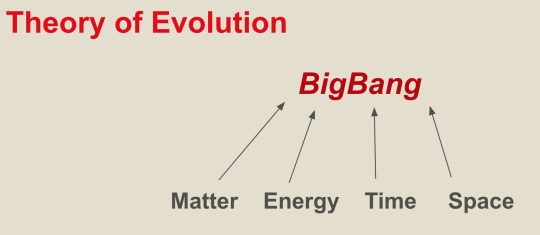

Timeline: Big Bang Theory: (13.5 Billion years ago)

Big Bang Theory A starting point for all the above Questions!! It gives an explanation about how the universe began.

At its simplest, it says the universe as we know it started with a small singularity. Physicist define Bigbang as Singularity! Its a point at which all known laws of nature id not exists, even time too did not exist.

Once all the matter, energy & space in the universe were once squeezed into an infinitesimally small volume, which erupted in a cataclysmic “explosion” which has become known as the Big Bang. Thus, space, time, energy and matter all came into being at an infinitely dense, infinitely hot gravitational singularity, and began expanding everywhere at once.

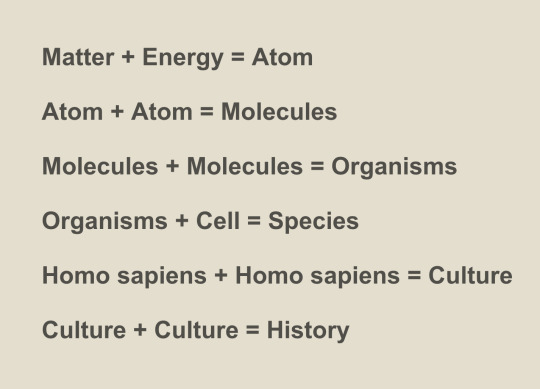

String Theory :(4.5 Billion years ago)

String theory helps us to group all Physics laws into the theoretical framework. which helps to understand the substance, matters & species formation of the Planet Earth leads to the Evolution of Biology & leaving organisms over a period of time to evolve the Homo Sapiens

Homo Sapiens : (2.5 million years ago)

The story of humanity is a story of adaptation. Over the past 200,000 years, ever since the first modern humans (Homo sapiens) appeared in Africa, people have been spreading outward from that continent in every possible direction. As they encountered new environments and challenges, our ancestors had to change in many ways to survive.

Discovered how to make fire. (300000 years ago) This small event transformed the way we ate, the way we grew to live on heated food, it changed our digestive system, it transformed our groups and societies as we literally came to gather around the fire and told each other stories. (Cognitive Revolution)

Above timeline from Bigbang exploration, String theory, Homo sapiens to the build a culture & creating a History.

we come in a long way.

This will give an answer to all the fundamental questions in the discipline of science, technology, Engineering, Mathematics (STEM)

How to cultivate the First Principle Thinking :

If I had an hour to solve a problem and my life depended on the solution,

I would spend the first 55 minutes determining the proper question to ask,

for once I know the proper question, I could solve the problem in less than five minutes. — Albert Einstein

✨ Most don’t know where to begin or how to attack the problem?

✨ Most lack a structured approach and don’t have the patience or time to dig deep enough?

✨ How you frame the problem is important??

How to think in a First Principles way:

🔸Keep asking “WHY” to get into the deeper layers of understanding

🔸Read more classics in the field

🔸 Learn the subjects that form the foundation of the field you are exploring. (math, physics, biology, etc)

✔️Want to learn marketing? Read Psychology.

✔️Want to learn Health and Fitness? Read Biology.

✔️Want to learn Economy ?? Read supply and demand.

✔️Want to learn Data Analyst/Science ?? Understand Excel, statistics.

✔️Want to understand relationships and trust work ?? Read Game theory.

✔️Want to understand Blockchain ?? Read Edge computing, attack vector, Encryption.

Moreover, try to study the fundamentals of *different* fields.

“The secret to a great life is to nail the basics.” — @Naval

Bottom line: The Future

Now, We are in the exact middle in the spectrum of the transformation of the Biological evolution to the Technological transform.

Globalization effect & rapid change in the competitive environment it's difficult to understand/learn everything!

learn from basic principle help to sustain in future!!

