#paper machine

Text

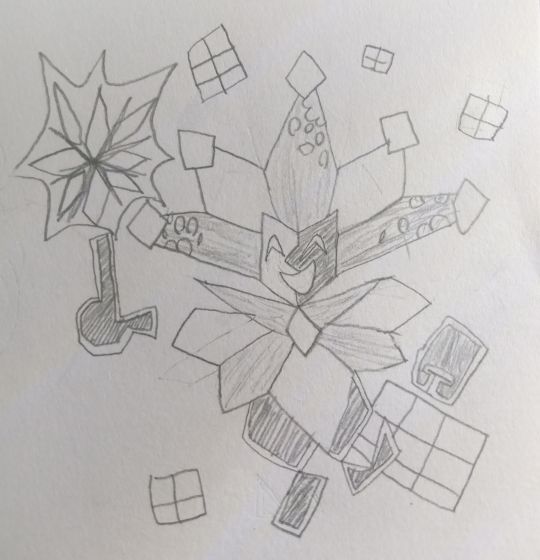

Prompt 29: On Paper..

Haha get it? A paper Mario character on a literal piece of paper??? Hehehehehhohohohohohhahahahahaha!!!!!!!!

Please laugh..

I'm not exactly a Dimentio fan but I admire the character design, so straight and spiky.. also I just felt like mentioning that for the left foot I tried to do some sort of perspective thing on it, didn't know how it would work exactly considering this clown, Flatness, but i made it work lol..

#dimentio#paper machine#Super Paper Mario#Paper mario series#sage/art#Getting better at art stuffcember

19 notes

·

View notes

Text

Delivery of Paper Pulping Equipment to Liaoning

Delivery of Paper Pulping Equipment to Liaoning

More details:

http://www.paperproductmachine.com/delivery-of-paper-pulping-equipment-to-liaoning.html

Welcome to contact if interested!

Email: [email protected]

WhatsApp: +86 18839545270

2 notes

·

View notes

Text

youtube

Leizhan, a leading pulping and papermaking company, specialize in developing state of the art pulping and papermaking equipment, backed by our strong technical expertise and numerous certifications. Our company integrates research and development, manufacturing and sales, and has successfully developed M.C. Pressure Screen, Inflow Pressure Screen and D-Type Pulper with market influence, and has become the leader in the development of this equipment in China. Welcome to contact us for cooperate! Email: [email protected] Whatsapp: +86 18738406635

1 note

·

View note

Text

Machinist Era

March, 2019

Medium: lumber crayon on crude paper

2 notes

·

View notes

Text

His name is bluish 💙

0 notes

Text

youtube

0 notes

Text

In the need for sustainable and eco-friendly alternatives to single-use plastic tableware, bagasse plates have emerged as a promising solution. Bagasse, the fibrous residue left after extracting sugarcane juice, serves as the raw material for manufacturing biodegradable and compostable plates, bowls, and cups. This blog explores the process of making bagasse tableware and highlights the functions and features of various bagasse plate-making machines.

Raw Material For Sugarcane Bagasse Plate Making

Molded Fiber pulp sheets are used as the essential raw material for the production of disposable plates, and they are easily available in the market at highly affordable prices.

The transformation of waste sugarcane bagasse into clear and readily usable Molded Fiber (Disposable) pulp sheets entails undergoing a series of mechanical and chemical stock preparation processes, which closely resemble those employed in the paper manufacturing industry.

The cost of establishing a stock preparation system for Molded Fiber Pulp Sheets is twice as high as that of a Disposable Tableware production line. However, these bagasse pulp sheets are readily accessible in the market at a convenient price, which is why manufacturers of bagasse tableware prefer to utilize them.

Machinery and Systems Required for Disposable Tableware Manufacturing

The manufacturing process of disposable tableware, utilizing sugarcane bagasse as the raw material, requires the integration of numerous auxiliary systems and specialized machinery.

#Sugarcane Bagasse Plate Making Machine#Sugarcane Bagasse Plate#Bagasse Plate Making Machine#Bagasse Plate#Bagasse Plate Machine#Bagasse Plate Making#Molded Fiber pulp#Pulping system#Sugarcane Bagasse Tableware Formation Machine#Tableware Trimming Machine#Tableware Molds#pulp machine#paper mill#paper machine#parason#paper industry

0 notes

Text

PaperMachine #PaperIndustry

Paper Pulp Making Line Equipment Agitator

More details:

https://www.paperproductmachine.com/paper-pulp-making-line-equipment-agitator.html

Welcome to contact me to inquire!

