#anchor fasteners brass

Text

We hold a reputation for being a reputable manufacturer, exporter, and supplier of a large selection of Brass Anchors.

This is made in accordance with global quality standards utilizing premium brass and cutting-edge technologies.

Many diverse sectors, like the pharmaceutical, petrochemical, chemical, and textile ones, employ the anchor we offer.

To meet the needs of our esteemed clients, this anchor is offered at market-beating costs in a wide range of forms, sizes, and patterns.

These are highly regarded by our clients as a result of its key qualities, such as precise design, simplicity of installation, tough construction, high strength, low maintenance requirements, and longevity.

We provide our product line in a variety of parameters to satisfy the needs of the plastic and automotive industries. We export our goods to places like Southeast Asia, South America, and North America.

· We have in house facilities for productions such as Extrusion, Casting, Forging & Machining, CNC – VMC Products.

· We have German spectrometer for perfect results and also can share the Material Test Certificate

· We can share the best quote in the industry.

· We have capacity of manufacturing as per customer drawing or samples provided

· We can supply the components with best quality and services

#brass anchors#brass drop in anchors#drop anchors#anchor fasteners brass#india#pool cover anchors#anchor pool covers#pool safety cover anchors#pool anchor#earth anchors#brass pool cover anchors#brass pipe fittings#pool cover anchors for concrete#drop in anchor#safety cover anchors#brass bolts#brass pool anchors#brass inserts#pool cover hooks#pool cover straps#wood deck anchors#manufacturer#exporters

0 notes

Text

Know About Reliable Brass Fasteners Manufacturers in Jamnagar

GK Metals is the leading brass fasteners manufacturers in Jamnagar India. It provides DIN standard brass fasteners like brass nuts, bolts, screws, hex bolts, rivets, washers, brass anchors and more that is suitable for various industrial applications.

#brass fasteners manufacturers in jamnagar#brass nut bolt manufacturer in jamnagar#brass screw manufacturer in jamnagar#brass washer manufacturers jamnagar#brass anchor manufacturer in jamnagar#brass fasteners exporters#brass fasteners suppliers#brass fasteners#fasteners#brass nuts#brass bolts#brass screws#brass rivets#washers#brass anchors

0 notes

Text

The Scarlet Pirate - Chapter 5

This is the penultimate section of a six-part "Chapter Story" for my OC for Twisted Wonderland, James Killian - based on Captain Hook from Disney's Peter Pan. (Also featured are Smitty McCarthy, based on Smee, and Matthew Satyr, based on Peter himself...oh, and Nakoda - my Kaa OC - also has a role here.) The basic premise of this story has been in my mind for almost as long as James has, but for numerous reasons, it wasn't till just within the past few weeks I finally got a chance to develop and write it out.

The result is, I think, the single longest "Chapter Story" for any of my OCs for TW I've created so far. Take that information however you will. So long as this tale, that it went from a planned three-parter, to a planned five-parter, to now being a six-parter, standing at approximately 150 pages in total! Hopefully, all the work and length will be for the best. XD

As is typical for my Chapter Stories, I will be posting this one chapter at a time per day over the course of this week. For future reference, you can find the previous chapter here.

You can find the next chapter here.

WARNING: While this story, throughout all six parts, does not FOCUS on my kinks, there are instances of very mild stuffing/belching related content sprinkled throughout, as well as various instances of implied or near vore situations. If you're into these things, good on ya. If you aren't, just be warned they will show up here and there, although not with any degree of spectacle.

With that said...I hope you enjoy.

----------------------------------------------------------

“Heigh-ho, and up she rises! Heigh-ho, and up she rises! Heigh-ho, and up she rises, early in the mornin’!”

The shanty’s tune echoed almost eerily through the bowels of the shadowy stone labyrinth. Down a sloping tunnel, at one end of the vast, maze-like network of passages in the old, abandoned mine, James Killian and Smitty McCarthy carefully marched. James had his right hand on the treasure chest, while Smitty used his left, as they cautiously carried it along between them. James grinned as he looked around at the dank cave at the bottom of the slope: long ago, the Dwarfs had found this spot in the midst of their mining. A part of the river, which ran through the woods and then down into the sea, came into the mountains via this cave. A deep pool of water stretched from the cavern into a short, black tunnel, beyond which was the river itself. There were several tall, rocky formations in the cavern, including one very high, flat-topped stone, almost like a miniature cliff or a rock hill, and a smaller, flatter spot towards the bottom.

In one part of the pool, near the tunnel, a sailboat had been moored. Its sails were closed, its anchor stretching into the water; for extra insurance, a sturdy rope had been fastened (with an equally sturdy knot) around a stalagmite that jutted out of the cave’s watery floor.

On the boat was brass plaque, which offered the name of the little craft: The Czarina. “Ah, my pretty little crate! We’re now only moments away from TRUE victory, Smitty!” laughed James Killian, his boisterous, booming voice rebounding off the cavern walls. “Who needs a contest prize, when I have enough treasure to pay off a King’s Ransom? This will be plenty for our purposes, once we reach a safe port!”

“Aye, James!” smiled Smitty, and paused, closing the eyes behind his glasses and tilting his head upwards, almost dreamily. “Just think of it…finally, out on the open ocean…in a proper ship, doing what we always wanted…”

“Indeed,” nodded James, with a more supercilious smile, flourishing his cane in his other hand as he spoke. “Where I shall be captain, and you shall sail with me! Split me infinitives, tis me hour of triumph!”

James laughed again; Smitty winced, wringing out one ear with his free hand, and offering a nervous sort of smile. There was a sort of wild gleam in Killian’s eyes, which the smaller man didn’t much like…and there was a strange scent in the air, too. Not just the brine and the earthy odors of the watery cave, but another, chemical sort of odor…like ink…

“I just hope it won’t take us too long to sail our way along the river to the sea,” McCarthy fretted.

“Ha! Would you think I’m fool enough to not check the miles and depths along the path, Smitty?” scoffed James, resting the long end of his cane upon his shoulder. “I sailed Czarina here meself, and checked the distance to the ocean from this part of the island. I tell you, Smitty, I’ve reached my peak already! NOTHING CAN STOP ME NOW!”

“HA HA HA HA HA HA!”

James and Smitty froze as a sudden, shrill, deranged laugh echoed through the cave. They looked around, startled to say the least, trying to spot the source.

“What in blue blazes?!” exclaimed James.

“Wh-who’s th-th-there?” stammered a rather scared Smitty.

The mad laugh came again; it sounded lower, more ominous. Cautiously, the pair put down the chest, glancing from the left to the right, peering all around the damp cavern.

“Speak!” demanded James. “Who are you, stranger?”

A diabolical sort of voice came drifting through the cave.

“You have stolen the cursed treasure,” it growled. “Now you shall face the ultimate penalty!”

“What are you talking about?” sneered James, standing defensively in front of the chest. “Tell me your name and show yourself, you craven…!”

“JAMES! LOOK!”

Smitty’s frightened shout alerted James. He saw his stout little companion pointing with a shaking finger up towards the ceiling of the cave. The scarlet pirate looked up…and his eyes widened as a group of five white-cloaked figures flew out from behind the stalactites that speared down from the roof of the cavern. They giggled and laughed and jeered, drifting together in a circle, like a collection of vultures. Most were roughly human in size, but one was much smaller, no bigger than a tiny child, at best.

