#Cement Machinery Cast Steel Parts

Text

R.P Alloys caters to heavy engineering needs with an in-house casting and machining shop equipped with the capability to manufacture almost every equipment our clients require. Our industrial gears are already a name to reckon with and find application in a wide variety of industries like Mining, Cement, and Power.

Visit:- https://www.rpalloys.com/

#RP Alloys & Steel Forgings#Machined Stainless Steel Cast Parts#Cast Components#Cement Machinery Cast#Steel Parts#Stainless Steel Casting#Aotomotive Steel Machined Casting Parts#Casting Machine Parts#Machining Casting Aluminum Parts#Large-Scale Stainless Steel Casting#Machine Tools Component#Common Materials for Casting Engine Parts#Cement Manufacturing Process#cast steel castings for cement machinery#Cement Machinery Cast Steel Parts#Concrete Machine Tool Structures#Cement Casting Machine Tools Component

0 notes

Text

Purpose of Tungsten Carbide Rods

Drills, end mills, and reamers are the major applications for tungsten carbide rods. Additionally, it can be utilized for measuring, punching, and cutting tools. It is employed in the non-ferrous metal processing, packaging, printing, and papermaking sectors. The processing of high-speed steel cutters, cemented carbide milling cutters, cemented carbide cutters, NAS cutting tools, aviation tools, milling cutter core bits, micro-end milling cutters, reaming pilots, electronic tools, step drills, metal cutting saws, double-guaranteed diamonds, gun barrels, angle milling cutters, and cemented carbide rotary files is also a common use of this technology.

More resistant to wear than MK6 are the grades YG6, YG8, and YG6X. The YG10 grade is wear-resistant, resistant to knocks, and may be used for processing hard wood, soft wood, ferrous metals, non-ferrous metals, aluminum alloy profiles, brass rods, and cast iron, among other things.

They are used as manufacturing standards and come with one, two, or three holes, a straight or twisted 30°or 40°spiral, or a solid non-porous material. For precision cutting of non-ferrous metals, sub-micron particle grade YG6X cutting and glass fiber reinforced plastics, titanium alloys, super hardened steel fine grain grade YG8X, etc., sub-micron grain grade YG10X end mills, drill bits, and tungsten carbide rods are typically used.

Carbide Rod with Two Helical Coolant Holes - 30°

1. Standard diameter: ø4-ø22, others are upon request.

2. Standard length: 330mm, others are upon request.

3. Also can be processed as per h5/h6 tolerance.

Carbide Rod with Two Helical Coolant Holes - 40°

1. Standard diameter: ø6-ø20, others are upon request.

2. Standard length: 330mm, others are upon request.

3. Also can be processed as per h5/h6 tolerance.

Tungsten carbide rods can be utilized as input needles, various roll wear parts, structural components, and cutting and drilling tools (such as micron, twiste, and drill vertical mining tool indicators). Additionally, it has a wide range of applications in a variety of industries, including the machinery, chemical, petroleum, metallurgy, electronics, and defense sectors.

Diatooling is a

tungsten carbide rod

manufacturer. We can manufacture carbide rods upon request. If you have any more to learn or share about the carbide rod China, please email or call us. We are more than happy to serve you.

0 notes

Text

The grinding, grinding ring change cycle is long

And during the working process, the shovel system have played a key important role ,which is positioned on the lower end of the grinding roller . The techniques is so subtly that insures the durability of whole plant.. 4.Mine ultra-mill Raymond machine adopts advanced structure of similar products at home and abroad, and in the same industry Raymond grinding based on update improvement designed and the equipment than the ball mill high efficiency, low power consumption, cover an area of an area small, one-time small investment.And then the materials will be crushed ,thus achieving the aim of the powder making.

Grinding roll in centrifugal force under the action of RCC tightly in grinding ring, so when the grinding, grinding ring wear to a certain thickness does not affect the finished product output and fineness. Driving system of main frame adopts airtight gearing and pulley, drives smoothly and China Extractor Fans Manufacturers operates reliably. The grinding, grinding ring change cycle is long, thereby eliminating centrifugal crusher damageable parts change cycle short ills.And at last ,the final products will be discharged out by the tripper . It is an independent production system from crushing of raw material to grinding and packing. The electric control system is centralized controlled, so the automatic is high, no people are needed in the operating room. And the required fine powder will enter the large cyclone collector by the air stream to receive the separation and collection . And the materials which have entered the grinding cavity will receive the grinding between the grinding roller and ring, thus producing the powder, which will be brought to the analyzer to grade by the wind machine.

As the professional manufacturer of complete sets of mining machinery, such as China cement mills,Secondary cone crusher,Rock crushing plant,Rock crushing plant, Henan Hongxing is always doing the best in products and service. Working principle of the Raymond mill: The Raymond mill can crush the large-size materials to the required feeding size and then will deliver the materials to the storehouse by the dustpan lift, which will be evenly delivered them to the crushing cavity of the main machine body by the electromagnetism vibrating feeder. The whole plant is a vertical structure of strong systematic characteristic, so it occupies small area.And the shovel and roller will shovel up the materials to the space between the grinding rollers and form the pad layer which will receive the extruding force produced by the rotating of the rollers . structure of raymond mill:

Main parts of the whole plant are made from cast and steel of high quality. This machine is FengXuan airflow grind shell in fan - fan cyclone separator inside the circulating operation, so than high-speed centrifuge crusher little dust, clean and environment friendly operation workshop. Compared with other milling plants, its passing ratio achieves 99%, this is what other mill cannot reach

0 notes

Text

Forms of steel used in different applications

Engineering and construction sector is one of the most prominent industries that contributes to a major part of the economy. It is an equally important sector in terms of employment and labour. To work in this industry, it is important to have specific skillset and talent in order to keep the competition level balanced. The foundation of any structure is the raw materials, that must be selected and moulded in a way so as to meet the requirement of that particular application. Steel is a major part of the economy as well as the manufacturing industry, which is used in various forms and grades specific for the application.

Bright bars- A form of steel

One of the basic yet most used form of stainless steel is bright bars. They are the raw material drawn out of stainless steel using a technique called cold drawing, basically within a cold drawing mill. Bright bars are available in different geometrical structures depending upon the applications they are used for. The surface of these bright bars is smooth and shiny, hence giving it the name. Of the many companies manufacturing it, SS Engineering works is one of the best and well known Square Bright Bar Manufacturer in Haryana. The main component of bright bars is steel with different composition of carbon and other elements added to it. It can be iron, chromium etc. Being a product of stainless steel, it is highly durable with high tensile strength. For being corrosion resistant and strong, these bars are used in multiple applications. They can be welded and moulded easily. The company is one of the reliable Round Bar Manufacturer in Haryana as well. The raw materials are melted to produce black bars, which then undergoes cold drawing process for further finishing processes. These processes include annealing, turning, grinding, and polishing to give it the desired texture. Bright bars have applications in various industries including engineering, automobile, defence, agriculture, textile and much more. The company ensures to manufacture and deliver high grade export quality finished products that can be easily moulded to get the desired geometrical tolerance and shape.

HB wires at SS Engineering works

Apart from these bright bars, the company is also a HB wires Manufacture in Haryana. Basically, these HB wires are raw materials used in the production of various other products including the likes of GI wires, weld mesh, cement pipe, cement pole among others. HB wires are mild steel wires that are produced using cold drawing process like the bright bars, using steel wire rods. There are different secondary processes involved in the production process that will ultimately produce mouldable wires. Using different castings, these wires can be moulded into different shapes based on the applications they are used for. HB or Hard Bright wires are used in different applications including the production of nails, wire mesh, handle for bucket among others. The manufacturing unit at SS Engineering Works is equipped with all latest technologies and machinery that produces high quality products within a dedicated workshop. These products are tested under different conditions to test its durability and strength before final delivery to the client.

