#plastic products

Text

Seriously why would you ever use a single use plastic bag? There are no advantages.

8 notes

·

View notes

Text

US appeals court kills ban on plastic containers contaminated with PFAS

Republicans absolutely do not give a fuck about your health so long as it affects profitability. They don't give la shit if a company produces a product that causes health problems.

Republicans will pretend to care about mothers and fertility with their anti-abortion bullshit whilst simultaneously allowing companies to pump fertility-destroying teratogenic compounds into their products.

#environmental protection agency#epa#texas#republicans#pfas#pfas pollution#plastic#plastic products#industry#fertility#miscarriage#abortion#republican hypocrisy#united states#capitalism#corporate greed#cancer#carcinogens

9 notes

·

View notes

Text

What material is PVDF?

PVDF is a very important high-performance engineering plastic. It has excellent chemical stability, heat resistance, weather resistance and mechanical properties, so it is widely used in various fields. The full name of PVDF is polyvinylidene fluoride, which is a thermoplastic fluoroplastic with excellent chemical corrosion resistance and electrical insulation properties. PVDF has attracted much attention due to its unique properties. Let’s take a closer look at what material PVDF is.

First, PVDF has excellent chemical resistance. PVDF has excellent acid and alkali resistance and good corrosion resistance to most organic solvents, acids, alkali and salts, so it is widely used in chemical pharmaceuticals, electroplating and other fields. In the chemical industry, PVDF is often used to manufacture pipes, pumps, valves and other equipment because it can effectively resist acid and alkali corrosion and ensure the stable operation of equipment.

Secondly, PVDF has excellent heat resistance. The melting point of PVDF is about 165°C, the long-term use temperature can reach 140°C, and the short-term use temperature is even higher. This allows PVDF to maintain stable performance in high temperature environments, so it is widely used in aerospace, automotive, electronics and other fields. For example, in the aerospace field, PVDF is often used to manufacture aircraft parts, such as pipes, connectors, etc., because it can maintain stable performance in high-temperature and high-pressure environments.

In addition, PVDF also has good weather resistance. PVDF has excellent UV resistance and anti-aging properties, so it can maintain stable performance for a long time in outdoor environments and is not prone to aging, discoloration, etc. Therefore, PVDF is often used to manufacture exterior wall panels in the fields of construction, billboards, solar energy, etc. , billboards, solar panels and other products to ensure their long-term stable performance in outdoor environments.

Finally, PVDF has excellent mechanical properties. PVDF has high strength and stiffness, as well as good toughness and impact properties, so it is widely used in machinery manufacturing, electrical equipment and other fields. In the field of machinery manufacturing, PVDF is often used to manufacture bearings, gears, seals and other products because it can maintain stable performance under high-speed, high-load working conditions.

To sum up, PVDF is a very important high-performance engineering plastic with excellent chemical stability, heat resistance, weather resistance and mechanical properties. Therefore, it is widely used in chemical industry, aerospace, construction, machinery manufacturing and other fields. It is believed that with the continuous advancement of technology, the application fields of PVDF will continue to expand, bringing more convenience and possibilities to all walks of life.

3 notes

·

View notes

Text

𝐋𝐞𝐚𝐝𝐢𝐧𝐠 𝐏𝐥𝐚𝐬𝐭𝐢𝐜 𝐏𝐫𝐨𝐝𝐮𝐜𝐭𝐬 𝐌𝐚𝐧𝐮𝐟𝐚𝐜𝐭𝐮𝐫𝐞𝐫 𝐢𝐧 𝐈𝐧𝐝𝐢𝐚.. Website: https://homeofplastics.com

#manufacturing#manufacturer#plastic products#plastic manufacturer#LDPE sheet#geo membrane sheet#home of plastic

4 notes

·

View notes

Text

Nirmalya Kalash: Bridging Tradition and Sustainability for Eco-Friendly Festivals

In India, religious festivals like Ganesh Chaturthi and Durga Puja are celebrated with great joy and tradition. One important part is immersing idols in water bodies. However, this leads to pollution from the materials used for idols and the waste produced during immersion, known as Nirmalya waste.

The effects of Nirmalya waste on the environment have come to light more and more recently. This has led to a number of attempts to identify long-term ways to efficiently handle this trash.

One such initiative taken by Swift Technoplast is of manufacturing and supplying Nirmalya Kalash, which is revolutionizing Nirmalya waste management practices.

What is Nirmalya Kalash?

Nirmalya are sacred leftovers from Hindu offerings. They can be anything from flowers to fruits, and they're offered to deities during worship ceremonies. However, the disposal of Nirmalya poses a significant environmental challenge, particularly during festivals when the volume of offerings surges.

