#Cement Machinery Cast

Text

R.P Alloys caters to heavy engineering needs with an in-house casting and machining shop equipped with the capability to manufacture almost every equipment our clients require. Our industrial gears are already a name to reckon with and find application in a wide variety of industries like Mining, Cement, and Power.

Visit:- https://www.rpalloys.com/

#RP Alloys & Steel Forgings#Machined Stainless Steel Cast Parts#Cast Components#Cement Machinery Cast#Steel Parts#Stainless Steel Casting#Aotomotive Steel Machined Casting Parts#Casting Machine Parts#Machining Casting Aluminum Parts#Large-Scale Stainless Steel Casting#Machine Tools Component#Common Materials for Casting Engine Parts#Cement Manufacturing Process#cast steel castings for cement machinery#Cement Machinery Cast Steel Parts#Concrete Machine Tool Structures#Cement Casting Machine Tools Component

0 notes

Text

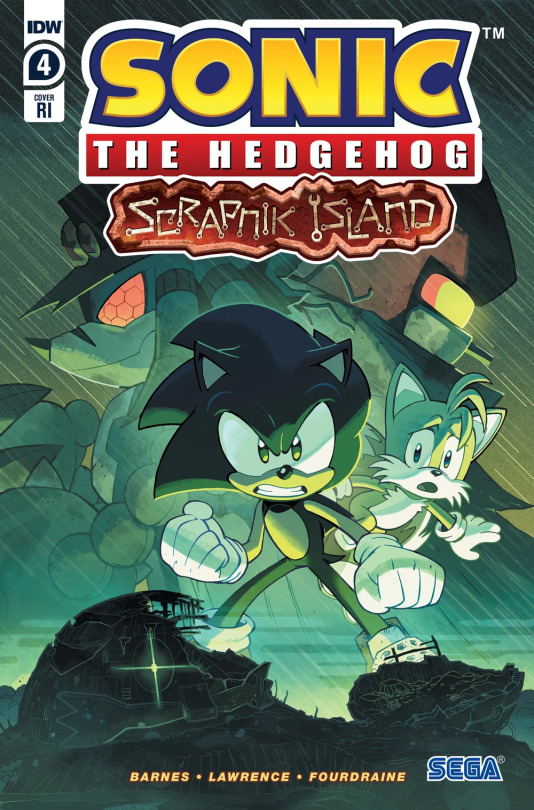

Sonic the Hedgehog Analyzer, Scrapnik Island Issue #4: Scrapnik Island (Part 4)

Welcome to the finale of Scrapnik Island! All I have to say for this is that I absolutely love it and the ending cements Scrapnik Island as my favorite Sonic IDW Miniseries.

Not to mention, the covers are absolutely amazing!

We kick off the story with Mecha Sonic preparing Sonic for the mind transfer, with Sonic wondering what the hell he’s talking about. Mecha explains how Eggman once tried to make a device that controls Badniks via his mind, but got bored and scrapped the project (I’m not surprised). Mecha used this in combination with Tails’ tablet to download his own mind into Sonic’s body, with Sonic suddenly realizing that he’s indeed serious about this.

Mecha explains that the Scrambled Egg Carrier is just a piece of junk, meaning there is no way for the Scrapniks to flee the island, so after transferring his mind into Sonic’s body, he’ll just run across the ocean and get his revenge on Eggman. Logistics aside on running across the ocean, something we saw in Sonic the Hedgehog 2 movie (and the fact that he could also just repair the Tornado), this sounds like a good plan.

Sonic questions him about Sigma and the other Scrapniks; y’know, his friends, but Mecha takes a moment, then tells him that friendship is weakness, a brief glitch in his software. As he talks, we can see the Scrapniks hide above them, horrified by Mecha saying they were never his friends.

Sonic calls him out on it, saying how he’s just full of it. He may have hit a nerve there, but Mecha just tells him to shut up and activates the machine and we get a really painful look of Mecha’s mind being transferred to Sonic’s. Sheesh, Sonic looks like he’s being electrocuted.

Okay, I will stop here for a moment just to note that I did speculate that, with how things were set up, Sonic would have to go through a typical “battle inside your mind” and try to expel Mecha somehow out of his mind and body, but what they did in the comic is actually much better!

The Scrapniks, witnessing this sin against nature, leap at Mecha, yelling at him to stop. Not only do they attack Mecha, but also the machine, breaking it in the process. *claps* Amazing job, guys!

Mecha is kneeling in the ashes and broken machinery, devastated. All of his hard work is gone thanks to the Scrapniks he rejected as his friends and he screams how they ruined everything. His eye glows, showing that he’s pissed.

“I’LL CRUSH YOU!”

Mecha gets up, charging at the Scrapniks (and making a reference to Super Mario Bros. Z).

While Mecha is busy, a few other Scrapniks quickly free Sonic, who is dazed and still fried from the incomplete mind transfer. He hears a voice inside his head, talking about how their plans are ruined, how they have to escape the island...

“I’m... not... trash...”

And there it is. Yeah, Sonic realizes that he’s picking up fragments of memories, thoughts and emotions, all of which belong to Mecha Sonic. Despite acting all aloof, it is clear that Mecha is still suffering from low self-esteem and just wants to prove he isn’t a piece of junk left to be abandoned.

Mecha slaps away another Scrapnik, which pisses off Sonic, who spin-dashes into Mecha, leaving the Scrapnik, who was about to be torn to shreds, surprised.

I really love the reaction Sonic has in the upper panel. It is not because he’s trying to protect them (although that’s part of it), but because he sees the Scrapniks as his friends. If you mess with his friends, you have to deal with him; and he’s furious.

During their race, it becomes clear that Sonic still can’t run properly because of his injured leg, describing it as being stabbed by thousand needles. However, he still pushes through, despite the agony he feels. Mecha then suddenly asks him what he even knows about pain, saying how what Sonic is feeling is nothing compared to what Mecha went through.

Unlike Sonic, he has been cast aside, robbed of his purpose, and while Sonic may have defeated him last time, he’s now completely alone and injured.

“You’ve reached your limits.”

“Ah. But see. That’s the thing about limits... they’re meant to be broken!”

Despite visibly sweating and being in pain, Sonic smiles through, accelerating his speed, much to Mecha’s shock and they speed right over the conveyor belts that lead to an active furnace. Honestly, I’m not surprised that this is happening. Sonic has a strong willpower and he’s determined enough to power through anything. We all saw what happened in Sonic Frontiers.

We see the two fighting, with Sonic still struggling, but he’s doing his best. Also, why is this slowly giving me Toy Story 3 vibes?

Sonic manages to catch Mecha off guard, kicking him in the face and shattering the brace the Scrapniks made for him, and Mecha falls into the scrapped metal, bested by Sonic once again. During his fall, we see a brief flashback to happier times, seen as friend and protector by the Scrapniks, shown love by those who care about him.

We also see his red eyes turn yellow as he lands. It seems as if his rage has vanished.

Sonic, seeing Mecha sinking into the pile of scraps that is going towards the furnace, calls out for him, telling to grab his hand, but Mecha swats it away.

Mecha tells Sonic that the cobalt hedgehog has the freedom to explore the world at his own leisure, unhindered by regret and and failure... and how that must be nice. He says how this is what he deserves, how he failed both of his directives to beat Sonic as Eggman’s creation and protect the Scrapniks.

“I am a failure. I am worthless. I am trash...”

Hm, who does this scene remind me of...

Scrapnik Island, DON’T YOU DARE TO PULL A SONIC OVA ON ME! DON’T YOU DARE TO KILL OF MECHA SONIC!!!

Sonic appears to share the same sentiment as I do, because look at him! He is furious!

He just yells at Mecha to cut the crap and extends his hand, giving us this amazing speech:

“You give yourself value and purpose! No one else! You gotta live for you! That’s what it really means to be free! NOW TAKE! MY! HAND!”

Mecha stares, then lifts his hand and grabs Sonic. Wow,... just, this is pure awesomeness! This is Sonic at his best, inspiring people to make choices! There is no way he’s going to let Mecha just die like that! Not to mention, his speech isn’t just directed to Mecha, but to everyone. Hell, this is what he hoped to teach Surge and Kit, but we know how that one turned out.