Sizes aside, it was clear what the pale, hooded creatures were.

“G-G-GHOSTS!” squeaked Smitty, and ducked behind James.

“What jiggery-pokery is this?” bellowed James, trying to seem unintimidated, but his voice carried an unsteady quiver.

“We are the Keepers of the Treasure!” declared the smallest figure, in a yowling sort of voice.

“Return to us what is rightfully ours, human!” another snarled.

“Or you may face the consequences,” another warned, in a sneaky, subtle, smooth tone.

“HA!” James rapped, and grinned ferociously. “I fear no ghosts. We have dozens of them at Night Raven College!”

“I fear them,” peeped Smitty, who was trying to hide behind his superior.

“Surrender the treasure to us!” hissed a fourth phantom.

“Or we will be forced to take it,” the fifth said, rather plainly.

James glowered. He had not come all this way to be foiled by a collection of meddlesome specters.

“You want it?” he growled, shifting his feet to brace himself. “Ha! Well come and get it!”

He then nudged the scared McCarthy aside and snapped at him: “SMITTY!” “Eep! Y-Yes, James?”

Killian gestured to the ghosts with a hard, stony sort of glare.

“Blast them,” he ordered, in a cold voice.

Smitty blinked. He looked pale as a ghost himself.

“But…b-but James…!”

“BLAST THEM!” James roared. “That’s an order, you blundering blue-footed booby!”

Smitty gulped nervously, lifting his arms, as if he were afraid of being struck, then nodded.

“Aye-Aye, James,” he whimpered, and paused to adjust his cap, jacket, and glasses before waddling forward. He looked up at the circling white spirits, who were making spooky “Ooooooooh…!” noises as they hovered. Smitty took a deep breath and seemed to pluck up courage…then lifted his right hand, holding the palm outwards.

“Hold back no longer. Throw restraint to the wind. Fire at will,” he intoned in an incantation…and as he did so, the ghosts could see what seemed to be a crimson aura, gathering around his right hand. Then Smitty seemed to physically brace himself, as he uttered the name of the signature spell he now planned to use: “CORKSCREW CANNON!”

BOOM!

With a sound like a cannon being shot, a crimson sphere of energy shot out from the gathered aura around Smitty’s hand. It blasted towards two of the ghosts, who darted out of the way as the ball of red light flew between them…

…But as the sphere hit the stone wall of the cave, it suddenly rebounded back again, bouncing like rubber towards the ghosts once more. The energy sphere struck one of them, and - BANG! - burst like some magical balloon. The concussive explosion knocked the ghost aside as they cried out, and flew back into a wall.

“What the…?!” exclaimed one of the phantoms.

“HA HA!” James crowed. “My compatriot’s Unique Magic creates an eruptive blast that stuns any enemy it comes in contact with. However, it only affects living things…or, in your case, things that were once living. If it hits anything else, it just bounces off.”

“It can only bounce three times,” peeped Smitty, seemingly blushing at James’ elaboration.”

“Minor details,” shrugged Killian, and pointed dramatically at the other ghosts, as the one who had been hit rather dizzily hovered away from the wall. “FIRE, SMITTY! SHOOT THEM DOWN AT ONCE!”

“Aye, James,” Smitty replied, and sent another ball of energy zipping up towards the cave ceiling, aiming this time for the smallest of the white-cloaked figures. The force of the blast was so great, that it actually made him stumble clumsily backwards, nearly knocking him off his feet.

The tiny ghost spun through the air, twirling out of the way. The Corkscrew Cannon once again rebounded off the wall behind them, but this time, the ghost was ready for it, and flew higher, the sphere passing beneath the cut of their white sheet. One of the other ghosts, however, was less fortunate, and got struck, smashing into a stalactite.

They had not recovered before a third sphere went zooming upwards. It passed over the head of one ghost, who ducked…bounced once, and missed another, who swerved to the side…bounced twice, missed ANOTHER, who cartwheeled out of the way through the air…but on the third rebound, it struck the tiniest phantom, who yowled and flew back…

…Only for one of the other ghosts to catch them.

“We have to avoid those blasts,” the small one whispered.

“I know,” their savior nodded, then looked to the others. “GATHER UP!”

The ghosts all huddled together, weaving and bobbing through the air as Smitty turned around to try and get a solid shot at them…but they kept ducking behind the stalactites and other cave formations.

“LET ‘EM HAVE IT!” James raged, waving his cane around like a madman. “COME ON, YOU IDIOT! HIT THEM AGAIN!”

“I-I can’t get a clear shot!” squeaked Smitty.

The ghosts suddenly dispersed once more, nodding to each other, as if they’d decided on a plan of action. One of them went flying at Smitty straightaway, while the other four flew off in other directions. Smitty opened fire, and the ghost zoomed out of the way…

…And as the red sphere of power struck the wall beyond, it came bouncing back…straight at Smitty McCarthy.

Smitty froze.

“...Oh, no.”

BANG!

The little man’s glasses fell from his face, and his cap was knocked askew, as the concussive blast burst before him and sent him shooting backwards. Two of the ghosts caught hold of him and lifted him into the air from under his arms. Smitty kicked and squirmed, crying out in alarm as they carried him to the sailboat. One of the pale, hooded specters in the white sheets produced a length of rope, and they tied him to the mast, making sure his hands were firmly set at his sides. Smitty struggled against the bindings as fiercely as he could.

“JAMES!” he hollered. “JAMES, HELP!”

James Killian hesitated, torn between helping his associate and guarding the treasure still behind him. Just then, he felt a rush of air behind him, and turned fast…just in time to see the remaining two spirits lift the treasure, each cackling wildly with seemingly crazed glee.

“GIVE THAT BACK!” James yelled, and threw himself forward…only for the chest to be pulled away before he could reach it. He fell onto his belly, growling as he pushed himself back to his feet, and watched the spirits lift the treasure into the air…

…Then felt something inside of him turn to ice.

The ghosts lowered the chest…and placed it on top of the high, sharp, flat-topped “cliff” of rock, overlooking the water. And there, hovering just a foot or two over the very tip of that outcropping, was a familiar, boldly grinning figure, dressed in green. A pixie sat upon his shoulder.

James felt one of his eyes twitch. His free hand curled into a tight, white-knuckled fist, as he gripped his cane tightly.

“So, Satyr,” he hissed through gritted teeth. “This is all your doing.”

Matthew Satyr grinned wider.

“Aye, James Killian,” he teased with a wink, hands on his hips. “Tis all my doing.”

“Hey!” one of the ghosts called out. “Don’t take all the credit…”

…And at that moment, you threw off the white sheet Sebek had conjured up, revealing yourself. One by one, your fellow “ghosts” did the same. You knew who they were.

“After all,” you continued. “It was MY idea.”

“Meh. Minor details,” shrugged Matthew, in a joking sort of way.

James Killian just glared with more hate than you’d ever seen another human being wear upon their face. And by now, you’d seen a LOT of hatred.

“How did you escape the beast?” he snarled.