Here steps in the Nirmalya Kalash, a simple yet ingenious solution. Instead of discarding Nirmalya directly into water bodies like rivers and lakes, devotees place them in designated Kalash (pots) at collection points. These Kalash serve as repositories for Nirmalya, facilitating its organized collection and subsequent eco-friendly processing.

How Nirmalya Kalash acts as a bridge between tradition and sustainability?

1. Preservation of Tradition:

Nirmalya Kalash honors age-old religious practices deeply ingrained in Indian culture. Nirmalya Kalash respects and preserves the traditional offerings made during festivals. By following these rituals, it keeps the connection with the past alive, helping communities maintain their cultural identity and heritage.

2. Adaptation to Modern Challenges:

While rooted in tradition, Nirmalya Kalash adapts to contemporary environmental challenges. Recognizing the detrimental impact of traditional Nirmalya disposal methods on water bodies, this practice offers a sustainable alternative. By channeling Nirmalya into designated Kalash for eco-friendly processing, it addresses concerns about water pollution and waste management, showcasing a willingness to adapt tradition to meet present-day needs.

3. Community Participation and Collaboration:

Nirmalya Kalash encourages active participation and collaboration within communities. Volunteers, religious organizations, and local authorities come together to set up collection points, manage Nirmalya disposal, and process organic waste. This team effort goes beyond individual convictions and differences to promote a sense of unity and shared responsibility. It strengthens the ties of community and tradition while highlighting the effectiveness of group effort in tackling environmental concerns.

4. Education and Awareness:

Nirmalya Kalash raises awareness about environmental issues and encourages sustainable practices. They use outreach programs, educational initiatives, and social media campaign to teach people about responsible waste management and how their actions affect the environment. By connecting traditional rituals with caring for the environment, Nirmalya Kalash helps people make eco-friendly choices.

5. Integration of Indigenous Knowledge:

Nirmalya Kalash combines ancient wisdom with modern science to tackle environmental issues. It uses traditional composting and waste management methods passed down through generations. By merging old practices with new technology, it offers a complete approach to sustainability that values and utilizes indigenous knowledge.

Conclusion:

Tradition and sustainability may coexist together, as demonstrated by Nirmalya Kalash, a living example. It creates a path towards a sustainable future by adopting the environmental demands while honouring the traditions of the past. Nirmalya Kalash encourages people and communities to enjoy their cultural heritage while actively participating in the preservation of the environment by serving as a link between tradition and sustainability.

#Nirmalya kalash#plastic products#plastic industry#plasticmanufacturer#Nirmalya kalash near me#swifttechnoplast#swifttechnoplastprivatelimited

0 notes

Text

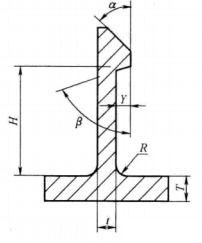

Plastic structure design 6 —part gaps, buckles and stops

To read previous article, please refer to Plastic structural design5 —hole, thread, and insert design requirements.

This article mainly introduces requirements for parts clearance, buckle positions and stops in design of plastic structures. See below for details;

1. Part clearance

In production and design of plastic products, it is very important to have a certain gap between parts (commonly…

View On WordPress

#Basic principles of buckle design#Buckle design#Buckle segmented design#Buckle-out glue design#Part clearance#plastic product parts#plastic products#Plastic structure design#production and design of plastic products#Stop design

0 notes

Text

Common Injection Molding Processes

Injection molding is a plastic processing technology widely used in the manufacturing industry, and common types of injection molding include the following:

Conventional injection molding: Conventional injection molding refers to the heating and melting of plastic materials into the mold, cooling to obtain a variety of different shapes of plastic products. Conventional injection molding is suitable for the production of various specifications, shapes and materials of plastic products, such as plastic tableware, home appliance shell and so on.

Two-color injection molding: Two-color injection molding refers to the injection molding of two different colors or materials of plastic materials in the same mold, so as to form different colors or materials on the same product. Two-color injection molding is suitable for the production of complex plastic products requiring multi-color or multi-material combinations, such as automotive interiors.

High-speed injection molding: High-speed injection molding refers to the use of high-speed injection, high-pressure injection and other technologies in the injection process, so as to achieve rapid production of plastic products. High-speed injection molding is suitable for the production of large volume, simple structure of plastic products, such as bottle caps.

Precision injection molding: Precision injection molding refers to the use of high-precision molds and high-precision injection machines in the injection process, so as to achieve high-precision, high-quality plastic products production. Precision injection molding is suitable for the production of precision, complex, high-quality plastic products, such as mobile phone shells, optical lenses, etc.

