#seismic engineering

Text

Starken Philippines Shakes Up Earthquake Preparedness with Groundbreaking Seismic Test

Starken Philippines, a frontrunner in construction innovation, unveiled a game-changing breakthrough in earthquake preparedness at the recent CoNNEX 2024 event. This innovation has the potential to revolutionize earthquake safety in the Philippines.

The company showcased the results of a pioneering earthquake test, marking a significant milestone in seismic engineering. Led by Engr. Rolando B…

View On WordPress

#autoclaved aerated concrete#CoNNEX 2024#Construction safety#earthquake#Earthquake Disaster Preparedness#Earthquake Mitigation#earthquake preparedness#Earthquake-resistant building materials#Seismic engineering#Starken Philippines

0 notes

Text

Little P.Eng. for Blue Hydrogen and Ammonia Engineering Services: A Comprehensive Engineering Aspect

Table of Contents

Introduction

Blue Hydrogen: An Overview

Importance of Engineering Services in Blue Hydrogen Production

Piping Stress Analysis

Structural Engineering

Seismic Engineering

Tank Design

Pressure Vessel Design

Ammonia Engineering Services: The Connection

Conclusion

1. Introduction

As the world accelerates its efforts to combat climate change, the focus on cleaner energy sources has never been sharper. Blue hydrogen, derived primarily from natural gas with the carbon emissions being captured and stored, presents a viable option in the pursuit of decarbonization. Its potential integration with ammonia production further highlights its significance. At the heart of this transformative energy landscape lies the vital role of engineering services. 'Little P.Eng.', a forerunner in this niche, offers specialized services such as piping stress analysis, structural and seismic engineering, and the design of tanks and pressure vessels. This article delves deep into these pivotal engineering domains and the implications for blue hydrogen and ammonia production.

2. Blue Hydrogen: An Overview

Blue hydrogen is produced when natural gas (primarily methane) undergoes steam methane reforming (SMR) to produce hydrogen and carbon dioxide. Unlike gray hydrogen, where CO2 is released into the atmosphere, blue hydrogen incorporates carbon capture and storage (CCS) technology. This ensures that a significant portion of the carbon emissions are captured and sequestered, making blue hydrogen a cleaner option.

3. Importance of Engineering Services in Blue Hydrogen Production

Engineering services ensure the efficiency, safety, and reliability of blue hydrogen production plants. Key considerations range from handling high pressures and temperatures to mitigating the effects of seismic events. Herein, Little P.Eng.'s expertise comes to the fore.

4. Piping Stress Analysis

Piping systems in hydrogen production facilities face stresses from internal pressures, thermal loads, and dynamic forces. Piping stress analysis ensures that pipes, flanges, and fittings can withstand these stresses without failure.

Objectives:

Safety of the piping system and its associated components.

Compliance with international standards, codes, and best practices.

Reduction of operational disruptions due to piping failures.

Little P.Eng. employs advanced computational tools and methodologies to evaluate the behavior of piping systems under various loading conditions, optimizing design and ensuring longevity.

5. Structural Engineering

Facilities producing blue hydrogen demand robust structures capable of supporting equipment, piping, and personnel.

Key Challenges:

Dynamic loads from equipment and flow-induced vibrations.

Corrosive environments due to the presence of hydrogen, steam, and other chemicals.

Little P.Eng.'s structural engineering services provide innovative solutions, ensuring that structures remain integral and safe throughout their operational life.

6. Seismic Engineering

Many industrial facilities are located in seismic zones. Earthquakes can be catastrophic for hydrogen production facilities, leading to leaks, explosions, and fires.

Seismic Analysis: Little P.Eng. evaluates potential seismic risks and designs structures and systems that can withstand seismic events. This encompasses:

Site-specific seismic hazard assessments.

Design of foundations and structural elements with sufficient ductility and resilience.

7. Tank Design

Storage tanks play a pivotal role in hydrogen and ammonia plants. They store feedstock, intermediate products, and final products.

Design Principles:

Safety: Ensuring that tanks do not leak or rupture.

Efficiency: Maximizing storage capacity while minimizing footprint.

Longevity: Ensuring resistance to corrosion, wear, and tear.