“Beast?” Smitty piped up, stopping his struggling. His eyes widened. “James! Wh-what do you mean ‘beast’?”

“I believe he’s referring to the giant monster that attacked us in the pit,” replied Azul, as he touched down upon the deck of the sailboat, standing beside the mast. Sebek touched down beside him, smirking and leaning back against said mast.

Nakoda touched down on James’ right, while you touched down on his left. Grim landed directly beside you. All of you glared at him critically. James briefly glanced at the three of you, but soon turned his attention back to Matthew.

“What saved you?” he demanded to know. “I would have thought that thing would have at least slowed you down.”

“You knew?” Smitty gasped, jaw dropping. “About…wh-whatever was there with them?”

James briefly looked back over his shoulder towards Smitty. His expression was dull and vacant.

Smitty looked hurt.

“But…but you said…”

“Quiet,” growled James, and then looked back at Matthew with a vengeful sneer. “How did you get away? Faith and Trust and all that rubbish?”

“That, and a little bit of help from my new friends,” Satyr shrugged cheerily.

“Easy on the ‘friends’ thing,” muttered Nakoda, who looked a bit uncomfortable at that endearment.

James just snarled at Matthew, his fingers tightening harder around his cane’s topper.

“Don’t you DARE use that word around me,” he said, venomously.

“That’s enough, James,” you interrupted, firmly, and began to approach him. “We’re going back to Night Raven-”

“WAIT!”

You jumped back as Satyr flew down from his perch and stopped, hovering about six inches off the ground, and a few feet away from James Killian. He pulled out his metal fighting rod, whipping out the collapsible object to its fullest extent, a steely look in his youthful eyes.

“We’re not going anywhere. Not yet,” he said sternly.

James grinned, as if he were pleased.

“Are you insssane?!” hissed Nakoda. “We’ve already beaten him, what’sss the point?!”

“I agree!” Azul called out. “We have what we came for, we should-”

“NO!” Matthew said indignantly…then a sort of sadness crept into his voice and his expression. “None of you understand. This isn’t a normal fight. This is a duel. And it’s been waiting for a very long time. I need this…we BOTH need this.”

He pointed his baton at James.

“This man is mine.”

James chuckled darkly and lifted his cane, holding it lengthwise in both hands.

“Well spoken, Satyr,” he slithered. “If it’s a final duel you want, I shall gladly give it to you.”

CLICK.

James gave his topper a slight twist, and a sound like a lock being undone was heard. Then - SCHLING! - the sound of steel scraping against wood rang through the cave. Yourself, Nako, and Grim all stepped back, and worry crept into the faces of Azul and Sebek alike.

James Killian flung aside the wooden “sheath” of his cane…and pointed the sharp, dangerous, very real sword tip of the weapon towards his nemesis.

“Proud and insolent fool,” he challenged, grandly. “Prepare to taste defeat.”

Even in the presence of an actual sword, Satyr showed no fear at all.

“Dark and sinister man,” he returned. “Have at thee!”

With a sort of scoffing battle cry, James Killian immediately plunged forward, and swung his sword around his head. CLANG! It connected with Matthew’s blade, as the smaller, hovering young half-fae blocked the attack. James whirled about, sweeping out for another, rather theatrical slash. CLING! His blade skimmed the rounded edge Matthew’s weapon, as it was batted away easily.

Matthew then went on the offensive himself, whipping his baton about to try and strike at James’ face. With sharp, jerking, almost imperceptible motions, James parried the attacks. From that point on, for a time, there was no advantage on either side. Matthew Satyr was a superb swordsman, jabbing with the baton the way a wasp does with its stinger, in between parries that knocked his rival’s attacks aside with dazzling rapidity. He had the shorter reach, and no cutting or stabbing edge, but his weapon was sturdy and his movements fast.

James Killian was scarcely inferior in brilliancy, but not quite so nimble in wrist play. The Pirate of Hearslabyul forced his opponent back by the weight of his onset, swinging hard and strong. Time and again, he thrust his weapon forward, and each time he did, a collective flinch flew through every heart of those of you that watched. Each time, however, the thrust was turned aside by Satyr’s dueling rod, and Killian was frustrated again.

Kes flitted about the dueling pair, ringing her bells in alarm. Annoyed, James swiped at her with his left hand…then squealed as Matthew smacked him in the rear, just as he had in the forest. With a roar of outrage, James lifted his sword up in a chopping motion, but the harsh blow was blocked by Satyr.

Kes zipped over to Sebek, flailing her arms as if to get his attention. He seemed to understand what she said…

“We should stop them!” he bellowed.

Nakoda hissed with a nod, and began to stride forward in an attempt to do just that…but Azul halted all with a sharp call.

“Don’t!” he snapped, and his own attention was on the dueling pair, his expression wary and razor-focused. “Let them sort out their differences. This is between them. It’s out of our hands now.”

“Then shouldn’t we leave?” Grim suggested, and winced at another loud CLANG! as the metal weapons met each other.

Azul shook his head, still focused on the battle. You soon understood…

“James is out for blood,” you whispered, worriedly. “If he manages to get an advantage…”

Grim gulped nervously, immediately realizing the gravity of the situation. You could see that Smitty McCarthy, still tied up where he was, seemed more than a little concerned. He was watching with very nervous eyes, chewing on his own fat little lip.

“B-be careful!” he called out to the fighters, as each swung and blocked the other’s weapon. Which one he was addressing remained a mystery thereafter.

James seemed to grow tired of the even nature of the duel. His sword had yet to gain its prize. He glared, trying to back Matthew towards a wall…but just as Satyr grew close to the stone behind his back, he leapt up and over James’ head, flipping clean over him and landing on the other side. James spun ‘round and lunged, but Matthew spun out of the way, flying over the water. He laughed and came swooping back, swiping with the baton. James ducked the attack, and scowled as he watched the young fairy-boy fly upwards again.

At that moment, as he saw Matthew zipping about overhead, a lightbulb seemed to come over James’ own head, and he began to move up the slope of the “cliff” inside the cave.

“Go on!” he called out, mockingly. “Fly! Fly! Fly, you COWARD!”

Matthew paused in mid-air, once more at the “tip” of the stone hill.

“Coward?” he repeated. “Me?!”

James laughed tauntingly as he prowled up the slope in a creeping predatory manner.

“Ha Ha HA! You’d never DARE to face me man-to-man, foot-to-foot! YOU NEVER COULD!” he barked. “You’ll always fly away, like a COWARDLY SPARROW!”

The words “cowardly sparrow” echoed through the cave for several seconds, as James finally reached the flat top of the rock, standing upon it at the ready. Matthew glared down at him, clearly offended.

“No one,” Satyr said, seriously, “Calls ME a coward. Least of all you, James!”

And then, Matthew Satyr did something you didn’t think you’d ever see him do on his own: he hovered down slowly towards the tall, stone tower…and landed upon it, his feet finally touching the ground.

“If that’s how you want it,” he said to James Killian, daringly, and held out his rod almost invitingly. “I’ll fight you man-to-man. One hand behind my back!”

James grinned ferociously. He leaned close, lifting his sword. Steel and steel slid against each other as weapons crossed, and he moved till he was almost nose to nose with Satyr’s defiant face.