#Square Bright Bar Manufacturer in Haryana#Round Bar Manufacturer in Haryana#HB wires Manufacture in Haryana

0 notes

Text

What are the air compressor application industries?

The air compressor is the main body of the electromechanical bleed air source device, which is the core equipment of the pneumatic system. It is a device that converts the mechanical energy of the prime mover (usually a motor) into gas pressure energy. device. The range of air compressor application is very wide. In this article, the editor will tell you what are the air compressor application industries.

General machinery processing industry

1. It is used in the production of the enterprise itself, including: boiler, pressure vessel manufacturing; oxygen generator, automobile turbine manufacturing; metallurgy, mining machinery manufacturing; electrical and electrical machinery manufacturing; chemical machinery, environmental protection machinery, construction machinery, construction Machinery, textile machinery, light industrial machinery, dyeing and finishing machinery, plastic machinery, food machinery and other types of machinery manufacturing.

2. Supporting industries: spraying machinery, environmental protection machinery, boilers, knitting machinery, large-scale asphalt mixing machinery, CNC machine tools, etc.

The wood furniture industry

1. Wood, woodware, plywood, all kinds of flooring manufacturers.

2. Various types of furniture, furniture manufacturing enterprises.

3. Sofa, mattress manufacturing enterprises.

General parts manufacturing industry

1. Bearing manufacturing enterprises.

2. Valve manufacturing enterprises.

3. Chain and spring manufacturing enterprises.

4. Standard parts, fasteners, seals manufacturers.

5. Various types of automobile and motorcycle accessories manufacturing enterprises.

Hardware and building materials industry

1. Various hardware products processing enterprises.

2. Foam color steel plate production enterprises

3. Various types of ceramic production enterprises

4. Manufacturers of cement and products, pipe piles, etc.

5. Various types of decoration and decorative materials manufacturers.

Electronics industry

Textile and knitting industry

1. Various types of chemical fiber polyester manufacturers

2. Various types of webbing and socks enterprises.

3. Printing and dyeing, bleaching and dyeing, refining and dyeing enterprises.

Daily necessities manufacturing enterprises

1. Enamel products manufacturing enterprises.

2. Clocks, glasses product manufacturing enterprises.

3. Various types of bicycle manufacturers.

4. Sewing machine manufacturers.

5. Glass products manufacturing enterprises.

6. Links, buttons, luggage manufacturing enterprises.

7. Leather and down products manufacturers.

8. Carpet weaving enterprises.

Medical enterprises

1. Various medical device manufacturers

2. Various types of hygiene products manufacturers

Paper printing and packaging industry

1. All kinds of paper mills.

2. Printing House

3. Various types of packaging and packaging material manufacturers

4. Printing iron cans, daily container manufacturing enterprises.

Metallurgical casting, metal processing industry

1. All kinds of metallurgy and mining enterprises.

2. Casting and forging enterprises.

3. Metal processing, sheet metal processing enterprises.

4. Various types of tools, molds and metal surface treatment enterprises.

Various household appliance manufacturers

Various instrumentation manufacturing enterprises

Air Compressor Supplier - YOUTENG

Wuxi Youteng Machinery mainly engaged in air compression system, vacuum system design consulting, engineering project and repairing services etc. Atlas Copco Screw Compressor GA 11-26&GA 11+-30 is one product of Atlas Air Compressor Machine series, more details as follow:

Rugged motor and rotor: GA11-26 adopts high-efficiency motor and cooperates with new rotors for efficient use; Compared with belt drive, gear drive is more efficient; High reliability of gear transmission and low maintenance.

Oil and gas separator with new technology: Avoid oil contamination: thanks to the vertical design of the oil separation tank to further reduce low oil residue; Minimal oil tank volume, resulting in loss of compressed air during loading and unloading reduce.

If you want to know more information about air compressor application industries, please click here.

0 notes

Text

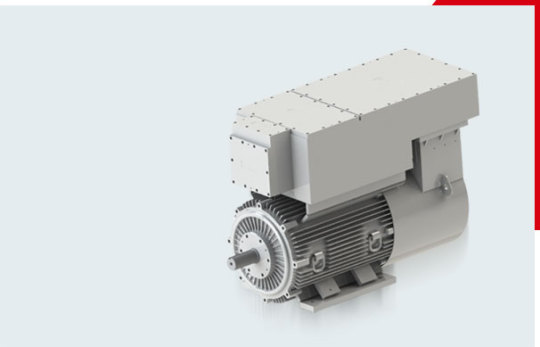

ELECTRICAL TRANSMISSION & POWER CONTROL EQUIPMENT IN CCS ELECTRIC

https://www.ccs-motors.com/products/

We at CCS can provide customers with a variety of electrical transmission equipment and electrical control solutions, which can meet the needs of various working conditions. We strictly control the quality, from raw material procurement to factory test, and all is in accordance with IEC standards.

As a professional power control equipment company, CCS has been providing mining with highly reliable electrical transmission equipment for more than 10 years. Recently, our customers have gradually expanded to oil and gas, port, steel, and other fields.

Types of Electrical Transmission & Power Control Devices

Why Choose Electrical Transmission & Power Control Equipments in CCS Electric

Professional Manfacturer

The company, with a complete system for R&D, design, manufacturing, marketing, and maintenance service, is professional in the manufacturing of high-quality electrical transmission equipment & electrical control equipment.

Well-equipped Production Facilities

We have a large-scale motor assembly machine, motor automatic assembly machine, intelligent CNC winding machine, iron core automatic stacking equipment, solid insulation vacuum casting equipment, inverter production line, vertical machining center, and other production equipment.

Complete Test Platform

CCS has an advanced 12MW loading test platform, high-precision power analyzer, power frequency, and turn to turn to withstand voltage tester, torque tester, and other facilities of the test and inspection center, and has obtained ISO9001 quality management system certification.

Good Development Prospect

With the increasing demand for electrification and intelligence in the industrial field, CCS electrical control devices have a broad market prospect in the industries of engineering, port, shipping, metallurgy, cement and other industries.

FAQs about Electrical Transmission & Power Control Equipments

Q.

What is electrical transmission equipment?

A.

Electrical power transmission equipment refers to various components that allow for internal parts to operate properly in machinery. These items typically include belts, chains, couplings, pulleys, sprockets, bushings, hubs, bearings, linear actuators, slide rails, bevel gears, worm gears, and various other components.

Q.

What are the types of power transmission system?

A.

4 Types of Power Transmission – Mechanical, Electrical, Hydraulic, and Pneumatic (Pros & Cons) The transmission method is an engineering method that matches the power machine and the working part of the machine in terms of energy configuration, movement speed, and motion form.

Q.

What material is used for electrical transmissions?

A.

Copper, aluminum, and steel are the primary conductor materials used in electrical power systems. Other types of conductors such as silver and gold are actually better conductors of electricity; however, cost prohibits wide use of these materials.

