#concrete batching plant in Gujarat

Text

Selecting Your Best Concrete Batching Plant Manufacturer

Concrete batching plants are the backbone of any construction project, ensuring that the right mix of concrete is delivered efficiently and consistently. When you’re in the market for a concrete batching plant, choosing the right manufacturer is a critical decision. Nilkanth Engineering Works, a renowned name in the industry, offers a wide range of batching plants to meet your construction needs. In this blog, we’ll guide you through the process of selecting the best concrete batching plant manufacturer, with a focus on Nilkanth Engineering Works.

1. Assess Your Needs

Before diving into the search for a manufacturer, it’s essential to assess your specific requirements. Consider factors like the type of construction projects you undertake, the volume of concrete needed, and any special features or requirements you have. This initial assessment will help you narrow down your options when choosing a batching plant manufacturer.

2. Research the Manufacturer

When considering Nilkanth Engineering Works or any other manufacturer, extensive research is key. Look for reviews and testimonials from other construction professionals who have used their products. Investigate the manufacturer’s history, reputation, and track record for quality and reliability.

3. Product Range and Customization

Nilkanth Engineering Works offers a diverse range of concrete batching plants, from mobile to stationary models, and with various production capacities. Ensure that the manufacturer can meet your specific needs and provide customization options if required. A reputable manufacturer should be able to tailor their products to suit your unique project requirements.

4. Quality and Durability

Quality is paramount when it comes to concrete batching plants. The equipment should be built to last, capable of withstanding the rigors of construction sites and adverse weather conditions. Check for certifications and quality control measures in place to guarantee the reliability and longevity of the batching plants.

5. Efficiency and Technology

Incorporating the latest technology can significantly enhance the efficiency of your batching plant. Nilkanth Engineering Works, for instance, offers state-of-the-art control systems that streamline the batching process, reduce waste, and improve accuracy. Look for manufacturers that stay up-to-date with technological advancements to ensure optimal performance.

6. After-Sales Support

The level of after-sales support and customer service provided by the manufacturer is crucial. Consider factors like warranty coverage, availability of spare parts, and technical support. A manufacturer like Nilkanth Engineering Works prides itself on excellent customer service, ensuring that you receive assistance whenever needed.

7. Cost and ROI

While price is a factor, it should not be the sole determinant in your decision-making process. Consider the long-term return on investment (ROI) of the batching plant. A slightly higher upfront cost for a reliable and efficient plant can save you money in the long run through reduced maintenance and increased productivity.

8. Environmental Considerations

As sustainability becomes increasingly important in construction, look for a manufacturer that offers eco-friendly options. Nilkanth Engineering Works provides batching plants that are designed with environmental consciousness in mind, helping you reduce your project’s carbon footprint.

In conclusion, selecting the concrete batching plant manufacturer for Nilkanth Engineering Works or any other reputable company involves careful consideration of your needs, research, and a focus on quality, technology, and support. With the right manufacturer by your side, you can ensure that your construction projects are equipped with reliable and efficient batching plants, setting the foundation for success.

#Tags:best Concrete batching plant Manufacturer#concrete batching plant#Concrete Batching Plant in Gujarat#Concrete Batching Plant in India#Concrete Batching Plant Manufacturer#concrete batching plant manufacturer in Gujarat#concrete batching plant manufacturer in India#concrete batching plants

0 notes

Text

#Concretes Batch Mix Plant Manufacturer in India#Concretes Batch Mix Plant Manufacturer in Gujarat#Construction Equipments Manufacturer in India#Construction Equipments Manufacturer in Gujarat

0 notes

Text

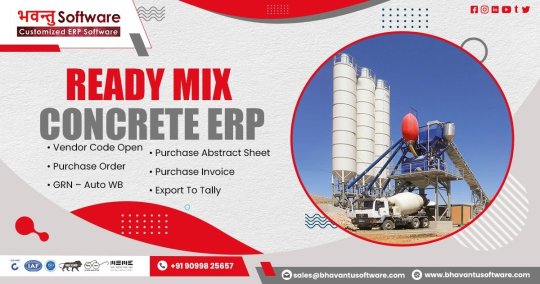

ERP Software for Ready Mix Concrete

Bhavantu Software Provides ERP Software for Ready Mix Concrete in Ahmedabad, Gujarat, India.