With advanced modeling and simulation, Little P.Eng. optimizes tank designs to meet these principles, while also adhering to strict regulatory standards.

8. Pressure Vessel Design

Pressure vessels in hydrogen production plants hold gases at high pressures. Their design is crucial for safety and efficiency.

Design Aspects:

Material selection to resist hydrogen embrittlement.

Wall thickness determination to withstand internal pressures.

Compliance with international standards, such as ASME codes.

Little P.Eng. employs a rigorous approach to pressure vessel design, ensuring optimal performance and safety.

9. Ammonia Engineering Services: The Connection

Ammonia, NH3, is produced by combining nitrogen from the air with hydrogen. As such, blue hydrogen can provide a clean hydrogen source for ammonia production. The engineering challenges in ammonia production mirror those of blue hydrogen: high pressures, corrosive environments, and the need for robust structures and equipment. Little P.Eng.'s suite of services naturally extends to this domain, further enhancing the synergies between blue hydrogen and ammonia production.

10. Conclusion

The transformation of the energy landscape hinges on the adoption of cleaner technologies, and blue hydrogen stands out in this endeavor. The role of engineering services, as championed by Little P.Eng., is paramount, ensuring that the transition is not just sustainable but also safe and efficient. From intricate piping designs to robust structural solutions, the contributions of engineering cannot be overstated. As we gaze into the future of energy, it's clear that the expertise of firms like Little P.Eng. will be at the very heart of this revolution.

Tags:

Engineering Services

Seismic Engineering

Little P.Eng.

Piping Stress Analysis

Structural Engineering

Material Selection

Tank Design

Pressure Vessels

ASME Codes

Clean Energy

Ammonia Production

Steam Methane Reforming

Computational Analysis

Infrastructure Safety

Blue Hydrogen

Carbon Capture

Simulation and Modeling

Ammonia Synthesis

Fluid Dynamics

Industrial Standards

Decarbonization

Load-bearing Structures

Industrial Integrity

Earthquake-Resilient Designs

Energy Transition

Environmental Factors

Hydrogen Storage

Seismic Zones

Foundation Designs

Hydrogen Embrittlement

Hydrogen Production Plant Design

Engineering Services

Structural Engineering Consultancy

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Engineering Services#Seismic Engineering#Little P.Eng.#Piping Stress Analysis#Structural Engineering#Material Selection#Tank Design#Pressure Vessels#ASME Codes#Clean Energy#Ammonia Production#Steam Methane Reforming#Computational Analysis#Infrastructure Safety#Blue Hydrogen#Carbon Capture#Simulation and Modeling#Ammonia Synthesis#Fluid Dynamics#Industrial Standards#Decarbonization#Load-bearing Structures#Industrial Integrity#Earthquake-Resilient Designs#Energy Transition#Environmental Factors#Hydrogen Storage#Seismic Zones#Foundation Designs#Hydrogen Embrittlement

0 notes

Text

Floating floors are a go-to solution for architects and acoustical consultants in Ontario. These specialized flooring systems create an air gap between the subfloor and the finished floor, effectively isolating sound and vibration. This technology is particularly valuable when designing recording studios, theaters, or residential spaces.

#floating floors#jack up floating floors#seismic engineering#architectural acoustics#complex engineering

0 notes

Text

Tecoustics has a big inventory of Mason Industries that can meet the clients demands and are certain to offer the greatest services possible in relation to their project's specification.

0 notes

Text

the problem with building out america's rail network btw is that it's privatized and there will never be a corporate incentive strong enough or backed enough to implement effective, accessible, AND privatized countrywide travel. nationalize railways deliver on the demands of railway workers and most importantly respect indigenous sovereignty/include indigenous design input when plotting routes

#and a million other things mostly to do with geology but in terms of politics and morals this is what im going with as far as a snappy#summary of 'the problem'#however geology elaboration: america is So hard to build railways across because our most populated areas along the west coast#(where most of the rail drought is; rail PRICING on the east coast is a whole nother thing)#are stupid mountainous. the california hsr plan is spending several million more on the rail line bc they gotta plan around a mountain#and the problem gets worse the farther north you get on account of the cascades and ESPECIALLY the region around shasta#in another life i was a seismic engineer. anyway#i'm looking for a papers or other peer-reviewed content on the history of american rail labor#if anyone has favorites send them my way cause all my research is locked on california and the pacific coast more broadly#'research' my font of pdfs i downloaded from ILLs lol