0 notes

Text

Categories of Aluma Coat Corrosion and Abrasion Resistant Coating compound

Consumption and scraped area safe coatings can allude to anything from tasteful auto paints or polymer based artistic coatings to substantial sealants. These coatings are specially formulated to protect structures in industrial materials from corrosion, damage and wear caused by many factors such as heat, moisture, pH, electrochemical potentials and many more.This polymer based ceramic coating has proven to be an excellent corrosion and abrasion resistant coating.We are fully committed to this and assure you of cutting-edge ingenuity through consistent distribution of quality ceramic corrosion and abrasion-resistant ceramic coating compounds. Alumna Coat is a protective coating that provides a surface resistant to abrasion, corrosion and chemical attack, except for resistance to hydrofluoric acid and temperatures up to 150ºC (302ºF). Aluma Coats allow thixotropic, brushable / spraying formulations, vertical and horizontal applications with simple hand tools.

Aluma Coat Corrosion and Abrasion Resistant Coating compound are available in two categories

Aluma-coat TW (Trowelable)

USP: Converts soft surfaces to abrasion and corrosion resistance.

Aluma-Coat TW: 2 parts epoxy resin based coating compound. It contains concentrated sapphire hard aluminum oxide ceramic micro beads doped in resin, designed to withstand chemical attack, cavitation, friction, moderate impact and maximum temperature up to 1500C / 3200F.

Use in major industries: mining and mineral processing, cement, electricity, petrochemical, paper and paper pulp, fertilizer, dredging and corrosion and abrasion resistant surface treatment.

Application Areas: Chutes, Rod & Ball Mill Feed Plates, Pan Feeders, Conveyors, Bucket Lifts, Dust Collectors, Hurricane, Soil & Rock Box Outlets, Hoppers, Classifiers, Pipe Corners, Slurry Lines, Coat Exhausts, Chip Cyclones, Tanks, etc. . .

Aluma-Coat BR (Brushable / Sprayable)

USP: A corrosion, abrasion and chemical resistant coating.

Aluma-coat BR: A specially formulated 2-part epoxy-based coating containing 80% micro-centered ceramic powder. It is a satin smooth, high gloss, low friction coating designed to protect the surface from turbulence, rust, corrosion, chemical attack and to withstand maximum temperatures. It can also be applied to steel and concrete structures that are prone to corrosion due to exposure to chemicals, saline environments and fluids.

Use in major industries: Shipping, cement, fertilizer, paper pulp, sugar and many other industries that require surface treatment for corrosion and corrosion resistance.

Areas of application: Fan propeller, pump shaft, pump housing, flange, machine wedge, anti-friction bearing housing, sleeve pots, casting of submersible water pumps, potable water tanks, chemical handling pumps, butterfly valves and other For many applications where abrasion, cavitation, rust and chemical rust are long term problems.

Alumina coatings are widely used in the cement industry to protect the metal surfaces of cement hoppers and storage silos. Aluma coat rust and abrasion resistant coating meets the needs of the heavy engineering industry by protecting their expensive machinery and equipment from severe rust and wear. We supply Aluma Coat to the Solar Water Heater Industry which is the fastest growing industry and use our Aluma Coat to protect solar water heater storage tanks from rust.

Aluma coat corrosion and abrasion resistant coating serves the needs of the heavy engineering Industry by protecting their costly machineries and equipment from severe Corrosion and Wear. Jyoti Ceramic provides an aluma coat to Solar Water Heater Industry which is the Fastest Growing Industry and uses our Aluma Coat to Protect Solar Water Heater Storage Tanks from Corrosion. Total customer satisfaction is our avowed goal.

Watch us: https://youtu.be/Ln-zV37d700

Contact: 02532365766

Visit US: http://www.jyoticeramic.com/aluma-coat.php

#coat corrosion and abrasion resistant coating#corrosion and abrasion resistant coating#ceramiccorrosionresistantcoatings

0 notes

Text

Soulbound Raptor

“Clockwerk (Sly Cooper)” © deviantArt user SacredRoses-Art, accessed at her gallery here

[Commissioned by @arachcobra. Another boss monster from a video game I’ve never played, Clockwerk is the main boss of the first Sly Cooper game, and a recurring background presence in the rest of the series. Since his whole deal is that he turned himself into a robot in order to pursue revenge on the Cooper family, I wanted him to be sapient, rather than “just” a mindless clockwork construct, and I wanted some continuity of intelligence rather than the brand-new intelligence of a Pathfinder robot.

Like with Dream Lord Grimm, the size is something of a fudge to keep the feel of the fight similar from screen to tabletop. Since I haven’t played any Sly Cooper games, I’m not sure if the funny animals within are roughly human-sized as a default, or if Sly Cooper is actually supposed to be the size of a raccoon.]

Soulbound Raptor

CR 15 LE Construct

This creature appears to be an owl the size of a dragon, constructed from metal machinery. Despite its weight, it flies effortlessly, gazing dispassionately from luminous eyes.

The soulbound raptor is an improvement on the soulbound shell, granting its soul a body not in mimicry of the humanoid form, but a mighty and oversized bird of prey. Most soulbound raptors are designed as the destination of the creator’s own soul, and they are animated by the ritualized death of their creator as the work is finished. Thus, an ambitious construct maker can gain immortality without all the fuss of dealing with undeath.

A soulbound raptor is a beast in combat, exulting in the strength and physical power they lacked in mortal life. Their talons are tipped with adamantine claws, and they can shrug off most physical attacks. Soulbound raptors are subject to the same cemented minds as lesser soulbound constructs, but are adept at self-delusion to the point where they assume that the spells they have are the perfect tools for almost every occasion. In the cases where they need different abilities, they collect magic items to supplement their powers. A soulbound raptor is difficult to kill, and they often fight until death in denial of any possible failure.

Since soulbound raptors maintain their ability to create constructs, they often surround themselves with armies of automata to acts as minions and soldiers. As the years pass and they become more detached from mortality and morality, their goals tend to become monomaniacal. Small whims or grudges of their original lives become all-consuming, obsessive hatreds, to the point where a soulbound raptor would not hesitate to spend a fortune in treasure and lives in pursuit of a single enemy.

Constructing a Soulbound Raptor

A soulbound raptor is made from steel and copper, adamantine worth 6,000 gp for the claws and a gemstone worth 5,000 gp as the soul focus. The soul of a willing 13th level or higher spellcaster is imbued into the raptor as part of the creation process.

Soulbound Raptor

CL 13th; Price 86,000 gp

Requirements Craft Construct, false life, geas/quest, magic jar, make whole, overland flight; Skill Craft (clockwork) DC 25; Cost 48,500 gp.

Soulbound Raptor CR 15

XP 51,200

LE Huge construct

Init +6; Senses darkvision 60 ft., Perception +21

Defense

AC 33, touch 14, flat-footed 27 (-2 size, +6 Dex, +15 natural, +4 armor)

hp 190 (20d10+60); fast healing 3

Fort +9, Ref +15, Will +12

DR 10/adamantine and magic; Immune construct traits; SR 26

Defensive Abilities resilience; Weakness cemented mind, susceptible to mind-influencing spells

Offense

Speed 20 ft., fly 60 ft. (average)

Melee 2 claws +26 (2d6+8 plus grab), bite +26 (2d8+8)

Space 15 ft.; Reach 10 ft.

