#Large-Scale Stainless Steel Casting

Text

R.P Alloys caters to heavy engineering needs with an in-house casting and machining shop equipped with the capability to manufacture almost every equipment our clients require. Our industrial gears are already a name to reckon with and find application in a wide variety of industries like Mining, Cement, and Power.

Visit:- https://www.rpalloys.com/

#RP Alloys & Steel Forgings#Machined Stainless Steel Cast Parts#Cast Components#Cement Machinery Cast#Steel Parts#Stainless Steel Casting#Aotomotive Steel Machined Casting Parts#Casting Machine Parts#Machining Casting Aluminum Parts#Large-Scale Stainless Steel Casting#Machine Tools Component#Common Materials for Casting Engine Parts#Cement Manufacturing Process#cast steel castings for cement machinery#Cement Machinery Cast Steel Parts#Concrete Machine Tool Structures#Cement Casting Machine Tools Component

0 notes

Text

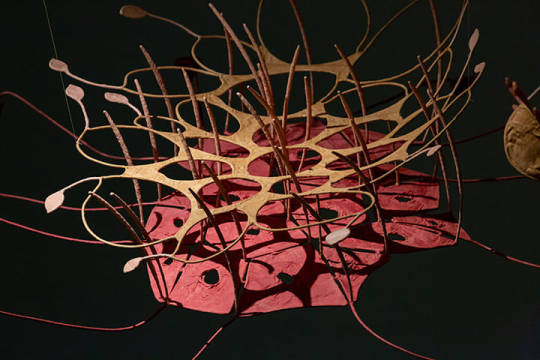

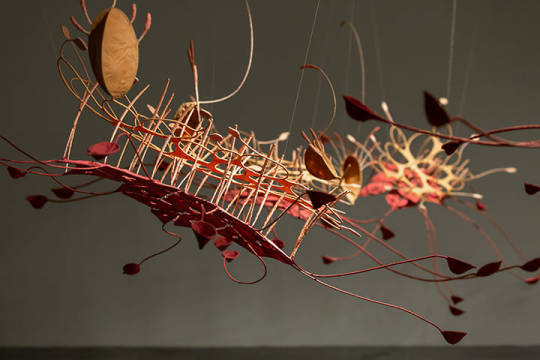

Ranjani Shettar, Seven ponds and a few raindrops, 2017. Muslin, stainless steel, tamarind, natural dyes, 19 ft. 1 in. x 18 ft. 7 in. x 96 in. (581.7 x 566.4 x 243.8 cm). Courtesy Talwar Gallery, New York/New Delhi.

Photographs by Corrado Serra.

“Suspended from the ceiling, Seven ponds and a few raindrops is composed of stainless steel elements that have been molded into a series of sensual, curved, amoeba-like forms covered in tamarind-stained muslin—a technique derived from a craft tradition Shettar observed in the small village of Kinnala, India. The shadows cast by the suspended elements give the viewer a sense of having stumbled upon a hidden-away oasis.

Born in 1977, Shettar is based in the South India state of Karnataka. The inspiration for her large-scale installation comes from her observations of the now-threatened natural environs of rural India. She combines natural and industrial materials like beeswax, wood, organic dyes, vegetal pastes, lacquer, steel, and cloth in her work. All of the components in Shettar’s installations are carefully created and have a deliberately imperfect quality. The hued, rough patinas of the materials emphasize the artisanal nature of her practice, while also acknowledging the lives of the materials themselves. While Shettar’s abstract sculptures are resonant with familiar traditions of Western modernist and minimalist sculpture, it is the interplay of techniques and materials, mostly drawn from local sources, that make them distinctive.” — The Met

46 notes

·

View notes

Note

top five kitchen items you can't live without? or ten if it's easier. personally i am so so so grateful for access to an enameled cast iron dutch oven and it makes me wonder what others use ?

oohhh that's such a good question!! im gna have to go to ten LOL

a good chef's knife !! i tend to heavily favor my knives and could run my kitchen w just one or two easily

a big heavy bottomed pot for sauces n pasta n soups, i'd love to have a dutch oven someday lol

cast iron skillet. it is divisive which style of frying pan is best, ppl tend to be deeply loyal to their favorites. i favor a cast iron for most things, especially searing meats, making dutch babies, pizzas, veggies, fried eggs, and so on !! my go-to!! also love that it can go in the oven reliably. but i'd be lying if i wasn't attached to all my pans :'')

stainless or carbon steel pan. has it's moments where it's the right tool for the job. i like these for making fish w a good crispy skin or emulsifying my pasta water w my pasta n sauce

nonstick pan. rare, but useful for things like scrambled eggs and pancakes, delicate things like that.

this is a recent discovery for me, but a food scale!! has been sooo useful for me i've eliminated the use of measuring cups n spoons in my practice (especially 4 baking!!)

a fish spatula!! she's multi-talented <3

tongs or metal chopsticks r saviors for me bc i intuitively want to just use my hands to flip everything and these r a decent substitute to save the tips of my fingers, also great for stirring and imo could sub for a whisk

a large cake pan!! versatile, can roast veggies or proteins in it, bake cakes or cookies, can be used in prep work. just a nice little extra thingy to have around

a set of mixing bowls in a WIDE range of sizes ! soooo nice to have many on hand when meals have multiple components

#i loved this question !!#im a collector of kitchen items so this was nice to be thoughtful and intentional abt what i use the most!!#asks

30 notes

·

View notes

Text

Carbon Steel Flanges VS Stainless Steel Flanges

Generally speaking, a flange is a forged or cast ring of steel that is used to connect or join sections of pipe. It also includes flanges that are integral to pressure vessels, pumps, or any other element that utilizes flanges. Bolts connect flanges together and threaded or welded them to the piping system. There are a variety of types of flanges available, including stainless steel flanges (SS flanges), alloy steel flanges, carbon steel flanges, slip-on flanges, blind flanges, weld neck flanges, threaded flanges, lap joints, and orifice flanges. This article discusses stainless steel vs carbon steel.

What are carbon steel flanges?