“Do you mean…you WON’T fly?” he cooed.

Something about the way James said that made your blood run cold.

“Don’t agree to that!” you shouted up at Satyr.

“Keep the advantage!” Azul called out.

“LISTEN NOT TO THAT RUFFIAN!” bellowed Sebek.

“It’sss a trick, I promissse you!” warned Nakoda.

Matthew Satyr didn’t seem to hear any of you.

“I won’t fly,” he promised. “I give my word, James.”

You heard Grim facepaw at your side and mumble, “Moron.”

James Killian, for his part, looked like he’d just been made the happiest sleaze to ever sail the seven seas.

“Good!” he cheered. “THEN LET’S HAVE AT IT!”

Without warning, James slammed himself against Matthew, knocking the smaller young man backwards. Matthew stumbled back with a grunt, and barely managed to avoid falling off the edge of the cliff. He had just enough time to block a ferocious, hacking slash from James’ sword, before the taller duelist swung up again, hammering blow after blow upon his foe, in a wild, frenzied sort of way. Killian seemed determined to drive Satyr over the edge.

Finally, Matthew managed to duck and get behind James, but if he hoped to find an advantage that way, he was sorely disappointed. James spun around and slashed again. Matthew barely had time to duck, and then lifted his rod to block another strike. James wasn’t slowing down at all, and - unable to flit and swerve out of the way as he so often did while airborne - Satyr was clearly beginning to lose the fight.

“I’ve had enough of thisss!” hissed Nakoda, clearly growing anxious, and began to try and run up the slope.

“NO, DON’T!” you called out, afraid he would end up cleaved by Killian in the proverbial crossfire.

James soon spotted Nakoda approaching and glowered.

“DON’T INTERFERE!” he roared, and shoved Matthew aside. Satyr cried out as he fell over the edge…but managed to catch himself before he could hit the water.

As Nakoda approached, extending an arm in an effort to grab hold of James, the left hand of his quarry swung out and slapped him across the cheek. Before Nakoda could recover from the sudden smack, James snapped his fingers…and Nakoda hit the stone slope like a sack of potatoes, weighed down by the crushing intensity of his own negativity.

“Nako!” you cried out, and hurried up the slope to check on him. Nakoda had his hands on his ears, gritting his fangs as he curled upon the ground.

“Sh-shut them up,” he whimpered, as if the fear, loathing, and sadness that filled his heart was bringing voices to his head. “Shut them up, please!”

Grim mewed as he trotted up beside you, nudging the naga, but Nakoda just flinched away. Both of you looked up with great concern as you saw Matthew then return to the top of the stone. James wasted no time and swung his sword again…

…And, to your horror, just as Satyr regained footing, his metal dueling rod was sliced clean in half. It had been weakened by the battle, and a final, strong strike had rendered it officially useless.

Desperately, Matthew flung the blunted half at James, who swatted it aside, then jabbed out with his sword. Satyr stumbled and fell onto his back. Matthew looked more scared than you’d ever expected, as James Killian pointed the tip of his cane-sword at his throat.

“Looks like I’ve got the upper ‘hook’ now!” taunted James, showing off the tattoo on his left hand. He then swept it behind his back and reeled back with his sword hand. “And now we end this…”

“NO! JAMES DON’T!” you shouted.

“YOU CAN’T!” Grim yowled in alarm.

James wasn’t listening. There was murder clearly visible in his eyes…

…But you two weren’t the only ones who saw it.

“He’s…he’s actually going to do it!” Azul gasped, as he heard James’ words.

“We should stop him!” insisted Sebek, as Kes frantically nodded in agreement beside him.

“How?” Azul said. “If we get close he’ll use his power on us.”

“We can hit him from afar!” Sebek insisted.

“Don’t you think he’d be expecting one of us to try that?” Azul snapped back.

“Let me loose.”

The two looked up at Smitty McCarthy.

“What?” they asked in unison.

“Let me loose!” Smitty repeated, struggling against the ropes. “And fast, before it’s too late!”

The head of Octavinelle and the guardian of Diasomnia looked at each other…then nodded. The octopus and the crocodile hurriedly undid the knots…and just as James began to ready himself for the killing strike, Smitty landed on the deck, and lifted his right hand.

“JAMES!” he shouted.

Killian looked up, alerted…just in time to see the red energy gathering around Smitty’s hand. His face showed something close to horror.

“HOLD IT, YOU FOOL!” he shrieked. “NO! NO!”

Smitty shut his eyes tight, as if to try and give himself deniability…and launched his attack.

BOOM!

The Corkscrew Cannon fired…and the sphere of concussive energy rocketed towards James. Killian quickly tried to plunge his sword down and finish the job…but Matthew, now with ample time and warning, was able to roll out of the way.

The sword’s edge was stuck in a crack in rock…and a second later, the concussive blast struck James Killian, and he was blasted clean off the cliff. He flew off the edge and plunged into the water below, landing with a murky, loud SPLASH!

Thus the duel between James Killian and Matthew Satyr was finished by Smitty McCarthy.

Smitty opened one eye…and when he saw the ripples in the water, indicating where James Killian had fallen, both eyes leapt wide open.

“JAMES!” he shouted, and scrambled his way off the Czarina, racing around the rocky “port” to the side of the deep pool in the center of the cave. Matthew, no longer obligated to keep his word, flew over to Smitty’s side as they approached the water’s edge.

Azul and Sebek crept off the ship and over to join them. You, meanwhile, helped Nakoda onto his feet, as he was still reeling from James’ Unique Magic. The naga was clutching his stomach with one hand, letting out sort of hissing whimpers, as if he felt as if he hadn’t eaten in days, or even weeks.

“Easy there,” you whispered, and helped him limp along to join the others. “I’ve got you.”

Nakoda just let out a feeble sound and slumped along beside you, one arm over your shoulder as your own arm slung over his. Grim followed close behind you both as you approached the lake. Kes was floating over Matthew’s head, a nervous look in her eyes, as if she was scared of the water…or something inside of it…

“James!” Smitty called out again to the water, as the pool began to still. His voice held a note of panic. “James, please, come up!”

“I’ll go in and get him,” Matthew said, sternly, and began to rise higher into the air.

“But he tried to kill you!” Sebek exclaimed.

“Yeah, I know,” Matthew sighed, and gave a sort of weary smile. He seemed ready to dive down into the water from his height. “It’s hard being a hero, isn’t it?”

Kes suddenly rang her pixie bells in wild alarm, and flew in front of Matthew’s face, shaking her head frantically.

“Don’t try to stop me!” Matthew snapped. “I can’t just-”

KA-ZLOOSH!

Satyr’s words were cut short, as was any attempt to rescue James Killian, when the water of the cave suddenly seemed to explode outwards, as if a bomb had gone off. Kes hid behind Matthew in an instant. All of you stepped back, Grim yelping and ducking behind your legs…as a familiar swirl of inky black mist came spiraling out of the cavern lake. In the middle of the black cloud, pulsing red and violet light could be seen, like a glowing heart beating rapidly.

“Wh-what’s going on?” Matthew exclaimed, somehow jumping in startlement in mid-air.

Azul and Grim shuddered. They knew very well.