Pneumatic injection molding: Pneumatic injection molding refers to the use of air pressure to drive plastic materials into the mold during the injection process, so as to achieve efficient and high-quality plastic product production. Pneumatic injection molding is suitable for the production of high-volume, thin-wall, high-transparency plastic products, such as plastic cups, plastic glass and so on.

Large injection molding: Large injection molding refers to the production of large size, large weight and large volume plastic products through large injection molding machines and large molds, such as auto parts and engineering plastic products.

Thin-wall injection molding: Thin-wall injection molding refers to the production of thin-wall plastic products with wall thickness below 0.5mm through high-speed injection molding and high-precision molds, such as plastic containers, boxes, etc.

Micro-injection molding: Micro-injection molding refers to the production of micro-size plastic products through micro-injection molding machines and micro-molds, such as micro-parts, micro-devices, etc.

Composite injection molding: Composite injection molding refers to the injection of plastic materials of different materials into the same mold, thereby forming plastic products of composite materials, such as plastic metal composite products, plastic rubber composite products, etc.

Hot runner injection molding: Hot runner injection molding refers to the setting of heating elements in the mold, by controlling the temperature and position of the heating elements, to achieve the precise control of plastic materials into the mold, so as to produce high-quality, high-precision plastic products.

Injection molding is a very flexible and efficient plastic processing technology that is suitable for the production of a wide variety of plastic products. With the continuous progress of technology and the constant change of market demand, injection molding technology is also constantly developing and innovating, and the types and application fields of injection molding are also constantly expanding and deepening.

0 notes

Text

Exploring the World of Pound Wholesalers

Exploring the world of pound wholesalers unveils a treasure trove of affordable goods for savvy shoppers. These wholesalers offer a diverse range of products, from household essentials to trendy gadgets, all at incredibly low prices. With their wide selection and budget-friendly options, pound wholesalers cater to both individual consumers and businesses looking to stock up on inventory. Whether you're hunting for everyday necessities or seeking out unique finds, pound wholesalers provide an unparalleled shopping experience.

Read More

#pound shop#Pound Wholesaler#pound supplier#wholesaler#wholesaler in bradford#Plastic Products#Kitchenware

0 notes

Text

Experience innovation and quality at Ankurwares! Explore our high-quality plastic Houseware, Moulded Furniture, and premium PET Preforms. Click here to visit our website and discover excellence: Ankurwares.com

0 notes

Text

10 Best Non-Toxic Dinnerware Sets

When it comes to choosing dinnerware sets, you want to go for materials that are non-toxic and easy to clean. Moreover, your dinnerware set should be comprehensive, consisting of different plates, bowls, and other items that will help you serve your food items according to their portions, sizes, and types.

Thus, if you are searching for the best dinnerware sets, we have you covered. Read on to find out the top dinnerware sets of 2023!

The 10 best dinnerware sets in 2023

A good dinnerware set creates an enjoyable and memorable dining experience. It also lets you express your unique personality and style at the dinner table. This is why we explored various dinnerware sets and brought you our favorites.

Below are our top choices for the best dinnerware sets in 2023!

Varmora Polypropylene Dinner Set

Varmora is one of the leading homeware brands in India, and their range of dinnerware sets just hits the spot, ticking all the boxes you want to be ticked.

This dinnerware set comprises 36 pieces, including 2 Rice Plates, 12 Bowls, 2 Serving Spoons, 2 Ladles, 2 Casseroles, 6 Dinner Plates, 6 Side Plates, and 6 Katoris. What’s more, this dinnerware set comes in a pleasant light blue shade and is microwave, freezer, and dishwasher safe.

Varmora Red Dinner Set

This is another top-notch dinner set from Varmora that combines aesthetics with functionality. It comes in a set of 9 pieces consisting of 3 Dinner Plates, 3 Side Plates, and 3 Pcs Bowls. Microwave and dishwasher safe, this dinnerware set is convenient to clean and easy to store.

Cello Opalware Dinner Set

This dinnerware set from Cello has a total of 18 pieces, consisting of 6 pieces of Full Plates, 6 Pieces of Quarter Plates, and 6 Pieces of Veg Bowls. Microwavable and chip and stain-resistant, this dinnerware set comes in a soothing white color, making your dining table look pristine and elegant.

Larah by Borosil Dinner Set

This bone ash-free 100% vegetarian dinnerware set by Borosil has a total of 27 pieces. It is microwave-safe, has a stain-proof surface, and is both scratch and fade-resistant. Since it's made out of opal glass, this dinner set can be used by vegetarians and also for religious purposes.