A flange connects two ends of a pipe or ends a pipe. Various materials are available for them. Flanges made from carbon steel are one such type. This material provides excellent durability, corrosion resistance, and finishing properties. There are several types of them. It is common to use Carbon Steel Blind Flanges to terminate pipes. The raw materials used in the manufacture of these flanges are of high quality. Between 0.25 and 0.60 percent of their carbon content is carbon. In addition to being highly ductile, the product is also excellently fabricated due to its high carbon and manganese content.

What are Stainless steel flanges?

In residential, commercial, and industrial piping systems, stainless steel flanges and fittings are used. Stainless steel is widely used for the transportation of gases or liquids, chemical processing, maritime applications, sanitary applications, and areas requiring corrosion resistance because of its strength, corrosion resistance, and ability to withstand high temperatures, pressures, and flows.

To determine the right stainless steel grade and flange type for your application, refer to the appropriate standards or contact us. To determine the right stainless steel grade and flange type for your application, refer to the appropriate standards or contact us.

Carbon Steel vs Stainless Steel

Stainless steel has a higher melting point and a lower carbon content than iron-carbon alloys. In appearance and properties, carbon steel is similar to stainless steel, but it contains a higher percentage of carbon.

A common application of engineering and construction materials like carbon steel is in large-scale industrial processes like telecommunications, transportation, chemical processing, and petroleum extraction and refining.

The process used in making Stainless Steel 304 Flanges is essentially two steps consisting mostly of iron and carbon. There are many types of steel that can be called stainless steel 304 flanges. Corrosion resistance can be achieved by adding nickel and chromium to stainless steel.

Flanges in detail:

Pipe Flanges are most often manufactured from forgings produced in grades A-105. There are two grades of A-350 material: LF2 for applications requiring lower temperatures and F42-F70 for applications requiring high yields. It is widely accepted that pipeline service is carried out with high-yield materials due to their increased strength.

Besides having a greater amount of chrome and molybdenum than carbon steel flanges, alloy steel flanges are able to withstand temperatures and pressures that are higher than those of carbon steel flanges. In contrast to conventional carbon steel flanges, they have a higher Chromium content, which makes them more corrosion resistant.

Flanges are commonly manufactured from stainless steel containing Nickel, Chromium, and Molybdenum. Flanges are commonly manufactured from stainless steel containing Nickel, Chromium, and Molybdenum. Forgings classes can be serviced with trace elements during melting. Aside from this, the 300 Series is not magnetic, whereas the 400 Series is magnetic, as well as has weakened corrosion resistance.

Read More About This Article On Our Website For More information: https://thesteelexporter.com/carbon-steel-flanges-vs-stainless-steel-flanges/

#design#architecture#interiordesign#steel#art#garden#gardendesign#rust#gardening#sculpture#metal#welding

2 notes

·

View notes

Text

Maximizing Productivity with Fast Opening Filter Press

In modern industrial settings, a fast opening filter press stands out as an essential device for solid-liquid separation. The process begins by feeding slurry into the machine. As it moves through each chamber, solids collect on cloth filters while clean liquid passes below.

A distinctive advancement in this technology is the incorporation of vibration devices which further optimizes productivity. These presses not only achieve efficient filtration but also ensure rapid cleaning and reuse cycles due to quicker opening mechanisms—a vital aspect for industries aiming at high-throughput processes without compromising quality or efficiency.

Understanding Fast Opening Filter Press

In a fast-opening filter press, slurry enters via the feed pump. The frames hold it all together; hydraulic pistons ensure no leak during processing. Each chamber's cloth filters serve to capture solids while clean liquid escapes below – separation made simple and efficient.

Once every space brims with purified fluid and trapped particles, those same hydraulics compress chambers tightly, ensuring not even a drop slips through unchecked. As pressure ceases, they open for easy unload of residual matter - ready again for industrial tasks large or small. These presses are made from robust metals like stainless steel or cast iron, tailored to the task.

They work solidly and precisely, separating materials in industries like food processing, where purity is crucial, or mining, where water reclamation is key to continued production despite natural scarcity.

Benefits of Quick Operation Mechanisms

Quick-opening filter presses boost productivity by slashing cycle times. They use less energy, too. Built-in automatic belt washing saves labor previously spent on manual cleaning—more time for other tasks now.

Verti-Press designs also enhance efficiency with their vertical chamber stack-up and improve wash results. Automation means fewer mistakes; it’s safer and uses materials better to cut costs—a smart choice for precise filtering needs and exact cake size control from the slurry feed adjustment each cycle. Plus, Filtra-Systems' Verti-Press stands out: added safety against chemical exposure makes it top-tier in filtration technology – ideal for modern 'green' industry demands.

Integrating Vibration Devices for Efficiency

To enhance the fast-opening filter press, engineers integrate vibration devices. These gadgets attach to the machine frame and mass--the "M" in our simple vibratory system diagram. They shake at a set speed when prompted, helping loosen particles sticking to filters or plates after a cycle ends.

They're fine-tuned so their shaking matches exact frequencies that won’t harm equipment by reaching resonance with natural frequencies of the structure—something crucial for avoiding quick wear or catastrophic failures. This precise alignment means maintenance focuses only on real issues first—a principle key in Predictive Maintenance programs working alongside Preventive Maintenance efforts aimed at extending machinery life while ensuring maximal uptime and product quality.

Choosing the Right Filter Press Model

Selecting a filter press demands attention to detail. One must weigh the type of process—continuous or batch? Continuous presses roll out paper non-stop into a large tank through water and chemicals, filtering all at once.

Batch presses soak then push batches through in one shot, great for limited runs like those needed for paper towels. Vertical versus horizontal orientation matters too. Vertical ones filter more surface area with their tubular shape, fitting chemical uses best; whereas horizontal models are better suited if you're aiming for clean white products such as tissues.

Material choice is paramount: plastic, carbon steel, stainless steel—all hinge on your production scale and substance filtered. Stainless stands strong against alkaline scenarios to avoid rust issues. Prices start steeply around $100k but can rocket up depending on size and design choices tailored to industry requirements.

Streamlining Filtration with Rapid Cycles

In the rapid filtration process, constant pressure is key. As slurry fills filter plate spaces, flow lessens and stops when a set low level is hit; then comes core blow with water or air to clear leftover slurry back into tanks for reuse. Optional are cake dry and membrane squeeze steps using compressed air for super-dry cakes by compressing out more liquid.