Email: [email protected]

WhatsApp: +86 18839545270

1 note

·

View note

Text

Good Quality Paper Machinery Manufacturers

Hardayal Engineering Works is a reputable Paper Machinery Manufacturers with over three decades of experience in the industry. Our unwavering commitment to quality and innovation has established us as a dependable supplier of cutting-edge paper machines globally. Our machines are customized to produce superior-quality paper products with optimal efficiency, and our adept professionals are readily available to provide bespoke solutions to meet individual customer needs. With our emphasis on excellence and customer satisfaction, Hardayal Engineering Works is a preferred choice for businesses seeking reliable and effective paper machines.

Call Us: +91-9811054591

Email id: [email protected]

Address: S- 5, 6 & 7, South Of Gt Road Industrial Area - 201001

URL: https://www.hardayalpapermachine.in/kraft-paper-machinery.html

0 notes

Text

AKD - Inevitable paper sizing

Alkyl ketene dimers (AKDs) are a family of organic compounds based on the 4-membered ring system of oxetan-2-one, which is also the central structural element of propiolactone and diketene. Attached to the oxetane ring of technically relevant alkyl ketene dimers there is a C12 – C16 alkyl group in the 3-position and a C13 – C17 alkylidene group in the 4-position.

The main application of alkylated ketene dimer is in the sizing of paper and cardboard, as well as in the hydrophobization of cellulose fibers. The products thus modified are distinguished by higher mechanical strengths and less penetration of water, inks, or printing inks.[1]

AKD’s feature hydrophobic alkyl groups extending from a beta-propiolactone ring. A specific example is derived from the dimerization of the ketene of stearic acid. This ketene is generated by pyrolysis of stearoyl chloride.[2] AKD’s react with the hydroxyl groups on the cellulose via an esterification reaction. The esterification is competitive with hydrolysis of the AKD. Prior to the development of AKD’s, hydrophobicity was imparted by incorporating rosin into the paper.

Related to AKDs, is alkenyl succinic anhydride which is another substitute used in sizing applications (ASA). As for AKDs, ASA reacts with hydroxy groups of the cellulose to form an ester, anchoring the hydrophobic group to the surface. ASA is prepared by thendne reaction of unsaturated hydrocarbons with maleic anhydride.

A continuous process in which long-chain carboxylic acid chloride and tertiary amine (e. g. dimethyl isopropylamine, dimethylcyclohexylamine or triethylamine) is supplied separately without solvents to a tube reactor, kneader or preferably a twin-screw extruder or planetary roller extruder and reacted at temperatures between 90 and 110 °C, delivers lactone contents of over 90% at short reaction times. Processing is carried out by phase separation or acidic extraction.[19]

Alkylated ketene dimers as paper sizing agents

The problems with the acidic (aluminum sulfate-mediated) mass sizing of paper with alkaline-digested colophony resins introduced since the early 19th century led beside the use of alkaline flocculants (such as chalk or calcium carbonate as the alkali reserve) to the search for alternative materials for sizing in a neutral or alkaline environment. In addition to the significantly more reactive alkenyl succinic anhydrides (which do also hydrolyze rapidly in the presence of water) alkylated ketene dimers were preferred surface and mass sizes in the paper industry from the 1960s onwards.

Industrially applied AKDs are derived from fatty acids with chain lengths between C14 (myristic acid) to C22 (behenic acid); palmityl (C16) diketene and stearyl (C18) ketene and mixtures thereof are preferably used, as well as fatty acid mixtures from the hydrolysis of animal and vegetable fats. Because of the chain length of the original fatty acids, AKD are waxy solids with melting points between 42oC and about 70 °C. Mixtures of alkylated ketene dimers and water are dispersions at temperatures below 40 °C or emulsions at temperatures above 45 °C. Liquid AKDs are widely used, they are based on unsaturated fatty acids like oleic acid or branched fatty acids, like iso-stearic acid.

Aqueous alkyl diketene dispersions generally contain 10-20 wt% of AKD, as well as active protective colloids (particularly polycations such as cationic starch, copolymers of N-vinylpyrrolidone and quaternized N-vinylimidazole, acylated polyethyleneimines or cationic high molecular weight polyacrylamides with an average molar mass up to 7 million g/mol) and other stabilizers (usually anionic surfactants, for example, lignin sulfonates or condensation products of naphthalene-sulfonic acid sodium salt and formaldehyde). Such stabilized AKD dispersions are active and stable at room temperature for up to three months and also tolerate the addition of different fillers for paper or cardboard (e.g. kaolin, chalk, talc, titanium dioxide, calcium sulfate, aluminum oxide, etc.) from 5 to 25%. The amounts of alkyl ketene dimers used for the sizing of paper and paper products are preferably in the range from 0.15 to 0.8 wt%, sometimes from 0.05 to 0.2 wt%, based on the dry paper stock.