35 notes

·

View notes

Text

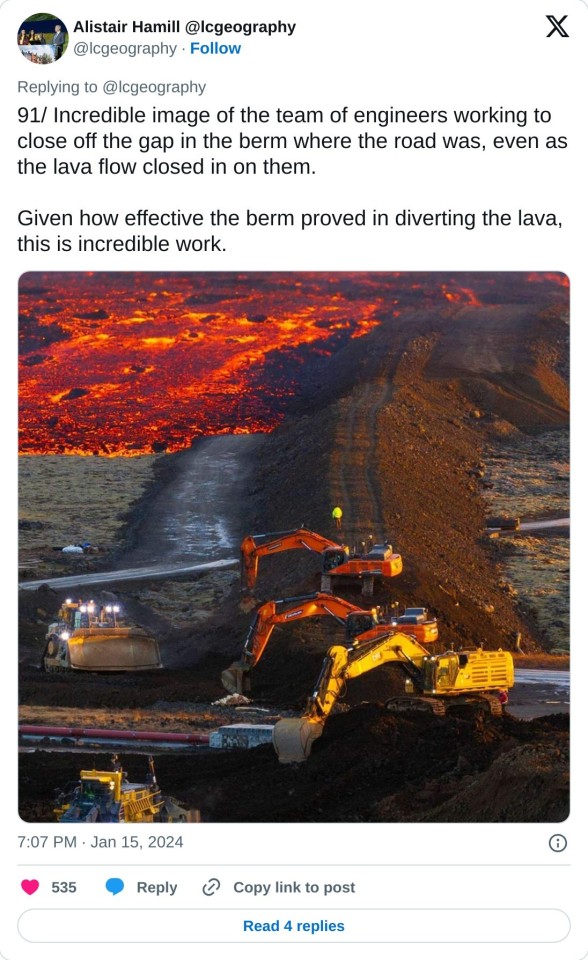

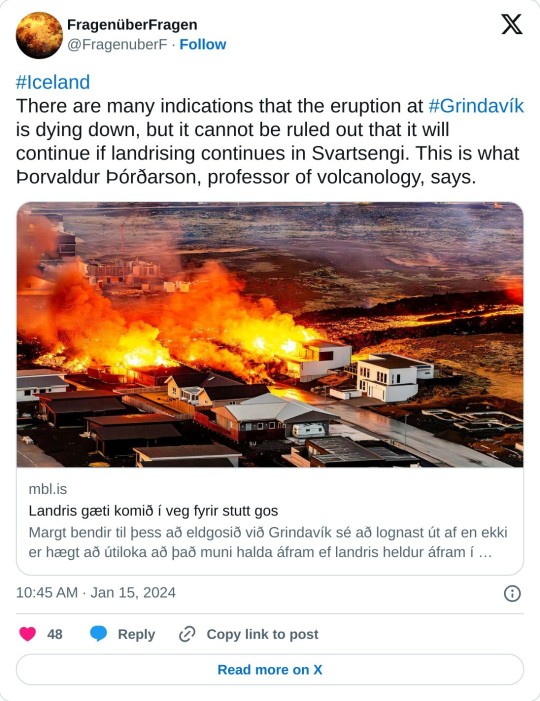

#iceland#bravo nicely done! Phew.....#news#engineer#engineering#lava#Grindavik#volcanic eruption#good people#Seismic

4 notes

·

View notes

Text

Protect Your Infrastructure from Natural Disasters

Our ordnance construction service ensures the longevity and functionality of installations from initial planning and design to construction and maintenance. Contact us now!