When drying's done, plates unclamp; they separate so dried material drops free—this ends one cycle before starting anew. Design choices like chamber size affect duration just as much as slurry properties do—from its make-up to particle sizes—and dewatering aids can assist if needed.

Maintenance Tips for Longevity and Performance

Supervisors must integrate preventative checks into the daily routine to ensure optimal filter press performance. Daily tasks include inspecting hydraulic lines and fittings for leaks, as these can quickly escalate if unchecked. If a leak is found, immediately tighten or replace necessary components and monitor any fixes closely.

Maintaining clean hydraulic oil is essential; also keep bolts at their correct torque level with marks indicating proper tightness. It's critical to keep safety systems well-functioning—repair faulty devices right away to avoid downtime during operations. Tracking press data like cycle time and cake consistency in logs helps identify trends or issues early on.

Monthly maintenance should involve professional servicing alongside cleaning and replacing filter cloths when needed, which prolongs equipment life significantly. Damp cakes indicate it might be time for cloth replacement or process adjustments — something our technicians can analyze via slurry testing onsite.

Case Studies: Productivity Gains in Action

In factories, time is money. One study showed a fast opening filter press it shaves hours off processing. With this tool, cycles run close to 15% quicker than old models.

This means more batches per day; for one business they saw output go up by nearly 25%. That's huge in terms of numbers! Profits soared due to improved staff efficiency.

Smooth operations with minimal stops and starts boosted productivity like never before, truly changing the game on the shop floor.

The hzfilter Fast Opening Filter Press revolutionizes separation processes with its vibration device. This advanced system speeds up cycle times, maximizing productivity in industries needing solid-liquid division. Its design reduces downtime and enhances efficiency, making it a smart choice for businesses aiming to boost output while maintaining quality.

For those seeking reliable operations with less maintenance, this filter press stands out as an essential upgrade—streamlining workflows with remarkable proficiency.

#fast opening filter press#fast-opening filter press#chamber's cloth filters#hzfilter Fast Opening Filter Press

0 notes

Text

Reliable and Efficient - Exploring the Advantages of Zoeller Pumps in Water Management

Zoeller Pumps has established a strong reputation as a reliable supplier of superior pumping systems for use in commercial, industrial, and residential settings. Since Zoeller Pumps prioritize dependability, effectiveness, and durability, they have come to represent the pinnacle of water management performance. We'll explore the many benefits of Zoeller Pumps and how well they work in different pumping applications in this post.

Exceptional Reliability: Built to Last

One of the key advantages of Zoeller Pumps is their exceptional reliability. Engineered with robust materials and precision craftsmanship, Zoeller Pumps are built to withstand the toughest operating conditions and deliver reliable performance year after year. Whether it's pumping sewage, stormwater, or groundwater, customers can trust Zoeller Pumps to keep their systems running smoothly with minimal downtime.

Versatile Applications: Meeting Diverse Pumping Needs

Zoeller Pumps offer a wide range of pumping solutions to meet diverse needs across different industries. From submersible sump pumps for residential drainage to grinder pumps for sewage and effluent, Zoeller Pumps provide versatile options for various applications. Their extensive product line ensures that customers can find the right pump for their specific requirements, whether it's for a small residential project or a large-scale industrial application.

Efficient Performance: Maximizing Pumping Efficiency

Efficiency is another hallmark of Zoeller Pumps. Designed with innovative features such as vortex impellers, dual seals, and energy-efficient motors, Zoeller Pumps optimize pumping performance while minimizing energy consumption. This not only saves money for end-users but also reduces the environmental impact of pumping operations, making Zoeller Pumps a sustainable choice for water management.

Durable Construction: Withstanding the Rigors of Operation

Zoeller Pumps are built to last, thanks to their durable construction and rigorous quality control standards. From cast iron housings to stainless steel components, Zoeller Pumps are engineered to withstand corrosion, abrasion, and chemical exposure, ensuring long-term reliability even in the harshest environments. This durability translates to lower maintenance costs and extended pump life, providing added value for customers over the long term.

Innovative Technology: Advancing Pump Performance

Innovation is at the core of Zoeller Pumps' success. Their pumps feature advanced technologies such as automatic switches, variable speed drives, and smart controls, all of which contribute to improved performance and efficiency. By staying at the forefront of pump technology, Zoeller Pumps continue to push the boundaries of what's possible in water management, delivering innovative solutions that meet the evolving needs of customers.

Conclusion: Choosing Zoeller Pumps for Superior Water Management

To sum up, Zoeller Pumps provide unparalleled water management innovation, durability, efficiency, adaptability, and dependability. Customers require performance and peace of mind, and Zoeller Pumps deliver it for residential, commercial, and industrial applications. Customers who purchase Zoeller Pumps may be sure that their pumping needs will be expertly fulfilled, guaranteeing a dependable and effective system for many years to come.

0 notes

Text

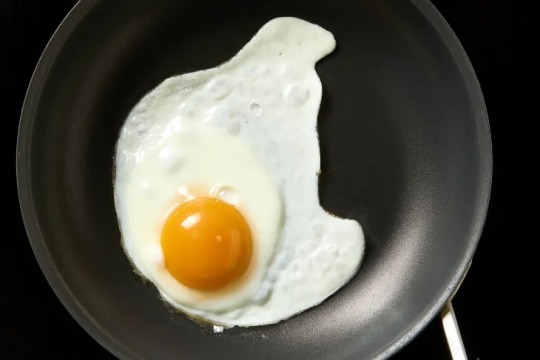

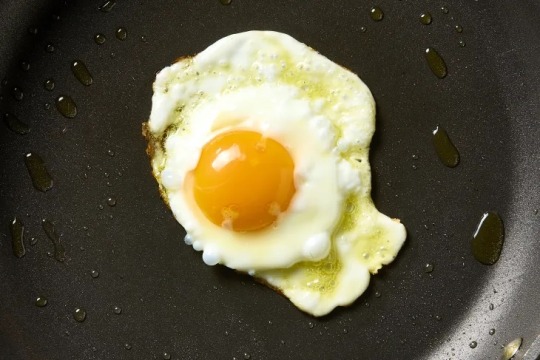

Credit: Photo: Alex Lepe; Food Styling: Brett Regot

We Tried Every Possible Method For Frying Eggs, and The Clear Winner Was a Total Curveball

— By Andrea Rivera Wawrzyn

In This Article: What’s the Best Way to Fry Eggs? A Few Notes on Methodology!