Bhavantu Software was established in 2023 in Ahmedabad, Gujarat, India.

We specializes in AAC ERP Solutions, Ready Mix Concrete ERP, AAC (Lightweight Block) ERP, CRM Management, and Customized ERP Solutions.

We provide an integrated information system tailored for the Ready Mix Concrete Industry.

Our solutions cater to high-value RMC manufacturers, seamlessly handling both concrete and counter sales, aiming to achieve optimum quality, reduce costs, and ensure customer satisfaction.

Functional Modules:

Vendor Code Open, Purchase Order, GRN – Auto WB, Purchase Abstract Sheet, Purchase Invoice, Export To Tally, Grade Master, Cube Test Report, Raw Material Test, Mix Design Certificate, Various QA & QC Reports, Concrete Test, Daily Schedule (Site wise), Delivery Challan, Sales Abstract, Sales Invoice, Export To Tally, Party O/S, Inquiry, Quotation, Sales Order (P.O), Proforma Invoice, Commercial Invoice, Vehicle Management, Weigh Bridge Software, Data Sync (SCADA), E-Mail/Whatsapp, Notification, Stock Control, Raw Material Stock Transfer, Stock Adjustment, Item Stock Statement.

Our affordable, powerful, and flexible web-based software seamlessly integrates concrete batch controls, tracks raw material consumption and finished goods output, ensures quality control, manages dispatch, offers GPS vehicle tracking, and handles business accounting all on a single platform.

Plant owners and managers benefit from real-time fleet information, from mixing recipes and ingredients to delivering the finished product, significantly enhancing business competitiveness and facilitating effective decision-making.

Bhavantu Software Provides ERP Software for Ready Mix Concrete Manufacturer in Ahmedabad, India including locations like Bhubaneswar, Cuttack, Rourkela, Paradeep, Angul, Jharsuguda, Balasore, Sambalpur, Berhampur, Rayagada, Bhadrak, Barbil, Talcher, Dhenkanal, Kendujhar, Sundergarh, Puri, Jajpur.

For additional information, please feel free to contact us.

Read the full article

0 notes

Text

Supplier of Concrete Block Making Machine in Surat

Supplier of Concrete Block Making Machine in Surat:

Company Overview:

A leading manufacturer and supplier based in Ahmedabad, Gujarat, India, specializing in Concrete Block Making Machine.

Robexo Industries emerged in 2015, introducing innovative concrete product-making machines designed for efficient and economical mass production.

Robexo Industries specializes in manufacturing premium fly ash and fully automatic bricks, interlocking bricks, paver blocks, concrete hollow and solid block machines, vibrating table sets, automatic batching plants, and silos.

A mechanical device used in construction to produce concrete blocks of various shapes and sizes. It typically consists of a frame, molds, and a system for mixing and compacting concrete materials.

The machine operates by pouring concrete mixture into the molds, allowing for the production of blocks with precision and efficiency.

Key Features of Concrete Block Making Machine:

Sturdy Construction: Made with durable materials like steel for long-lasting performance.

Versatility: Can produce various concrete products including blocks, paving stones, etc.

Adjustable Molds: Allows customization of block sizes and shapes according to project requirements.

Automation: Automates material feeding, mixing, molding, and block ejection processes for enhanced efficiency.

High Capacity: Capable of producing large quantities of blocks quickly, ideal for mass production.

Precision Engineering: Ensures accurate shaping and compacting of blocks for consistent quality.

User-Friendly: Equipped with easy-to-use controls and interfaces for operators, simplifying operation and maintenance.

Applications of Concrete Block Making Machine:

Construction Projects

Road and Pavement Construction

Landscaping and Hardscaping

Disaster Relief and Housing

Industrial Applications

Geographical Coverage in Surat:

Robexo Industries serves Supplier of Concrete Block Making Machine in Surat, Gujarat, India including Valod, Khatodara, Bardoli, Nizar, Olpad, Katargam, Doswada, Pandesara, Hazira, Sachin, Ichchapore, Ahmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Gandhinagar, Junagadh, Gandhidham, Anand, Navsari, Morbi, Nadiad, Surendranagar, Bharuch, Mehsana, Bhuj, Porbandar, Palanpur, Valsad, Vapi, Rajkot, Veraval, Patan, Kalol, Botad, Amreli, Deesa, Jetpur.