Signoraware Plastic Dinnerware Set

This plastic dinnerware set from Signoraware is made from 100% food-grade plastic. It comes in a set of appetizing colors and is both microwave, dishwasher, and freezer-safe. What’s more, it is unbreakable, so those occasional drops and falls won’t matter.

Sarthak Uphaar Plastic

This dinnerware set from Sarthak has a playful look, making it a great choice for kids. It comes in a set of 24 pieces, consisting of 6 big plates, 6 quarter plates, 6 bowls and 6 Soup Spoons. Both BPA-free and odour-resistant, this dinner set can be a perfect addition to your dining table.

Nayasa Plastic Printed Dinner Set

This 32 pieces dinner set comes in a white color, complemented by soft pink hues. Consisting of 32 pieces, it has 6 pieces-full plate, 6-pieces quarter plate, 12-pieces small bowls, 2-pieces serving bowls, 1-piece rice plate, 2-pieces serving spoons and 1-piece rice serving spoon. Moreover, this dinnerware set adds a sense of style and sophistication to your dinner table.

Larah by Borosil Plain White Silk Series

Don’t fancy colored dinnerware sets? Well, then, this plain white dinnerware set by Borosil might be your perfect choice. Consisting of 35 pieces, it is made out of opal glass and has a space-saving stacking design. Oh, and it’s also microwave-safe and chip-resistant.

KORBOX Donut 5 Meal Dinnerware Set

Want something simple? Well, check out this dinnerware set by Korbox. This set of 4 dinnerware set is perfect for children or serving a two-person meal. It is made out of BPA-free plastic and is also top-rack dishwasher safe.

MEZON Wheat Straw Dinnerware Sets

Are you looking for a one-person meal dinnerware set? If yes, then this dinnerware set is perfect for you. Made from recyclable wheat straw and PP plastic, you can feel good about using this set as it is biodegradable. Moreover, it's also microwavable and dishwasher safe.

Final Thoughts

There you have it, our list of the top 10 dinnerware sets of 2023. Choose the one that suits your preferences, style and unique needs.

0 notes

Text

The Unrivaled Impact of Sin Ee Sheng Import & Export in the World of Plastic Products

In the intricate web of industries worldwide, plastic products emerge as the silent heroes, facilitating seamless operations and elevating efficiency across sectors. At the forefront of this revolution stands Sin Ee Sheng Import & Export, an industry leader since its establishment in 1987. With a legacy spanning over three decades, our company has been the cornerstone of innovation, specializing in the general wholesale and distribution of heavy-duty & multi-purpose industrial plastic containers. Let's delve into the story of how Sin Ee Sheng Import & Export has transformed the landscape of plastic products, leaving an indelible mark on various industries.

A Journey of Excellence: Since 1987

Sin Ee Sheng Import & Export embarked on its journey with a clear vision – to provide superior quality plastic products that redefine industry standards. With a commitment to excellence and an unwavering focus on customer satisfaction, our company swiftly gained recognition as a reliable supplier of heavy-duty and multi-purpose industrial plastic containers. This recognition, earned through years of dedication, laid the foundation for our enduring success.

Unveiling the Essence: Heavy Duty & Multi-Purpose Industrial Plastic Containers

At the heart of Sin Ee Sheng Import & Export's offerings lie heavy-duty and multi-purpose industrial plastic containers. Crafted with precision and designed for versatility, these containers have become integral to a myriad of industries. From manufacturing units requiring robust storage solutions to logistics companies seeking secure transportation options, our containers have seamlessly integrated into diverse workflows. Their impact extends to agriculture, retail, and beyond, underscoring their adaptability and reliability.

Quality Redefined: The Sin Ee Sheng Standard

Quality is not merely a feature of our products; it is the essence of our brand. Each plastic container that bears the Sin Ee Sheng Import & Export name undergoes stringent quality checks, ensuring it meets and exceeds industry benchmarks. Durability, resilience, and functionality are not compromises but guarantees. Our clients have come to expect nothing less than perfection, and we deliver precisely that.

Versatility: Tailored Solutions for Varied Needs

The versatility of our plastic products is a testament to our commitment to meeting diverse industry needs. Sin Ee Sheng Import & Export understands that every sector has unique requirements. As a result, our product range is not one-size-fits-all but a spectrum of options catering to specific demands. Whether it's safeguarding fragile goods during transit or optimizing storage space for bulk materials, our plastic containers are engineered to perform with finesse.

Innovation Driving Progress: Staying Ahead of the Curve

Innovation is the cornerstone of Sin Ee Sheng Import & Export's success. We are not content with meeting existing standards; we strive to set new ones. Through continuous research and development, we stay ahead of industry trends, integrating cutting-edge materials and design concepts into our products. This forward-thinking approach ensures that our clients receive solutions that are not only current but also future-proof.