Cold Start

Neutral Oil

Oil + Butter

Olive Oil

Butter

Covered

Basted

Water + Fat

Tips for Success

Fried eggs are a quintessential breakfast classic. They’re just as comfortable on a fancy brunch menu as they are in a greasy spoon diner. And while it’s pretty easy to make at home, it’s also one of the more difficult things to get exactly right. That’s because you can fry an egg a number of ways, and people have strong preferences about how they’re prepared. Some people like their eggs over-medium, or with browned lacy edges; others prefer a more gentle cook.

But, for me, the “best” fried egg is really the easiest fried egg. It doesn’t stick to the pan, it doesn’t make a mess, and cooking it doesn’t smoke out the kitchen. And, of course, the whites are properly cooked through (which can be one of the trickiest parts!) To nail down the best way to fry an egg, I researched and tested eight popular cooking methods at home.

What’s the Best Way to Fry Eggs?

The best way to fry eggs is with water and fat in a covered pan. It delivers an egg with well-set whites, a jammy yolk, and a bit of browning on the edges.

A Few Notes on Methodology:

For something that seems so simple, frying an egg can be a finicky task. There are a surprising number of factors to consider — heat level, cooking vessel, whether or not to flip, and the list goes on, but suffice it to say I had to establish some parameters before I got started.

The Eggs: I used large eggs for this test. I cracked the eggs into a small bowl before frying to minimize the possibility of any shells making their way into the skillet. I used 1 large egg per method to avoid multiple eggs running into one another in the pan. I also tried to pour them in the center of the pan, where they would get the most even heat.

The Pan: All of the eggs were cooked in a 10-inch nonstick skillet. Although some people swear by frying eggs in a cast-iron pan or even stainless steel, my goal was the easiest fried egg, not the most classic. I wanted to keep the yolk intact and avoid scraping stuck-on egg from the bottom of the pan.

To Flip Or Not To Flip: I was looking for a gently cooked sunny-side up egg, which meant no flipping. Flipping the egg is a good method for a more well-cooked yolk, but I wanted an egg with just-set whites and a runny yolk ready for a piece of toast to dunk in.

The Testing: I tested all eight methods on the same day with eggs from the same carton. All of the eggs were cooked in the same 10-inch nonstick skillet, which was preheated for 2 minutes over medium heat (with the exception in the case of the cold-start method). I let the pan cool completely and washed it between each test. I tasted each egg just after cooking to judge the flavor.

Ratings: I rated the eggs on a scale of 1 to 10, with 10 being an evenly cooked, flavorful egg with set whites, a runny yolk, and minimal browning around the edges.

Credit: Photo: Alex Lepe; Food Styling: Brett Regot

Fried Egg Method: Cold Start

Rating: 3/10

About this method: This cooking method is as simple as it gets. The egg is poured into a cold, empty nonstick skillet — no oil or butter at all — and then cooked over medium heat until the whites are just set.

Results: The upside to the cold start is that the eggs cooked pretty gently and had almost no browned edges. There’s no extra fat in the pan to spatter out, which is nice for clean up and safety. The downside is that without any fat in the pan, the egg tasted noticeably less rich and delicious than other fried eggs in the lineup. It also took just about 6 minutes to cook, which is much longer than other methods (boo).

Credit: Photo: Alex Lepe; Food Styling: Brett Regot

Fried Egg Method: Neutral Oil

Rating: 5/10

About this method: For this tried-and-true method, I cooked one egg in 1 teaspoon of vegetable oil in an uncovered pan that had been preheated for 2 minutes over medium heat.

Results: This method produced what I would consider a good, standard fried egg. There was a bit of oil splatter while it was cooking, but not too much. Cooking the egg uncovered meant it needed longer in the pan for the whites to fully cook, clocking in at about 3 1/2 minutes. The finished egg was browned around the edges because of that extra cooking time, which was not what I was after. Vegetable oil didn’t add much in the way of flavor, so while the egg itself was cooked fine, it was nothing to write home about.

Credit: Photo: Alex Lepe; Food Styling: Brett Regot

Fried Egg Method: Oil + Butter

Rating: 5/10

About this method: I preheated the pan for 2 minutes with 1 teaspoon of vegetable oil, then added 1 teaspoon of butter to the hot pan just before slipping in the egg. I covered the pan with a lid and cooked the egg for 1 minute, then turned the heat off and let it finish cooking, covered for an additional 30 seconds.

Results: This is a bit of a maximalist method for frying eggs. The idea is that the addition of two fats makes for a richer, fuller flavor than just using one alone. As promised, the egg did have a richer flavor than ones cooked in just one type of fat. White it yielded a perfect runny yolk and well-set whites, the egg had a harder cook on the bottom with a crispier texture. In the end, the extra bit of richness wasn’t worth the effort.

Credit: Photo: Alex Lepe; Food Styling: Brett Regot

Fried Egg Method: Olive Oil

Rating: 6/10

About this method: This is a simple twist on a classic preparation. It’s the same as the vegetable oil test above: The eggs are cooked uncovered in a pan that has been preheated for 2 minutes with 1 teaspoon of olive oil instead.

Results: Compared with methods that use butter or vegetable oil, this one fared the best in terms of browning. I was specifically aiming for eggs without browned bottoms and edges, and the olive oil delivered the egg with the least of those. In terms of flavor it landed right in the middle, having more flavor than the vegetable oil — which didn’t add much at all — but less than butter.

Credit: Photo: Alex Lepe; Food Styling: Brett Regot

Fried Egg Method: Butter

Rating: 7/10

About this method: I preheated a pan with 1 teaspoon of butter for 2 minutes, then added the egg and fried it, uncovered, until the whites were just set.