“Overblot,” hissed Nakoda, ominously; he was equally familiar.

Sebek growled, gritting his teeth and moving into a battle-ready pose. As for yourself and Smitty, the two of you watched with matching, anxious expressions, as the black cloud began to dissipate…

…And the first thing you saw were the iron hooks. Upon James’ left hand was visible a metal gauntlet, the fingers of which ended in long, hook-shaped claws, almost like a raptor’s talons. Upon the back of the gauntlet was painted the image of a red skull and crossbones, a shade of crimson that matched his long, red coat. The coat now more closely resembled a red Naval uniform coat from days long past…the cuffs of which were completely soaked in black ink, as if they had been dipped in the stuff, some of the ink spilling in ribbon-like patterns back along the sleeves. The brass buttons of the coat also were speckled with ink, and the black lapels seemed to drip ink onto other parts of the tarnished red outfit as well.

The coat and the skull-and-crossbones were the only signs of vibrant color upon the whole ensemble. Beneath this, James’ usual outfit was visible, but the colors had changed; the boots were still black, but now ended in what looked like steel toes, which were spattered with drops of ink. He wore black trousers, a black shirt, and a belt the color of mud, the Jolly Roger buckle of which had turned silver instead of gold. Instead of a bandana, atop his head was perched a tricorn hat, colored a sort of pale, grayish purple, with a raven’s feather stuck in it.

To top all of this off, the rings around James’ fingers on his un-gauntleted hand had also turned to silver…and one of his eyes had turned a glowing shade of crimson, with a familiar, fiery aura surrounding it.

James glared at you all, sneering as he floated downwards, soon lighting upon the rocky poolside of the dank cave. His voice echoed through the cavern, and seemingly through the entire mine, as frigid as a bitter North Wind.

“Children,” he snarled. “I am surrounded by children. Selfish, idiotic, backstabbing little monsters who think they know better, when they know absolutely nothing. And the worst part is, when I decide to show the same form, they seem to think I’m being unfair. Loathsome! All of you! Well, I’m through playing games. I’m through spoiling you all with victory after victory. This time, I’M going to win! This time, I’M going to come out on top! And so I think it’s time all of you recognized…”

He held out the gauntlet clad hand, fingers splayed out.

“...What it feels like to grow up.”

To Be Concluded in Part 6…

#fanfic#my writing#kink-related#but only peripherally#gonna tag kinks in each post#just in case#implied vore#stuffing#belching#burping#not sure if any of these apply to this specific chapter#but they permeate the others#so whatever#disney#twisted wonderland#chapter story#the scarlet pirate#chapter 5#oc story#ocs#james#james killian#smitty#smitty mccarthy#matthew#matthew satyr#nako#nakoda#nakoda spivak#non-ocs

10 notes

·

View notes

Text

Fastener Manufacturer, fastener supplier

Fasteners are vital components used to join or regular or more objects together. From simple screws and bolts to specialized rivets and anchors, fasteners are available in severa sorts and sizes, each designed for precise packages. In this blog publish, Fasteners LLP will help you discover the tremendous kinds of fasteners, their uses, and provide recommendations on a way to pick out the right one to your desires.

Types of Fasteners:

1. Screws: Screws are threaded fasteners with a helical ridge that allows them to be pushed into substances which includes wooden, metal, or plastic. They are to be had in numerous head sorts, such as flat head, spherical head, pan head, and countersunk head, each appropriate for extremely good packages.

2. Bolts: Bolts are much like screws however are usually used with a nut to lock or more elements collectively. They are to be had in one-of-a-kind lengths, diameters, and thread pitches, and are to be had in a vast sort of materials, which incorporates steel, stainless steel, and brass.

3. Nuts: Nuts are internally threaded fasteners which can be used collectively with bolts to secure gadgets together. They are available in various sorts, which includes hex nuts, lock nuts, wing nuts, and acorn nuts, every designed for particular packages and environments.

4. Washers: Washers are skinny, flat discs with a hole inside the middle which might be placed some of the top of a bolt or screw and the surface of the material being fixed. They distribute the burden and prevent damage to the material, in addition to offer an easy bearing surface for the fastener.

5. Rivets: Rivets are permanent fasteners used to enroll in or greater substances collectively. They include a cylindrical shaft with a head on one give up and are hooked up thru deforming the shaft to form a 2d head, growing a sturdy and constant connection.

Uses of Fasteners:

Fasteners by Fasteners LLP are used in an extensive sort of industries and applications, together with advent, automotive, aerospace, electronics, and manufacturing. Some not unusual uses of fasteners embody:

- Joining structural components in buildings and bridges.

- Assembling fixtures and cabinetry.

- Securing electric and plumbing furniture.

- Mounting hardware and system.

- Repairing device and device.

- Installing car components and add-ons.

- Fabricating sheet metal assemblies.

- Constructing and repairing fences, gates, and railings.

How to Choose the Right Fastener:

Choosing the right fastener on your application is based upon on numerous elements, along side:

1. Material Compatibility: Consider the material of the gadgets being joined and select fasteners made from compatible substances to save you corrosion and make certain long-time period durability.

2. Strength Requirements: Determine the load and stress necessities of the utility and pick out fasteners with the right electricity score to face up to the forces they may be subjected to.

3. Environmental Conditions: Consider the running environment, collectively with factors together with temperature, humidity, exposure to chemical substances, and corrosion, and select fasteners with appropriate coatings or substances that may withstand the ones conditions.

4. Size and Dimensions: Ensure that the dimensions, diameter, length, and thread pitch of the fastener are well suited with the substances being joined and the layout specifications of the software.

5. Head Type: Choose the first-rate head kind for the software, thinking about elements together with accessibility, look, and the want for flush or countersunk set up.

6. Installation Method: Consider the method of set up, whether or not guide or automated, and pick fasteners which are probably well suited with the installation equipment and techniques to be had.

Conclusion:

Fasteners are crucial components applied in a large form of programs to enroll in or stable devices together. By recording the special types of fasteners they make use of, and the manner to select the proper one for your wishes, you can ensure strong, steady, and reliable connections to your tasks. Whether you're building a shape, assembling fixtures, or repairing equipment, deciding on the right fastener is crucial for accomplishing maximum beneficial general overall performance and sturdiness.

0 notes

Text

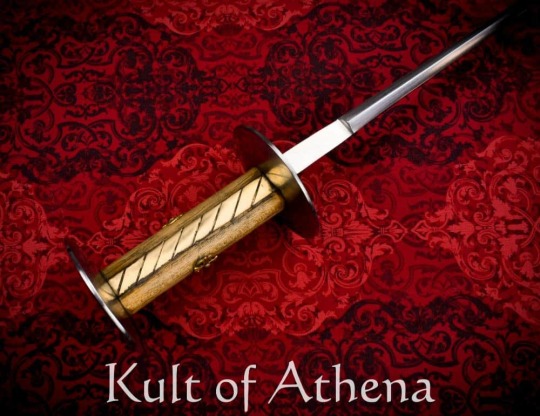

Tod Cutler – 15th Century Wallace Rondel Dagger

This is possibly the most iconic Medieval Rondel Dagger that exists, dating from the first half of the 15th Century. It is very heavily based on a piece in the Wallace Collection. It has a very heavy hollow ground, single edged blade with a 14 mm thick section at the hilt, diving down over the first 50mm to around 9-10 mm thick. The massive rondels are, of course, hollow and each made from two dished pieces of steel. The slab tang passes through the wood handle and the edges are finished with decorated brass plates and the center of the grip is finished with a brass flower shaped medallion.