Special Attacks adamantine claws

Wizard Spells Prepared CL 13th, concentration +20 (+24 casting defensively)

7th—delayed blast fireball (DC 26), waves of exhaustion

6th—chain lightning (DC 25), contagious flame, geas/quest

5th—cloudkill (DC 22), cone of cold (DC 24), telekinesis (DC 22), teleport

4th—ball lightning (DC 23), dimensional anchor, fire shield, scrying (DC 21), stone shape

3rd—arcane sight, blink, dispel magic, elemental aura (DC 22), fireball (DC 22), lightning bolt (DC 22)

2nd—blur, false life, make whole, scorching ray (x2), see invisibility

1st—floating disk, mage armor (already cast), magic missile (x3), unseen servant

0th—detect magic, mage hand, read magic, open/close

Statistics

Str 27, Dex 23, Con -, Int 25, Wis 12, Cha 16

Base Atk +20; CMB +30 (+32 sunder, +34 grapple); CMD 46 (48 vs. sunder)

Feats Combat Casting, Combat Reflexes, Craft Construct (B), Greater Spell Focus (evocation), Improved Sunder, Iron Will, Power Attack, Quick Draw, Skill Focus (Spellcraft), Spell Focus (evocation), Toughness

Skills Craft (clockwork) +27, Fly +22, Intimidate +23, Knowledge (arcana, engineering, history) +27, Perception +21, Spellcraft +33, Use Magic Device +23

Languages Common, Draconic, Infernal

SQ soul focus

Ecology

Environment any land or underground

Organization solitary

Treasure double standard

Special Abilities

Adamantine Claws (Ex) A soulbound raptor’s claws overcome damage reduction and hardness as if they were adamantine.

Cemented Mind (Ex) A soulbound raptor can never change its known or prepared spells.

Resilience (Ex) A soulbound raptor gains a +3 resistance bonus to saving throws.

Soul Focus (Su) The soul bound to the raptor lives within a gem inside its head. As long as this soul focus remains intact, it can be used to animate another soulbound raptor, at the same cost as creating a new soulbound raptor, and retains its personality and memories. A soul focus has hardness 8, 12 hit points, and a break DC of 20.

Spells A spellbound raptor casts spells as a 13th-level cleric, witch, or wizard, but does not gain any other class abilities.

Susceptible to Mind-Affecting Effects (Ex) A soulbound raptor is not immune to mind-affecting effects.

69 notes

·

View notes

Link

Imagine that the world as we know it ends tomorrow. There’s a global catastrophe: a pandemic virus, an asteroid strike, or perhaps a nuclear holocaust. The vast majority of the human race perishes. Our civilisation collapses. The post-apocalyptic survivors find themselves in a devastated world of decaying, deserted cities and roving gangs of bandits looting and taking by force.

Bad as things sound, that’s not the end for humanity. We bounce back. Sooner or later, peace and order emerge again, just as they have time and again through history. Stable communities take shape. They begin the agonising process of rebuilding their technological base from scratch. But here’s the question: how far could such a society rebuild? Is there any chance, for instance, that a post-apocalyptic society could reboot a technological civilisation?

Let’s make the basis of this thought experiment a little more specific. Today, we have already consumed the most easily drainable crude oil and, particularly in Britain, much of the shallowest, most readily mined deposits of coal. Fossil fuels are central to the organisation of modern industrial society, just as they were central to its development. Those, by the way, are distinct roles: even if we could somehow do without fossil fuels now (which we can’t, quite), it’s a different question whether we could have got to where we are without ever having had them.

So, would a society starting over on a planet stripped of its fossil fuel deposits have the chance to progress through its own Industrial Revolution? Or to phrase it another way, what might have happened if, for whatever reason, the Earth had never acquired its extensive underground deposits of coal and oil in the first place? Would our progress necessarily have halted in the 18th century, in a pre-industrial state?

It’s easy to underestimate our current dependence on fossil fuels. In everyday life, their most visible use is the petrol or diesel pumped into the vehicles that fill our roads, and the coal and natural gas which fire the power stations that electrify our modern lives. But we also rely on a range of different industrial materials, and in most cases, high temperatures are required to transform the stuff we dig out of the ground or harvest from the landscape into something useful. You can’t smelt metal, make glass, roast the ingredients of concrete, or synthesise artificial fertiliser without a lot of heat. It is fossil fuels – coal, gas and oil – that provide most of this thermal energy.

In fact, the problem is even worse than that. Many of the chemicals required in bulk to run the modern world, from pesticides to plastics, derive from the diverse organic compounds in crude oil. Given the dwindling reserves of crude oil left in the world, it could be argued that the most wasteful use for this limited resource is to simply burn it. We should be carefully preserving what’s left for the vital repertoire of valuable organic compounds it offers.

But my topic here is not what we should do now. Presumably everybody knows that we must transition to a low-carbon economy one way or another. No, I want to answer a question whose interest is (let’s hope) more theoretical. Is the emergence of a technologically advanced civilisation necessarily contingent on the easy availability of ancient energy? Is it possible to build an industrialised civilisation without fossil fuels? And the answer to that question is: maybe – but it would be extremely difficult. Let’s see how.

…

Well, it could, in a very limited way. If you find yourself among the survivors in a post-apocalyptic world, you could scavenge enough working solar panels to keep your lifestyle electrified for a good long while. Without moving parts, photovoltaic cells require little maintenance and are remarkably resilient. They do deteriorate over time, though, from moisture penetrating the casing and from sunlight itself degrading the high-purity silicon layers. The electricity generated by a solar panel declines by about 1 per cent every year so, after a few generations, all our hand-me-down solar panels will have degraded to the point of uselessness. Then what?

New ones would be fiendishly difficult to create from scratch. Solar panels are made from thin slices of extremely pure silicon, and although the raw material is common sand, it must be processed and refined using complex and precise techniques – the same technological capabilities, more or less, that we need for modern semiconductor electronics components. These techniques took a long time to develop, and would presumably take a long time to recover. So photovoltaic solar power would not be within the capability of a society early in the industrialisation process.

…

On the face of it, it’s not beyond the bounds of possibility that a progressing society could construct electrical generators and couple them to simple windmills and waterwheels, later progressing to wind turbines and hydroelectric dams. In a world without fossil fuels, one might envisage an electrified civilisation that largely bypasses combustion engines, building its transport infrastructure around electric trains and trams for long-distance and urban transport. I say ‘largely’. We couldn’t get round it all together.

While the electric motor could perhaps replace the coal-burning steam engine for mechanical applications, society, as we’ve already seen, also relies upon thermal energy to drive the essential chemical and physical transformations it needs. How could an industrialising society produce crucial building materials such as iron and steel, brick, mortar, cement and glass without resorting to deposits of coal?

You can of course create heat from electricity. We already use electric ovens and kilns. Modern arc furnaces are used for producing cast iron or recycling steel. The problem isn’t so much that electricity can’t be used to heat things, but that for meaningful industrial activity you’ve got to generate prodigious amounts of it, which is challenging using only renewable energy sources such as wind and water.

An alternative is to generate high temperatures using solar power directly. Rather than relying on photovoltaic panels, concentrated solar thermal farms use giant mirrors to focus the sun’s rays onto a small spot. The heat concentrated in this way can be exploited to drive certain chemical or industrial processes, or else to raise steam and drive a generator. Even so, it is difficult (for example) to produce the very high temperatures inside an iron-smelting blast furnace using such a system. What’s more, it goes without saying that the effectiveness of concentrated solar power depends strongly on the local climate.

No, when it comes to generating the white heat demanded by modern industry, there are few good options but to burn stuff.

…

But charcoal-based industry didn’t die out altogether. In fact, it survived to flourish in Brazil. Because it has substantial iron deposits but few coalmines, Brazil is the largest charcoal producer in the world and the ninth biggest steel producer. We aren’t talking about a cottage industry here, and this makes Brazil a very encouraging example for our thought experiment.

The trees used in Brazil’s charcoal industry are mainly fast-growing eucalyptus, cultivated specifically for the purpose. The traditional method for creating charcoal is to pile chopped staves of air-dried timber into a great dome-shaped mound and then cover it with turf or soil to restrict airflow as the wood smoulders. The Brazilian enterprise has scaled up this traditional craft to an industrial operation. Dried timber is stacked into squat, cylindrical kilns, built of brick or masonry and arranged in long lines so that they can be easily filled and unloaded in sequence. The largest sites can sport hundreds of such kilns. Once filled, their entrances are sealed and a fire is lit from the top.