Not only that, but it also applies to real life. We live in a world where it is easier to accept being told by other people what you can do and what you can’t do. We just conform to the masses. Sonic tells you to screw that option and live for yourself. It doesn’t matter what others think about you, but what you think about yourself. It is a really powerful message.

Sonic attempts to pull Mecha out, only to pause, with Mecha wondering what’s wrong. Sonic grins sheepishly, admitting that he may have overdid it with his foot and now he can’t move it.

Mecha’s reaction is priceless. You can just hear the “You gotta be kidding me?!” line as he notes how there was all this big talk and Sonic can’t even get them out. Sonic replies how he’s working on it. Absolutely hilarious!

Fortunately for Sonic, someone familiar grabs him.

It is Tails! Not only did he survive the fall, but also brought along Sigma and all of the other Scrapniks to form a chain-link line and pull Sonic and Mecha out of the furnace. Awesome job, guys!

Once they’re finally safe and sound, the Scrapniks and Sigma just hug Mecha, with Sigma apologizing for being unaware of his inner turmoil. It doesn’t matter, though, as Mecha is just happy to be surrounded by his friends and family.

Sonic and Tails observe the reunion, both happy, but... is Sonic crying? Yeah, he is! He’s crying! Sonic is legit crying!

Screw you, SEGA mandates!

Tails turns to him, surprised to see Sonic smiling and crying, but Sonic replies how those aren’t his tears...

They’re Mecha’s.

Honestly, I teared up during this page, because this is so heartwarming... and a great loophole around SEGA’s mandates. Yeah, sure Sonic can’t cry, so how about we say those were Mecha’s tears thanks to their mind link. That’s okay, but let’s be honest here, fans know that Sonic probably also shed a tear of his own during this scene.

So, all that is left is Tails removing Eggman’s programming from both Mecha Sonic and Mecha Knuckles (who seems to now behave like regular Knuckles, being aloof and all that), and Sigma and Mecha are thankful for their help, with Mecha finally being free to be his own person.

Have I already said how much I love this? Because I do!

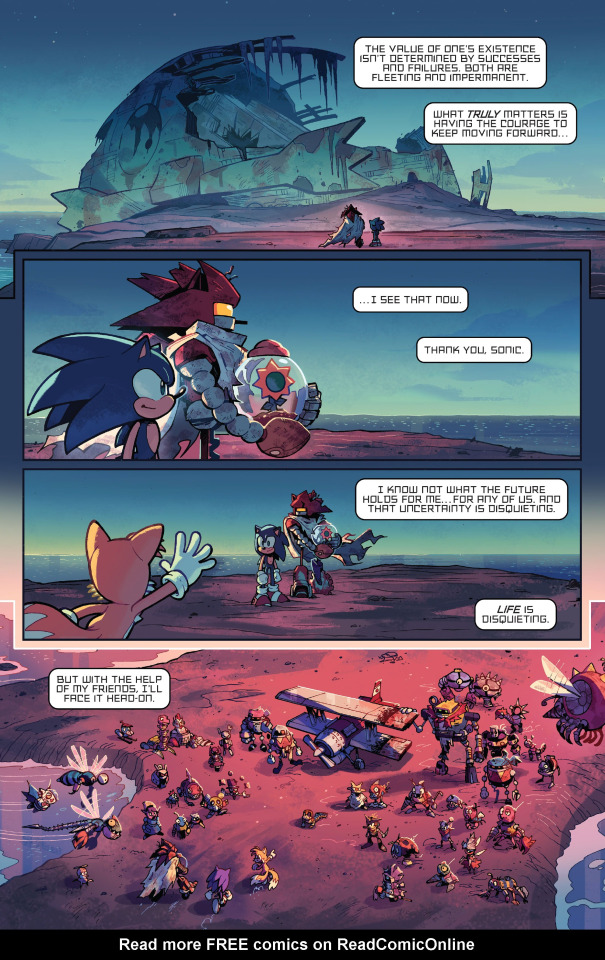

“The value of one’s existence isn’t determined by successes and failures. Both are fleeting and impermanent. What truly matters is having the courage to keep moving forward... I see that now. Thank you, Sonic.”

Okay, is it just me or does this really give off Pokémon: Mewtwo Strikes Back vibes? Because it does!

In any case, we see Mecha thanking Sonic for making him realize how he’s the one who gives himself value, holding the sunflower as they’re called over by Tails, Sigma and the other Scrapniks to the fixed tornado. Mecha notes how he has no idea what the future holds for him, but despite the uncertainty, he’s ready to face it head-on with the help of his friends.

As Sonic and Tails depart, bidding good-bye to their new friends, we are left with Mecha’s thoughts.

“I’m done being controlled by yesterday. I’m going to live for tomorrow.”

...

Damn, just damn...

THIS WAS AMAZING! SCRAPNIK ISLAND IS AMAZING!

The premise is so simple, but the message is incredibly powerful! I really hope we get to see Mecha Sonic, Sigma, Mecha Knuckles and the Scrapniks again. As a matter of fact, their presence could be linked with Belle’s decision to help abandoned Badniks. It’s just perfect!

This story is perfect and I hope we can get more stories like this one in the future.

Links:

#Previous Issue

#Next Issue

#Sonic the Hedgehog Analyzer (Masterlist)

#Sonic the Hedgehog Analyzer#sonic idw#scrapnik island#sonic the hedgehog#mecha sonic#dr eggman#scrapniks#e-117 sigma#metal sonic#sonic ova#miles tails prower#mecha knuckles

74 notes

·

View notes

Text

Undertale Orange Concepts

Okay, so, after binging every piece of content I could squeeze out of Undertale Yellow, I found myself inspired to write some concepts for a possible Undertale Orange game, and I sorta got carried away. Made an idea for the main character and the main antagonist, but still working on the rest. If y'all like it and wanna see more, tell me and I will continue to think really hard

My concept for a theoretical Undertale Orange named the human Jessie, which was derived from Gesture, because in the Photoshop Flowey fight, the healing attacks from Bravery was a thumbs up, a gesture of goodwill.

My concept for the main antag of Undertale Orange is named Masquerade (pronounced Masker Odd), a tall humanoid figure who wears a large tophat and an elegant black and white mask. He's a very enigmatic figure, and only appears when Jessie is alone. He's got a very vested interest in seeing them succeed and seems to be the only one who hasn't attempted to kill Jess. In fact, he was actually the one with the medical skills to patch Jessie up after their fall into the Underground, since the flowers hadn't grown in yet, so, they broke their ribs. When the player gets far into the game, they'll eventually see popular fiction books with a character who looks startlingly like Masquerade. Eventually, it's revealed Masquerade is a robot, the only successful one of many failed prototypes, of the character built by a mourning roboticist.

The roboticist's partner was the one who wrote the successful fiction book, and when they fell down, the roboticist was heartbroken and tried to replicate the characters to keep a vague legacy alive. Eventually, their lab was shut down when the Core had to expand to power the Underground, sorta taking over the lab for the Core's maintenance. Masquerade, however, was activated, and spent the first year of his life clawing his way out of the scrap heap of his clones. Upon learning the nature of his existence, he was stricken with a need to find a purpose, one he ripped pieces of from his fictional counterpart.

He was programmed to hunt humans, as that was the cause of the author's death, but he quickly grew to hate monsters as well due to his isolation and ostracization. He planned to goad the human (Jessie) into killing, thus sparking further tensions between humans and monsters, ensuring the war between the two species would never end, mutually assured destruction. So, he saved Jessie when they fell from above. If Jessie goes pacifist, he's pissed and tries to take matters into his own hands.