For inquiries or customization options, interested parties can contact Robexo Industries for further assistance.

Read the full article

#Ahmedabad#Amreli#Anand#Bardoli#Bharuch#Bhavnagar#Bhuj#Botad#ConcreteBlockMakingMachineinAhmedabad#ConcreteBlockMakingMachineinIndia#ConcreteBlockMakingMachineinSurat#Deesa#Doswada#Exporter#Gandhidham#Gandhinagar#Gujarat#Hazira#Ichchapore#India#Jamnagar#Jetpur#Junagadh#Kalol#Katargam#Khatodara#Manufacturer#ManufacturerofConcreteBlockMakingMachineinSurat#Mehsana#Morbi

0 notes

Text

Mini concrete batching plant | Small batch mix plant for sale

Mini concrete batching plant of 12-15 m3/hr. installed and working Near Halol, Gujarat. Click to see photos of the small batch mix plant for sale in action.

0 notes

Text

Ready Mix Concrete Plant Manufacturer

Proc Tech Machineries India Pvt. Ltd. is a well-known Brand as an Exporters, Supplier, and Premium Ready Mix Concrete Plant Manufacturer in Ahmedabad, Gujarat, India.

Proc Tech Machineries India Pvt. Ltd. specializes in manufacturing, exporting, and supplying diverse products, including Industrial Rotary Dryers, Air Classification Plants, Chilly Processing Plants, Asphalt Drum Mix Plants, RMC Plants, Turmeric Processing Plants, Waste Type Pyrolysis Plants, Jaggery Plants, Coriander Processing Plants, and more.

The RMC facility has bins and silos for storing aggregates and cement, respectively, weigh batchers for dividing up the various components of concrete, a high-efficiency mixer for thoroughly blending the ingredients, and a computerized system that manages the entire manufacturing process.

Our RMC units are renowned for producing precise results and are prepared to offer our customers years of happy service.

We managed to turn our agency into such a significant project with astute commercial acumen and expertise.

We bring customized concrete batch plants for your construction site to fulfill all your needs in terms of manufacturing high-quality concrete.

Features:

Effective Concrete Model Mixer to ensure proper durability and consistency

Guarantee good quality

Quantity concrete supply computerized batching plant

Manufacture reliably high-performance concrete included in different capacities Highly efficient

Proc Tech Machineries India Pvt. Ltd. Is a Premium Ready Mix Concrete Plant Manufacturer in Ahmedabad, Gujarat, India, and includes various locations like Chhattisgarh, Raipur, Bhilai, Bilaspur, Korba, Durg, Rajnandgaon, Raigarh, Jagdalpur, Ambikapur, Kawardha, Mahasamund, Bhatapara, Dhamtari, Baloda Bazar, Balod, Mungeli, Pandariya, Takhatpur, Bhilai Charoda, Kumhari, Bemetara, Basna.

For detailed information or inquiries, please feel free to contact us.

Read the full article

0 notes

Text

Top AAC Block Plant Manufacturer

Excellent En-Fab Incorporation:

Excellent En-Fab Incorporation is a Manufacturer and Supplier of the Top AAC Block Plant in Kerala.

Situated in Ahmedabad, Gujarat, India, we operate from our headquarters.

Excellent En-Fab Incorporation is a recognized hub for Process & Construction Equipment Manufacturing in India.

The company has a primary focus on supplying high-pressure autoclaves to AAC block plants.

Excellent En-Fab Incorporation takes pride in being a leading manufacturer of Autoclaved Aerated Concrete Plant (AAC Plant) in India.

Engineers specially design the AAC Plant to produce AAC Blocks, renowned for their exceptional heat, fire, and sound resistance.

Innovative AAC Block Manufacturing Process: The AAC block manufacturing process involves several key steps:

Raw Material Preparation: The mixing process precisely combines silica sand, cement, lime, and aluminum powder.

Batching and Mixing: The mixture, combined with water, is placed in molds.

Curing: Molded blocks undergo curing in autoclaves with steam and high pressure, forming air bubbles that give AAC blocks their lightweight and insulating properties.