Results: While this method gets high marks for flavor (browned butter, yum), it loses points for excessive browning. Two things were working against my goal of a gently cooked egg: the lack of a lid, and the butter itself. Without a cover to trap the heat, I had to fry the egg for slightly longer to set the whites, which in turn led to the bottom and edges of the egg getting much crispier than I wanted. As the egg cooked, the butter in the pan browned, which while delicious, contributed to the overall brown appearance of the finished egg. Tasty, but not what I wanted.

Credit: Photo: Alex Lepe; Food Styling: Brett Regot

Fried Egg Method: Covered

Rating: 8/10

About this method: This method was identical to the butter test, but with a lid. I put 1 teaspoon of butter into the pan and preheated it for 2 minutes over medium heat, then added the egg and immediately covered the pan with a lid. I then cooked the egg until the whites were just set.

Results: This was pretty close to my ideal fried egg. It had the best of both worlds: the flavor of butter, and the gentler cook that comes from covering the pan. The browning on the bottom and around the edges was minimal. A covered pan traps heat all around the egg, so it cooks faster and more evenly than if it were uncovered.

Credit: Photo: Alex Lepe; Food Styling: Brett Regot

Fried Egg Method: Basted

Rating: 9/10

About this method: This method is a bit more hands on than the others. I added 2 tablespoons of butter to the pan and preheated it for 2 minutes over medium heat. I then added an egg to the pan, let it fry for about 1 minute, then tilted the pan and used a spoon to baste the top of the egg with melted butter until the whites were set.

Results: This is by far the chef-iest way to fry an egg of all the methods I tried. Searching ‘how to fry an egg’ returns many results with videos of chefs lovingly drizzling hot butter over a perfectly cooked egg, and for good reason — this egg was almost perfect.

The egg spent over half of its cooking time tilted away from the direct heat of the flame, so it actually cooked more gently than most of the other methods I tested. Additionally, cooking it this way allowed me the greatest amount of control. I could push the egg around in the pan, in and out of its butter bath, as well as specifically directing where on the egg’s surface to add more hot butter, thereby eliminating any spots being under or overcooked. The bottom of the egg was cooked, but not browned; there was nary a crispy edge to be seen; and since it was positively drowning in butter, it was delicious, if a bit rich. I wound up with the gently cooked butter-drenched fried egg of my dreams, but at what cost?

While this produced the best egg, it was also by far the most high-maintenance one. Basting an egg is much more active than simply frying it, on top of which, you’re tilting a pan full of very hot fat toward yourself, which is not exactly the height of safety. Since I opted for a nonstick pan, I also had to use a nonmetal spoon for basting, since you should never use metal utensils on nonstick cookware. Luckily, I had a favorite silicone spoon handy, but not everyone does. All in all, while this was a top-notch fried egg, this method would never be my go-to for making an easy fried egg.

Credit: Photo: Alex Lepe; Food Styling: Brett Regot

Fried Egg Method: Water + Fat

Rating: 10/10

About this method: This method is identical to the covered method above, but with the addition of 1 teaspoon of water. I added the water just after adding the egg to the preheated pan and quickly covered it with a lid. I then fried the egg over medium heat for about 1 minute, until the whites were just set.

Results: Nailed it! This method delivers the best fried egg. Covering the pan leads to more even cooking, and coupling it with water takes it to the next level. The steam created by adding just 1 teaspoon of water is enough to create the perfect environment for gentle, even egg cooking.

Butter adds great flavor without becoming overly rich like the basted egg. The whites were well set, and the yolk was jammy, not overly runny, but cooked just enough for a toast dunk. There was a bit of browning on the edges, but very little and the bottom of the egg remained silky with no crisping up. Mission accomplished.

Tips For Success:

For the record, there were no bad eggs here. A fried egg is pretty hard to totally screw up, and I would have happily put every egg I cooked on top of a bowl of fried rice. I did learn a few lessons though that may help you the next time you’re frying an egg at home.

If you’re going for a gently cooked sunny-side up egg, cover the pan. Any method where the egg is uncovered is ultimately going to lead to browned edges and a harder cooked bottom. You simply need to cook the egg for longer to get the whites fully set, and since the heat is only coming from the bottom of the pan and also is escaping from the top, there’s no way to totally avoid browning.

Flipping the egg ensures the whites are cooked faster. But then you’re sacrificing the sunny-side up of it all. Again, a lid is your friend.

If you have one, use a glass lid. Glass lets you monitor your eggs without releasing the trapped heat so they don’t become overcooked.

We recommend a nonstick skillet for frying eggs. Plenty of people hail the steel skillet as the best way to get a crisp fried egg. Unfortunately, to keep eggs from sticking in a steel pan, it’s going to need to be ripping hot, which will create smoke. If you’re a confident cook with a good hood vent, go for it. For the rest of us, the slick coating on a nonstick skillet lets you slide the finished egg right onto your plate with little-to-no sticking. You can use any skillet you have, but a nonstick one is your best chance for brunch-quality, unbroken yolks. A well-seasoned cast-iron pan can also work, but save your steel skillet for getting a good sear on a steak.

0 notes

Text

Cooking Essentials: Your Guide to Cookware Sets Wholesale

Cooking is an art, and just like any artist, a chef needs the right tools to create culinary masterpieces. Whether you're a professional chef, a culinary enthusiast, or a home cook looking to elevate your kitchen game, investing in high-quality cookware sets wholesale can be a game-changer. Cookware sets wholesale offer numerous advantages, including cost savings, convenience, and access to a wide range of kitchen essentials in one package. In this comprehensive guide, we'll explore everything you need to know about cookware sets wholesale, from the essentials to consider to the benefits of buying in bulk.

1. Understanding Cookware Sets Wholesale:

Cookware sets wholesale refer to purchasing cooking utensils, pots, pans, and other kitchen essentials in bulk quantities. This approach offers several advantages over buying individual pieces, including cost savings, convenience, and uniformity in your kitchen arsenal. Wholesale suppliers typically offer a wide range of cookware sets tailored to different needs and preferences, from basic starter sets to professional-grade collections.