Understand the concept from First principles. First, deconstructs knowledge into fundamental principles Next, reconstructs the fundamental principles in new fields to become world-class Modern Polymath!

Footnote:

* https://medium.com/the-mission/elon-musks-3-step-first-principles-thinking-how-to-think-and-solve-difficult-problems-like-a-ba1e73a9f6c0

* https://gainweightjournal.com/elon-musk-problem-solving-applications-of-first-principles-thinking/

*https://twitter.com/ARanganathan72/status/846697666608189441

*https://iascurrentaffairsbyamityadav.wordpress.com/2017/06/22/what-are-the-benefits-of-neam-coated-urea-ncu/

*http://theengineeringmanager.com/growth/first-principles-and-asking-why/

1 note

·

View note

Text

Products

https://www.cn-jkz.com/products/

JKZ Electronic has been engaged in the manufacturing of induction heating equipment for nearly 30 years. At present, there are currently more than 10,000 JKZ induction heating devices working all over the world. These induction heating inverters are widely used in mechanical forging heating processing, industrial heat treatment manufacturing, tool induction brazing manufacturing, food heating processing, and other fields. Based on the principles of induction technological updates and customers' needs, JKZ Electonic has always been striving to produce industrial induction heating machines with JKZ's own characteristics and independent core technologies in the heating industry. With the upgrading of equipment from generation to generation, as well as our rich experience in induction heating applications, we serve end customers with high-quality industrial induction heating machines all over the world. Taking "win-win with customers" as our value foundation, JKZ Electronic, with our complete R&D designs, project solutions, production team, and after-sales support, are looking forward to cooperating with you.

Difference between Medium and High Frequency Induction Heating Equipment

1. Different frequencies: induction heating equipment with a frequency of 1-10Khz is usually regarded as medium-frequency induction heating equipment, and induction heating equipment with a frequency above 50Khz as high-frequency induction heating equipment.

2. Affected by the frequency of induction heating equipment, the quenching depth of the two is also different. The quenching depth of medium frequency induction heating equipment is generally 3.5-6mm, while that of high frequency induction heating equipment is 1.2-1.5mm.

3. Different diathermy diameters: medium frequency induction heating equipment has great advantages in the diathermy of workpieces. It is mainly used for diathermic heat treatment of workpieces. It can perform diathermic heat treatment on workpieces with a diameter of 45-90mm. However, high-frequency induction heating equipment can only dilute the thin and small workpieces.

Induction Heating VS Other Methods

Induction heating is different from some common heating methods in that it does not rely on convection and radiation to transfer heat to the surface of the product. Instead, the surface of the product generates heat through current, and then the heat from the surface of the product is transferred to the product through heat conduction. The depth of direct heating using induction current depends on the electrical reference depth.

Unlike some combustion methods, induction heating can be precisely controlled regardless of batch size. By changing the current, voltage and frequency of the induction coil, fine-tuned engineering heating can be achieved, which is very suitable for precision applications such as surface quenching, quenching and tempering, and annealing. High precision is essential for key applications such as automotive, aerospace, fiber optics, ammunition bonding, wire hardening, and spring wire tempering. Induction heating is very suitable for specialty metal applications involving titanium, precious metals and advanced composite materials. The precise heating control provided by induction is unparalleled. In addition, using the same heating principle as the vacuum crucible heating application, induction heating can be carried out in the atmosphere for continuous application. For example, bright annealing of stainless steel tubes.

Induction Heating Equipment for Sale

Explore JKZ Brand Industrial Induction Heating Machines

High Frequency Induction Heating Machine

The CX series high-frequency induction heating equipment's working frequency covers 50KHZ ~ 120KHZ. This high-frequency induction heating machine is widely used in induction welding, tool welding, pipe welding, thermal nesting, etc.

Ultrasonic Frequency Induction Heating Machine

SWS series ultrasonic frequency induction heating unit can be used in many fields, including automobile and motorcycle parts production, metal hot forging, metal heat treatment, etc.

Medium Frequency Induction Heating Machine

MFS series intermediate frequency induction heating equipment is perfect for hot forging for large workpieces, smelting for ferrous or non-ferrous metals or deep heat treatment, etc.

