#Boeing 737 Max 9

Text

Of course I went looking

562 notes

·

View notes

Text

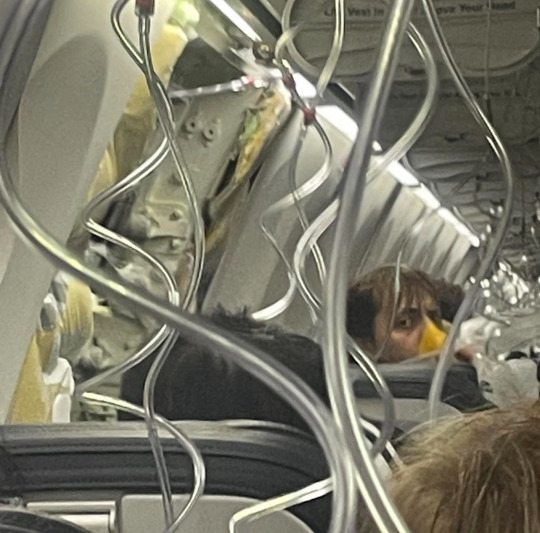

Holy…! 😳

No one has been reported as hurt, but the two people calmly sitting right next to the large OPEN FUCKING HOLE! in the aircraft fuselage need some kind of cash award or something (maybe like a class action lawsuit award or something, for mental anguish or pain and suffering, idk)

As far as I’m concerned, Boeing already has two strikes against them for their previous lies about their 747s that got innocent people killed

👉🏿 https://www.washingtonpost.com/travel/2024/01/05/alaska-airlines-plane-emergency-landing-portland/

#flight 1282#alaska airlines#boeing 737#boeing#alaska 1282#explosive decompression#boeing 737 max 9#mcas#maneuvering characteristics augmentation system

93 notes

·

View notes

Text

3 notes

·

View notes

Text

2 notes

·

View notes

Text

Opinión | Crisis en las alturas: Boeing 737, la FAA y el acoso institucional en México

Opinión | Crisis en las alturas: Boeing 737, la FAA y el acoso institucional en México

#PeriodismoParaTi #SociedadNoticias

#IPN #GómezMancilla @IPN_MX @SEP_mx @ONUDHmexico @STPS_mx @GobiernoMX @Letamaya @ArturoReyesS_ @Boeing @ArtsetMetiers_ #Boeing

La solución a este tipo de problemas en aeronaves de Boeing implica formar especialistas de alto nivel, pero lamentablemente, la situación en México se ve empañada por la falta de apoyo y el acoso institucional desde el mismo IPN.

Por Julio César Gómez Mancilla*

Antecedentes

La tragedia del vuelo 243 de Aloha Airlines que viajaba al Aeropuerto…

View On WordPress

#000 Km/hr en metales. La Ley postulada por nuestro profesor son teoría y ecuaciones sobre el crecimiento estable de fisuras; también su libr#000 y 7#acoso institucional en México#Administración Federal de Aviación#Al día siguiente en la Washington University St. Louis#Aloha Airlines#Andrés Manuel López Obrador#Arts et Métiers ParisTech (ENSAM)#Boeing#Boeing 737#Boeing 737 Max 9#Boeing de Alask Airlines#Cdmx#Claude Bathias#CNTE#Conacyt#coso#Crisis en las alturas#de allí la descripción#Educación#en la clase de Mecánica de la Fractura#esta última entre 5#Estados Unidos#explosiva. Una propagación inestable viaja a cerca de la mitad de la velocidad del sonido en el material fracturado#FAA#Fatiga de Alta Frecuencia#Fatiga por GIGA ciclos en la Práctica Mecánica#Fatiga por GIGA ciclos en la Práctica Mecánica es otra contribución#fatigada arriba del Kic#FATT

0 notes

Text

[ iPhone Survives Drop From Airplane ]

#wauln#fc 24#iphone#alaska airlines#Boeing 737 max 9#FAA#NTSB#ASA 1282#emergency landing#grounding#inspections#recall

0 notes

Text

Today’s ride

#travel#Boeing#boeing 737#737 max-9#united airlines#boston logan airport#aviation#transcontinental#jet#airport

3 notes

·

View notes

Text

Boeing pays Alaska Airlines $160 Million after in-flight panel blowout

By Frank Savage, The Chicago Times

April 5, 2024

SEATTLE, WA – In a move to compensate for a dramatic mid-air incident, Boeing has agreed to pay Alaska Airlines $160 million. This settlement stems from a harrowing experience on an Alaska Airlines Boeing 737 Max 9 flight back in January.