Cutting and Shaping: Based on project requirements, workers cut cured blocks into various sizes and shapes.

Final Curing: Blocks undergo final curing to strengthen their structure.

Packaging: Workers package and prepare finished AAC blocks for distribution.

Export Excellence Across Sectors: Excellent En-Fab Incorporation has demonstrated commendable export performance across sectors,

including pharmaceuticals, chemicals, food processing, minerals, and more.

Supplying AAC Block Plant in Kerala:

The company provides the Top AAC Block Plant Manufacturer in Kerala, serving cities such as Thiruvananthapuram, Kochi, Kozhikode, Thrissur, Kollam, Alappuzha, Kannur, Palakkad, Kottayam, and Malappuram.

Read the full article

#AACBlockPlant#Alappuzha#Exporter#India#Kannur#Kochi#Kollam#Kottayam#Kozhikode#Malappuram#Manufacturer#Palakkad#Supplier#Thiruvananthapuram#Thrissur

0 notes

Text

Understanding the Role of Cement Batching Plants in Construction Projects

Cement batching plants play a crucial role in construction projects, providing a steady supply of high-quality concrete. These plants are essential for ensuring the timely and efficient production of concrete mixtures that meet specific project requirements. In this article, we will delve into the significance of cement batching plants, their advantages, and considerations for choosing a cement batching plant manufacturer.

Let’s explore.

What is a Cement Batching Plant?

A cement batching plant is a specialized facility designed to produce concrete in large quantities. It consists of several key components that work together to ensure the accurate weighing, proportioning, and mixing of materials. These components include cement silos for storage, aggregate bins, conveyor systems, weighing and mixing equipment, and a control system to manage the entire process.

Advantages of Cement Batching Plants in Construction Projects

Cement batching plants offer numerous advantages that contribute to the success of construction projects:

Improved Efficiency and Productivity: By employing batch production methods, cement batching plants ensure a consistent and timely supply of concrete. This eliminates delays caused by waiting for ready-mix deliveries and optimizes project schedules. Additionally, increased automation reduces the reliance on manual labor, enhancing overall productivity.

Quality Assurance: The use of cement batching plants allows for precise proportioning and thorough mixing of materials. This results in concrete mixtures with consistent quality, strength, and durability. Quality assurance measures ensure that the produced concrete meets or exceeds project specifications, enhancing structural integrity and longevity.

Cost Savings: Cement batching plants enable optimized material usage, reducing waste and minimizing costs associated with over-ordering or under-utilization of ready-mix deliveries. Furthermore, on-site production reduces transportation expenses, as concrete can be produced instantly at the construction site, eliminating the need for long-distance transportation.

Flexibility and Customization: Cement batching plants offer flexibility in adjusting concrete mixtures based on project requirements. Construction projects often demand specific concrete properties, and on-site production allows for customization and adjustments to meet these needs. This adaptability accommodates varying construction needs and specifications.

Considerations for Selecting Cement Batching Plants Manufacturer

When you're on the hunt for a cement batching plant manufacturer, there are a few things to consider. Here are those:

Reputation and Experience: Look for manufacturers with a solid reputation and extensive experience in the construction industry. A manufacturer with a proven track record is more likely to deliver high-quality and reliable batching plants.

Quality Standards: Check if the manufacturer adheres to strict quality standards in the production of their batching plants. Quality certifications such as ISO 9001 can provide assurance of the manufacturer's commitment to delivering top-notch products.

Delivery and Installation: Evaluate the manufacturer's ability to deliver and install the batching plant within the required timeframe. Timely delivery and efficient installation services are crucial to avoid delays in your construction projects.

Price and Value for Money: Compare prices and consider 100% value for money offered by different manufacturers. While it's important to consider budget constraints, prioritize the quality, reliability, and performance of the batching plant over the initial cost.

Confinra Machinery Pvt. Ltd. – Leading Cement Batching Plants Manufacturer in India

Confinra Machinery Pvt. Ltd. is a leading manufacturer and exporter of cement batching plants in Gujarat, India. We have been serving the market for many years now and have developed expertise in the field of cement production.