…

Around two-thirds of Brazilian charcoal comes from sustainable plantations, and so this modern-day practice has been dubbed ‘green steel’. Sadly, the final third is supplied by the non-sustainable felling of primary forest. Even so, the Brazilian case does provide an example of how the raw materials of modern civilisation can be supplied without reliance on fossil fuels.

…

Is that our solution, then? Could our rebooting society run on wood, supplemented with electricity from renewable sources? Maybe so, if the population was fairly small. But here’s the catch. These options all presuppose that our survivors are able to construct efficient steam turbines, CHP stations and internal combustion engines. We know how to do all that, of course – but in the event of a civilisational collapse, who is to say that the knowledge won’t be lost? And if it is, what are the chances that our descendants could reconstruct it?

In our own history, the first successful application of steam engines was in pumping out coal mines. This was a setting in which fuel was already abundant, so it didn’t matter that the first, primitive designs were terribly inefficient. The increased output of coal from the mines was used to first smelt and then forge more iron. Iron components were used to construct further steam engines, which were in turn used to pump mines or drive the blast furnaces at iron foundries.

And of course, steam engines were themselves employed at machine shops to construct yet more steam engines. It was only once steam engines were being built and operated that subsequent engineers were able to devise ways to increase their efficiency and shrink fuel demands. They found ways to reduce their size and weight, adapting them for applications in transport or factory machinery. In other words, there was a positive feedback loop at the very core of the industrial revolution: the production of coal, iron and steam engines were all mutually supportive.

In a world without readily mined coal, would there ever be the opportunity to test profligate prototypes of steam engines, even if they could mature and become more efficient over time? How feasible is it that a society could attain a sufficient understanding of thermodynamics, metallurgy and mechanics to make the precisely interacting components of an internal combustion engine, without first cutting its teeth on much simpler external combustion engines – the separate boiler and cylinder-piston of steam engines?

It took a lot of energy to develop our technologies to their present heights, and presumably it would take a lot of energy to do it again. Fossil fuels are out. That means our future society will need an awful lot of timber.

In a temperate climate such as the UK’s, an acre of broadleaf trees produces about four to five tonnes of biomass fuel every year. If you cultivated fast-growing kinds such as willow or miscanthus grass, you could quadruple that. The trick to maximising timber production is to employ coppicing – cultivating trees such as ash or willow that resprout from their own stump, becoming ready for harvest again in five to 15 years. This way you can ensure a sustained supply of timber and not face an energy crisis once you’ve deforested your surroundings.

But here’s the thing: coppicing was already a well-developed technique in pre-industrial Britain. It couldn’t meet all of the energy requirements of the burgeoning society. The central problem is that woodland, even when it is well-managed, competes with other land uses, principally agriculture. The double-whammy of development is that, as a society’s population grows, it requires more farmland to provide enough food and also greater timber production for energy. The two needs compete for largely the same land areas.

We know how this played out in our own past. From the mid-16th century, Britain responded to these factors by increasing the exploitation of its coal fields – essentially harvesting the energy of ancient forests beneath the ground without compromising its agricultural output. The same energy provided by one hectare of coppice for a year is provided by about five to 10 tonnes of coal, and it can be dug out of the ground an awful lot quicker than waiting for the woodland to regrow.

It is this limitation in the supply of thermal energy that would pose the biggest problem to a society trying to industrialise without easy access to fossil fuels. This is true in our post-apocalyptic scenario, and it would be equally true in any counterfactual world that never developed fossil fuels for whatever reason. For a society to stand any chance of industrialising under such conditions, it would have to focus its efforts in certain, very favourable natural environments: not the coal-island of 18th-century Britain, but perhaps areas of Scandinavia or Canada that combine fast-flowing streams for hydroelectric power and large areas of forest that can be harvested sustainably for thermal energy.

Even so, an industrial revolution without coal would be, at a minimum, very difficult. Today, use of fossil fuels is actually growing, which is worrying for a number of reasons too familiar to rehearse here. Steps towards a low-carbon economy are vital. But we should also recognise how pivotal those accumulated reservoirs of thermal energy were in getting us to where we are. Maybe we could have made it the hard way. A slow-burn progression through the stages of mechanisation, supported by a combination of renewable electricity and sustainably grown biomass, might be possible after all. Then again, it might not. We’d better hope we can secure the future of our own civilisation, because we might have scuppered the chances of any society to follow in our wake.

2 notes

·

View notes

Text

How to start a construction business?

Starting a construction company or a construction business is a profitable way to start in a robust sector with an extensive field of action. However, careful planning and extensive market research is required here . And this in order to be clear about the challenges and opportunities that you will face along the way. Next, we will mention some key aspects to consider when creating this type of business:

Business plan

It is the guide on which you will give a structure to your company and you will carry out all the actions to meet your objectives . Here you must define the business idea and analyze the environment (market, competitors, audience, etc.). As well as planning marketing strategies, estimating the budget and projecting profits.

Name and legal procedures

You will also have to give your business a name and legally register the business name with the competent authorities. The legal procedures for the creation of new companies generally involve choosing a legal structure and registering with the commercial register. Like making a public deed and appointing a legal representative.

Licensing

Depending on the country you are in, you will have to manage the specific licenses and operating permits for this type of activity. Consult the regulations established by the national government and get advice from the entities that regulate the creation of businesses.

Suppliers and inventory

Search and select quality suppliers that provide you with all the necessary inputs to start your business. Depending on the nature of the company and the type of products and / or services that you are going to sell, you can establish the inventory . It will include all the tools and equipment for carrying out construction tasks by Abdul Rimaaz MT65 SOLUTIONS LTD.

Budget and financing

The budget must include all the investment costs necessary to start the business . These include branding, legal paperwork, licenses, location, equipment and supplies, starting inventory, etc. Therefore, you should look for a search engine positioning to cover these costs, either your own through savings, or external by requesting a loan from third parties.

Promotion

A business that is not shown does not sell. Therefore, it is essential to plan and manage marketing strategies to promote it , make it known and connect it with the audience. This is one of the key aspects in successful construction businesses, since investment to position itself in the market is crucial to boost growth.

The above, through traditional marketing techniques such as print advertising or merchandising. As well as digital marketing techniques such as social media marketing, video marketing or search engine optimization .

8 construction related business ideas

In a construction business it is possible to market different products and services related to this economic activity. The variety is wide and you can even combine one or more alternatives. So pay close attention to the following list of 8 successful construction business ideas . With them, you can start your business in this sector.

1. Manufacture or distribution of cement

Cement is one of the most demanded products in the construction industry , as it is used to join blocks, cure surfaces, make bricks, etc. This is a mixture of clay, alumina, calcium carbonate, and other elements. According to the need or type of construction, different varieties of cement are used, such as Portland cement for the manufacture of concrete, .

Here you have two business alternatives , one is to set up a cement production plant , and the other is to distribute recognized brands of cement . The first is an idea that requires more capital, since you must have a large structure and specialized machinery, as well as quality raw materials, fuels and high-power electricity. In addition, you must manage some compulsory environmental permits and licenses to be able to carry out the activity.