Sustainability: A Responsible Commitment

In an era where environmental consciousness is paramount, Sin Ee Sheng Import & Export leads the way in sustainable practices. We are committed to eco-friendly manufacturing processes, emphasizing the use of recyclable materials. Our containers are not just reliable; they are also environmentally responsible, contributing to a greener planet.

A Partnership for Progress: Sin Ee Sheng Import & Export and Industries Worldwide

Beyond being a supplier, Sin Ee Sheng Import & Export is a partner in progress for industries across the globe. Our clients do not just receive plastic products; they receive solutions that enhance their operations, streamline their processes, and bolster their efficiency. We take pride in being an integral part of their success stories, enabling them to navigate the complexities of their respective industries with confidence.

Conclusion: A Future Defined by Excellence

As we reflect on our journey, Sin Ee Sheng Import & Export stands as a beacon of quality, innovation, and reliability. The trust bestowed upon us by industries worldwide fuels our determination to continue shaping the world of plastic products. The years behind us are a testament to our capabilities; the years ahead of us hold the promise of further achievements and advancements.

In every plastic product that bears our name, there is not just functionality but a legacy of excellence. Sin Ee Sheng Import & Export is not just a company; it is a commitment to the future, a promise of unparalleled quality, and a catalyst for progress. As industries evolve, so do we, ensuring that the Sin Ee Sheng standard remains synonymous with excellence in the realm of plastic products. Together with our clients, we embark on a future defined by innovation, sustainability, and unwavering dedication to perfection.

0 notes

Link

Industries That Use Industrial Vacuum Forming Machines!

Vacuum forming machines are used to create a wide range of plastic products, from automotive components to medical devices. Ridat, a leading manufacturer of vacuum forming machines, discusses the top industries that use thermoforming processes to design their products.

#vacuum forming machines#Thermoforming#plastic products#Automotive#Medical#Aerospace#Construction#Ridat

0 notes

Text

Fluorine products processing

PVDF has multiple excellent properties such as elasticity, low weight, low thermal conductivity, high chemical resistance and heat resistance.

Henan Six Fluorochemical Co., Ltd

WhatsApp/Telegram:+(86)15038852660

1 note

·

View note

Text

EU has recently banned glitter and the ban will become effective on October 15th this year. Plastic straws and some other single-use plastic productions like plates and cotton buds got banned back in summer 2021, and have since been replaced with non-plastic ones

While I'm definitely not against minimizing the amount of microplastics ending up in the environment, this still feels so strange... Like, I know it's a good thing to get rid of plastic products but they have been around since 1960s (actually much longer than that but that's when the became common) and that's what people in western societies, including me, are used to

0 notes

Text

Single Drum Spill Containment Pallets

Swift's Single Drum Spill Containment Pallets is designed for secure containment and effortless handling of stored drums. Crafted from premium quality of food-grade materials and trusted by over 5000 global brands, our pallets guarantee 100% customer satisfaction. Ensure reliable protection and seamless maneuverability for your drums with Swift. Elevate your containment solutions with the leading manufacturer and supplier in India.

🏢 Swift Technoplast Pvt Ltd

🌐 www.swiftind.co.in

📞 +91-88888 00064

#Spillage Plastic Pallet#Spill Containment Pallet#Spill Pallets#Spillage Pallet#Drum Spill Pallets#Drum Spillage Pallet#plastic products#swifttechnoplast#plastic industry#plasticmanufacturer

0 notes

Text

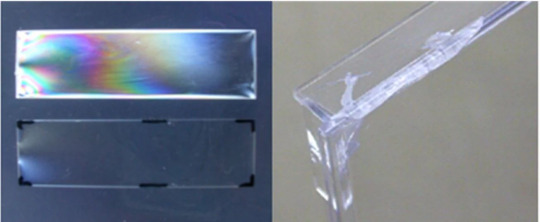

Technical Article] Key Factors to Reduce Residual Stress in Plastic Parts

Preface

In design of plastic parts, generation of residual stress has a significant impact on performance and life of parts. Residual stress is internal stress generated during molding process of plastic parts. It mainly includes two types: one is internal stress (flow residual stress) that still exists after external load is removed, the other is internal stress (thermal residual stress) caused…

View On WordPress

#Core-pulling design#injection products#Key Factors to Reduce Residual Stress in Plastic Parts#machining process#mold design#molded part#molding process#molding process of plastic parts#plastic parts#plastic products#polymer molecular chain#thermal residual stress

0 notes