We also know that you want to be able to rely on your supplier for quality products and outstanding customer service. That's why we've been in business for over 30 years: because we work hard to understand our customers' requirements so that we can provide them with the construction products they need at an affordable price.

We're proud of our reputation as one of India's leading manufacturers of cement batching plants—and we hope you'll give us a chance to show you what makes us so good!

Call our expert engineers at +91 90999 41311 or drop us an email at [email protected] to learn more about our cement batching plant.

0 notes

Text

https://proplusexim.com/concrete-batching-mixing-plant/

Concrete Batching / Mixing Plant in Arusha, Tanzania

Proplus Exim is a Merchant Exporter based in Ahmedabad, Gujarat. We export products such as concrete equipment, road construction equipment, personal care, dairy & bakery, sanitary, food, and so on. Our construction equipment includes compact concrete batching plants, asphalt drum mix plants, cement and fly ash silo systems, concrete batching / mixing plants, GDB / DLC plant, hydraulic broomer, mobile batching plant with pan mixer, skid type concrete batching plant and wet mix macadam plant. The company's primary focus is customer service.

1 note

·

View note

Text

Parker Plant – Manufacturer & Supplier of Modular Asphalt Batch Plant

Parker Plant is a renowned manufacturer and supplier of reliable solutions for asphalt, crushing screening, sand and gravel, concrete, and material handling equipment across the globe. With 100+ years of experience, this business was set up by Mr. Frederick Parker in 1911 beneath a railway arch in Leicester and went on to achieve the pinnacle of success with its products sold to more than 150 countries.

Parker Plant Ltd of the UK kingdom and Apollo Inffratech group of India entered into a joint venture and has extended their portfolio range to incorporate asphalt plant machinery from 80 to 360 TPH. This venture is a wake-up call to the respected Prime Ministers' dream of’ Make in India’ and the manufacturing equipment meets the demands of a vibrant market. While deepening global integration and value chains this joint venture brings in world-class technology with the best innovation in the construction industry. The trajectory of India's growth has been witnessed high and the joint venture would significantly contribute to the motto of ‘Atma Nirbhar’ or self-reliance.

The mobile asphalt plants and the static asphalt plants are engineered to provide a seamless and trouble-free performance facilitating the maintenance of excellent work culture. Parker Plant Ltd has always strived to serve its clients with utility, quality, durability, and innovation to ensure maximum satisfaction. The state-of-the-art facilities conform to international standards and maintain impeccable standards of quality providing unmatched and unparalleled competition. The manufacturing asphalt plant would be based in Mehsana, Gujarat with all the modern facilities and infrastructure. When one talks about reliable solutions for quarrying, construction, road infrastructure, and recycling projects in the world, the name that comes first to anyone’s mind is Parker Plant India Pvt. Ltd.

The asphalt batching plants helps in a flexible production process with hassle-free and smooth operation and ease of installation and use. Modular Asphalt Batch Plants are designed with perfection and compactness with total sophistication in performance. While considering the project one can opt for mobile asphalt batching plant or a static asphalt batching plant to mix the asphalt with quickness and ease. It offers continuous service and production with volumes gets easier and better.

The Product range with a difference

The Products at Parker Plant Pvt Ltd include the following ranges-

Star Mix Range - This range has the modular asphalt batch plant which has high and low-level options. This is the ultimate choice for users and serves as an excellent long-term investment and gives a superlative performance with longevity. There are products like the cold feed, aggregate dryer, screen paddle mixer, and Star Mix 100, 140, 180, and 220 editions. The Star Mix range offers a flexible plant layout with replaceable filter designs. The mixing just gets easier and the mobile asphalt mixing plants is a great investment for any business that needs to be able to move their plant from one location to another. The range embodies all the advanced features that are needed for the smooth functioning of the production process.

Star Batch Range- This European-designed modular asphalt plant is now being manufactured in India and utilizes the latest technology to meet modern-day road projects. It has advanced features and offers a totally low capital cost. Being the leading Asphalt Machinery manufacturer, the strong team delivers customized options from individual machines to an entire range for the complete cycle. The range is also equipped with a high thermal efficiency dryer and thrust rollers for reduced dryer wear and noise. The maintenance is minimal and so is the wastage. To control the costs, it is automated with multi-fuel burner options.