SWP Ultra High Frequency Induction Heating Machine

JKZ launched a new generation of induction heating equipment - SWP. The actual working frequency of this industrial induction heating system can reach 8-60khz. Its power is fully upgraded to 800kw.

0 notes

Photo

First flight of 15 minutes of Rolls-Royce fully-electric aircraft

Rolls Royce, which is best known in the aviation industry for its jet engines, has embarked on the world’s First flight of 15 minutes of Rolls-Royce fully-electric aircraft. According to the firm, “The Spirit of Innovation” flew for 15 minutes and “began a rigorous flight-testing phase during which we will gather critical performance data on the aircraft’s electrical power and propulsion systems.”

According to Rolls Royce, the one-seat plane has equipped with “the most power-dense battery pack ever built for an aircraft”. As reported by Rolls-Royce, the aircraft will ultimately reach speeds of more than 300 miles per hour. Thanks to a 6,000-cell battery pack and a three-motor engine that presently generates 400kW (500-plus horsepower).

The flight will take place around a year after the initially anticipated takeoff and approximately six months following taxiing tests. According to the businesses, Rolls-Royce is also working on an air taxi with manufacturer Tecnam. With the goal of producing a “all-electric passenger aircraft for the commuter market” by 2020. It has previously collaborated with Siemens and Airbus on an alternative electric-powered aircraft idea.

Airlines and freight firms have been investigating the feasibility of electric aeroplanes for some years. As air travel and cargo contribute to a growing quantity of greenhouse emissions. In the words of the World Wildlife Foundation, it is now “the most carbon-intensive activity that a human can engage in.”

Ford’s Fully-Electric Lightning Truck

Weight, on the other hand, is a considerably larger issue for aeroplanes than it is for automobiles. Ford’s all-electric Lightning truck weights 1,800 pounds heavier than the gas-powered version. And has a range that is slightly less than half that of the gas-powered variant. A Cessna 206 Turbo Stationair, on the other hand, would be unable to take off. Since the weight of the passengers (including the pilot) would exceed the aircraft’s usable load by 500 pounds before it could even take off.

The Aerospace Technology Institute and the United Kingdom government each contributed half of the project’s funding. Which has the goal of ultimately developing all-electric passenger jets. It is not just about setting a world record of First flight of 15 minutes of Rolls-Royce fully-electric aircraft. The advanced battery and propulsion technology developed for this plan has exciting applications in the Urban Air Mobility market. And has the potential to help make the goal of achieving a zero-emissions aircraft a reality, according to Warren East, the CEO of Rolls-Royce. We are not simply trying to break a world record. The improved battery and propulsion technology being developed for this initiative has interesting implications in the Urban Air Mobility industry. And has the potential to contribute to the realization of the “jet zero” goal.

Read Also: Epic has challenged Friday’s verdict in the Epic vs Apple case

Published in Lahore Herald #lahoreherald #breakingnews #breaking

#first flight of rolls royce electric aircraft#rolls royce#rolls royce electric aircraft#world record of electric aircraft#Latest#Tech

0 notes

Text

Wire Thread Inserts Market - Global Outlook and Forecast 2021-2027

This report contains market size and forecasts of Wire Thread Inserts in global, including the following market information:

Global Wire Thread Inserts Market Revenue, 2016-2021, 2022-2027, ($ millions)

Global Wire Thread Inserts Market Sales, 2016-2021, 2022-2027, (M Units)

Global top five Wire Thread Inserts companies in 2020 (%)

The global Wire Thread Inserts market was valued at 363.7 million in 2020 and is projected to reach US$ 419.6 million by 2027, at a CAGR of 3.6% during the forecast period.

We surveyed the Wire Thread Inserts manufacturers, suppliers, distributors and industry experts on this industry, involving the sales, revenue, demand, price change, product type, recent development and plan, industry trends, drivers, challenges, obstacles, and potential risks.