This leads to another character walloping him with a blast that breaks half of his mask, exposing the machinery and wiring. Then he engages them in combat, using physical attacks rather than magical ones, that way, Jessie can't just heal with some crummy food, instead inflicting serious actual attacks. Or, well, he would if he didn't get blasted into next week, damaging his body beyond repair. His wounded form inches off as the cast regroups, only for the Core to start heating exponentially. They know it's coming from the Robotics Lab that got assimilated into the Core, and pursue Masquerade there. He's plugged himself into the systems and has started to Overclock the Core. He explains that he alerted the citizens about the Human heading to the Core before he started heating it up. He aims to cause a full scale meltdown, Chernobyl level destruction, that would all be pinned on Jessie, which would cement humans as the enemies for good, at least, for whatever monsters remained.

There IS more for this concept and final confrontation stuff, but mainly just testing the waters to see if y'all like the direction it's going

13 notes

·

View notes

Text

The Dawn of Modern Construction: Machinery for Cement Wall Panels

As the construction industry strides into a future where efficiency, sustainability, and quality are paramount, the demand for innovative building solutions has never been higher. Cement wall panels, known for their durability, fire resistance, and excellent thermal insulation, are at the forefront of this revolution. The machinery to make cement wall panels is the unsung hero, enabling the mass production of this versatile building material and paving the way for modern construction methodologies.

The Evolution of Cement Wall Panels

Cement wall panels represent a significant advancement in building technology, offering a lightweight yet strong alternative to traditional bricks and mortar. These panels are composed of a mixture of cement, aggregate, and reinforcing fibers, which are cast in molds to create large, flat sheets. Once cured, these sheets can be used in both residential and commercial construction for walls, floors, and even roofs. The key to producing these innovative panels lies in the specialized machinery that automates the process, ensuring consistency, quality, and efficiency.

A Closer Look at the Production Machinery

The machinery involved in the production of cement wall panels is a marvel of engineering, designed to streamline the manufacturing process from start to finish. The production line typically includes several key components:

Batching Plant: The journey of a cement wall panel begins at the batching plant, where raw materials (cement, sand, aggregates, and fibers) are accurately measured and mixed to create the concrete slurry.

Casting Machine: The slurry is then poured into molds. Advanced casting machines ensure the mixture is evenly distributed and compacted, eliminating air pockets and ensuring uniform density across the panel.

Vibration Table: To further compact the mixture and enhance the panel's structural integrity, the filled molds are placed on a vibration table. This process helps in achieving a smooth, flawless finish.

Curing Chamber: Once cast, the panels are moved to a curing chamber where controlled temperature and humidity conditions allow for the gradual hardening of the concrete. This stage is crucial for developing the panel's strength and durability.

Demolding and Trimming: After curing, the panels are carefully demolded. Any excess material is trimmed, and the panels are finished to the required size and shape.

Quality Control Station: Each panel undergoes rigorous testing to ensure it meets strict standards for strength, durability, and thermal insulation.

The Benefits Unleashed

The automation and precision provided by this machinery bring several benefits to the construction industry:

Efficiency: Automated production lines significantly reduce the time required to produce cement wall panels, enabling rapid construction and faster project completions.

Consistency: Machinery ensures each panel is produced to the same high standards, leading to uniform quality in construction projects.

Sustainability: Cement wall panels are known for their energy efficiency, contributing to greener buildings. Additionally, the production process minimizes waste, aligning with environmental sustainability goals.

Versatility: The ability to produce panels in various sizes and finishes allows for architectural flexibility, enabling creative and innovative building designs.

The Future of Construction

The machinery used to make cement wall panels is not just transforming the way buildings are constructed; it's redefining what's possible in modern architecture. As technology advances, we can expect further enhancements in production machinery, making cement wall panels even more efficient, sustainable, and versatile.

In conclusion, the machinery for producing cement wall panels is at the heart of a construction industry revolution. By enabling the mass production of this innovative building material, it opens up new possibilities for sustainable, efficient, and high-quality construction. As we look to the future, the role of this machinery in shaping our built environment will undoubtedly continue to grow, marking a new era in construction technology.

0 notes

Text

Vibrating Tables Supplier in Maharashtra

Vibrating Tables Supplier in Maharashtra:

Akshar Precast Industries Overview:

Akshar Precast Industries is a leading Manufacturer, Exporter, and Supplier of Vibrating Tablets in Maharashtra, India.

Established in 2018, specializes in the manufacturing of construction machinery.

We are offering Semi Automatic Fly Ash Brick Machine, Manual Bricks Making Machine, Block Making Machine, Paver Block Vibrating Table, Cement Brick Making Machine, etc.

Industries use vibrating tables as essential devices for consolidating and compacting materials.

These tables feature a flat surface that vibrates, generating a shaking or oscillating motion.

They find primary application in compacting materials such as concrete, granular soils, powders, and other bulk materials.

The vibrations aid in settling and removing air voids, resulting in a denser and more uniform product.

An electric motor equipped with an eccentric weight generates vibration, causing vibrations in the table.

Manufacturers can customize vibrating tables based on industry or application-specific requirements.

Customization may include variations in size, vibration frequency, and control mechanisms.

Applications of Vibrating Tables:

In the Concrete Industry, they eliminate trapped air bubbles and ensure proper compaction of concrete mixes for stronger products.

Casting and Molding industries achieve a smooth and uniform distribution of materials within molds.

Laboratories employ them for testing the compaction properties of different materials.

Geographical Coverage:

Akshar Precast Industries serves as a Vibrating Tables Supplier in Maharashtra Including Mumbai, Pune, Nagpur, Nashik, Vasai-Virar, Solapur, Bhiwandi, Amravati, Kolhapur, Akola, Latur, Jalna, Panvel, Navi Mumbai, Parbhani, Dhule, Nanded, Jalgaon, Ahmadnagar, Chandrapur Etc.

For detailed information and inquiries, please feel free to contact us.

Read the full article

#Ahmadnagar#Akola#Amravati#Bhiwandi#Chandrapur#Dhule#Exporter#ExporterofVibratingTables#India#Jalgaon#Jalna#Kolhapur#Latur#maharashtra#Manufacturer#Mumbai#Nagpur#Nanded#Nashik#NaviMumbai#Panvel#Parbhani#Pune#Solapur#Supplier#SupplierofVibratingTables#Vasai-Virar#VibratingTablesManufacturerinMaharashtra#VibratingTablesSupplierinIndia#VibratingTablesSupplierinMaharashtra

0 notes

Text

AAC Block Pricing Unveiled in Hyderabad

AAC blocks price in Hyderabad have emerged as a groundbreaking choice, presenting a plethora of advantages over conventional options. Hyderabad, a vibrant nucleus of progress, witnesses a burgeoning demand for AAC blocks owing to their unmatched attributes. In this all-encompassing exposition, we embark on a journey into the depths of AAC block pricing in Hyderabad, illuminating the myriad factors that influence their economic worth.

Top AAC Block Price in Hyderabad

The elemental constitution of AAC blocks encompasses a fusion of cement, fly ash, lime, gypsum, aluminum powder, and water. The availability and pricing dynamics of these raw materials wield a considerable sway over the ultimate cost of AAC blocks. In the labyrinthine maze of Hyderabad, the proximity to manufacturing bastions and the accessibility of raw materials emerge as pivotal determinants dictating prices.

The intricate tale of AAC block manufacturing unfurls against a backdrop of avant-garde technology and machinery. The labyrinth of energy expenditures, labor outlays, and overhead encumbrances incurred during the production saga intricately interlace to shape the overarching pricing schema. Manufacturers embracing cutting-edge facilities may proffer premium-grade AAC blocks at competitive price points, thereby sculpting the pricing landscape.

Best AAC Block price in Hyderabad

The undulating tides of market demand ebb and flow, exerting an indelible impact on AAC block prices In Hyderabad, a burgeoning bastion of construction fervor, galvanized by the relentless march of urbanization and infrastructure metamorphosis, the crescendo of demand invariably propels prices skyward. The capricious cadence of demand-supply dynamics orchestrates a symphony of pricing vicissitudes, with periods of fervent demand unfailingly precipitating price escalations.

AAC blocks are subject to exacting quality paradigms delineated by regulatory authorities. Blocks hewn in adherence to these benchmarks may command a premium owing to their peerless fortitude, resilience, and thermal enshrouding capabilities. Discerning consumers often bestow primacy upon quality over pecuniary considerations, thus elevating premium-grade AAC blocks to the zenith of preference.