The incident involved a panel blowout at 16,000 feet over Oregon. Thankfully, the pilots managed to land…

View On WordPress

#737 MAX 9#ALASKA AIRLINES#BOEING#FAA#FEDERAL AVAIATION ADMINISTRATION#FINANCIAL DAMAGES#MID-AIR INCIDENT#PANEL BLOWOUT

0 notes

Text

What Has Happened to Boeing Since the 737 Max Crashes

— By Priyanka Boghani and Kaela Malig | March 13, 2024

A still from "Boeing's Fatal Flaw," a new FRONTLINE Documentary with The New York Times.

Five years ago, 346 people were killed in two crashes involving Boeing 737 Max planes within the span of almost five months: first off the coast of Indonesia in October 2018 and then in Ethiopia in March 2019.

Boeing’s Fatal Flaw, a 2021 FRONTLINE investigation with The New York Times, examined how commercial pressures, flawed design and failed oversight contributed to those devastating tragedies and a catastrophic crisis at one of the world’s most iconic industrial names.

In recent months, Boeing has come under renewed scrutiny after a door-like panel on a Boeing 737 Max 9 operated by Alaska Airlines blew off just a few minutes after takeoff in January 2024. An updated version of our documentary examines the impact of this latest crisis.

“This was supposed to be one of the most highly scrutinized planes in the world. And here you are with another incident that was risking passengers’ lives,” the Times’ Sydney Ember says in the updated documentary.

Here we take a brief look at what has happened to Boeing since the deadly 2018 and 2019 crashes and the recent Alaska Airlines incident.

Change in Leadership

Dennis Muilenburg had been CEO of Boeing since 2015. In the aftermath of the crashes, he testified before U.S. Senate and House Committees in October 2019, acknowledging the fatal accidents happened “on my watch” and saying he and the company were accountable. He told the House Committee on Transportation and Infrastructure, “If we knew back then what we know now, we would have grounded [the 737 Max] right after the first accident.”

Two months after the congressional hearings, on Dec. 23, 2019, Muilenburg was fired by Boeing. The company described the move as “necessary to restore confidence” in Boeing “as it works to repair relationships with regulators, customers, and all other stakeholders.”

David Calhoun stepped into the role of CEO in January 2020 and continues to fill the position.

A $2.5 Billion DOJ Settlement and Challenges

On Jan. 7, 2021, the Department of Justice announced that Boeing would pay a $2.5 billion settlement, resolving a DOJ charge that the company had conspired to defraud the Federal Aviation Administration’s Aircraft Evaluation Group.

The DOJ’s criminal investigation focused on the actions of two employees who Boeing said in court documents “deceived the FAA AEG” about the Maneuvering Characteristics Augmentation System (MCAS) onboard the 737 Max — a system the DOJ said “may have played a role” in both 737 Max crashes. The DOJ said the employees’ “deception” led to information about MCAS being left out of a key document released by the FAA, as well as airplane manuals and pilot-training materials.

As Boeing’s Fatal Flaw recounts, congressional investigators found internal documents showing that, after Boeing realized the impact MCAS would have on pilot training and FAA certification, some Boeing employees suggested removing all references to MCAS from training manuals.

“Boeing’s employees chose the path of profit over candor by concealing material information from the FAA concerning the operation of its 737 Max airplane and engaging in an effort to cover up their deception,” said David P. Burns, the acting assistant attorney general of the DOJ’s criminal division when the settlement was announced.

The company entered into a deferred prosecution agreement with the DOJ, in which Boeing agreed to pay a nearly $244 million fine, to set up a $500-million fund for the families of people who died in the two crashes, and to pay $1.77 billion to airlines that had been affected by the 20-month grounding of the 737 Max that began in March 2019.

Boeing also agreed to continue cooperating with the DOJ’s Fraud Section on “any ongoing or future investigations and prosecutions” and is required to report any alleged violation of fraud laws by Boeing employees when dealing with foreign or domestic agencies, regulators or airline customers.