The blade is EN45 high carbon steel and its clipped-spine form gives it a wide and durable base which then aggressively tapers to a stout piercing point which is kept rigid by a very thick spine and base. This dagger is purpose-designed to be a powerful puncturing weapon for defeating the heaviest of armored harnesses. The blade is anchored into the hilt with a peen over a nut on the pommel. Included with the dagger is a double-layered scabbard of vegetable tanned leather. It has a chape of brass and two leather cords to fasten it to your arming belt.

#Kult of Athena#KultOfAthena#New Item Wednesday#Tod Cutler#14th Century Effigy Rondel Dagger#Knives & Daggers#Medieval Knives & Daggers#Medieval Weapons#15th century#the Wallace Collection#Battle Ready#EN45 High Carbon Steel

1 note

·

View note

Text

A Comprehensive Overview of Fasteners for Beginners

Ananka Group is among the best Fasteners Manufacturer in India.Fasteners are a necessary part of manufacturing, DIY projects, and the construction industry. It is essential to grasp the fundamentals of fasteners, whether you are working on your car, building a structure, or assembling furniture. Here, we'll take a deep dive into the world of fasteners, examining their various types, purposes, and beginner-friendly tips.

What are Fasteners?

Fasteners are hardware components that are used to attach or join two or more items. For machinery, buildings, and common objects to remain stable and intact, they are essential. To suit various purposes, fasteners are available in an array of sizes, shapes, and compositions. Additionally, we are the Bolt Supplier in India

Types of Fasteners:

Nuts and Bolts:

Fasteners that are used most frequently are nuts and bolts. Bolts and nuts make a secure connection because their internal threads match. They are made of brass, stainless steel, and steel, and they come in a variety of lengths.

Screws:

Screws are adaptable fasteners that pierce through the material they are driven into thanks to their helical threads. They have a variety of uses, such as fastening metal parts and holding wood pieces together.

Anchors:

In materials like concrete or masonry, anchors are used to give stability. Depending on the application, they are available in a variety of forms, such as wall anchors, wedge anchors, and concrete screws.

Rivets:

Permanent fasteners known as rivets are used to permanently join two or more materials together by bending the river's end to ensure a tight fit. The aircraft, automotive, and construction industries frequently use them.

Clips and Clamps:

Fasteners made for quick and temporary attachment are called clips and clamps. They are frequently used in DIY, car, and woodworking projects.

Materials Used in Fasteners:

Steel:

Steel fasteners are widely used because of their robustness and longevity. They are frequently used in industrial, automotive, and construction settings.

Stainless Steel:

Stainless steel fasteners are perfect for outdoor or marine applications because they resist corrosion. They are frequently utilised in settings where rust is an issue, such as construction.

Brass:

Brass fasteners have a beautiful appearance and are resistant to corrosion. They are frequently used in ornamental items like jewellery and furniture.

Aluminium:

Aluminium fasteners are ideal for marine and aerospace applications because they are corrosion-resistant and lightweight.

Choosing the Right Fastener:

Consider the materials you are joining.

Assess the load and stress the fastener will endure.

Understand the environment – indoor, outdoor, high-temperature, or corrosive conditions.

Pay attention to size, length, and thread type.

Installation Tips for Beginners:

Use the right tool for the job.

Ensure proper alignment and fit.

Apply the correct amount of torque.

Follow the manufacturer's guidelines.

A basic understanding of fasteners is necessary for anyone working on manufacturing, construction, or do-it-yourself projects. Having a thorough understanding of fasteners, regardless of experience level, enables you to make wise choices and assures the longevity and safety of your projects. When you start your projects, keep in mind that the longevity and structural integrity of your work can be greatly affected by the choice of fastener.Our team produces customised fasteners goods in accordance with customer specifications.

For more details:

Product Source: Fasteners Manufacturer & Bolt Manufacturer in India

0 notes

Text

What industries use fasteners?

Fasteners play a critical role in construction, manufacturing, and engineering. As a leading force in the industry, Bullion Pipes & Tubes LLP stands out as the premier fasteners manufacturer, supplier, stockist, and exporter worldwide. With an extensive range that includes Bolts, Nuts, Screws, Washers, Studs, Rivets, Self-Clinching Fasteners, and more, our commitment is to provide top-notch solutions that cater to diverse project requirements.

This blog post aims to shed light on the diverse industries that heavily rely on fasteners, emphasizing the broad spectrum of applications our products cater to.

Types of Fasteners We Offer

With us, we offer fasteners with a variety of Types and Features, including the following;

Bolts: These threaded fasteners require corresponding nuts for secure connections. Choose from an array of head styles, including hex head, socket head, and round head.

Nuts: Complementing bolts, nuts secure connections. Opt for hex nuts, lock nuts, or wing nuts based on specific application requirements.

Screws: Known for versatility, screws find use in diverse applications. Choose from different head styles like Phillips, flat, or hex, and opt for self-tapping or machine screws.

Washers: Flat and disk-shaped, washers play a pivotal role in distributing fastener loads and protecting surfaces. Types include flat, lock, and spring washers.

Studs: Characterized by threaded rods without heads on one end, studs are ideal for dual-threaded connections and situations where nuts are impractical.

Rivets: Permanent fasteners with a cylindrical shaft and deformed head create a secure connection.

Pins: Cylindrical fasteners for alignment, securing, or support, including types like dowel, cotter, and clevis pins.

Anchors: These fasteners affix objects to hard surfaces, such as concrete. Common types involve wedge, sleeve, and drop-in anchors.

Clips and Clamps: Secure items like hoses and cables using clips and clamps, such as hose clamps, spring clips, and wire rope clamps.

Threaded Rods: Lengthy straight rods with continuous threading, frequently used for hanging and providing support.

U-Bolts: Featuring a U-shaped design with threads on both ends, they secure round objects to surfaces.

Eye Bolts: Equipped with a loop or "eye," these bolts are designed for lifting and securing heavy loads.

Stud Bolts: Threaded at both ends with an unthreaded portion in the middle, commonly used in flange connections.

Self-Clinching Fasteners: Specifically designed for sheet metal and thin materials, including self-clinching nuts, studs, and standoffs.

Hinges and Latches: Serving as fasteners for attaching doors, gates, and panels, they include hinges, hasps, and latches.