Top 8-inch AAC Block Price in Hyderabad

The tribulations of transit loom large, casting a formidable shadow over the definitive price tag of AAC blocks. The calculus of transit expenses is contingent upon sundry factors such as the geographic span to the construction locus, the modalities of conveyance, and the logistical dexterity unfurled. Manufacturers strategically ensconced in proximity to arterial conduits of transit may proffer competitive pricing schemes to assuage the transit tribulations.

The 8-inch variant of AAC blocks emerges as a stalwart choice for construction endeavors necessitating robust structural integuments. The expanded expanse engenders augmented load-bearing prowess and thermal encasing propensities, rendering them eminently suitable for a panoply of applications. In Hyderabad's eclectic milieu, the pricing panoramas of 8-inch AAC blocks oscillate contingent upon the aforestated determinants.

Best 8-inch AAC Block Price in Hyderabad

The economic constellation of 8-inch AAC blocks in Hyderabad orchestrates a symphony of price permutations, with the spectrum typically spanning [insert price range]. It behooves one to acknowledge that the pricing tapestry may exhibit variegations across manufacturers predicated on considerations of quality, repute, and ancillary amenities proffered. Prudent customers are enjoined to canvass quotes from a multiplicity of suppliers to ensnare the most competitive pricing permutations.

Despite the incipient fiscal outlay, 8-inch AAC blocks furnish a vista of long-term economic equilibrium courtesy of their indomitable tenacity and energy parsimony. Their ethereal demeanor expedites swifter constructional denouements, thereby alleviating labor overheads and temporal exigencies. Moreover, the superlative thermal insulative attributes of AAC blocks precipitate diminished energy outflows over the lifecycle of the edifice, thereby connoting fiscal prudence.

Conclusion

In denouement, the elucidation of AAC block pricing in Hyderabad emerges as a sine qua non for stakeholders ensnared in the labyrinth of construction enterprises. By espousing a holistic cognizance of factors encompassing raw material dynamics, manufacturing modalities, market pulsations, quality benchmarks, and transit tribulations, stakeholders are poised to orchestrate informed decisions and procure superlative-grade AAC blocks at competitive price points.

Hyderabad embarks upon a trajectory of accelerated urban evolution, the clarion call for AAC blocks reverberates with heightened intensity, underscoring the imperativeness of unraveling pricing paradigms in the region.

0 notes

Text

AAC Block Plant in Hyderabad

AAC Block Plant in Hyderabad:

Excellent En-Fab Incorporation

Excellent En-Fab Incorporation, based in Ahmedabad, Gujarat, is a prominent player in India's Process and Construction Equipment Manufacturing Hubs.

Established in 2010, Excellent En-Fab is dedicated to supplying high-pressure autoclaves tailored for AAC (Autoclaved Aerated Concrete) block plants.

An AAC Block Plant is a specialized facility for manufacturing lightweight AAC blocks, a popular building material. It involves machinery for raw material processing, AAC slurry mixing and casting, and block cutting and curing.

AAC Block Production Process:

Raw Material Preparation: Precisely mix silica sand, cement, lime, and aluminum powder to form base materials.

Batching and Mixing: The mixture, along with water, is placed in molds.

Curing: Autoclaves cure blocks using steam and high pressure, creating air bubbles that impart lightweight and insulating properties.

Cutting and Shaping: After curing, cut blocks into various sizes and shapes as per project requirements.

Final Curing: Apply additional curing to strengthen the block structure.

Packaging: Finished AAC blocks undergo packaging for distribution.

Applications of AAC Blocks:

AAC blocks find application in diverse construction projects, including residential and commercial buildings, schools, hospitals, and industrial structures. Construction firms, builders, and developers utilize AAC block facilities for production.

Service Coverage in Hyderabad:

Providing AAC Block Plant in Hyderabad, Telangana, and various locations including Warangal, Nizamabad, Khammam, Karimnagar, Ramagundam, Mahbubnagar, Nalgonda, Siddipet, Miryalaguda, Suryapet, Jagtial, Bhongir, Kamareddy, Mancherial, Wanaparthy, and Jangaon.

Read the full article

0 notes

Text

Knife Gate valve manufacturer in Germany

Knife Gate valve manufacturer in Germany

Knife Gate valve manufacturer in Germany

Valvesonly Europe is one of the reputed Knife gate valve manufacturer in germany.

Valvesonly Europe is a leading manufacturer of Knife gate valves in Germany. A knife is used in a knife-shaped gate valve to cut through heavy liquid blockages. They come in larger sizes to make them easier to handle and are used in many processing operations. These valves are typically used to completely shut off fluid flow or to provide full flow when fully open.It's used by industries which deal with highly viscous fluids. Both manually and automatically controlling it are options. Because they offer high-quality valves without compromising quality, Valvesonly Europe is the ideal place to buy knife gate valves. Our knife gate valves are designed to perform well in harsh environments and with viscous, abrasive, and acidic fluids. These valves are incredibly lightweight and have excellent liquid pressure regulation capabilities. The chemical, mining, power, paper, and steel industries all generate viscous acidic sludge, and these substances can withstand and perform effectively in high temperatures. The stainless steel door can be fully opened and closed while being protected from corrosion by the regulated system of the knife gate valves.

An instrument with a blade known as a knife gate valve is used to cut through thick fluid blockages. The seat and wedge of a traditional gate valve could become clogged with stringy pulp, preventing flow. Knife gate valves seal the pulp by cutting through it with a sharp edge.

Industries that use Knife Gate Valve:

• Chemical industry

• Refineries

• Mining and Mineral process

• Power Plant

• Cement Industry

Types of knife gate valve:

• Unidirectional

• Bidirectional

• Slurry

• Through Conduit

Knife Gate Valves Have the Following Advantages:

• Their edges can immediately slice through thick fluids, making them useful in slurry applications.

• Knife Gate valves are available in huge sizes since large machinery and equipment are necessary for tasks.

• Slurry applications benefit from the usage of Knife Gate valves because its blades can quickly cut through dense liquids.

• Knife Gate valves are available in big sizes since businesses require large machineries and equipment.

Available materials: WCB, WC6, WCC, LCB, LCC, Cast iron, Ductile Iron, SS316, SS304

Size: 2" to 80"

Class: 150 to 300

Nominal Pressure: PN6 to PN40

Operation: Handwheel, Electric and Pneumatic Actuated, Gear operated

Ends: Wafer, Lug, Flanged

For more details visit here : https://www.valvesonlyeurope.com/product-category/knife-gate-valve/

0 notes

Text

Precision Machining Revolutionised: The WIDMA Story

With disruptive technologies, sustainability, productivity, and connectivity taking centre stage in the rapidly changing Industry 4.0 landscape, WIDMA emerges as a key player who goes above and beyond product delivery to build enduring relationships.

With a rich history that dates back to 1984, WIDMA began as the machine tool building branch of Kennametal in Bengaluru, India, and has since expanded to become a leader in the world of turnkey solutions and customised CNC machines for metal cutting.

The Method of WIDMA

Initially, WIDMA concentrated on high-precision machining operations. Currently leading the industry, the company provides a variety of semi-standard, standard, and customized machines to meet a wide range of machining needs. WIDMA's expertise is broad, ranging from small tools to large structural parts for the locomotive and general engineering industries.

Quality at Every Stage

The company's extensive manufacturing process demonstrates its dedication to quality. With over 40 highly qualified design engineers working for them in-house, WIDMA can handle all aspects of product development, from concept to design, assembly, and after-sales support. These experts work together harmoniously to deliver value that raises productivity and quality while setting the bar for manufacturing of the highest calibre.

Best-in-Class Facilities

WIDMA's impressive 75,000-square-foot state-of-the-art manufacturing facility is located in Bengaluru. ft., accommodating multiple squads under one roof. The assembly and application team, design team, manufacturing team, sales and engineering team, and service support staff are all housed in the facility. Advanced machinery such as CNC surface grinders, CNC cylindrical grinding machines, jig boring machines, and horizontal and vertical machining centres are responsible for the precision attained in the manufacturing of critical components.