Read also: How to start a construction company

For its part, the second option does not require taking over production and a location is not strictly necessary. With a medium warehouse to store the product inventory it will be enough. The idea is that you carry out a study of the national and foreign cement brands and that you make a careful selection of which ones to sell, taking into account aspects such as the variety of the catalog, the quality of the products, the prices and the demand in the market. After that, you can make alliances with the same brands or with wholesale stores, assemble your inventory and start selling.

2. Post-construction cleaning service

After a construction work is finished, there are surplus materials, residues and waste that must be collected and disposed of correctly . This before the final closure of the project. Therefore, many companies in the union decide to hire providers of final cleaning services on site to take care of this work and thus save time and optimize functions. This results in a very valuable opportunity to enter successful construction businesses.

The portfolio handled by construction cleaning companies includes debris management, blemish removal, air freshening and deodorization. This is ideal to complement the construction tasks properly, because while these types of businesses are in charge of cleaning, builders can perform other types of finishes and finishes.

Here you need trained and experienced personnel, specialized cleaning machinery and sustainable cleaning products. In addition to knowledge of occupational health and safety protocols to control risks within construction.

3. Plumbing services

Another complementary service that can be offered in successful construction businesses is plumbing. There, work is carried out such as installation and maintenance of sewage and inspection of wells and sewers. Plumbers also take care of locating pipes and plumbing and plumbing in buildings. Without a doubt, indispensable and highly required tasks regardless of the type of project.

One of the advantages of this business is that you can start as an independent , offering professional services to construction companies. This if you have the experience, the certified knowledge and the equipment for it. In this way, you will be able to consolidate a client portfolio and work alternately on several projects .

Then, as you gain recognition, you can expand the business , including more staff and setting up a company specialized in this work.

4. Sale of sand

One of the essential materials in construction is sand. Although there are many stores that sell it, construction companies look for suppliers that work exclusively with the trade of this material, with the intention of making wholesale purchases and guaranteeing its acquisition in large quantities.

This is why this is one of the successful construction businesses that many independents point to. To start it, it is important that you carry out an investigation about the allowed locations for the extraction of sand . And that in turn you inform yourself about the legislation of your country that governs this type of activity.

Once the above is clear, the sale of construction sand can be worked in two ways. The first is through a sand deposit in the city , where you can store the material, serve customers and sell directly on site.

The second way is by dispatching the material at home and having only one storage warehouse. Here you can also offer the option for the client, after the purchase, to collect the material at the warehouse location.

In any of the options, remember to choose a location close to the extraction site that is easily accessible. And that it has the optimal conditions for loading and unloading the material.

5. Rental of construction machinery

In many construction projects, the choice is to rent the machinery instead of buying it, in order to execute medium and short-term contracts and thus reduce costs . As well as to carry out projects faster and contribute to business development.

As a result, this is a business that has a significant demand in the market, because the service can be requested by bricklayers, independent builders and large construction companies .

There is an extensive range of construction machinery, so the main thing is to identify the needs of your potential customers . And thus have the equipment most required in the sector, such as:

· Mixers

· Rammers

· Water pumps

· Concrete mixers

· Concrete trowels

· Air compressors

· Excavators

· Lift truck

You can start with the equipment with the highest demand and as the business grows, offer the most specialized and exclusive rental of machines .

6. Building materials business

This is one of the successful construction business ideas that encompasses almost all of the above ideas . Here you will have to select a location, set up a store and create alliances with suppliers and wholesalers. In addition, you must do a market study to gain knowledge of the most popular products . This with the aim of putting together a catalog that meets the needs of buyers. Finally, you will have to plan a promotion and sales strategy to boost the growth of your store.

Some of the materials that you can distribute in your business are:

· Cast

· Cement

· Bricks

· Steel

· Glass

· Sand

· Roof tiles

· Tiles

· Metallic profiles

· Scaffolding

· Rods

· PVC pipes

In the same way, you should include hand tools, instruments and equipment such as:

· Gauges

· Hammers

· Pliers

· Wheelbarrows

· Drills

· Sanders

· Saws

7. Demolition company

Another successful construction business, which is rarely talked about but has a considerable market share, is demolition services. Here, basically, you are in charge of demolishing homes, buildings and constructions located on land destined for new works.

You will offer your services to private and public entities that require it and that have the pertinent permits to carry out the demolition.

Demolitions, generally, are carried out in large cities or capitals , so it is important that you locate yourself, positions and offer your services in these locations. In addition, these types of companies usually offer excavation and rubble collection services. And they focus on the industrial and residential sectors mainly.

8. Remodeling of buildings

We end our list of successful construction businesses with this idea that is the protagonist in civil construction works. Well, the sector is not only concerned with carrying out building projects from scratch. It also handles renovation works for buildings that have flaws in their architecture, design or distribution of spaces . Therefore, the services of remodeling professionals are very necessary.

Here, you can partner with construction companies to be part of their supplier portfolio and work with them on different projects. In the same way, you can dedicate yourself to offering these services on your own and set up a remodeling and interior design agency . And so, take care of the remodeling of houses, apartments, offices and commercial establishments.

Final words

The construction industry MT65 SOLUTIONS LTD is in constant motion, because regardless of the season of the year it is common to see that new building works are started, as well as architectural projects, public works, structural reforms, etc. So if you are interested in this area and have the experience and knowledge to offer any of the related services, do not hesitate and start your venture.

2 notes

·

View notes

Text

How to deal with the anticorrosion of Roots blower?

Three lobe double oil tank Roots Blower are widely used in medical and pharmaceutical, semiconductor, mechanical chemical, low temperature equipment, electronics, metallurgy, petroleum mining and other fields, and their related technologies have also been developed by leaps and bounds. During the application process of the Roots blower, the blower will be corroded to different degrees due to different production processes. If the protective measures are not appropriate, the production will often be stopped due to the corrosion of the Roots blower. Therefore, the anti-corrosion of the blower is a practical problem that needs to be solved urgently to prolong the service life of the blower in the current production.

At present, domestic anti-corrosion technologies for blowers are mainly aimed at Roots blowers, water-ring blowers, steam blowers, liquid-ring blowers, diaphragm blowers, turbomolecular pumps, etc. The anti-corrosion technologies used mainly include three types:

1. By coating a layer of anti-corrosion coating on the surface of the Roots blower, such as chlorotrifluoroethylene anti-corrosion layer, Teflon coating, corrosion-resistant oxide layer or nitride layer, corrosion-resistant and weather-resistant paint, etc.;

Second, the improvement of anti-corrosion materials, commonly used coating materials are stainless steel, tin bronze, cemented carbide and other metal materials, natural rubber, phosphorus sheet, synthetic rubber, ceramics, plastics and other non-metallic materials, precision ceramics, organic polymers or New materials such as temperature-resistant, corrosion-resistant and wear-resistant polymer materials, among which polymer materials include fluoroplastics, polyethylene, polyvinyl chloride, etc.;

3. The structural transformation of the fan, such as the installation of an air chamber on the upper part of the body, and the installation of an upper-mounted corrosion-resistant gas-water separator.

We has invested a lot of manpower and material resources in the field of Roots blower anti-corrosion. It not only developed multi-layer nickel plating and nanotechnology in anti-corrosion technology, but also directly launched a stainless steel Roots blower, which can make the blower easily cope with high levels of hydrochloric acid. Corrosive medium environment, walking in the world's leading ranks.

The Compact integrated Roots blower efficiencyshows that high-pressure Roots blowers are generally steel castings, which are also common in the market. What are the anti-corrosion methods for Roots blowers? Which methods can ensure the integrity of our equipment and avoid the erosion of corrosive substances Woolen cloth?

1. Anti-corrosion coating

Generally, Roots fans made of steel castings will use outer coating for anti-corrosion. After the equipment is sprayed with anti-corrosion materials, it can effectively prevent the fan from being corroded.