#Engineering Contractor#Seismic#Construction#Structural#Soft-Story#Retrofit#Earthquake#Non-Ductile#Ordinance#Multifamily Construction

0 notes

Text

What to Do During an Earthquake in an Earthquake-Resistant Building

Earthquakes: A Technical Challenge for Structural Engineering

Earthquakes pose a significant technical challenge to structural engineering, as they can cause significant damage to buildings and infrastructure. However, with the development of earthquake-resistant buildings, it is possible to minimize the impact of earthquakes on human life and property. Earthquake-resistant buildings are designed…

View On WordPress

#beams#columns#communication plan.#connection joints#earthquake preparedness#earthquake resistant buildings#earthquakes#emergency kit#foundations#Ground Shaking#safety#Seismic Design#seismic retrofitting#structural damage#structural engineering

0 notes

Video

youtube

How the Temple will Survive Earthquakes

#youtube#seismic upgrades#earthquakes#architecture#renovation#temple#temples#lds temple#lds temples#mormon temple#mormon temples#church of jesus christ of latter day saints#lds church#mormon church#engineering#salt lake city temple#salt lake city#utah

0 notes

Text

In 1972, the Pacific Earthquake Engineering Research Center (PEER) shaking table, located at the Richmond Field Station, was unveiled as the world’s first modern shaking table.

#berkeley#engineering#science#uc berkeley#university#bay area#earthquake#seismic#scientific research

0 notes

Text

Earthquake-Resistant Building Design: A Guide to Safer Structures

In regions prone to seismic activity, earthquake-resistant building design is not a luxury but a necessity. The primary goal of such design is to ensure that structures can withstand the shaking and shifting of the earth without catastrophic failure. This is achieved through a deep understanding of geotechnical engineering principles, materials science, and the dynamics of seismic forces. By…

View On WordPress

#architecture#base isolation#building construction#building innovation#community resilience#construction technology#ductility in structures#earthquake preparedness#earthquake-resistant design#retrofitting#seismic codes#seismic safety#shock absorbers#smart materials#structural engineering

0 notes

Text

Philippines Urged to Step Up Earthquake Preparedness After Taiwan Quake

Scan the QR code to get this post on the go.

Reflecting on recent seismic activity and the devastating potential of earthquakes, Ariel Nepomuceno, the administrator of the Office of Civil Defense (OCD), has emphasized the paramount importance of bolstering engineering solutions and ensuring compliance with building codes. This imperative comes in anticipation of seismic events, particularly the…

View On WordPress

#Building code compliance#Building code enforcement#Disaster mitigation#Earthquake Disaster Preparedness#Engineering solutions#Infrastructure Resilience#National Building Code#Natural disasters#Office of Civil Defense#Seismic Activity#Seismic risks#Taiwan earthquake#the big one#west valley fault

0 notes

Text

Comprehensive Seismic Engineering Design Services Offered by Little P.Eng. and its Importance in Piping Stress Analysis

In the world of engineering and construction, seismic engineering is a specialized field crucial for ensuring the safety and resilience of structures in earthquake-prone regions. Little P.Eng. is a renowned seismic engineering firm that provides a wide range of services to address the unique challenges posed by seismic activity. In this comprehensive article, we will explore the multitude of services offered by Little P.Eng., highlighting their expertise, innovation, and dedication to creating structures that can withstand the forces of nature.

Seismic Risk Assessment

One of the foundational services offered by Little P.Eng. is seismic risk assessment. Before embarking on any seismic engineering project, it's essential to understand the level of risk posed by potential earthquakes in a specific area. Little P.Eng. utilizes advanced methodologies and data analysis to assess seismic hazards accurately. This assessment helps clients make informed decisions about construction and retrofitting, ensuring the safety of occupants and the protection of valuable assets.

Structural Analysis and Design

Seismic engineering begins with the structural analysis and design of buildings and infrastructure. Little P.Eng.'s team of experienced engineers specializes in developing seismic-resistant structural systems. They work closely with architects, builders, and developers to create designs that can withstand seismic forces, ensuring structural integrity and occupant safety during earthquakes.

Retrofitting Existing Structures

In regions with older buildings, retrofitting is often necessary to bring them up to current seismic safety standards. Little P.Eng. offers retrofitting services that involve the modification and strengthening of existing structures. Their engineers assess the specific needs of each building, considering factors such as its age, construction materials, and seismic vulnerabilities. They then implement retrofitting strategies that enhance the building's earthquake resistance, preserving its historical value while ensuring safety.