Worldwide Installations

For more than thirty years, WIDMA has made a lasting impression on the world scene. Some of the biggest and most well-known global brands have praised the company's high-performing machines, which have installations in a variety of industries throughout the world. WIDMA's standing as the go-to partner for machining needs has been cemented by its capacity to provide customized solutions.

Complete Fixture Providers

WIDMA's expertise in machine building, tooling solutions, and process knowledge is demonstrated by its ability to provide turnkey fixture solutions for machining centres. The organization has effectively implemented more than 2500 turnkey fixture and tooling solutions throughout the world, serving a range of Horizontal Machining Centres (HMCs) and Vertical Machining Centres (VMCs).

WIDMA provides mechanical, pneumatic, and hydraulic fixtures in accordance with customer specifications. It also supports the complete manufacturing process, from casting to the final component. The team's proficiency encompasses ideation, design, production, assembly, testing, and installation, guaranteeing a smooth amalgamation with application assistance and component precision verification.

The process engineering team specializes in identifying machining operations, estimating cycle times, planning the manufacturing process for components, and choosing the required tools. They also conduct thorough studies. Working together with parent tooling company Kennametal guarantees accuracy in the cutting parameters.

Fixture Building Superiority

The business has easily evolved into a top option for manufacturers, suppliers, and machine tool manufacturers by utilizing its experience in machine building. The design team ensures precise and seamless execution by using the most recent 3D software for fixture design and modelling.

The fact that WIDMA can complete fixture projects for components up to six meters in length is noteworthy. Fixture elements, such as base plates and clamping elements, undergo stress analysis in order to maximize their design for the efficient handling of cutting forces.

The WIDMA advantage in fixtures includes:

1. In-depth knowledge of process engineering

2. Turnkey fixture-tooling solutions for machining centres

3. Integration of fixtures with automation

4. Additional functionalities such as machine interfacing and programming

5. Support for machine accessories like hydraulic power packs and air-catch sensors

6. Application engineering and service support

Drilling machines of the BTA (BTH Series)

WIDMA presents its BTA Drilling Machines, namely the BTH Series, in the field of deep hole drilling. These devices, which are robustly designed and built for speed, mark a breakthrough in accuracy and productivity. WIDMA's BTA machines are prepared to take on the challenges posed by the industry's increasing demand for drilling solutions that are more dependable and expedient.

Hob Sharpeners: A Redefining of Precision

WIDMA's Hob Sharpeners round out the three essential products. These sharpeners redefine accuracy in hob cutting at a time when accuracy is critical. Whether in general engineering, automotive, or aerospace, WIDMA's Hob Sharpeners raise the bar for hob machining and guarantee the best possible gear production.

Innovation, accuracy, and a dedication to client satisfaction have characterized WIDMA's transition from a division that built machine tools to a worldwide leader in machining solutions. WIDMA continues to shape the future of precision machining with its turnkey fixture solutions, BTA drilling machines, and hob sharpeners, offering solutions that not only meet but surpass the expectations of its international clientele.

WIDMA is a shining example of excellence in a time when every cut counts. In addition to providing goods, the company builds enduring relationships and shapes the future of Industry 4.0.

0 notes

Text

Mapping Out India’s Future: The Road-Building Giant with Big Plans Ahead

As India continues its remarkable economic emergence, ambitious infrastructure projects are laying the foundations for sustainable nationwide growth. Leading the charge in connecting India through world-class road infrastructure is VRC Constructions — India’s biggest road construction company.

Connecting India Through Infrastructure

Quality highways form the arteries that pump life into a nation’s economy by enabling seamless people-to-people connections and freight movement. As a critical player executing India’s infrastructure vision, VRC Constructions undertakes end-to-end development of national and state highway projects of all sizes and complexity levels.

Over the past 27 years, we have led the construction of thousands of highway roads across varied terrains — from dense urban spaces to treacherous mountain passes. Its projects include infrastructure wonders like the 6-lane Greenfield highway from Deogarh to Rajasthan/Gujarat Border, Four Lane Road Transport and Highway from Tallewal-Barnala, and Four Laning Highway from Rohtak-Jind Section of NH-71 Highway network spanning 6000+ km across India.

Equipped with advanced construction equipment and patented innovations for faster project turnaround, VRC builds over 2000 km of roadways annually. It has earned many accolades for its expertise in pre-cast construction technology, sustainable materials, and quality benchmarks. Our commitment to building vital roads and highways makes us one of the top 10 road construction companies in India.

We make a substantial contribution to economic growth by promoting smooth mobility and improving connections between urban and rural areas. Our programmes aim to save travel time while also creating new opportunities for trade, economics, and cultural interaction.

Ambitious Roadways for an Emerging Economy

As India invests thousands of crores to develop world-class road infrastructure and put itself on the global map, VRC Constructions is geared to move ahead.

With visionary leadership focused on innovation, we build roads specifically engineered for Indian conditions — extreme weather events, heavy traffic loads, and tricky urban constraints.

As the best road construction company in India, we are pioneering improved financing models and public-private partnerships to expand funding avenues for India’s infrastructure vision.

Strategic partnerships with leading international infrastructure majors have honed VRC’s project management expertise. Large-scale capacity expansion via new machinery, construction camps, and a growing skilled workforce cement our position among the top 10 road construction companies In India. We also incubate innovation by running a state-of-the-art R&D facility for greener construction materials and methods.

Building National Highways Network — Arteries for Growth

The Six Lane Greenfield highway from the Sangaria-Rasisar project set the foundation for connectivity between the Amritsar-Jamnagar Economic Corridor. This expressway will significantly reduce travel time and improve connectivity between major cities and industrial corridors. The Bharatmala Pariyojana is an initiative by the Indian government to upgrade the national highway network, and the Amritsar-Jamnagar Economic Corridor is a crucial aspect of it. This project will enhance road connectivity and promote economic growth in the area.

Under the National Highways network’s next phase, over 50,000 km, VRC Constructions will undertake critical links connecting lagging regions with major economic zones. These strategic highways serve as catalysts for unlocking hinterland prosperity by enabling more effortless movement of goods and labor.

For example, the Four Laning Highway Rohtak-Jind highway built by VRC Constructions drastically reduced travel time between crucial Haryana cities. After its launch, regions adjoining this 4-lane highway have witnessed over 30% rise in local commerce and mobility.

Multifold projects like these by India’s biggest road construction company are bridging rural-urban divides across states — strengthening domestic supply chains and enabling equitable development nationwide.

Source Link: https://vrcgroup.in/the-road-building-giant-with-big-plans-ahead/

Boost Your Online Presence with Free Backlinks

https://qr.ae/pKOHgP

http://forum.dbaclass.com/question/can-you-recommend-a-reliable-mall-construction-company-in-india/

https://startuppoint.copiny.com/question/details/id/789321

https://praktik.copiny.com/question/details/id/789322

https://www.pawnplusnorman.com/question/can-you-recommend-a-reliable-mall-construction-company-in-india/

https://butik.copiny.com/question/details/id/789323

https://questionsweb.in/question/can-you-recommend-a-reliable-mall-construction-company-in-india/

https://docs.gifs.com/discuss/6572ed9f13280e007a3593a0

https://loginza.copiny.com/question/details/id/789324

https://legalforms.ng/ask-a-lawyer/question/can-you-recommend-a-reliable-mall-construction-company-in-india/

https://www.buzzbii.com/vrcconstructions

http://riosabeloco.com/User-Profile/userId/210546

https://doodleordie.com/profile/vrcconstructions

https://unsplash.com/@vrcconstructions

https://startupxplore.com/en/person/vrcconstructions

https://paperdoor.in/user/profile/35368

https://soundcloud.com/vrc-group

https://developer.cisco.com/user/profile/ebc0a796-17e2-5d09-ac96-752d717d19dd

https://europe-jobs.eu/index.php/profile-1932834

https://lichess.org/@/vrcconstructions

https://www.locanto.ae/by/vRC760121/33c20e/

https://uconnect.ae/vrcconstructions

https://www.dogforum.com/members/vrcgroup9.254601/#about

http://molbiol.ru/forums/index.php?showtopic=1055416

https://www.ambercutie.com/forums/members/vrcconstructions.78683/#about

https://www.redbubble.com/people/vrcgroup9/shop?asc=u

https://artscardsindianapolis.mn.co/posts/46071711

https://aspiringexecutives.mn.co/posts/46071826

https://forum.openbadania.pl/memberlist.php?mode=viewprofile&u=260399

https://www.medicinacinesenews.it/forum/memberlist.php?mode=viewprofile&u=3041418