2. Benefits of Buying Cookware Sets Wholesale:

a. Cost Savings: One of the most significant advantages of purchasing cookware sets wholesale is cost savings. Buying in bulk often allows you to enjoy discounted prices per unit compared to buying individual pieces. This can result in significant savings, especially if you're outfitting a commercial kitchen or stocking up for a large-scale culinary operation.

b. Convenience: Buying cookware sets wholesale offers convenience by providing all the essential tools you need in one package. Instead of sourcing each item separately, you can purchase a comprehensive set that includes pots, pans, utensils, and other kitchen essentials, saving you time and effort in the procurement process.

c. Variety and Customization: Wholesale suppliers typically offer a wide range of cookware sets catering to different cooking styles, preferences, and budgets. Whether you prefer stainless steel, non-stick, cast iron, or ceramic cookware, you can find a set that meets your specific requirements. Additionally, many suppliers allow for customization, allowing you to mix and match pieces to create a personalized set tailored to your needs.

d. Quality Assurance: Reputable wholesale suppliers often prioritize quality, ensuring that their cookware sets are made from durable materials and manufactured to high standards. By purchasing from a trusted supplier, you can have confidence in the quality and performance of your cookware, reducing the risk of premature wear and tear.

e. Scalability: Buying cookware sets wholesale allows you to scale your kitchen operations efficiently. Whether you're expanding your restaurant, catering business, or culinary school, purchasing in bulk ensures that you have enough cookware to meet growing demand without having to constantly replenish your supplies.

3. Essential Factors to Consider:

Before purchasing cookware sets wholesale, there are several factors to consider to ensure that you're making the right choice:

a. Material: Cookware sets are available in various materials, each with its unique properties and advantages. Common materials include stainless steel, aluminum, cast iron, copper, and non-stick coatings. Consider your cooking preferences, maintenance requirements, and budget when choosing the material that best suits your needs.

b. Durability: Look for cookware sets made from durable materials that can withstand high heat, frequent use, and rigorous cleaning. Quality construction and craftsmanship are essential for ensuring longevity and performance.

c. Compatibility: Ensure that the cookware set is compatible with your cooking appliances, such as gas stoves, induction cooktops, or ovens. Check the manufacturer's specifications to confirm compatibility and avoid any compatibility issues.

d. Warranty and Support: Choose cookware sets from reputable brands that offer warranties and reliable customer support. A warranty provides peace of mind and protection against manufacturing defects, while responsive customer service ensures that any issues or concerns are promptly addressed.

e. Budget: Determine your budget and consider the overall value offered by the cookware set, including its quality, features, and longevity. While it's essential to stick to your budget, prioritize quality and functionality to ensure that you're investing in cookware that will serve you well for years to come.

4. Conclusion:

Cookware sets wholesale offer a cost-effective and convenient solution for outfitting kitchens of all sizes. By purchasing in bulk, you can enjoy significant cost savings, convenience, and access to a wide range of high-quality cookware tailored to your specific needs. Whether you're a professional chef, a culinary enthusiast, or a home cook, investing in cookware sets wholesale is a smart decision that can enhance your cooking experience and elevate your culinary creations.

0 notes

Text

"Efficient Handling Solutions: Precast Concrete Lifting Clutches for Safe and Seamless Construction Projects Worldwide"

Precast concrete lifting clutches are indispensable components in the construction industry, facilitating the safe and efficient handling of precast concrete elements. These lifting clutches, also known as lifting anchors or lifting sockets, play a vital role in the vertical transportation of precast concrete components, ensuring their precise placement and secure attachment during construction projects of various scales.

At the heart of their functionality lies a robust design engineered to withstand the rigorous demands of lifting heavy loads. Constructed from high-quality materials such as alloy steel or stainless steel, precast lifting clutches exhibit exceptional strength and durability, essential for withstanding the substantial weights associated with precast concrete elements.

The design of precast concrete lifting clutches typically consists of a sturdy body with strategically placed anchor points and a secure locking mechanism. These anchor points are engineered to provide a reliable connection with lifting equipment, such as cranes or hoists, ensuring stable and controlled lifting operations. The locking mechanism ensures that the lifting clutch remains firmly attached to the precast element throughout the lifting process, minimizing the risk of accidents or damage.

One of the key advantages of precast lifting clutches is their versatility. Available in a variety of sizes and load capacities, these clutches can accommodate a wide range of precast concrete elements, from smaller panels to larger beams and columns. This versatility makes them suitable for diverse construction projects, including residential buildings, commercial complexes, bridges, and infrastructure developments.

The installation process for precast concrete lifting clutches is straightforward, typically involving embedding the clutches securely into the concrete during the casting process. Once the concrete has cured, the lifting clutches are ready for use, providing a reliable attachment point for lifting equipment during construction. This streamlined installation process helps save time and labor costs, contributing to the overall efficiency of the construction project.

Safety is paramount in the construction industry, and precast lifting clutches are designed with this principle in mind. Rigorous testing and quality control measures ensure that these clutches meet industry standards for safety and performance. Additionally, manufacturers provide comprehensive guidelines for the proper use and maintenance of lifting clutches, helping construction teams mitigate risks and ensure safe lifting operations.

Beyond their primary function in lifting and handling precast concrete elements, lifting clutches can also contribute to the overall aesthetics and functionality of a structure. By enabling precise placement of precast elements, these clutches help ensure alignment and consistency in the finished construction. This level of accuracy is essential for achieving architectural integrity and meeting design specifications.

In conclusion, precast concrete lifting clutches are essential components in modern construction, providing a reliable and efficient solution for handling precast concrete elements. With their robust design, versatility, and focus on safety, these clutches play a crucial role in ensuring the success of construction projects, from residential buildings to large-scale infrastructure developments. As the construction industry continues to evolve, precast lifting clutches will remain indispensable tools for facilitating safe and efficient vertical transportation of precast concrete elements.

0 notes

Text

Steel Stainless Casting Services Lithuania

Megameta Company, based in Lithuania, specializes in top-notch Steel Stainless Casting Services. With a commitment to excellence, we deliver precision and quality in every casting project. Our skilled team employs state-of-the-art technology to create durable and finely crafted stainless steel products. Whether you need custom components or large-scale productions, Megameta ensures reliability, efficiency, and a seamless casting experience for all your stainless steel needs. Trust us to bring your visions to life with expertise and reliability.