Boeing declined FRONTLINE’s request to be interviewed for the documentary. In a statement, the company said safety is its top priority and it has worked closely with regulators, investigators and stakeholders “to implement changes that ensure accidents like these never happen again.”

Former Boeing Pilot Found Not Guilty for Fraud

In October 2021, a federal grand jury criminally indicted Mark Forkner, Boeing’s Former Chief Technical Pilot for the 737 Max Airplane, on fraud charges. Forkner, who became the first and so far only individual to face criminal charges after the two fatal crashes, was accused of providing “materially false, inaccurate and incomplete information” to FAA regulators about flight-control software involved in the 2018 and 2019 crashes. Forkner was later found not guilty of all charges in federal court.

Forkner declined to be interviewed for the documentary, but his lawyer told the Times that his communications with the FAA were honest and that “he would never jeopardize the safety of other pilots or their passengers.”

Lawsuits by Families of Crash Victims

By November 2019, Boeing was facing more than 150 lawsuits filed by families of people who had died in the two crashes — over 50 of the suits stemming from the Indonesian crash and about 100 from the crash in Ethiopia, according to the Associated Press’ review of federal court records.

In July 2020, Boeing told a U.S. federal court that claims related to 171 of the 189 people killed in the Indonesia crash were either partially or fully settled, although the settlements were not publicly disclosed.

As of June 2023, cases related to 68 passengers from the Ethiopian Airlines crash were pending.

The Grounding and Return of the 737 Max 8 and Max 9

In the days after the second 737 Max crashed in March 2019, regulators around the world — from China to the European Union and several other countries — grounded the plane. The U.S. Federal Aviation Administration followed suit on March 13, 2019, after initially saying the planes were safe to fly.

When the FAA retested and approved the 737 Max 8 and Max 9, ending the grounding in November 2020, it required airlines to take the following steps before putting the planes back into service: installing new flight-control-computer and display-system software; incorporating revised flight-crew procedures; rerouting wiring; completing a test of the “angle of attack” sensor system, which had contributed to both the 2018 and 2019 crashes; and performing an operational readiness flight.

The FAA, in conjunction with aviation agencies from Canada, Brazil and the European Union, also concluded that pilots operating the 737 Max would need to complete special training. It is not clear who would pay for this additional training, which reversed one of Boeing’s original sales pitches to airlines for the 737 Max: that the plane would require minimal pilot training.

A December 2020 Senate committee report criticized Boeing and the FAA’s handling of the 737 Max recertification testing, saying that, based on whistleblower information and testimony, it appeared Boeing and FAA officials had “established a pre-determined outcome,” and that Boeing officials “inappropriately coached” test pilots in the MCAS simulator. The report alleged, “It appears, in this instance, FAA and Boeing were attempting to cover up important information that may have contributed to the 737 MAX tragedies.”

The FAA responded at the time, saying: “Working closely with other international regulators, the FAA conducted a thorough and deliberate review of the 737 Max.” The agency added it was “confident” the issues that led to the two crashes had been “addressed through the design changes required and independently approved by the FAA and its partners.”

“We have learned many hard lessons” from the crashes, Boeing said in its own statement at the time. The company said it took the committee’s findings seriously and would continue to review the report in full.

Following the Senate report, families of the 2019 Ethiopian crash victims wrote to the FAA and the U.S. Department of Transportation in a letter dated Dec. 22, 2020, and reviewed by Reuters, asking for the 737 Max approval to be rescinded and for an investigation to “determine whether the MAX recertification process was tainted.”

A Brazilian airline was the first to fly a 737 Max after regulators there followed the FAA in ungrounding the plane. On Dec. 29, 2020 — a week after the families’ letter — the 737 Max flew paying passengers in America for the first time after nearly two years of being grounded. A month later, Europe’s aviation authority also gave the 737 Max clearance to fly.

On Aug. 26, 2021, India lifted its ban on the 737 Max after “closely” monitoring the plane’s performance elsewhere and noting “no untoward reporting.” China, which was the first country to ground Max jets after the deadly crashes, resumed commercial flights with the model in January 2023.