0 notes

Text

Behind the Scenes: How Concrete Batching Plant Manufacturers Shape the Industry

The importance of concrete batching plants cannot be overstated in the construction world. These machines are the backbone of any concrete production operation, responsible for mixing the precise combination of ingredients that form the foundation of our buildings, roads, and infrastructure. One company that has been making a significant impact in this field is Nilkanth Engineering Works. In this blog, we’ll take you behind the scenes to explore how concrete batching plant manufacturers like Nilkanth are shaping the industry.

The Foundation of Construction

Concrete is the most widely used construction material in the world. It’s versatile, durable, and can be molded into various shapes and sizes to meet the needs of countless projects. At the heart of every concrete production process is the concrete batching plant. These plants are designed to carefully weigh and mix aggregates, cement, water, and other additives to create the perfect concrete blend.

Nilkanth Engineering Works: A Brief Introduction

Nilkanth Engineering Works is renowned in the concrete batching plant manufacturing industry. Established with a vision to provide cutting-edge solutions to the construction sector, Nilkanth has consistently strived for excellence. They have gained a reputation for producing high-quality, efficient, and innovative concrete batching plants that cater to the evolving needs of the construction industry.

Innovative Designs for Efficiency

Concrete batching plant manufacturers like Nilkanth are at the forefront of innovation. They constantly research and develop new technologies to enhance the efficiency and sustainability of their plants. Features like computerized control systems, moisture sensors, and automated production processes ensure that the produced concrete meets the highest quality standards.

Customization to Suit Every Project

One of the critical ways manufacturers like Nilkanth Engineering Works shape the industry is through customization. They understand that every construction project is unique and has specific requirements. As a result, they offer a range of batching plant models with varying capacities and configurations to cater to different project scales and site conditions. This level of customization ensures that builders have the right tools for the job, optimizing both efficiency and cost-effectiveness.

Environmental Responsibility

Concrete production is often associated with a significant environmental footprint. However, concrete batching plant manufacturers are taking steps to reduce this impact. Nilkanth Engineering Works, for instance, offers environmentally friendly features in their plants, such as water recycling systems and dust control measures. These advancements reduce environmental harm and align with global sustainability goals.

Global Reach and Impact

Manufacturers like Nilkanth Engineering Works don’t just shape the industry on a local level; they have a global presence. Their machines are used in construction projects worldwide, contributing to the growth and development of infrastructure everywhere. This international reach allows them to share their expertise and innovation across borders.

Conclusion

Concrete batching plant manufacturers in India like Nilkanth Engineering Works are the unsung heroes of the construction industry. They play a pivotal role in shaping the way we build our world. Through innovation, customization, and a commitment to environmental responsibility, companies like Nilkanth are meeting industry needs and driving it forward into a more efficient and sustainable future. As the construction industry continues to evolve, we can be sure that manufacturers like Nilkanth Engineering Works will be at the forefront, pushing the boundaries of what is possible in concrete production.

#Concrete batching plant manufacturers in India#Concrete batching plant manufacturers in Gujarat#Concrete batching plant manufacturers#Concrete batching plant#Concrete batching plant in India#Concrete batching plant in Gujarat#Concrete batching plants

0 notes

Link

#mobile concrete batching plant#mobile concrete batching plant manufacturer#mobile concrete batching plant exporter

0 notes

Text

Ready Mix Concrete ERP in Gujarat

Bhavantu Software is a Provides Ready Mix Concrete ERP in Gujarat, India.

Bhavantu Software Established in 2023 in Ahmedabad, Gujarat, India.

Products:

Ready Mix Concrete ERP

AAC (Lightweight Block) ERP

CRM Management

Customized ERP Solutions

We specialize in an integrated information system designed for the Ready Mix Concrete Industry.

Our solution is perfect for high-value RMC manufacturers seeking to achieve optimum quality, reduce costs, and ensure customer satisfaction by handling both concrete and counter sales seamlessly.

Our software is an affordable, powerful, and flexible web-based solution that integrates concrete batch controls, tracks raw material consumption and finished goods output, manages quality control, dispatch, GPS vehicle tracking, and business accounting on a single platform.

We provide plant owners and managers with a real-time fleet information system, from mixing recipes and ingredients to delivering finished products.