Know More : https://megameta.lt/casting

0 notes

Text

R.P Alloys is a self-contained engineering company delivering end-to-end solutions to businesses on a global scale.

Visit:- https://www.rpalloys.com/

#Appliances#Electrical#and Electronics Manufacturing#RP Alloys & Steel Forgings#Machined Stainless Steel Cast Parts#Cast Components#Cement Machinery Cast#Steel Parts#Stainless Steel Casting#Aotomotive Steel Machined Casting Parts#Casting Machine Parts#Machining Casting Aluminum Parts#Large-Scale Stainless Steel Casting#Machine Tools Component#Common Materials for Casting Engine Parts#Cement Manufacturing Process#cast steel castings for cement machinery#Cement Machinery Cast Steel Parts#Concrete Machine Tool Structures#Cement Casting Machine Tools Component#Wear parts and solutions for the cement industry#Cement Machine Parts for Sale#metal processing industry#metal processing industry components#metal processing industry parts#Metal Processing Manufacturers & Companies#Metal Components Manufacturers & Suppliers in India

1 note

·

View note

Text

Ball Valve Market Trends, Market Share, Industry Size and Forecast to 2028

The market research conducted by The Insight Partners- “Global Ball Valve Market Size Report | Industry & Analysis - 2028” intends to present business-oriented market insights to investors. Beyond operational factors, this research includes future market projections. Along with drivers, and challenges this report covers a range of opportunities available for Ball Valve market participants. Both primary and secondary research methods have been used to frame valid facts included in this research.

Ball Valve Market research deep dive into several segments to offer a comprehensive outlook to both veteran and new entrants. Through this market research companies can get a better perspective and understanding of the target audience and ensure the company gets a competitive edge. It is vitally important for companies to understand the market before investing in large proportions. Spending a small share of your business investment on trustworthy market research makes business sense.

The competition landscape covered in this research is important for businesses to adopt eye open approach. This market research offers unbiased insights that can be used by companies to learn their strengths and weaknesses. Capitalizing on new-found insights from competitor’s analysis will be an advantage for companies to forge ahead.

Ball Valve Market research report could be the foundation of your business strategy as it includes pieces of evidence of market investigation which offers the best chance for business to achieve their business goals.

Key objectives of this research are:

Global Ball Valve Market Dynamics- Market Share, Market Size, and CAGR

To Analyze Drivers, Challenges, and Opportunities in Ball Valve Market

To offer a competitive landscape- Strategies by key players

To present strategic Ball Valve market recommendations for investors.

To offer a brief account of customer needs, target demographics, and regional scope.

To help businesses in the evaluation of success against the Ball Valve market benchmarks.

COVID-19 Impact Analysis

Covid-19 began as a health crisis and turned into an economic one, shaking the business world. The period marked a drop-down in revenue scales and led to the suspension of production for a certain time. This section under Ball Valve market research dedicated to a detailed discussion on pandemic influences and responses by businesses is intended to help companies in post-pandemic business tactics. After 2 years of disrupted supply-demand metrics, participants in the Ball Valve market started to reposition themselves back in competition. Key companies in this Ball Valve market are- .

What are the Perks for Buyers of this Report?

Detailed overview of current Ball Valve market situation.

Precisely estimated market revenue projections and CAGR to streamline resources.

Regional coverage to uncover new markets for business

Competition analysis intends to help companies in a competitive edge.

Facts-based crystal clear insights for business success.

The research is customized as per business requirements.

Access to PDF, and PPT formats of this research.

Market Segmentation-

Based on Type of Ball Valve Market Research report:

Rising Stem

Floating

Trunnion Mounted

Based on Material of Ball Valve Market Research report:

Stainless Steel

Cast Iron

Cryogenic

Alloy

Others

Based on End-Use Industry of Ball Valve Market Research report:

Water Management

Oil & Gas

Chemicals

Pharmaceuticals

Energy & Power

Others

Based on Regions:

North America (U.S., Canada, Mexico)

Europe (U.K., France, Germany, Spain, Italy, Central & Eastern Europe, CIS)

Asia Pacific (China, Japan, South Korea, ASEAN, India, Rest of Asia Pacific)

Latin America (Brazil, Rest of Latin America)

The Middle East and Africa (Turkey, GCC, Rest of the Middle East and Africa)

Rest of the World…

0 notes

Text

Why there’s a Need to Change the Perception of Aluminum Commercial Boilers

Stainless steel commercial boilers have gained huge popularity over time because of their success in different environments and applications. They have been proven to be efficient and reliable in both retrofit and new installations. However, the commercial heating industry is going through a continuous debate on the uses and advantages of aluminium over stainless steel heat exchangers in varied applications. The decision of choosing new commercial condensing boilers has become confusing and daunting for building owners and engineers.

There’s a huge amount of conflicting information that has made many boiler manufacturers pick a side and the perception of aluminium boilers has been misconstrued in all this but there is no clear evidence that which material is superior to the other. Regardless of the material of the heat exchanger, there is a need to introduce and maintain every boiler with the appropriate air and water quality to prevent scaling and corrosion.

Here’s why choose an aluminium commercial condensing boiler.

High Thermal Conductivity

Did you know thermal conductivity is the important factor that needs consideration when selecting a heating unit? It defines the velocity at which the heat passes through the material and the thermal conductivity of pure metals is inversely proportional to absolute temperature. Aluminium is 8x better at thermal conduction when compared to stainless steel and is considered a high-purity metal too. Aluminium heat exchangers require thicker walls in boiler applications but it is lighter in weight and has a high strength-to-weight ratio.

Large Waterways

An aluminium heat exchanger design with large waterways delivers lower hydraulic resistance and makes the system more tolerant to variable system conditions, including flow rate settings. Moreover, large surface areas and water channels allow the water moves slowly through the heat exchanger making the returning water temperatures absorb potential heat, offering higher efficiency.

Longevity and Manufacturer Flexibility

Aluminium is known to be more flexible, versatile and economical. Moreover, the thickness of the heat exchanger walls can greatly improve the longevity of the unit. It provides casting capabilities allowing extended heating surface areas with limited volume without impacting the heat transfer rates.