The 737 Max 10

On June 18, 2021, Boeing’s new model 737 Max 10 took to the skies for its first flight. The Max 10 is larger than the Max 8, which was involved in the 2018 and 2019 crashes, and the Max 9. According to Boeing’s technical specs, the Max 10 is 14 feet longer than the Max 8 and can seat a maximum of 230 people, compared to the Max 8’s capacity of 210.

At the time of the test flight, Boeing was already working on additional safety features in the Max 10 requested by European regulators, according to Reuters.

“We’re going to take our time on this certification,” Stan Deal, who became president and CEO of Boeing’s Commercial Airplanes division in October 2019, said at the time of the Max 10’s first flight, according to The Seattle Times. “We’re committed to make further safety enhancements.”’

The FAA cleared the Max 10 to begin test flights, a step towards certification, last November.

Alaska Airlines Plane Incident

On January 5, an Alaska Airlines jet made an emergency landing in Portland, Oregon, after a portion of its fuselage blew out and left a door-sized hole in the side of the aircraft while it was around 16,000 feet in the sky. None of the 171 passengers and six crew members were seriously injured. The FAA temporarily grounded more than 170 Max 9 jets so they could be inspected.

In the aftermath, Boeing CEO David Calhoun has said, “Boeing is accountable for what happened.”

A Feb. 6 preliminary report from the National Transportation Safety Board said that the bolts meant to secure the door-like panel appeared to be missing before the flight.

Later the same month, the FAA released a long-awaited report that found that Boeing’s safety culture has been “inadequate” and “confusing.” The FAA gave Boeing 90 days to come up with a plan to address quality control issues.

The FAA conducted a six-week audit after the Alaska Airlines incident, and on March 4 said that it found Boeing had allegedly failed to comply with manufacturing quality control requirements.

Boeing now faces legal trouble in relation to the Jan. 5 event, including lawsuits filed by passengers and shareholders.

On Feb. 21, Boeing told employees that Ed Clark, who led the 737 program since 2021, would be replaced. The memo announcing Clark’s departure and other changes said the company was focused “on ensuring that every airplane we deliver meets or exceeds all quality and safety requirements.”

The Justice Department has also begun a criminal investigation into Boeing in the aftermath of the Alaska Airlines incident, as reported first by The Wall Street Journal.

“Cultural change doesn’t happen overnight, especially at big corporations like this,” David Gelles, one of the Times reporters featured in Boeing’s Fatal Flaw, says. “If Boeing wants to get back to that place of grandeur where it was for so long one of the most important American companies, it’s going to take not four years, but it might take 14.”

#Boeing#Frontline#737 Max Crashes#Priyanka Boghani and Kaela Malig#Leadership#A $2.5 Billion DOJ Settlement#Mark Forkner | Boeing’s Former Chief Technical Pilot | 737 Max Airplane#Lawsuits By Families#Grounding | Returning | 737 Max 8 | 737 Max 9#737 Max 10#Alaska Airlines | Plane Incident#Boeing’s Fatal Flaws#The New York Times#U.S. Senate and House Committees#House Committee on Transportation and Infrastructure#Dennis Muilenburg | CEO of Boeing | Fired#New CEO | Boeing | David Calhoun#Maneuvering Characteristics Augmentation System (MCAS)#150 Lawsuits Filed By families | 50 By Indonesian Families#MCAS Simulator

0 notes

Text

notes of a restless girl.

Okay then...

Word on the street is that Tom Brady would come back out of retirement if he only had to work on Sunday's. Okay then... come back.

If you react with kindness, sympathy, and compassion, you put the best part of yourself out there. And that is definitely going to come back to you. Okay then, I have to remember that.

Oh great, now there's lead in Stanley cups! But they only pose a risk of lead exposure if the cover on the bottom of the tumbler comes off and exposes the pellet used to seal the cup's vacuum insulation. Okay then, they're okay to put liquid in.

Okay then...

Here's an old journal entry I wrote in my wordpress page talking about my lovers... (my love of poetry and who were my favorite poets metaphorically). January 2016

my lovers

I’ve danced a thousand beats in time to F. Scott Fitzgerald. On occasion we sleep side by side, he is a wonderful lover and a fellow hopeless romantic. We meet on the streets of Paris and dance at the stroke of midnight, reminiscing the roaring 20’s, the age of intolerance with so much jazz and modernness.