https://www.aleviforum.com/forums/thread/255/

https://medium.com/@vrcgroup9/transforming-dreams-into-reality-in-indias-real-estate-landscape-412070399bac

https://diy-vision.mn.co/posts/44366529

https://freedomlifestyle.mn.co/posts/44366581

https://qr.ae/pKyDZ9

https://secrets-of-our-city.mn.co/posts/44366596

http://molbiol.ru/forums/index.php?showtopic=1049973

https://pub18.bravenet.com/forum/static/show.php?usernum=1462320821&frmid=8211&msgid=1978697&cmd=show

https://pub2.bravenet.com/forum/static/show.php?usernum=151201847&frmid=768&msgid=922232&cmd=show

https://jobs.newsadvertiser.com/profiles/3876012-vrc-constructions

0 notes

Text

Stainless Steel Casting Machine Tools Component

Stainless steel casting has revolutionized the world of machine tools, providing components with unmatched durability and precision. In the realm of manufacturing, the quality of machine tools directly impacts efficiency and productivity. Let's delve into the realm of stainless steel casting for machine tools and explore why it stands out in the industry.

The Advantages of Stainless Steel Casting

When it comes to crafting machine tool components, stainless steel casting offers a myriad of advantages. The inherent durability and longevity of stainless steel make it an ideal choice for components subjected to high stress and wear. Additionally, its resistance to corrosion ensures a longer lifespan for the machine tools.

Applications of Stainless Steel Casting in Machine Tools

Stainless steel casting finds diverse applications in the production of machine tools. From crafting cutting-edge cutting tools to intricate molds and dies, the versatility of stainless steel enhances the functionality of various machine components. Moreover, it plays a crucial role in constructing stable machine bases and frames.

Quality Assurance in Stainless Steel Casting

Ensuring the quality of stainless steel casting involves meticulous inspection processes, careful material selection, and precision machining. Manufacturers adhere to strict standards to guarantee that each component meets the required specifications, contributing to the overall reliability of the machine tools.

The Role of Stainless Steel in Machine Tool Efficiency

The use of stainless steel in machine tools significantly improves efficiency. Its resistance to wear and tear, even in challenging conditions, means reduced maintenance and downtime. The enhanced performance of machine tools directly translates to increased productivity and cost savings for businesses.

Innovations in Stainless Steel Casting Technology

Recent advancements in stainless steel casting technology have propelled the industry forward. The integration of advanced casting methods and digital technologies allows for more intricate designs and customization. Manufacturers can now meet specific requirements with unprecedented precision.

Economic and Environmental Benefits

Opting for stainless steel casting brings about economic benefits in the long run. While the initial costs may be higher, the longevity and reduced maintenance requirements result in substantial savings over time. Additionally, stainless steel is highly recyclable, contributing to environmentally friendly manufacturing practices.

Challenges in Stainless Steel Casting for Machine Tools

Despite its numerous advantages, stainless steel casting for machine tools comes with its set of challenges. Complex designs may require specialized skills, leading to higher labor costs. The initial investment can also be a barrier for some manufacturers. Overcoming these challenges requires a strategic approach to reap the full benefits of stainless steel casting.

Case Studies: Successful Implementations

Examining real-world examples of industries successfully implementing stainless steel casting in machine tools provides valuable insights. From aerospace to automotive, the positive impact on machine performance and reliability is evident. These case studies serve as testaments to the effectiveness of stainless steel casting.

Choosing the Right Stainless Steel Alloy

Selecting the appropriate stainless steel alloy is crucial for the performance of machine tools. Factors such as the application, environmental conditions, and required durability influence alloy choices. Manufacturers must match the specific requirements of machine components with the suitable stainless steel alloy to ensure optimal performance.

Future Trends in Stainless Steel Casting for Machine Tools

The future of stainless steel casting in machine tools holds exciting possibilities. Integration with smart technologies, a focus on sustainable practices, and evolving industry standards are shaping the trajectory of the industry. Staying abreast of these trends is essential for manufacturers aiming to stay competitive in the market.

Customer Testimonials

Real-world experiences with stainless steel casting provide valuable insights into its impact on machine tools. Customers across various industries attest to the improved efficiency, longevity, and overall performance of machine tools equipped with stainless steel components. These testimonials serve as compelling endorsements for the reliability of stainless steel casting.

Comparative Analysis with Other Materials

To understand the full scope of stainless steel casting, it's essential to compare it with other materials commonly used in machine tools. Analyzing the strengths and weaknesses of stainless steel in comparison to alternatives helps manufacturers make informed decisions about material selection.

Maintenance Tips for Stainless Steel Machine Tools

Proper maintenance is crucial for maximizing the lifespan and performance of machine tools with stainless steel components. Regular cleaning, timely inspections, and effective lubrication practices are key to preventing issues and ensuring smooth operation. Addressing minor issues promptly can prevent major breakdowns and extend the life of the machine tools.

Conclusion

In conclusion, stainless steel casting has emerged as a game-changer in the realm of machine tools. Its unparalleled durability, precision, and resistance to corrosion make it the material of choice for manufacturers aiming for top-notch performance. As industries evolve, the role of stainless steel casting in shaping the future of machine tools is undeniable.

#RP Alloys & Steel Forgings#Machined Stainless Steel Cast Parts#Cast Components#Cement Machinery Cast#Steel Parts#Stainless Steel Casting#Aotomotive Steel Machined Casting Parts

0 notes

Text

Title: Beyond Hard Hats: Unleashing the Power of Branding in the Construction Sector

For those operating in the bustling construction sector, the storyline often orbits around heavy machinery, rolled blueprints, never-quenching cement mixers and omnipresent hard hats. While these elements painstakingly shape our towering structures, we need to also capitalize and emphasize on another dimension of the construction industry, often under-explored: Branding.

More than a buzzword, branding is an invaluable asset, a trust-building mechanism, and an unspoken contract between your business and its potential customers. It is a layered narrative reflecting your company’s ethos, service quality, and business aspirations.

The construction sector is no exception to this pivotal business element. At first glance, construction may not appear to be a sector where branding holds much water. Often, the logistical nature of the industry casts a shade on the importance of a strong brand. Yet, it's precisely because of this operational focus that there's immense untapped potential for brands to differentiate themselves and potentially dominate.

Branding in construction weaves itself into all aspects of your firm- from the way your front office staff interact with clients, to the professionals managing your construction sites. A strong brand can pull you ahead in the competitive race, helping you command a higher premium and establish meaningful partnerships.

Successfully branded construction companies are not defined by their size; instead, they are marked by their recognition. Consider the impact of a Bechtel, Balfour Beatty, or Vinci. The very mention of these names brings certain qualities to mind - reliability, technical excellence, and ethical practice, all hallmarks of a strong brand.

Good branding goes beyond just well-designed logos and catchy taglines. It permeates each part of a company, from corporate culture to customer communication. The right brand positioning can paint your construction company as reliable and predictable, a trait highly revered in an industry often beset with project delays and cost overruns.

Companies in the construction sector can enhance their reputation by consistently delivering on promise, and aligning their service with what their brand's image represents.

An effective brand also aids in winning contracts. Whether for small residential remodeling or large-scale infrastructure projects, clients appreciate and trust a company with clear, consistent branding. Decision makers often cite firm’s reputation, which stems from its branding, as the primary factor in awarding contracts.

Branding also drives employee satisfaction and fosters a sense of pride. Employees are more likely to stay with a company that resonates with them beyond their paychecks.

