#ptfe

Text

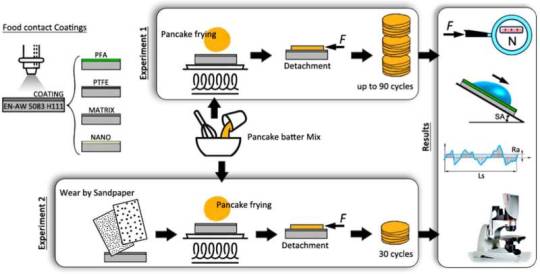

The technological challenge of non-stick pans: Teflon is still more effective than other coatings

A protocol designed by the University of Cordoba yields a simple and robust evaluation of the efficiency and durability of different commercial non-stick coatings used for food preparation

By the time a dish reaches a table, science has already been applied to a myriad of processes. From growing techniques that achieve sustainable, high-quality food to technology that prevents food from sticking to the cookware used to prepare it. In fact, non-stick coatings have been enhancing the relationship between pans and food for more than 60 years thanks to the invention of polytetrafluoroethylene, better known by its trade name, Teflon.

These fluoropolymer coatings, standing out for their anti-adhesive power, seem to have their days numbered; however, as the European Union's medium-term strategy is to reduce or eliminate their use due to possibly harmful effects on health and the environment produced during their manufacture, though this is still being debated in the international scientific community.

Read more.

#Materials Science#Science#Polytetrafluorethylene#PTFE#Coatings#Polymers#Toxicity#University of Cordoba#Food science

10 notes

·

View notes

Video

youtube

PFA reaction tank can extract experimental reaction liquid

2 notes

·

View notes

Text

Ống Teflon PTFE

Ống Teflon PTFE hay ống nhựa Teflon PTFE chịu nhiệt độ cao Với khả năng chịu nhiệt từ -200oC đến 260oC, ống nhựa Teflon không chỉ giữ vững tính ổn định dưới những điều kiện nhiệt độ cao mà còn có nhiều tính chất đáng chú ý. Bề mặt trơn trượt của nó giúp giảm ma sát và tăng hiệu suất hoạt động và cùng với đó là khả năng chịu áp, khả năng chống lại dầu, hóa chất và khả năng chống mài mòn xuất sắc đặc biệt đã biến ống Teflon PTFE thành một sự lựa chọn lý tưởng cho nhiều ứng dụng.

2 notes

·

View notes

Text

IHF single stage single suction pump PTFE lined pump centrifugal chemical pump is working for highly corrosive mediums between -85°C~120°C (-121°F~248°F), such as arbitrary concentration of vitriol, muriatic acid, hydrofluoric acid, nitric acid, aqua regia, strong base, strong oxidant, organic solvent, reducing agent, etc.

Pump Model: IHF65-50-160

Flow rate:25m3/h

Head:32

Inlet/outlet diameter:65mm/50mm

Seal: single mechancial seal

Motor power:5.5kw/400v/3Ph/50Hz/2900rpm

Pump destination: Vietnam chemical project

#chemical#chemicalpumps#ptfe#pumps#chemicalindustry#chemicalengineering#chemicalplant#vietnam#jushipump#teflonpump#PTFELINEDPUMP#endsuctionpump#singlestagepump#IHFPUMP#centrifugalpump

If you have any inquiry or question, please feel free to contact me at [email protected] and WhatsApp +86 155 87495056.

#chemical#chemicalpumps#ptfe#pumps#chemicalindustry#chemicalengineering#chemicalplant#vietnam#jushipump#teflonpump#PTFELINEDPUMP#endsuctionpump#singlestagepump#IHFPUMP#centrifugalpump#jushi

4 notes

·

View notes

Text

PTFE

PTFE molding powder middle particle

PTFE molding powder small particle

PTFE fine powder

Please contact me for a quote if required.

Henan Sixfluorine Chemical Co.,Ltd

WhatsApp/Telegram:+(86)15038852660

Mail:[email protected]

1 note

·

View note

Text

Oh, interesting! So non-stick frying pans are just the new thing to panic about, huh?