I take bubble baths with E.E. cumings, he likes the smell of lavender, and he scrubs my back as he dons his hat smoking his most favorite lush cigar. We listen to French music, J’ai d’amour, he likes to do things his way, or nothing at all, he’s so bizarre.

I share wine underneath the trees with Robert Frost. He likes red, Pinot Noir, and whistles show tunes from his lips. He loves the countryside and to feel the grass between his toes, a giver of life’s beauty... he always hands me a rose.

Charles Bukowski just wants to have sex with me and at times I find that a thrill… a tad arrogant and rude, but still, I respect his undying words, they are so real. We’ve had many talks about his “whore” ways, but he still makes me giggle as he drinks his cheap whiskey, and smokes like a stack, he’s so frisky.

William Shakespeare whispers softly in my ear, a classical touch so debonair, on a starry night and his words never bore me, thou shall live in my soul and love thee for an eternity.

Edgar Allen Poe, well… what can I say about him? He has my undying attention, and whispers from his grave where he is safely kept in. I listen to him on the eve of a moonlit night, his haunting blooms that saturate the sky and succumb to the beats of his heart, where we feast our eyes on the raven’s claw as hollow as the echoes that chant nearby, from the souls of the lost departed, who simply just cry.

0 notes

Text

Here we go again...

Doubtful the airlines are going to want to pay out of pocket for this expensive grounding.

1 note

·

View note

Text

Boeing 737 MAX 9 has issues with incorrectly drilled holes and missing bolts apparently.

157 notes

·

View notes

Text

Boeing internal whistleblower RE: MAX DOOR

Via hacker news: A Boeing whistleblower commenting on an airline forum about the cause of the MAX-9 emergency door blowout on January 22nd, based on the detailed internal chat history about that aircraft he was able to find. Seems to be entirely born out by the FAA's preliminary incident report released this afternoon:

With that out of the way… why did the left hand (LH) mid-exit door plug blow off of the 737-9 registered as N704AL? Simple- as has been covered in a number of articles and videos across aviation channels, there are 4 bolts that prevent the mid-exit door plug from sliding up off of the door stop fittings that take the actual pressurization loads in flight, and these 4 bolts were not installed when Boeing delivered the airplane, our own records reflect this.

The mid-exit doors on a 737-9 of both the regular and plug variety come from Spirit already installed in what is supposed to be the final configuration and in the Renton factory, there is a job for the doors team to verify this “final” install and rigging meets drawing requirements. In a healthy production system, this would be a “belt and suspenders” sort of check, but the 737 production system is quite far from healthy, its a rambling, shambling, disaster waiting to happen. As a result, this check job that should find minimal defects has in the past 365 calendar days recorded 392 nonconforming findings on 737 mid fuselage door installations (so both actual doors for the high density configs, and plugs like the one that blew out). That is a hideously high and very alarming number, and if our quality system on 737 was healthy, it would have stopped the line and driven the issue back to supplier after the first few instances. Obviously, this did not happen. Now, on the incident aircraft this check job was completed on 31 August 2023, and did turn up discrepancies, but on the RH side door, not the LH that actually failed. I could blame the team for missing certain details, but given the enormous volume of defects they were already finding and fixing, it was inevitable something would slip through- and on the incident aircraft something did. I know what you are thinking at this point, but grab some popcorn because there is a plot twist coming up.

114 notes

·

View notes

Text

The documents, obtained exclusively by Al Jazeera via a freedom of information request, do not provide details of the alleged workplace violations or alleged retaliation by Boeing in each case.

However, 13 of the complaints were filed under a statute that protects whistleblowing related to aviation safety.

Fifteen of the complaints were filed under a statute related to workplace safety, two were filed under the category of fraud, and one related to the control of toxic chemicals.

Apart from monetary restitution being awarded in two cases, all of the complaints where an outcome was specified were closed without the agency taking action, according to the figures.

[...]OSHA did not respond to requests for comment. Boeing did not respond to inquiries in time for publication.

The revelations come as the public testimony of a number of current and former Boeing employees is refocusing attention on the aircraft manufacturer’s allegedly hostile environment for whistleblowers and lax safety standards.