2. Select anti-corrosion materials

Roots blowers are made of steel castings, stainless steel, and glass fiber reinforced plastic. The latter two are relatively expensive and generally used less. Roots blowers using stainless steel and glass fiber reinforced plastic can also effectively prevent equipment corrosion.

3. Internal anticorrosion

If the medium we transport has a certain degree of corrosiveness, then the inside of the fan needs to be sprayed with anti-corrosion materials, and spraying anti-corrosion metal can effectively prevent corrosion. The internal use of anti-corrosion materials can also choose electroplating, which can carry out anti-corrosion more uniformly.

Ming Ye Machinery products include three-leaf Roots blower, rotary blower, Air suspension centrifugal turbo blower , mainly serving electric power, petroleum, steel, metallurgy, chemical, steel and other industries, with broad market prospects. The company has pursued the sales and after-sales service tenet of "professional management, honest service, customer first" for many years, and the company's sales and after-sales service are all over the country. The company strives to create products with superior performance and stable operation for our customers. We sincerely hope to cooperate with you sincerely and create a beautiful chapter together!

0 notes

Text

R.P Alloys is a self-contained engineering company delivering end-to-end solutions to businesses on a global scale.

Visit:- https://www.rpalloys.com/

#Appliances#Electrical#and Electronics Manufacturing#RP Alloys & Steel Forgings#Machined Stainless Steel Cast Parts#Cast Components#Cement Machinery Cast#Steel Parts#Stainless Steel Casting#Aotomotive Steel Machined Casting Parts#Casting Machine Parts#Machining Casting Aluminum Parts#Large-Scale Stainless Steel Casting#Machine Tools Component#Common Materials for Casting Engine Parts#Cement Manufacturing Process#cast steel castings for cement machinery#Cement Machinery Cast Steel Parts#Concrete Machine Tool Structures#Cement Casting Machine Tools Component#Wear parts and solutions for the cement industry#Cement Machine Parts for Sale#metal processing industry#metal processing industry components#metal processing industry parts#Metal Processing Manufacturers & Companies#Metal Components Manufacturers & Suppliers in India

1 note

·

View note

Text

What Are Uses of Carbide Rod?

Brief introduction to carbide rod

Carbide rod, commonly referred to as tungsten carbide bars, is a cemented carbide round rod. Carbide rod is a composite material created by powder metallurgy, to put it simply. It is made up of bonding metal and refractory metal compound. The word used locally differs significantly from cemented carbide, also referred to as tungsten carbide.

Uses of carbide rod

Carbide rod is mainly used for a drill bit, end mill, and cutter. Tools for cutting, stamping, and measuring can also be made out of it. It is utilized in the non-ferrous metal processing, printing, packaging, and papermaking sectors . Carbide rod is also frequently used to machine high-speed steel tools, cemented carbide cutters, NAS cutting tools, aviation tools, micro end milling cutters, tapered milling cutters, metric milling cutters, reaming pilot, electronic tools, step milling cutters, metal cutting saws, double guarantee gold drills, gun rods, angle cutter millings, cemented carbide Rotary files, and carbide tipped drills.

As production specifications, one, two, or three holes, a 30° or 40° spiral, straight or twisted, or nonporous solids are utilized. The principal tools for precision cutting of non-ferrous metals and submicron particle size YG6X cutting, glass fiber reinforced plastics, titanium alloy, etc. include submicron grain grade YG10X end milling cutters, drill bits, and cemented carbide bars.

Carbide rods can be used not only for cutting and drilling tools ,like micrometer, twist drill, drill vertical mining tool index, but also as input needles, various roller worn parts, and structural materials. In addition, it can be used in many fields , such as machinery, chemical industry, petroleum, electronics,etc.

Grades of carbide rods

Compared to MK6, grade YG6, YG8, and YG6X are more wear-resistant. Hard wood, cast iron, brass bars, aluminum alloy profiles, and other materials can all be employed with them. Hard wood, soft wood, black metal, and non-ferrous metals are all processed using the YG10 grade, which is wear- and impact-resistant.

If you have any more to learn or share about the

carbide rod China

, please email or call us. We are more than happy to serve you.

0 notes

Photo

Keshet Rewatches All of Scooby-Doo, Pt. 12: "Scooby Doo and a Mummy, Too"

("Scooby-Doo, Where Are You", Season 1 Episode 12)

AKA "We Forgot One Universal Monster Last Episode"

The episode opens on a view of a university campus, with the usual spooky musical sting in spite of nothing being visibly eerie... until we cut into a building identified “DEPARTMENT OF ARCHEOLOGY” (sic). Inside, a professor is introducing the gang to the mummified remains of Ankha, an ancient Egyptian ruler who was once “the most feared ruler”—though we’re never given a reason why he was feared. What did he do that was so terrible?

I’ll note that the subtitles spell the name as “Anka”, but the Scooby Doo wiki gives the more standard-looking “Ankha”. As is oddly typical of adults who are not the culprit in a given episode, the Professor is never given a name, though he introduces his colleague as Dr. Najib, who helped bring the mummy over for the university’s replica of Ankha’s tomb.

A middle eastern man with narrow eyes and permanently lowered brow, voiced by Vic Perrin in an almost exact duplicate of his portrayal of Jonny Quest villain Doctor Zin, Najib raises the subject of the curse of Ankha, relating his hope that it did not follow them. I’ll say it right here, because it’s not much of a spoiler when so many flags are triggered right away: Najib is the culprit, and it’s another example of casual racism this season. The thieving, scheming Arab was a popular villain trope of the day, and while Najib isn’t quite as overt as some other variations on the trope, he’s far from a deconstruction or a subversion.

As Najib makes his exit, the gang agree to help the Professor, and Shaggy lays his filthy mitts on an ancient golden medallion the entire cast identify as a coin in spite of a lack of any evidence that it is currency. As Shaggy manhandles priceless ancient artifacts, the Professor explains it’s part of an unsolved mystery, and suggests the gang pick up some sandwiches on his dollar in order to satisfy Shaggy’s appetite.

While they’re gone, the Professor hears a crash, and comes out to find the mummy gone and a mummy-shaped hole in the glass doors. Meanwhile, Shaggy receives an order of three burgers and three sandwiches—liverwurst, à la mode. The chef spoons bright pink ice cream onto three open-face sandwiches, and Shaggy hands him a dollar bill and a half-dollar coin... that is actually the ancient Egyptian coin!

Shaggy has unconsciously pocketed it, demonstrating kleptomaniac tendencies that are never commented upon. The gang pay properly and Fred suggests they grab the sandwiches and get back to the Professor to return the coin. I’ll note that the food is clearly served on dine-in plates, rather than to-go containers, and when the food is taken from the counter off-screen, it makes a plate-rattling sound. Did they just walk out with burgers and open-faced sandwiches in-hand, sans any kind of container or wrapper?

When the gang return, they find the Professor in his office, where he’s been TURNED TO STONE! “14-karat stone”, Shaggy quips. Velma, bastion of rational, scientific skepticism, observes that only one person could be responsible: the mummy.

The gang look outside and find the busted glass, but Velma notes that it’s broken in rather than out, making it clear this wasn’t an exit. Fred orders the gang to split up and search for the mummy, and Shaggy soon accidentally discovers the bandaged terror hiding in the Janitor’s Closet. Locking him in, Shaggy, Velma, and Scooby flee in terror, instead of doing the reasonable thing and making sure the mummy is properly trapped.