This system vastly enhances business competitiveness and enables effective decision-making.

The Ready Mix Concrete industry grapples with the challenge of maintaining low operating costs while striving to reach distant customers.

Variations in production costs and limited visibility into the delivery process result in significant revenue leakage for plant owners and managers.

An ERMC solution provides plant owners with detailed real-time updates, from the mixing of ingredients to the delivery of the finished product. This on-the-go information keeps both management and line workers well-informed.

Bhavantu Software is a Ready Mix Concrete ERP in Gujarat, India and including locations

Like Ahmedabad, Amreli, Anand, Aravalli, Banaskantha, Palanpur, Bharuch, Bhavnagar, Botad, Chhota Udaipur, Dahod, Dang, Devbhoomi Dwarka, Gandhinagar, Gir Somnath, Veraval, Jamnagar, Junagadh, Kheda, Kutch, Mahisagar, Mehsana, Morbi, Narmada, Navsari, Panchmahal, Godhra , Patan, Porbandar, Rajkot, Sabarkantha, Himmatnagar, Surat, Surendranagar, Tapi (Vyara), Vadodara, Valsad.

For additional information, please feel free to contact us.

Read the full article

0 notes

Text

Retaining Block Making Machine in Ahmedabad

Company Overview:

Robexo Industries is a Manufacturer and Supplier of Retaining Block Making Machine in Ahmedabad, Gujarat, India.

Established in 2015, the company is ISO 9001:2015 certified, offering cutting-edge technology with distinctive reliability features.

Specializes in producing fly ash and fully automatic bricks, interlocking bricks, paver blocks, concrete hollow and solid block machines, vibrating table sets, automatic batching plants, and silos for concrete raw materials.

A device used to manufacture retaining blocks, concrete blocks designed to retain soil or other materials in landscaping and construction projects.

Automates the process of crafting retaining blocks, significantly reducing time and manpower.

Offers a cost-effective solution for construction companies by minimizing wastage and maximizing efficiency.

Finds diverse applications in various construction projects due to its efficiency and versatility.

Advantages of Retaining Block Making Machine:

Precision engineering ensures uniformity in size and shape of blocks.

Streamlined processes enhance efficiency and cost-effectiveness.

Environmental sustainability with minimized wastage and eco-friendly practices.

Applications of Retaining Block Making Machine:

Landscaping

Road construction

Retaining wall installation

Erosion control

Infrastructure development

Robexo Industries are Retaining Block Making Machine in Ahmedabad, Gujarat, India, and surrounding areas including Sanand, Vani, Kathawada, Odhav, Vatva, Rakhial, Singarva, Bakrol, Kadi, Kalol, Kanbha, Kujad, Changodar, Naroda, Dhandhuka, Dholka, Viramgam, Kerala, and Vatva.

Interested parties can contact Robexo Industries for inquiries or additional information

Read the full article

#Ahmedabad#Bakrol#Changodar#Dhandhuka#Dholka#Erosioncontrol#Exporter#ExporterofRetainingBlockMakingMachine#Gujarat#India#Infrastructuredevelopment#Kadi#Kalol#Kanbha#Kathawada#Kerala#Kujad#landscaping#Manufacturer#ManufacturerofRetainingBlockMakingMachineinAhmedabad#Naroda#Odhav#Rakhial#RetainingBlockMakingMachineinAhmedabad#RetainingBlockMakingMachineinGujarat#RetainingBlockMakingMachineinIndia#Retainingwallinstallation#Roadconstruction#Sanand#Singarva

0 notes

Text

Mini concrete batching plant | Small batch mix plant for sale

Mini concrete batching plant of 12-15 m3/hr. installed and working Near Halol, Gujarat. Click to see photos of the small batch mix plant for sale in action.

0 notes

Link

Atlas is concrete plant with pan mixer manufacturer. Buy batching mixing plant from leading exporter from Gujarat. Mobile plant and maintenance free design. We have stationary rmc plant installations in countries like Nigeria, Angola, Philippines, Bhutan, Cameroon, Myanmar and Israel.

#concrete batching mixing plant#Concrete Batching Plant#mobile concrete batching plant#concret mixer#construction equipment

0 notes