Foundation Design and Soil Analysis

The foundation is the bedrock of any structure's stability during an earthquake. Little P.Eng. conducts in-depth soil analysis to understand the geotechnical characteristics of the site. Based on this analysis, they design and recommend appropriate foundation systems tailored to the specific needs of the project. Their expertise in foundation design ensures that structures can effectively dissipate seismic forces into the ground, preventing catastrophic failure.

Compliance with Seismic Codes

Adherence to seismic codes and standards is paramount in seismic engineering. Little P.Eng. has an in-depth understanding of local, national, and international building codes related to earthquake-resistant construction. They ensure that all their designs and retrofitting projects comply with these regulations, providing clients with peace of mind that their structures meet the highest safety standards.

Advanced Computer Modeling and Simulation

Little P.Eng. leverages cutting-edge computer modeling and simulation tools to analyze and predict how structures will respond to seismic forces. These simulations allow for precise refinement of designs and provide valuable insights into structural performance during earthquakes. By simulating a wide range of seismic scenarios, engineers can optimize designs for maximum safety and efficiency.

Continuous Monitoring and Evaluation

The commitment of Little P.Eng. extends beyond the design and construction phase. They recommend and implement structural health monitoring systems that allow for real-time assessment of a building's integrity. Continuous monitoring enables early detection of potential issues, ensuring prompt maintenance or repairs to preserve structural stability.

Research and Innovation

Innovation is at the heart of Little P.Eng.'s approach to seismic engineering. Their team actively engages in research and development to push the boundaries of seismic-resistant technologies and construction practices. They explore innovative materials, construction techniques, and design methodologies to advance the field and provide clients with the latest and most effective solutions.

Emergency Response Planning

In addition to structural engineering services, Little P.Eng. assists communities, businesses, and organizations in developing emergency response plans for seismic events. They collaborate with stakeholders to create comprehensive strategies for minimizing risks, protecting lives, and reducing damage during earthquakes.

Public Education and Outreach

Little P.Eng. recognizes the importance of public awareness and education regarding seismic risks and safety. They engage in outreach programs to educate communities on earthquake preparedness, emergency response, and the importance of seismic-resistant construction.

Conclusion

Seismic engineering design plays a crucial role in piping stress analysis within industrial facilities, especially in regions prone to earthquakes. Piping stress analysis involves evaluating the forces and stresses that piping systems experience during various operational conditions, including seismic events.

Here's how seismic engineering design is important for piping stress analysis:

Safety and Structural Integrity: Seismic engineering design ensures that the entire facility, including piping systems, is built to withstand the forces generated by earthquakes. The structural integrity of piping systems is paramount for preventing leaks, ruptures, or catastrophic failures during seismic events. Piping stress analysis assesses the impact of seismic forces on the pipes, supports, and attachments to verify that they can withstand the dynamic loads and deformations caused by earthquakes.

Compliance with Building Codes: Piping systems within industrial facilities must adhere to building codes and standards related to earthquake-resistant design. Seismic engineering design ensures that piping systems are compliant with these codes. Non-compliance can lead to costly retrofitting efforts or, in the worst-case scenario, dangerous failures during an earthquake.

Identifying Vulnerabilities: Seismic engineering design involves conducting a seismic risk assessment for the facility. This assessment helps identify vulnerabilities in the piping systems, such as weak points in support structures or connections that may be prone to failure during seismic events. Piping stress analysis considers these vulnerabilities and recommends improvements to enhance seismic resilience.

Optimal Pipe Routing and Support: Piping stress analysis incorporates considerations for seismic forces when determining the routing of pipes and the design of pipe supports. Proper pipe routing and support are essential to prevent excessive stresses, vibrations, and displacements during an earthquake. Seismic engineering design helps optimize these factors to minimize potential damage to the piping systems.

Dynamic Load Analysis: Seismic events introduce dynamic loads on piping systems, which are significantly different from static loads. Piping stress analysis uses dynamic load analysis techniques to simulate the effects of seismic forces on pipes, fittings, and supports. This analysis ensures that the piping systems can handle the dynamic loads without exceeding their stress limits.