0 notes

Text

The PTFE Ring Gasket Revolution

The PTFE ring gasket is a beacon of innovation and efficiency in the intricate world of industrial sealing solutions, where precision and reliability are paramount. Crafted from Polytetrafluoroethylene (PTFE), this specialized gasket offers a unique combination of properties that make it indispensable across many industries. In this blog post, we delve into the intricacies of PTFE ring gaskets, exploring their features, benefits, and transformative impact on industrial applications.

Understanding PTFE Ring Gaskets

PTFE ring gaskets are precision-engineered seals that provide tight and reliable sealing in various applications. These gaskets are composed of high-quality PTFE material and boast exceptional chemical resistance, temperature tolerance, and low friction properties. Their ring-shaped design allows for easy installation and ensures uniform compression, resulting in a secure seal that effectively prevents leaks and contamination.

Features and Benefits

Chemical Resistance: PTFE ring gaskets exhibit unparalleled resistance to various chemicals, acids, and solvents, making them ideal for sealing applications in corrosive environments.

Temperature Tolerance: Withstanding extreme temperatures ranging from cryogenic to high heat, PTFE ring gaskets maintain their integrity and sealing performance across various operating conditions.

Low Friction: PTFE's inherently low friction coefficient reduces the risk of gasket extrusion and ensures smooth operation even under high-pressure conditions, contributing to extended gasket lifespan and reduced maintenance requirements.

Versatility: PTFE ring gaskets are used in diverse industries, such as chemical processing, pharmaceuticals, food and beverage, oil and gas, automotive, and more. Their versatility makes them adaptable to a wide range of sealing challenges.

Conformability: PTFE ring gaskets conform well to irregularities in sealing surfaces, ensuring a tight and reliable seal even on uneven or rough mating surfaces.

Conclusion

In conclusion, PTFE ring gaskets represent a paradigm shift in industrial sealing solutions, offering unmatched performance, reliability, and versatility. With their exceptional chemical resistance, temperature tolerance, low friction properties, and conformability, PTFE ring gaskets ensure tight and reliable seals in the most demanding environments. As industries continue to evolve, PTFE ring gaskets stand poised to meet the challenges of tomorrow, driving efficiency, safety, and innovation.

For businesses seeking reliable sealing solutions backed by precision engineering and proven performance, PTFE ring gaskets emerge as the epitome of sealing excellence, ensuring optimal performance and peace of mind.

0 notes

Text

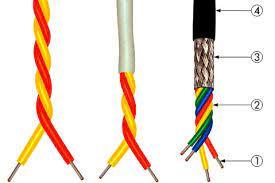

2024 - Best Quality PTFE Cables

PTFE Cables

PTFE, or polytetrafluoroethylene, is a revolutionary material that has transformed the world of electrical engineering with its exceptional properties. Tanya Enterprises, a leading manufacturer of PTFE Cables, and it has harnessed the power of PTFE to create a line of cables that offer unparalleled flexibility, durability, and resistance to extreme temperatures.

PTFE Cables

Tanya Enterprises' PTFE cables are renowned for their remarkable flexibility, which allows them to withstand the rigors of demanding applications. This flexibility is a direct result of PTFE's unique molecular structure, which enables the cable to bend and twist without compromising its integrity.

Tanya Enterprises

Tanya Enterprises' PTFE cables are used in a wide range of industries, including aerospace, automotive, and chemical processing. As the demand for high-performance cables continues to grow, Tanya Enterprises is committed to pushing the boundaries of what is possible with PTFE cables. The company is constantly innovating and developing new products to meet the evolving needs of its customers. Tanya Enterprises' PTFE cables are a game-changer in the world of electrical engineering.

PTFE Cables

If you want to know more about our product how they are useful for your work , please contact us today . Our team is always here to help and find best solutions for your specific needs.