Materials Wise Grade We Offer – Fasteners

At, Bullion Pipes & Tubes LLP, provides a wide variety of fasteners, including;

Copper – CDA 102, CDA 101, CDA 110

Titanium – Titanium Alloy Gr 2 & Titanium Alloy Gr 5

Monel – Monel K500 & Monel 400

Carbon Steel – ASTM A193/194 & ASME SA193/194 Carbon Steel

Brass – Alloy 260, Alloy C48200 – C48500, Alloy 385, Alloy 360, Alloy 353, Alloy 330, Alloy 272, Alloy 464

Tantalum – RO5200, RO5400, RO5252(Ta2.5W), RO5255(Ta10W)

Inconel – Inconel 718, Inconel 600, Inconel 601, Inconel 625

Aluminum – he 20 65032 6061, he 30 64430, ASTM 6061, 6063, 6351

Nickel – Nickel Alloy 200/201

SMO 254 – ASTM A 479 ASME SA 479

Duplex Steel – Duplex Steel UNS S32205, Duplex Steel UNS S31803

Hastelloy – Hastelloy C22 & Hastelloy B2, Hastelloy C276

Super Duplex Steel – Super Duplex Steel UNS S32750, Super Duplex Steel UNS S32760

Incoloy – Incoloy 800/800H/800HT, Incoloy 825

Alloy 20 – DIN 2.4460 Alloy Hexagonal Nut, Alloy 20 Bolts, UNS N08020 Alloy 20 Screws, Alloy 20 Washers

Industries Uses Fasteners

Here are some industries where fasteners are used extensively:

Construction: Fasteners such as bolts, nuts, screws, and anchors are widely used in the construction industry for connecting structural elements like beams, columns, and panels.

Automotive: The automotive industry relies heavily on fasteners for assembling vehicles. A variety of screws, bolts, nuts, and clips are used in the manufacturing of cars, trucks, motorcycles, and other vehicles.

Aerospace: Aerospace applications require precision and reliability. Fasteners play a critical role in assembling aircraft and spacecraft components, ensuring safety and structural integrity.

Manufacturing: In general manufacturing processes, fasteners are used to assemble a wide range of products across different industries, including appliances, electronics, and consumer goods.

Energy: Fasteners are used in the energy sector for assembling components in power plants, wind turbines, solar panels, and other energy infrastructure.

Shipbuilding: The shipbuilding industry relies on fasteners for assembling the various components of ships, including the hull, decks, and internal structures.

Railway: They are crucial in the railway industry for connecting rail tracks, assembling train components, and maintaining the structural integrity of railway infrastructure.

Oil and Gas: In the oil and gas industry, fasteners are used in the construction and maintenance of pipelines, platforms, and other infrastructure.

Electronics: Fasteners play a role in the assembly of electronic devices and equipment. They are used to secure components on circuit boards and in the housing of electronic products.

Medical Devices: Fasteners are used to ensure that components are held together in a precise manner in medical devices and equipment.

Furniture: In the furniture industry, fasteners such as screws, bolts, and nuts are used to assemble various types of furniture, from simple household items to complex office furniture.

Final Words!

As a global Fasteners Supplier, Manufacturer Stockist, and Exporter, Bullion Pipes & Tubes LLP takes pride in contributing to the success of diverse industries. Our fasteners, available in an array of sizes, specifications, standards, grades, materials, and types, offer versatility and reliability. Whether it's bolts, nuts, screws, washers, studs, rivets, or self-clinching fasteners, our commitment to quality ensures that our customers can confidently choose the perfect solution for their project requirements. Contact us today at [email protected] or [email protected] to explore how our fasteners can enhance the strength and durability of your applications.

0 notes

Text

DIY Projects That Can Only Be Achieved With Eye Bolts

Discover reliable and precision-crafted eye bolts from the leading eye bolt manufacturer in Mumbai - Delta Fitt Inc. Our commitment to quality ensures durable and secure fastening solutions for a range of applications. Whether you're tackling DIY projects or engaged in industrial endeavours, trust the excellence of Delta Fitt Inc. in Mumbai for top-notch eye bolts that stand the test of reliability and craftsmanship. Secure your projects with confidence choose , Your trusted eye bolt supplier in Mumbai.

What is an eye bolt ?

An eye bolt is a type of fastener with a looped end in the shape of an eye. It's usually composed of metal, like steel, and has a threaded shaft that may be screwed into a variety of surfaces. Following a thorough examination of the construction blueprints, the eye bolt manufacturers in Mumbai, presented a complete report on structural integrity, identifying critical Eye Bolt Details critical to the project's safety. At a reasonable Eye Bolt Price, the looped end provides a simple connection point for fastening ropes, cables, chains, or other equipment.

Out of our standard offerings, we also supply female eye bolts, 6mm eye bolts, swing eye bolts, corrosion-resistant brass eyebolts with collared holes for corrosion resistance and improved durability, as well as double eye bolts with welding capabilities for special uses.

Why would you use an eye bolt?

In a nutshell, eye bolts are indispensable fasteners known for their versatility and strength. Their distinctive "eye" design serves as a secure anchor point, making them essential in a myriad of applications. From lifting and rigging to DIY projects and artistic installations, eye bolts provide a reliable and adaptable solution. Whether you're securing loads during transportation, crafting a DIY masterpiece, or enhancing architectural designs, the use of eye bolts ensures a stable and dependable connection. Join us in exploring the diverse world of eye bolts, where practicality meets creativity, and secure solutions abound.

Choosing eye bolts from a trusted manufacturer like Delta Fitt Inc. in Mumbai not only guarantees a secure and robust fastening solution but also reflects a commitment to quality craftsmanship. Whether you're embarking on DIY ventures, construction projects, or industrial applications, the advice is clear: opt for the excellence offered by eye bolts manufacturers in Mumbai, with Delta Fitt Inc. at the forefront of reliable manufacturing.

Certainly! Eye bolts are versatile fasteners that can be used in various DIY projects. Here are some ideas:

Hanging Planters:

Use eye bolts to create stylish and functional hanging planters. Attach them to a wooden board or a piece of driftwood, and suspend your favourite plants in a unique and space-saving way.

Outdoor Swing:

Build a sturdy outdoor swing using eye bolts for secure attachment points. This project can be a fun addition to your backyard or patio.

DIY Hammock:

Create your own hammock by tying a strong fabric or netting to multiple eye bolts secured between two sturdy supports. It's a relaxing project for your outdoor space.

Curtain Tiebacks:

Use decorative eye bolts to make curtain tiebacks. This adds a touch of uniqueness to your window treatments while serving a practical purpose.

Gymnastic Rings Setup:

Install eye bolts in a sturdy ceiling or beam to create a DIY gymnastic rings setup. It's a great addition to a home gym or outdoor workout area.

Clothesline System:

Set up a retractable clothesline system using eye bolts. This is a space-efficient and practical solution for drying clothes outdoors.

DIY Cable Railing:

Use eye bolts to create a stylish and modern cable railing for your deck or staircase. This gives your space an open and contemporary look.

Outdoor Shade Sail:

Design a shade sail using eye bolts to secure the corners. This project provides a stylish and functional way to create shade in your outdoor space.

Dog Leash Holder:

Craft a personalised dog leash holder by attaching eye bolts to a wooden board. This keeps your pet's essentials organised and easily accessible.

Art Display System:

Create a flexible and adjustable art display system using eye bolts and wire. This allows you to easily showcase and change your artwork without damaging walls.

Remember to choose the appropriate size and strength of eye bolts for each project, considering the weight and intended use. Have fun exploring these DIY projects!