At a US Senate committee hearing on Wednesday, Boeing engineer Sam Salehpour testified that he had been threatened for raising concerns about gaps between key sections of the 787 Dreamliner.

"They are putting out defective airplanes,” Salephour said. “I have serious concerns about the safety of the 787 and 777 aircraft, and I’m willing to take on professional risk to talk about them.”

Another witness, Ed Pierson, a former Boeing engineer, accused the company of a “criminal cover-up” in the investigation of the midair blowout of a Boeing 737 Max 9 in January that prompted regulators to put a cap on the manufacturer’s production.

92 notes

·

View notes

Text

Remember that 737 MAX whose door plug blew out in flight?

A boeing whistleblower created a burner account and reported the following (reproduced here in its entirety in case the original gets deleted):

Current Boeing employee here – I will save you waiting two years for the NTSB report to come out and give it to you for free: the reason the door blew off is stated in black and white in Boeings own records. It is also very, very stupid and speaks volumes about the quality culture at certain portions of the business.

A couple of things to cover before we begin:

Q1) Why should we believe you?

A) You shouldn’t, I’m some random throwaway account, do your own due diligence. Others who work at Boeing can verify what I say is true, but all I ask is you consider the following based on its own merits.

Q2) Why are you doing this?

A) Because there are many cultures at Boeing, and while the executive culture may be throughly compromised since we were bought by McD, there are many other people who still push for a quality product with cutting edge design. My hope is that this is the wake up call that finally forces the Board to take decisive action, and remove the executives that are resisting the necessary cultural changes to return to a company that values safety and quality above schedule.

With that out of the way… why did the left hand (LH) mid-exit door plug blow off of the 737-9 registered as N704AL? Simple- as has been covered in a number of articles and videos across aviation channels, there are 4 bolts that prevent the mid-exit door plug from sliding up off of the door stop fittings that take the actual pressurization loads in flight, and these 4 bolts were not installed when Boeing delivered the airplane, our own records reflect this.

The mid-exit doors on a 737-9 of both the regular and plug variety come from Spirit already installed in what is supposed to be the final configuration and in the Renton factory, there is a job for the doors team to verify this “final” install and rigging meets drawing requirements. In a healthy production system, this would be a “belt and suspenders” sort of check, but the 737 production system is quite far from healthy, its a rambling, shambling, disaster waiting to happen. As a result, this check job that should find minimal defects has in the past 365 calendar days recorded 392 nonconforming findings on 737 mid fuselage door installations (so both actual doors for the high density configs, and plugs like the one that blew out). That is a hideously high and very alarming number, and if our quality system on 737 was healthy, it would have stopped the line and driven the issue back to supplier after the first few instances. Obviously, this did not happen. Now, on the incident aircraft this check job was completed on 31 August 2023, and did turn up discrepancies, but on the RH side door, not the LH that actually failed. I could blame the team for missing certain details, but given the enormous volume of defects they were already finding and fixing, it was inevitable something would slip through- and on the incident aircraft something did. I know what you are thinking at this point, but grab some popcorn because there is a plot twist coming up.

The next day on 1 September 2023 a different team (remember 737s flow through the factory quite quickly, 24 hours completely changes who is working on the plane) wrote up a finding for damaged and improperly installed rivets on the LH mid-exit door of the incident aircraft.

A brief aside to explain two of the record systems Boeing uses in production. The first is a program called CMES which stands for something boring and unimportant but what is important is that CMES is the sole authoritative repository for airplane build records (except on 787 which uses a different program). If a build record in CMES says something was built, inspected, and stamped in accordance with the drawing, then the airplane damn well better be per drawing. The second is a program called SAT, which also stands for something boring and unimportant but what is important is that SAT is *not* an authoritative records system, its a bullentin board where various things affecting the airplane build get posted about and updated with resolutions. You can think of it sort of like a idiots version of Slack or something. Wise readers will already be shuddering and wondering how many consultants were involved, because, yes SAT is a *management visibilty tool*. Like any good management visibilty tool, SAT can generate metrics, lots of metrics, and oh God do Boeing managers love their metrics. As a result, SAT postings are the primary topic of discussion at most daily status meetings, and the whole system is perceived as being extremely important despite, I reiterate, it holding no actual authority at all.