Visit:- https://www.insulatedwires.com/ptfe-wires

Address : Factory:46- Vedvyaspuri Industrial Area, Sector-8, Meerut Pin- 250103, India

1 note

·

View note

Text

#mechanical seals#manufacturer#mumbai#pune#gujarat#quantech seals#qtseals#supplier#tamilnadu#uae#teflon bellow#ptfe#karnataka#maharashtra#tamil nadu#petrochemical#food and beverages#biotech and pharmaceuticals#oil gas industry#biotechnology

1 note

·

View note

Text

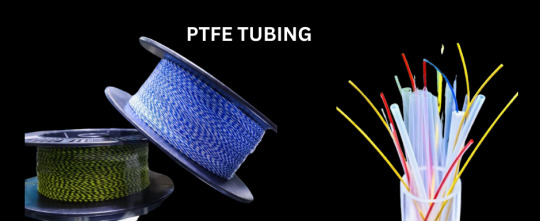

High-quality PTFE/FEP/PFA/PVDF flexible tubing: plain, colored, multi-lumen, radio-opaque, striped

We offer high-quality, perfectly concentric PTFE/PFA/FEP/PVDF/ETFE/PEEK/PI tubing with dependable pressure ratings and electric breakdown strengths. Used for chemicals and gases, electronic, electric, automotive, medical devices, semi-con, food/pharms, and instrumentation applications. Over 1500 sizes in stock. Quick deliveries for non-stock items also.

PTFE/PFA/FEP/PVDF/ETFE/PEEK/PI tubing

0 notes

Text

Polymers in Low Friction Applications

Polymers in Low Friction Applications: Reducing Wear and Tear and Keeping it Smooth.

The development of faster, more durable equipment usually calls for efficiency in energy utilisation and components that can sustain either rotary or linear motion over a very long product life cycle. This problem always boils down to the management of friction. Moving parts will typically experience wear and tear due to friction, leading to both part failure and an unnecessary build up of heat (and therefore a loss of energy).

Advancements in polymer science have allowed a significant number of metal parts to be replaced with specific, high-performance plastics that combine a low coefficient of friction with a high wear rate (also called the Pressure x Velocity, or PV value). These polymers, often when combined with specific fillers, are able to perform for far longer, minimising replacement costs and boosting energy efficiency.

One of the primary advantages of polymers in low friction applications is their innate lubricating properties. Unlike traditional lubricants that require constant replenishment, polymers can provide a durable and long-lasting solution. Polymeric materials, such as polyethylene and polytetrafluoroethylene (PTFE or Teflon), have self-lubricating properties, reducing the need for external lubricants and minimizing maintenance efforts. In the case of PTFE (Teflon) and UHMWPE, the static and dynamic coefficients of friction are so low that when sliding against certain materials (for example: polished stainless steel) the coefficient could fall to as little as 0.03. In layman’s terms: it would take only 30grams of horizonal push to move a 1Kg block across the surface of the PTFE. This is something we also call ‘near rolling friction’.

In the case of PTFE, the addition of specific fillers – such as bronze, glass, carbon, or MoS2 – can further enhance the wear properties of the material, making it more robust in certain industrial applications. PTFE can itself be used as a filler in other polymers, including PEEK, POM (Delrin), PPS (Ryton) or even Nylons. The addition of PTFE micro powders into these polymers – usually in a concentration of 5-25% - gives an appreciable boost to the low-friction properties of the base polymer, while allowing the polymer to retain its other characteristics.

In addition to their lubricating properties, polymers offer excellent resistance to wear and corrosion. When used in bearings, gears, or sliding components, polymers can withstand harsh conditions and maintain their integrity over time. This resilience contributes to the longevity of the components and reduces the frequency of replacements, ultimately leading to cost savings for industries. PEEK is highly sought after in gears. The hardness of PEEK ensures that the part will not wear out over time, while PEEK’s low density (specific gravity of 1.3) gives the added benefit of weight saving in the system.

Many polymeric materials excel in low friction applications due to their lightweight nature. In industries where weight is a critical factor, such as aerospace and automotive, using polymers can lead to significant fuel savings. With specific gravities as low as 0.9, the weight saving over a metal component can be as high as 90%. Especially in aerospace applications, this is a benefit that creates immense savings for the end users. The reduced weight contributes to improved fuel efficiency and overall performance, making polymers both an eco-friendly and economically viable choice.