Thus ensues the usual hide-and-chase sequence, although the mummy only groans and shambles slowly rather than running. Of course, there’s still extensive damage done to priceless museum artifacts by the B Team’s attempts to hide. Eventually cornered, the mummy begins to demand, “coin... coin!!” and nods and grunts in the affirmative when Velma suggests he means the old Egyptian one, and not the quarter Shaggy offers him.

When Velma insists they don’t give him what he wants, it falls to Scooby to defend them, and he demands a hefty price of Scooby Snacks.

I believe this is the first time we see a box of Scooby Snacks, which are drawn as being about half the size of previous appearances, and the box simply reads “SCOOBY SNACKS”. It’s also the first implication that “Scooby Snacks” is the name of a product on the market, rather than just what the gang call dog treats, or a home-made specialty.

Emboldened, Scooby tries taking a swing at the mummy with his left foreleg, but there’s a sound like a steel drum being struck, and Scooby’s metacarpals collapse and fold inward like a limp accordion tube. This does not deter the carb-loaded canine, who dashes offscreen and returns in a karate gi, and begins to yelp out kiais so badly stereotypical that the captioning refused to display them as he chops at the motionless mummy. It’s no more effective, so Scooby tries one last attack:

A little of the old razzmatazz.

At first, the soft-shoe routine seems to be Scooby’s attempt at desertion, but in spite of Velma’s shock, the dog sneaks back in behind the advancing mummy and nails his rags to the floor with a hammer.

Once again, the trio flee without making sure that Ankha is captured, even though Velma says they’re going to tell Daphne and Fred that they just did that. Meanwhile, Fred and Daphne are exploring outside, having found what look to be the mummy’s footprints going into a construction area. They discover Dr. Najib’s car, with what appears to be the doctor turned to stone, and wonder if Shaggy and Velma have run into the mummy themselves, not seeming to be concerned that their friends could be turned to stone any moment.

Having returned, Shaggy and Velma find that the mummy has escaped and disappeared, and inspect the piece of bandage left nailed to the floor. They retreat to a laboratory to investigate the new-feeling wrappings and determine its actual age, where an unattended Scooby drinks three large glasses of a chartreuse liquid. There’s an odd screen-filling animation of an explosion that fades in and out, and Scooby’s head has turned into that of a frog!

He lets out a few confused ribbits, and the effect reverses, explosion included—without Shaggy or Velma noticing. Meanwhile, the mummy reappears, demanding the coin before Velma can finish her analysis. While the two humans flee the room in an improvised smokescreen, Scooby is left behind, and the duo only realize as Daphne and Fred rejoin them. The room is empty except for evidence of a struggle, and a window is left open in the back. Fred worries that he’ll end up like the Professor and Dr. Najib...

...and sure enough, the gang discover a stone Scooby back outside. As Shaggy mourns the loss of his friend, the real Scooby digs his way up out of the ground to join him in tearfully weeping over the sad scene.

“Look, Scoob! You’ve been turned to stone!”

Rather than questioning Scooby about what happened to him, the gang decide to backtrack and ignore the great huge clue right in front of them.

Investigating the Professor’s office, Velma learns that Ankha was also the wealthiest ruler of ancient Egypt, and thinks she’s discovered the solution to the mystery of the coin, finding a photo of a statue of a hippo-headed figure that may or may not be a badly rendered representation of the goddess Taweret (understandably lacking the usual large sagging breasts of images of that deity; this is a kids’ show). The likeness of the coin appears with some other symbols on the statue’s belly, but just as the gang realize it, Ankha busts down the office door.

Retreating to the second floor, the gang duck into the wood shop, where—i’m sorry, why is there a WOOD SHOP in a university’s DEPARTMENT OF ARCHAEOLOGY?

Fred tells Daphne to hit the lights so that they can hide in the darkness of a room full of sharp objects and heavy machinery, but Daphne hits the wrong switch and turns on a handheld, corded buzz saw that spins to life and climbs up the wall by cutting through the surface of it.

Now, in addition to majoring in anthropology and library science, i took an elective class in the extremely well-appointed woodworking facility at SUNY Purchase College, and i have at least a basic sense of shop safety. So i speak from something of a position of experience when i say, WHY WOULD YOU PUT THOSE SWITCHES NEXT TO EACH OTHER?

As the saw cuts across the ceiling, back down the wall, and past the mummy, it moves on to circle the gang, cutting through the floor and sending the gang dropping down to the floor below... where there’s a swimming pool.

WHAT KIND OF ARCHAEOLOGY DEPARTMENT IS THIS? A WOOD SHOP? A SWIMMING POOL? WHO DESIGNED THIS COLLEGE, MC ESCHER?

The enraged mummy tosses the saw down at the gang, and its improbably long power cord reaches far enough that the saw moves through the water, chasing the gang as they paddle for their lives. Kudos to the saw’s manufacturers for so extensively waterproofing it, but i really don’t think a 100 meter power cord is a necessity.

Continuing to flee the mummy, Shaggy and Scooby enter the construction area from before, stumbling into a work space where Shaggy notices bags of “Quick Drying Mold Cement”, and “spray molds” that actually appear to be just wooden crates with cement poured in around an empty space in the shape of a standing human being.

“Ruh-huh!” Scooby replies. You could’ve told them that, Scooby. It would have been helpful.

I’ll note that the mold is in the shape of someone standing or laying straight, and all the “stone” figures we’ve seen so far were sitting down. This is what happens when you don’t communicate plot details to your art department, people.

The mummy of Ankha catches up, and the boys flee into a groundskeeper’s shack. When Shaggy peeks out to see if the coast is clear, however...

FOR THE LOVE OF GOD!

Yes, for the love of god.

Ankha continues to demand the coin, but meanwhile, Scooby and Shaggy find the Professor bound, gagged, and stuffed into a bag in the corner. Shaggy pulls down his gag, and asks, “are you alright, Professor?”

“I’m fine!”

“Groovy,” Shaggy replies, putting the gag back in place. “Be back for you later.”

The duo make their escape and the chase scene starts up again, now involving a ride on an improbably speedy lawnmower through an empty gymnasium, and a bit more in the way of trampoline antics. This show loves trampoline antics. Mid-bounce, Scooby, grabs onto a pair of gymnastics rings, and uses his hind legs to kick the mummy across the gym, dunking his bandaged butt into the basketball hoop.

It’s stuff like this that led to the Globetrotters crossovers, i’m sure.

The gang unmask "Ankha”, who, as i’d spoiled ahead of time, is Dr. Najib. He had faked his own petrification as part of a plan to get his hands on the coin—actually the key to the statue in the photo from the book. The gang and the Professor discover that a slot on the back of the statue serves as the keyhole, because apparently no-one was ever diligent enough to examine the back side of this stone figure, and its mouth opens to reveal a “glass beetle”.

Not quite, says the Professor.

There’s no resolution about what happens to this obscenely large “diamond”, identified as such at a glance without any kind of testing of its hardness. Scooby finds the whereabouts of the real mummy of Ankha, and the gang celebrate as Dr. Najib is probably in the midst of arguing his diplomatic immunity somewhere downtown.

And once again, no “meddling kids”, not even a scene of the authorities arriving. All we see of Najib unmasked is the usual silent, glaring fuming, and the explanation falls to the gang and the Professor relaxing calmly in the epilogue.

(like what i’m doing here? It’s not what pays the bills, so i’d really appreciate it if you could send me a bit at my paypal.me or via my ko-fi. Click here to see more entries in this series of posts, or here to go in chronological order)

81 notes

·

View notes

Photo

The Perfect Tiles for Farmhouse Decor