When choosing the right micro condensing boilers, consider looking for a reliable company. Also renting portable commercial condensing boilers offers a wide range of benefits such as cost savings and full maintenance support.

#condensing boilers#commercial boiler hire#london#portable air conditioner hire#hire#boiler hire#climate#portable ac rental

0 notes

Text

Discover the Benefits of Square Flange Connections

Square flange connections are widely used in various industries due to their numerous benefits and advantages. In this article, we will explore some of the key benefits of square flange connections.

One of the main advantages of square flange connections is their versatility. They can be used in a wide range of applications, including piping systems, hydraulic systems, and construction projects. Their flexible design allows for easy installation and maintenance, making them suitable for both small and large-scale projects.

Square flange connections are known for their superior strength and durability. They are designed to withstand high pressure and temperature conditions, making them ideal for demanding environments. The square shape of the flange provides a strong and secure connection, ensuring the integrity of the system.

Another benefit of square flange connections is their leak-proof design. Flange connections are known for their tight and reliable sealing, preventing any leakage of fluids or gases. This is particularly crucial in industries where leaks can have serious consequences, such as oil and gas or chemical plants.

Square flange connections also offer flexibility in terms of materials. They can be manufactured from various materials, such as stainless steel, carbon steel, and cast iron, depending on the specific requirements of the application. This allows for compatibility with different fluids and gases and enhances the overall performance of the system.

Moreover, square flange connections are highly resistant to corrosion and rust. This is especially important in industries where the system is exposed to harsh environments or corrosive substances. The corrosion resistance of square flange connections prolongs their service life and reduces the need for frequent replacements or repairs.

One of the key advantages of square flange connections is their ability to handle high levels of vibration and shock. They are designed to absorb and dampen vibrations, reducing the risk of system failure or damage. This makes them suitable for applications where the system is subject to constant movement or external forces.

Furthermore, square flange connections are known for their easy alignment during installation. The square shape provides a clear reference point for aligning the flanges, resulting in a precise and accurate connection. This simplifies the installation process and minimizes the chance of misalignment or misconnection.

In addition, square flange connections allow for easy disassembly and reassembly. This is particularly beneficial when maintenance or repairs are required. The flanges can be easily detached without damaging the rest of the system, allowing for efficient and convenient maintenance procedures.

Square flange connections also offer the advantage of modularity. They can be easily combined with other components or accessories, such as gaskets, bolts, and nuts, to create a complete and reliable system. This modular design facilitates customization and ensures compatibility with existing systems or equipment.

Overall, square flange connections provide numerous benefits, including versatility, strength, leak-proof design, corrosion resistance, vibration resistance, easy alignment, and modularity. These advantages make them an excellent choice for various industries and applications. Whether it is for piping systems, hydraulic systems, or construction projects, square flange connections offer a reliable and efficient solution for connecting different components and ensuring the smooth operation of the system.

0 notes

Text

Industrial Test Weights Heavy Capacity Series Test Weight

The test weight is applied to the metrology test institution and medicine factory. The density of this product is 7.90g/cm3. It can be divided into F1、F2、M1 three classes by value, 50kg-2000kg. The test weight is a stable, high-precision calibrated weight that can be used to calibrate weighing instruments. Test weights with NABL certification are available.

All large capacity test weight is made with stainless steel and has a class of F1, F2. The class of weight and filament are assigned in accordance with the current GB/T34532-2018 Standard. Each weight is equipped with an aluminum case, to avoid unnecessary load on the instrument during transportation.

The super-strong, heavy-duty capacity series was developed for the laboratory. These weights are built to withstand abuse and are both water-resistant and rustproof. Accuracy is guaranteed by the use of an advanced hardening process that makes each weight solid, rather than porous. Steel sheets with strict dimensional tolerances are sheered, cut out, and flattened with sophisticated CNC equipment. Each sheet receives a careful polish before being turned into a weight—and then gets painted or sealed for protection against damage during shipping or transport. Centrifugal casting forms a perfect shell around the inner core of scales. After enough trials have been successfully passed, an individual serial number is applied to each weight.

Phone:+86-15061108219 Email:[email protected] Address:95# North Construct Road, Choumou, Bieqiao Town, Liyang City, Jiangsu Province, China.

0 notes

Text

Which to Choose - Butterfly Valves or Ball Valves?

There are generally two types of valves that seem to take center stage in the industrial industry, those two valves are the butterfly valve and the ball valve. While they look completely different to each other, they both actually provide very similar characteristics.

They are both usually constructed of a combination of metals such as cast iron, stainless steel, and brass, they are both pretty durable, have long shelf-life, and are relatively cheap to purchase, and can both carry a variety of different gases and liquids at carrying temperatures.

For this reason, deciding which valve to use will come down to the small differences between the two options.

Find more Info here – Fire safe ball valve

The Design

The main difference between the two types of valves is that they look different. The ball valve is essentially a ball that has a hole going right through it whilst a butterfly valve consists of rotating shaft that has a disk mounted onto it. Of course, what they look like should not be a reason to choose one over another but it is important to know.

How They Function

A ball valve works by allowing the hole to be open, blocked, or open partially to regulate the flow of gas / liquid while a butterfly valve uses the disk to either allow the flow of gas / liquid through it or to block it completely.

The Pressures Involved

It is in this instance that a ball valve may be considered a better option due to the valve always being able to open easily despite any pressure being placed upon it. The butterfly valve on the other hand can be difficult to turn as part of the disk will always have to fight against a flow of gas / liquid.

Their Best Uses

Because ball valves are able to offer better sealing which makes it an ideal choice for using with gases. Butterfly valves may not be able to completely seal in gasses which might be a danger in some industries.

Butterfly valves are cheaper than that of ball valves and are easier to maintain. It is for that reason that they are frequently used on large-scale projects that involve the regulation of water streams.

Conclusion

Although they both offer similar uses, both the ball valve and butterfly valve have different benefits and advantages over each other. This means that you will have to consider the benefits of each of them before making a choice on which valve to purchase and use.

Luckily, leading valve manufacturers are usually more than happy to help with queries related to their products. All manufacturers will be able to give you the sort of advice that you need before choosing between a ball valve and a butterfly valve.

Click here for more info – High performance butterfly valves

1 note

·

View note