Retrofitting and Modifications: In existing facilities, seismic engineering design may involve retrofitting or modifying piping systems to meet current seismic standards. Piping stress analysis helps identify areas that require reinforcement, redesign, or additional support. Retrofitting ensures that older facilities can withstand seismic events and meet modern safety requirements.

Mitigation Strategies: Seismic engineering design doesn't only focus on evaluating existing conditions but also includes the development of mitigation strategies. These strategies may involve the use of seismic expansion joints, dampers, or flexible connectors to absorb seismic energy and reduce stress on the piping systems.

Emergency Response Planning: In the event of a seismic event, having a well-designed piping system is crucial for quick recovery and minimizing damage. Seismic engineering design contributes to emergency response planning by ensuring that piping systems are less likely to rupture or leak during an earthquake, reducing potential hazards and environmental damage.

In summary, seismic engineering design is vital for piping stress analysis because it ensures the safety, compliance, and resilience of piping systems in the face of seismic events. It helps identify vulnerabilities, optimize designs, and implement mitigation measures, ultimately safeguarding industrial facilities and the surrounding environment during earthquakes.

The listing below indicates a few of Meena Development’s most commonly served industries.

Steel and Metals Industry

Energy and Power Generation Industry

Water and Wastewater Industry

Oil & Gas Industry

Chemicals and Plastics Industry

Pulp & Paper Industry

Facility Services

Residential Buildings Sector

Hospitality and Hotel Sector

Commercial Buildings Sectors

Sports and Stadia Buildings Sector

Education Buildings Sector

Government Buildings Sector

Hospitals Engineering Services

Biotech / Pharmaceutical – Engineering Services

Food & Beverage – Engineering Services

Tags:

Meena Rezkallah

Little P.Eng.

piping stress analysis

Piping stress analysis

Structural analysis

Seismic engineering

Seismic risk assessment

Retrofitting

Foundation design

Compliance with seismic codes

Computer modeling

Advanced simulation

Optimal pipe routing

Support systems

Pipe design

Seismic forces

Seismic expansion joints

Flexible connectors

Engineering Services

Pipe Stress Analysis Services

Seismic Bracing Experts

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#•#Meena Rezkallah#Little P.Eng.#piping stress analysis#Piping stress analysis#Structural analysis#Seismic engineering#Seismic risk assessment#Retrofitting#Foundation design#Compliance with seismic codes#Computer modeling#Advanced simulation#Optimal pipe routing#Support systems#Pipe design#Seismic forces#Seismic expansion joints#Flexible connectors

0 notes

Text

Robotic and electro-mechanical manipulators have revolutionized complex engineering across industries. Uncover the capabilities of these advanced systems and their pivotal role in heavy industrial and facility asset integration markets. Delve into their integration with other components such as weldments, mechatronic systems, and material handling and moving technologies.

#complex engineering#mechatronic#heavy weldments#weldments#seismic engineering#logistics and installation#high load supports

0 notes

Text

To reduce vibrational energy transfer between the equipment, system, and the building, Tecoustics noise and vibration control devices are tailored to the equipment's unique mounting interfaces and vibratory characteristics.

0 notes

Text

Spring vibration isolators - Easyflex

Easyflex spring vibration isolators are cutting-edge solutions for noise and vibration control. Engineered with precision, they effectively reduce vibrations, ensuring a quieter and more stable environment. These isolators are your go-to choice for superior performance and peace of mind.

For More Info visit : https://easyflex.in/spring-based-vibrations-isolators/

Kanwal Industrial CorporationB- 168, Phase – II, Distt. Gautam Budh Nagar -201 305 Noida, Uttar Pradesh , India

Phone: 91-0120-4734500 | +91-9811319020

#spring vibration isolators#spring vibration#Easyflex Vibration Isolation#Spring Isolators#Easyflex Products#Mechanical Engineering#Noise Reduction#Industrial Equipment#Shock Absorption#Structural Engineering#Noise Control#Anti-vibration Solutions#Machinery Isolation#Seismic Isolation#Engineering Components#Equipment Mounting#Noise and Vibration Control#Isolation Systems#Industrial Machinery#Vibration Damping#Elastic Support#Mechanical Isolation

0 notes