Paper sizing with alkylated ketene dimers

For paper sizing with AKD, a three-step process was proposed which, despite controversial discussions in the 1990s, seems to describe the processes that are taking place.

Decisive criteria for the quality of the hydrophobicity of papers are

The retention of the AKD particles on the wet paper mass on the paper screen

The spreading of the AKD particles on the surface and the penetration in the paper mass

The chemical reaction of the hydroxyl groups of the cellulose (esterification) with the alkylated ketene dimers to form beta-ketocarboxylic esters.

The molecular structure (i.e., molar mass and cross-linking degree), the molar charge density of cationic groups, the exact dosage of the cationic polymer as a dispersion stabilizer and retention aid as well as keeping the other process parameters such as temperature, pH and residence times is crucial.

After removal of excess water – also to avoid hydrolysis of the AKD to the beta-keto acid and subsequent decarboxylation to the ketone – follows the cracking of the stabilized AKD particles on the base paper mass, the melting of the solid AKD wax (at approx. 90 °C), the spreading of the liquid AKD wax by surface diffusion on the cellulose fibers, and the formation of closed hydrophobic layers. The thickness of the hydrophobic layers depends on the AKD concentration in the dispersion.

Ad 3. The hydrophobization of cellulose fibers with alkylated ketene dimers takes place most effectively in neutral or preferably weakly alkaline media (pH 7.5-9.0). The reaction temperature is generally 90-110 °C, with approximately 40% of the AKD used reacting with the cellulose. After the reaction contact angles of >100° are measured, indicating the hydrophobic character of the AKD-modified model surfaces. The esterification of hydroxyl groups of cellulose fibers was also demonstrated by comparison reactions with 14C-labeled AKD.

The sizing with AKD is suitable for the permanent hydrophobization of newsprint, printing and writing paper and cardboard used as a container for liquids (including foodstuffs such as milk), as well as for the improvement of shape stability and runnability.

Commercial Production

At Advance Chemicals, undergoing robust testing frequently, the production of AKD is strictly under defined and controlled conditions thus giving out world call AKD for application in various grades of paper making.

0 notes

Text

The amount of b-grade/miscut/misprint stickers I get when making batches is goofy

What's in my hand is usable and can be sent out, the boxes behind it are all ones with imperfections/ damage but can't bring myself to throw away because it feels like I'm being wasteful. I might make 'scrap baggies' for each fandom and offer them on kofi for like 7-10 stickers for the price of one or something again

#sara shush#sticker stuff#on the up note i switched paper type and it has a better time reading the lines#but all my machine mats are lowkey destroyed and unusable because of use and cutting damage#none of them are sticky ive been using scotch tape to put the page on there#ordered some more#still deciding between manufacturers

634 notes

·

View notes

Text

Lord help me, I'm back on my bullshit.

More so because I -am- a preschool teacher who often engages in leading small children through arts and crafts and it truly can be a trial in patience and frequent mutterings of 'Process over product'

#fnaf daycare attendant#fnaf#fnaf sb#fnaf security breach#fnaf sun#fnaf dca#i just found out that there is a machine that basically recycles paper into fresh blank sheets and thats fucking neat#fnaf help wanted#help wanted 2#spoilers

843 notes

·

View notes

Note

Wait, for real!?!?!?!👀

Yep yep! Ink has two dads, and one of them is Zephyr!Gaster or Aster. He's super adorable, you should check out his FAQ!

Ink and his other dad (Undertop!Gaster) teaches him about the Multiverse and on the other hand Aster teaches Ink to enjoy things (machinery, blueprints, astrophysics) that don't rely on his inky creation powers!

Ink does some other non paint stuff too, he plays the flute for one and iirc, he is trying sewing, which is why I made my variant of him get into embroidery

( > 〰 < )♡

#im too tired to draw anything on that paper and im no blueprint expert so. feel free to imagine whatever they are building and talking about#maybe hes letting ink try and make his own machine! and giving him a blank paper to start#i love seeing lineless but making one is an oof#i love em either way tho#junie art post#ink sans#inktale sans#zephyrtale#zt!gaster#IVE FINALLY DRAWN ONE OF THE DADS YIPEE#utmv

259 notes

·

View notes

Text

PaperMachine #PaperIndustry

100tpd Kraft Paper Machine of Leizhan

More details:

https://www.paperproductmachine.com/100tpd-kraft-paper-machine-of-leizhan.html

Welcome to contact me to inquire!

Email: [email protected]

WhatsApp: +86 18839545270

1 note

·

View note