Current market conditions are reshaping the business landscape at an incredible pace. More and more clients are placing value not just on the quality of work, but also on the quality of interaction and values that the contractor intends to bring to the table. Putting forth a strong, consistent brand ensures your construction company isn't just viewed as a provider of a commodity service, but is seen as a valuable partner in your client's endeavors.

As construction entrepreneurs, we must look beyond our hard hats and machinery, and realize that our company name carries substantial weight. From your business cards to your project boards, every little detail coalesces to form an image of what you stand for. In a reality where perception often is reality, investing in branding can be your concrete step towards solidifying your stature in the construction sector.

Unearth the potential of your brand’s hammer and chisel- let them sculpt a story, an experience, and a promise that echo louder than the vibrant hum of your construction sites.

Finally, remember that branding in the construction sector is not a sprint; it's a painstakingly constructed infrastructure akin to our monumental projects.

It requires both the precision of an architect and the patience of a mason. So strap on your hard hat, pick up your branding tools, and start building. You are nearer to breaking ground on your firm’s reputation than you think.

The construction industry has for a long time focused heavily on the practical aspect of the business: building robust, durable structures. Immersed in a world of blueprints, hard hats, and heavy equipment, many construction firms have not always fully embraced the power of marketing, more specifically, branding. "Beyond Hard Hats: Unleashing the Power of Branding in the Construction Sector," examines how much more than just the physical aspects of construction a company’s brand can encompass.

Think about this. Brands like Caterpillar and Komatsu don’t just sell construction machinery; they sell a promise of reliability, durability, and top-notch performance. That is the power of branding; it transcends the tangible to create an emotional connection with the customer. Let's delve into how construction companies can harness this power.

_Be Consistent in Messaging_

Consistency is the key to establishing a strong brand. Consider Turner Construction Company, one of the leading construction firms in the US. Their consistent message of being committed to “Building the Future” underscores everything they do and is deeply ingrained in their brand. It infuses their promotional items, external communications, and even how they handle their daily operations on-site. When you consistently reinforce your message, you not only become more memorable but also build customer trust and loyalty.

_Embrace Digital and Inbound Marketing_

The rise of the digital era meant traditional ways of marketing were no longer enough. Thankfully, the construction industry is starting to keep pace. For example, UK-based construction company Balfour Beatty used twitter to solicit feedback, suggestions, and ideas from the public before embarking on a high-profile construction project. By leveraging digital marketing, Balfour Beatty not only improved its brand visibility but also established itself as a community-centric brand.

Additionally, construction companies can employ inbound marketing techniques such as SEO optimized blogs containing valuable information for potential clients, email newsletters, and informative videos. These strategies draw clients towards your brand rather than you chasing after them.

_Build a Robust Online Presence_

Today, more than ever, an impactful online presence is crucial. This includes having an engaging, easy-to-navigate, and informative website. Hensel Phelps, a renowned construction firm, adopted virtual reality in their operations, giving clients a unique, realistic view of prospective projects. Their website is interactive and inviting, providing clients everything they need at their fingertips. Such robust online presence not only bolsters your credibility but also makes it easier for potential clients to find you.

_Humanize Your Brand_

Behind every construction project is a team of dedicated professionals. Showcasing these individuals and their stories helps humanize your brand. DPR construction does an excellent job of this. On their website, you will find a section dedicated to profiling their employees and the unique skills they bring on board.

In conclusion, the construction sector has traditionally been viewed as a tough, no-nonsense industry. However, powerful brands like Caterpillar, Balfour Beatty, and Turner Construction Company have shown that integrating effective marketing strategies into their operations can yield significant returns. By consistently delivering your brand message, harnessing the power of digital marketing, building a robust online presence, and humanizing your brand, you, too, can make a disruptive impact on this sector. So, let’s ditch the hard hats, at least in marketing terms, and unleash the full potential of branding in the construction industry.

0 notes

Text

Your Trusted Sodium Silicate Supplier in India

In the world of industrial chemicals and compounds, sodium silicate holds a significant place due to its versatility and wide-ranging applications. Whether you're involved in manufacturing, construction, or various other industries, having a reliable Sodium Silicate supplier in India is crucial. One name that stands out in this domain is the Sudarshan Group.

About Sudarshan Group

The Sudarshan Group is a renowned conglomerate in India with a rich legacy spanning decades. Established with a commitment to excellence, innovation, and customer satisfaction, the group has diversified its operations across various industries. We have earned a reputation for delivering top-notch quality products and services, and our sodium silicate division is no exception.

Sodium Silicate: A Versatile Industrial Compound

Sodium silicate, often referred to as "liquid glass," is a compound derived from sodium carbonate and silica. It comes in various forms, including solid and liquid, and is widely used across industries for its diverse applications. Sodium silicate is known for its remarkable properties, including:

1. Binding Strength:

Sodium silicate acts as an excellent adhesive, cementing agent, and binder in various applications such as foundry casting, construction, and manufacturing of detergents and soaps.

2. Corrosion Resistance:

In the automotive and machinery industries, sodium silicate is used to prevent rust and corrosion by forming a protective layer on metal surfaces.

3. Fire Resistance:

Due to its fire-resistant properties, sodium silicate finds use in the manufacturing of fire-resistant materials, including firebricks and fireproof textiles.

4. Water Treatment:

Sodium silicate is a key component in water treatment processes, aiding in the removal of impurities and heavy metals from water.

5. Detergent Manufacturing:

It plays a vital role in detergent production, where it acts as a surfactant and builder, enhancing the cleaning capabilities of detergents.

Why Choose Sudarshan Group as Your Sodium Silicate Supplier?

1. Quality Assurance:

At Sudarshan Group, quality is of paramount importance. We adhere to stringent quality control measures to ensure that our sodium silicate products meet or exceed industry standards. This commitment to quality has earned us the trust of clients across various sectors.

2. Customized Solutions:

Sudarshan Group understands that different industries have unique requirements. We offer a range of sodium silicate products tailored to meet the specific needs of your business. Whether you need a particular grade, concentration, or packaging, we can provide customized solutions.

3. Sustainability:

The Sudarshan Group is committed to environmental sustainability. Our sodium silicate manufacturing processes are designed to minimize environmental impact while maintaining the highest product quality. By choosing us as your supplier, you're making an eco-conscious choice.

Industries Served

Sudarshan Group's sodium silicate products cater to a wide range of industries, including:

1. Foundry and Casting:

Our high-quality sodium silicate binders are integral in foundry casting processes, ensuring precision and durability in metal casting.

2. Construction:

Sodium silicate is used in construction as a concrete sealer, admixture, and binder for specialized applications.

3. Detergent and Soap Manufacturing:

The detergent industry relies on Sudarshan Group's sodium silicate to enhance the cleaning power of our products.

4. Water Treatment:

Municipalities and industrial facilities trust our sodium silicate for effective water treatment and purification.

5. Automotive and Machinery:

Sudarshan Group's sodium silicate helps protect metal surfaces from corrosion in the automotive and machinery sectors.

ConclusionIn the dynamic landscape of industrial chemicals, having a trusted sodium silicate supplier in India is essential for the success of your business. The Sudarshan Group, with its unwavering commitment to quality, customization, sustainability, and technical support, emerges as a leader in this space. Our diverse range of sodium silicate products serves numerous industries, making us the go-to choice for businesses across India. Partner with the Sudarshan Group, and experience the difference that a reliable and quality-focused supplier can make in your operations.

0 notes

Text

Leading Transformer Manufacturers Energizing the Global Energy Demand

Originally Published on: SpendEdge |Top Transformer Manufacturers Powering the World’s Energy Needs

A transformer is a piece of electrical equipment that uses the electromagnetic induction principle to transfer electrical energy between two or more circuits. It is a crucial piece of machinery that effectively distributes power throughout the electric grid. Power is generated at a low voltage in modern power plants, and step-up transformers are used to raise the voltage so that it may be transmitted across long distances with little loss. The voltage is then lowered before being distributed to homes and businesses using a second step-down transformer. According to usage, the four main types of transformers are power transformers, distribution transformers, measurement transformers, and protection transformers. The demand for transformers is anticipated to be driven by the quick expansion of power generating and distribution projects in the APAC region. Utility firms are buying products from transformer manufacturers to replace their outdated transformers with more recent models. The market appears to be lucrative for manufacturers of transformers.