We now return to our incident aircraft, which was written up for having defective rivets on the LH mid-exit door. Now as is standard practice kn Renton (but not to my knowledge in Everett on wide bodies) this write-up happened in two forms, one in CMES, which is the correct venue, and once in SAT to “coordinate the response” but really as a behind-covering measure so the manager of the team that wrote it can show his boss he’s shoved the problem onto someone else. Because there are so many problems with the Spirit build in the 737, Spirit has teams on site in Renton performing warranty work for all of their shoddy quality, and this SAT promptly gets shunted into their queue as a warranty item. Lots of bickering ensues in the SAT messages, and it takes a bit for Spirit to get to the work package. Once they have finished, they send it back to a Boeing QA for final acceptance, but then Malicious Stupid Happens! The Boeing QA writes another record in CMES (again, the correct venue) stating (with pictures) that Spirit has not actually reworked the discrepant rivets, they *just painted over the defects*. In Boeing production speak, this is a “process failure”. For an A&P mechanic at an airline, this would be called “federal crime”.

Presented with evidence of their malfeasance, Spirit reopens the package and admits that not only did they not rework the rivets properly, there is a damaged pressure seal they need to replace (who damaged it, and when it was damaged is not clear to me). The big deal with this seal, at least according to frantic SAT postings, is the part is not on hand, and will need to be ordered, which is going to impact schedule, and (reading between the lines here) Management is Not Happy. 1/2

2/2

However, more critical for purposes of the accident investigation, the pressure seal is unsurprisingly sandwiched between the plug and the fuselage, and you cannot replace it without opening the door plug to gain access. All of this conversation is documented in increasingly aggressive posts in the SAT, but finally we get to the damning entry which reads something along the lines of “coordinating with the doors team to determine if the door will have to be removed entirely, or just opened. If it is removed then a Removal will have to be written.” Note: a Removal is a type of record in CMES that requires formal sign off from QA that the airplane been restored to drawing requirements.

If you have been paying attention to this situation closely, you may be able to spot the critical error: regardless of whether the door is simply opened or removed entirely, the 4 retaining bolts that keep it from sliding off of the door stops have to be pulled out. A removal should be written in either case for QA to verify install, but as it turns out, someone (exactly who will be a fun question for investigators) decides that the door only needs to be opened, and no formal Removal is generated in CMES (the reason for which is unclear, and a major process failure). Therefore, in the official build records of the airplane, a pressure seal that cannot be accessed without opening the door (and thereby removing retaining bolts) is documented as being replaced, but the door is never officially opened and thus no QA inspection is required.

This entire sequence is documented in the SAT, and the nonconformance records in CMES address the damaged rivets and pressure seal, but at no point is the verification job reopened, or is any record of removed retention bolts created, despite it this being a physical impossibility. Finally with Spirit completing their work to Boeing QAs satisfaction, the two rivet-related records in CMES are stamped complete, and the SAT closed on 19 September 2023. No record or comment regarding the retention bolts is made.

I told you it was stupid.

So, where are the bolts? Probably sitting forgotten and unlabeled (because there is no formal record number to label them with) on a work-in-progress bench, unless someone already tossed them in the scrap bin to tidy up.

There’s lots more to be said about the culture that enabled this to happened, but thats the basic details of what happened, the NTSB report will say it in more elegant terms in a few years.

73 notes

·

View notes

Text

SEATTLE, WA — Amid growing concerns over safety after several devastating mechanical failures on Boeing 737-9 Max aircraft, Boeing CEO Dave Calhoun assured hesitant travelers that all their aircraft are built according to the highest standards of diversity.

"I know everyone is nervous about the doors of their planes blowing off the aircraft mid-flight or the entire fuselage buckling due to faulty parts, but let me assure you: Boeing is diverse," said Calhoun in a CNBC interview. "In fact, our design and manufacturing crews are the most diverse in our company's history. Nothing to worry about."

Boeing is facing NTSB investigations after several mechanical failures that caused Alaska Airlines to ground all 737-9 Max aircraft. Calhoun said such concerns are unwarranted. "We have women, people of color, and even autistic paraplegics working on the 737," he said. "There's nothing safer than a plane built by diversity!"

At publishing time, 3 more airlines had grounded the aircraft, likely because they hate diversity.

58 notes

·

View notes