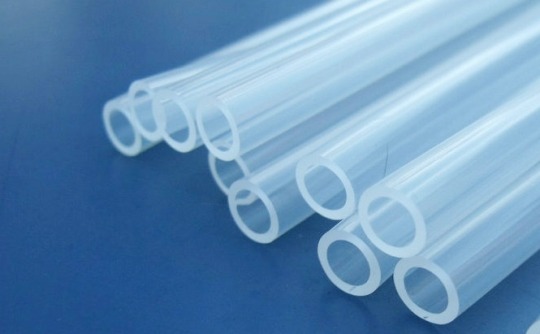

Medical devices also benefit greatly from the incorporation of polymers in low friction applications. Prosthetic joints, for example, often utilize polymer components to mimic the natural lubrication of human joints. The biocompatibility of certain polymers ensures that they can be safely used within the human body, providing low friction solutions for a wide range of medical applications. Similarly, PTFE tubes (usually with radiopaque fillers) are used in medical applications that require the tube to slide in and out of the patient’s body. Amplatz sheaths, for example, are used in urology wherein the tube is pushed in to make a channel through which a guidewire can be passed. The smoothness of the PTFE minimises the discomfort to the patient.

In conclusion, the use of polymers in low friction applications has ushered in a new era of efficiency, durability, and sustainability. Their innate lubricating properties, resistance to wear, and versatility make them indispensable in various industries. As technology advances and the demand for high-performance materials grows, polymers are likely to play an even more significant role in shaping the future of low friction applications.

0 notes

Text

0 notes

Text

Tìm hiểu về Ống Teflon FEP

Ống Teflon FEP là một sản phẩm fluoropolymer độ trong suốt cao, được thiết kế để có khả năng kháng vật lý và hóa học xuất sắc trong các ứng dụng liên quan đến việc chuyển hóa chất. Khác biệt với các tùy chọn kim loại và cao su, sản phẩm này không bị ăn mòn và không bị oxy hóa. Điều quan trọng hơn, không giống như nhiều loại nhựa khác, nó không bị tác động bởi hầu hết các dung môi, axit, và nhiên liệu. Có nhiều biến thể FEP khác nhau có sẵn, cho phép khách hàng điều chỉnh các tính chất của ống để phù hợp với nhu cầu cụ thể của ứng dụng. Nhiệt độ làm việc thấp hơn: Nếu ứng dụng yêu cầu mức độ chịu nhiệt độ không quá cao, ống FEP có thể là lựa chọn phù hợp hơn so với PTFE và PFA. Giá thành: Ống FEP thường có giá thành thấp hơn so với PTFE và PFA, làm cho nó trở thành lựa chọn ưu việt trong các ứng dụng có ngân sách hạn chế. Khả năng trong suốt: Do FEP có độ trong suốt cao, nên nó thích hợp cho các ứng dụng đòi hỏi khả năng quan sát và kiểm tra chất lỏng bên trong ống. Điều này có thể dẫn đến sự biến đổi trong sự lựa chọn và ứng dụng của ống FEP, tùy thuộc vào yêu cầu cụ thể của từng trường hợp sử dụng.

1 note

·

View note

Video

youtube

50ml PFA digestion tube with lid

PFA digestion tubes are produced independently by our company and the size can be customized.

If you are interested, please contact us, we will be happy to serve you.

Clive

----------------------------

Nanjing Binzhenghong Instrument Co., Ltd

Whatsapp/WeChat:+86 133 7609 1871

Mail: [email protected]

Company web:https://www.njbinglab.com/

1 note

·

View note

Text

Fluorine products processing

PVDF has multiple excellent properties such as elasticity, low weight, low thermal conductivity, high chemical resistance and heat resistance.

Henan Six Fluorochemical Co., Ltd

WhatsApp/Telegram:+(86)15038852660

1 note

·

View note