Top Manufacturers of Transformers

Siemens

One of the biggest industrial manufacturing companies in Europe is a German multinational company by the name of Siemens. Siemens provides services to the following sectors: cranes, cement, pharmaceuticals, mining, oil and gas, chemical, automotive, aerospace, and automobile. The firm, which is among the biggest transformer producers, has items for every output and voltage. In addition to adhering to EU standards and rules, the company creates its products with environmental sustainability and efficiency in mind. The company sells a variety of goods, including power transformers, reactors, phase-shifting transformers, HVDC transformers, distribution transformers, and tractional transformers.

GE

Energy SE banner Square (002)connections, digital, oil and gas, renewable energy, transportation, electricity, and healthcare are just a few of the industries that GE serves. It conducts business as a provider of infrastructure and technology. Additionally, it provides transformer-equipped solutions for gas and steam power systems. As one of the most effective transformer producers, GE asserts that its products are among the most efficient on the market thanks to additional features and compliance with the DOE 2016 efficiency standard. The company essentially divides its transformers into the following categories: control power core and coil, secondary substation, power, and distribution. Dry type vented, dry type non ventilated, dry type encased and enclosed.

ABB

Robotics, electricity, and automation services are the main areas of focus for the international firm ABB. It offers tools and equipment for utilities, electrification of transportation, and power networks. Additionally, it creates circuit breakers, medium voltage switch gears, and measuring and sensing devices to keep track of energy usage. One of the top producers of transformers is ABB, which offers both liquid-filled and dry-type transformers as well as full life-cycle support, including replacement parts and components.

Heavy Industries Hyundai

One of the top heavy industries in the world is Hyundai Heavy Industries. In addition to offshore and engineering, industrial plant and engineering, and engine and machinery areas, it has expanded outside shipbuilding. Power transformers made by the company satisfy customer needs thanks to cutting-edge design and technology. A cast resin transformer, an oil-immersed transformer, a dry-type transformer, and a unique type transformer make up their product line.

TBEA

Electric power transmission and generating are two sectors in which TBEA works. Transformers, HV switches, wires, and cables are just a few of the items it manufactures and distributes. All of its projects have a combined yearly production capacity of more than 200 million kVA. Under its new energy business area, it also offers inverter and energy solutions for the design, construction, debugging, operation, and maintenance of photovoltaic electric and wind power plants. The business offers high-voltage transformers ranging from 110kV to 800kV and was also one of the first transformer manufacturers in China.

Consult Our Experts

0 notes

Text

Finding The Best Ready Mix Concrete Near You: Convenience And Quality Assurance

Diving headfirst into the ocean of construction materials can be a daunting endeavor, particularly when your project demands something as ubiquitous yet mystifying as concrete. However, armed with the keyword "ready mix concrete near me," you're now on the path to uncovering the convenience and quality assurance offered by these local ready-mixed concrete providers.

Delving Deeper: Ready Mix Concrete Uncovered

Sifting through the complex strata of construction materials, we land on the intriguing world of ready mix concrete. This pre-made concoction of cement, aggregates, and water, carefully calibrated for specific tasks, provides consistency and saves valuable time on job sites. From casting sturdy home foundations to creating intricate architectural elements, its versatility is unquestionable.

On Your Doorstep: The Convenience Of Local Sourcing

When you key in "ready mix concrete near me" into your preferred search engine, you're tapping into the essence of local sourcing. Imagine the convenience - no more fretting over logistics, delays, or damaged products during transit. This is particularly handy when unforeseen circumstances necessitate additional supplies. And speaking of supplies, this brings us to another key component in your construction arsenal.

Complementing Concrete: Supplementary Supplies Nearby

Complementing your concrete mix with other essential elements is pivotal for a successful project. Secondary supplies range from reinforcement materials to finishing tools, and finding a local source – by searching "concrete supplies near me" - simplifies the construction process considerably.

Safe Thaw: A Consideration For Concrete Maintenance

While we're on the subject of concrete, it's worthwhile noting that maintenance, especially in colder climes, is as crucial as choosing the right ready mix. Safe Thaw, a non-toxic, chemical-free ice melt perfect for industrial use, is the ace up your sleeve in this regard. Its gentle yet effective formulation doesn't harm machinery or the concrete itself, making it an ideal choice for de-icing concrete driveways and sidewalks.

Take Heed: A Gentle Reminder

A disclaimer for the enthusiastic: if your concrete is younger than 12 months, it's advisable to hold back from applying any ice melt, even Safe Thaw. Young concrete is susceptible to damage from freeze-thaw cycles, so it's crucial to let it mature before introducing de-icing agents.

Bringing It All Together: Achieving Success With Concrete

With a mindful approach and informed decisions, managing a construction project can be less intimidating. Remember, local sourcing with "ready mix concrete near me" and "concrete supplies near me" saves you valuable time and effort. Paired with the conscientious use of maintenance products like Safe Thaw, you are setting the stage for a successful and long-lasting construction endeavor.

Read the full article

0 notes

Text

The Journey of Materials through Concrete Batching Plants

Concrete is the backbone of construction, forming the very foundation of our modern infrastructure. Behind every successful concrete structure lies a well-designed and meticulously executed concrete batching plant. Nilkanth Engineering Works, a leader in construction machinery, brings you a detailed insight into the journey of materials through their advanced concrete batching plants. Join us as we unravel the intricate process that transforms raw ingredients into the sturdy structures that shape our world.

The Ingredients of Concrete

Before we dive into the journey, let’s understand the crucial ingredients that make up concrete: cement, aggregates (such as sand and gravel), water, and additives. The precise measurement and mixing of these components lay the foundation for high-quality concrete.

Step 1: Batching

The journey begins with batching – the process of measuring and combining the ingredients in the right proportions. Nilkanth Engineering Works’ batching plants feature state-of-the-art control systems that ensure accuracy in weighing and proportioning. This precision guarantees consistent quality in the final concrete mix.

Step 2: Mixing

Once the ingredients are accurately measured, it’s time for the magic of mixing. Nilkanth Engineering Works’ batching plants are equipped with advanced mixers that thoroughly blend the components, resulting in a homogenous mixture with optimal strength and durability. The mixers are designed to cater to various concrete types, from regular to special mixes.

Step 3: Storage and Conveyance

After the mixing process, the freshly prepared concrete needs proper storage and efficient conveyance. Nilkanth Engineering Works offers solutions that include cement silos for storage and conveyors or belt systems for transporting the concrete to its destination. These systems maintain the integrity of the mix and ensure timely delivery.

Advertisement

Step 4: Quality Control

Nilkanth Engineering Works understands the importance of quality control at every stage. Their batching plants are equipped with advanced monitoring systems that track factors like mixing time, temperature, and consistency. This real-time data helps maintain the desired concrete properties and allows for adjustments if needed.

Step 5: Pouring and Casting

With the concrete mix primed for use, it’s time for pouring and casting. Nilkanth Engineering Works’ solutions cater to various application methods, whether it’s through transit mixers for large construction sites or mobile units for smaller projects. This adaptability ensures the right concrete is delivered to the right place, at the right time.

Step 6: On-Site Production Advantages

Nilkanth Engineering Works’ mobile Concrete batching plants offer on-site concrete production, reducing transportation costs and delays associated with ready-mix delivery. This approach allows for greater project flexibility and efficiency, especially in remote or rapidly changing construction sites.

Conclusion

The journey of materials through Nilkanth Engineering Works’ concrete batching plants showcases the company’s commitment to precision, innovation, and quality. From accurate batching and thorough mixing to efficient storage and delivery, their solutions streamline the process of turning raw materials into strong, durable concrete structures. As construction continues to evolve, these advanced batching plants play a pivotal role in shaping the world around us, one solid foundation at a time.

#concrete batching plant#concrete batching plant in India#Best concrete batching plant#concrete batching plant in Gujarat#concrete batching plant for sale#compact concrete batching plant#mobile concrete batching plant

0 notes