Total Market by Segment:

Global Wire Thread Inserts Market, By Type, 2016-2021, 2022-2027 ($ Millions) & (M Units)

Global Wire Thread Inserts Market Segment Percentages, By Type, 2020 (%)

Free Running Inserts

Screw Locking Inserts

Global Wire Thread Inserts Market, By Application, 2016-2021, 2022-2027 ($ Millions) & (M Units)

Global Wire Thread Inserts Market Segment Percentages, By Application, 2020 (%)

Automotive Industry

Electric & Electronics

Aerospace & Defense

Machinery Industry

Others

Download FREE Sample of this Report @ https://www.grandresearchstore.com/report-sample/global-wire-thread-inserts-2021-2027-603

Global Wire Thread Inserts Market, By Region and Country, 2016-2021, 2022-2027 ($ Millions) & (M Units)

Global Wire Thread Inserts Market Segment Percentages, By Region and Country, 2020 (%)

North America

US

Canada

Mexico

Europe

Germany

France

U.K.

Italy

Russia

Nordic Countries

Benelux

Rest of Europe

Asia

China

Japan

South Korea

Southeast Asia

India

Rest of Asia

South America

Brazil

Argentina

Rest of South America

Middle East & Africa

Turkey

Israel

Saudi Arabia

UAE

Rest of Middle East & Africa

Competitor Analysis

The report also provides analysis of leading market participants including:

Key companies Wire Thread Inserts revenues in global market, 2016-2021 (Estimated), ($ millions)

Key companies Wire Thread Inserts revenues share in global market, 2020 (%)

Key companies Wire Thread Inserts sales in global market, 2016-2021 (Estimated), (M Units)

Key companies Wire Thread Inserts sales share in global market, 2020 (%)

Further, the report presents profiles of competitors in the market, key players include:

B?llhoff

STANLEY Engineered Fastening

Recoil (Howmet Fastening Systems)

KATO Fastening Systems

Helical Wire, Inc.

Bossard Group

V?LKEL

WTI Fasteners

E-Z LOK (Tool Components, Inc.)

AMECA

KKV

Hepyc

BAER Vertriebs GmbH

Chrislynn Inserts

Bordo International

HONSEL

Harishrum Engineers (Gripcoil)

Dalian Andi

Shenzhen Civada

Xinxiang Zhongguan

Xinxiang Donghai Industry

Get the Complete Report & TOC @ https://www.grandresearchstore.com/manufacturing-and-construction/global-wire-thread-inserts-2021-2027-603

Table of content

1 Introduction to Research & Analysis Reports

1.1 Wire Thread Inserts Market Definition

1.2 Market Segments

1.2.1 Market by Type

1.2.2 Market by Application

1.3 Global Wire Thread Inserts Market Overview

1.4 Features & Benefits of This Report

1.5 Methodology & Sources of Information

1.5.1 Research Methodology

1.5.2 Research Process

1.5.3 Base Year

1.5.4 Report Assumptions & Caveats

2 Global Wire Thread Inserts Overall Market Size

2.1 Global Wire Thread Inserts Market Size: 2021 VS 2027

2.2 Global Wire Thread Inserts Revenue, Prospects & Forecasts: 2016-2027

2.3 Global Wire Thread Inserts Sales (Consumption): 2016-2027

3 Company Landscape

3.1 Top Wire Thread Inserts Players in Global Market

3.2 Top Global Wire Thread Inserts Companies Ranked by Revenue

3.3 Global Wire Thread Inserts Revenue by Companies

3.4 Global Wire Thread Inserts Sales by Companies

3.5 Global Wire Thread Inserts Price by Manufacturer (2016-2021)

3.6 Top 3 and Top 5 Wire Thread Inserts Companies in Global Market, by Revenue in 2020

3.7 Global Manufacturers Wire Thread Inserts Product Type

3.8 Tier 1, Tier 2 and Tier 3 Wire Thread Inserts Players in Global Market

3.8.1 List of Global Tier 1 Wire Thread Inserts Companies

3.8.2 List of Global Tier 2 and Tier 3 Wire Thread Inserts Companies

4 Sights by Product

4.1 Overview

4.1.1 By Type - Global

If You Have Any Question Related To This Report Contact Us @ https://www.grandresearchstore.com/enquire-now/global-wire-thread-inserts-2021-2027-603

CONTACT US:

276 5th Avenue, New York, NY 10001, United States

International: +1(646)-781-7170 / +91 8087042414

Follow Us On linkedin :- https://www.linkedin.com/company/grand-research-store

0 notes