Conclusion

In conclusion, the humble eye bolt suppliers as a versatile hero in the realm of fasteners, offering a secure anchor for a wide array of applications. When seeking top-notch eye bolts for your projects, consider the expertise and reliability offered by eye bolts manufacturer in Mumbai, particularly the reputable Delta Fitt Inc. As a leading manufacturer in the heart of Mumbai, Delta Fitt Inc. stands out for its commitment to quality and precision. Their range of eye bolts is not only crafted with meticulous attention to detail but also adheres to stringent standards, ensuring durability and reliability in various applications. Choosing eye bolts from a trusted manufacturer like Delta Fitt Inc.

0 notes

Text

Ananka

Q1) Fastening Solutions for HVAC and Plumbing Systems

Ans) Fastening solutions for HVAC (Heating, Ventilation, and Air Conditioning) and plumbing systems are essential to ensure the stability, safety, and efficient functioning of these installations. Here are some common fastening solutions used in HVAC and plumbing systems:

1. Pipe Clamps: Pipe clamps are widely used to secure pipes to walls, ceilings, or other structural components. They come in various sizes and materials (such as metal or plastic) to accommodate different pipe diameters and provide robust support.

2. Hangers and Supports: Hangers and supports are used to suspend pipes, ductwork, and equipment from ceilings, walls, or beams. They help prevent sagging or excessive movement, ensuring that the systems maintain their proper alignment.

3. Threaded Rods and Struts: Threaded rods and struts are often employed in conjunction with pipe clamps and hangers to provide additional support for long runs of piping or ductwork.

4. Fasteners for Ductwork: HVAC ducts require specific fastening solutions, such as sheet metal screws, clips, and flange connectors, to join duct sections together securely and maintain proper airflow.

5. Anchor Bolts and Concrete Inserts: For heavy HVAC equipment and structural components that need to be attached to concrete or masonry surfaces, anchor bolts and concrete inserts provide secure fastening points.

6. Flanges and Gaskets: Flanges and gaskets are used to connect pipes, valves, and fittings together in plumbing systems, ensuring leak-free joints.

7. Cable Ties and Straps: Cable ties and straps are versatile solutions for organizing and securing electrical wiring, hoses, or small pipes within HVAC and plumbing systems.

8. Insulation Fasteners: Insulation fasteners are designed to attach insulation materials to HVAC ducts or pipes, helping to improve energy efficiency and reduce heat loss or gain.

9. Fasteners for Equipment Mounting: Fasteners, such as bolts and screws, are used to secure HVAC and plumbing equipment to mounting brackets or frames.

10. Fasteners for Electrical Components: HVAC and plumbing systems often include various electrical components that require secure mounting using screws or specialized clips.

When selecting fastening solutions for HVAC and plumbing systems, it's crucial to consider factors such as the materials used (for corrosion resistance and durability), load-bearing capacity, environmental conditions (such as exposure to moisture or chemicals), and compliance with relevant building codes and regulations.

Proper installation of fasteners and adherence to best practices are vital to ensure the longevity and reliability of HVAC and plumbing systems. If in doubt, it's recommended to consult with professionals or engineers experienced in the specific installation requirements of HVAC and plumbing systems.

Bolt Manufacturers in India

Q2) The Art of Fasteners: Celebrating Design and Craftsmanship

Ans) Fasteners, though often overlooked, play a vital role in design and craftsmanship, serving as unsung heroes that uphold the strength, stability, and reliability of numerous products and structures.

Craftsmanship in fastener design entails creating solutions that not only fulfill their functional purpose but also exhibit aesthetic appeal. Despite their seemingly insignificant size, fasteners can be meticulously designed with attention to detail and beauty, especially in applications where they remain visible, such as in high-end furniture, architectural elements, and luxury products.

Precision engineering is fundamental to crafting high-quality fasteners. Every dimension, tolerance, and material used must be thoughtfully considered to ensure optimal performance, creating fasteners that fit flawlessly, are easy to use, and stand the test of time.

Material selection is a key aspect of craftsmanship, with different applications demanding specific materials, such as stainless steel, brass, aluminum, or even exotic materials for specialized uses. Choosing the right material ensures that the fasteners can withstand the environmental conditions they encounter.

Innovation and problem-solving are inherent in fastener design, as engineers and designers continuously seek ways to enhance their efficiency, ease of installation, and suitability for specific tasks. The artistry lies in finding elegant and effective solutions to complex challenges.

Craftsmanship in fasteners extends to considerations of sustainability and environmental impact. Emphasizing eco-friendly materials, designing fasteners for easy recycling, and creating reusable fastening systems all contribute to responsible craftsmanship.

The historical significance of fasteners lies in preserving traditional techniques while embracing modern advancements. This pays homage to the artisans and craftspeople of the past who contributed to the development of the fasteners we rely on today.

Collaboration and integration are vital in fastener design. They must seamlessly complement the products they hold together, whether it's furniture, building facades, or mechanical systems. Achieving this requires close cooperation between designers, engineers, and manufacturers.

In conclusion, celebrating the art of fasteners entails recognizing their indispensable role in daily life and appreciating the craftsmanship involved in their design and production. Each fastener, from the simplest screw to the most intricate connector, symbolizes the harmonious blend of functionality and artistry.

Eye Bolt Manufacturer in Mumbai

Q3) Fasteners and Fire Safety: Ensuring Building Code Compliance

Ans) Fasteners play a crucial role in ensuring fire safety and complying with building codes. They are essential in maintaining the integrity of fire-rated assemblies, preventing the spread of fire and smoke, and safeguarding the lives of building occupants. Here are some key considerations to keep in mind regarding fasteners and fire safety in building construction:

1. Fire-Rated Assemblies: Building codes often mandate the use of fire-rated assemblies, such as fire-rated walls, ceilings, and floors, to contain the spread of fire. These assemblies are designed and tested to withstand fire for a specific duration, providing occupants with more time to evacuate safely. Fasteners used in these assemblies must also possess fire-resistant properties to preserve the fire rating.

2. Fire-Resistant Materials: Fasteners should be made from fire-resistant materials like steel to endure high temperatures and prevent contributing as fuel to the fire. Using non-combustible materials ensures the integrity of the fire-rated assembly.

3. Type and Size of Fasteners: Building codes may specify the appropriate type and size of fasteners for use in fire-rated assemblies. Using incorrect fasteners can compromise the fire resistance of the assembly.

4. Penetrations and Sealing: Properly sealing penetrations, such as pipes, ducts, or cables passing through walls or floors, is crucial in fire-rated assemblies. Firestop systems and fire caulk are commonly used to seal penetrations and maintain the fire rating.

5. Assembly Testing and Certification: It's essential to use fasteners that have been tested and certified as part of the fire-rated assembly. This ensures that the entire system, including the fasteners, has been evaluated for its fire resistance.

6. Adherence to Manufacturer's Instructions: Following the manufacturer's instructions for installing fire-rated assemblies and using approved fasteners is critical. Deviating from these instructions may void the fire rating and compromise fire safety.

7. Regular Inspections and Maintenance: Regular inspections and maintenance of fire-rated assemblies are vital to ensure that fasteners and other components remain in good condition, providing continued fire protection.

8. Consultation with Experts: When dealing with complex fire-rated assemblies or uncertain about the appropriate fasteners to use, seeking advice from fire safety experts, structural engineers, or building code officials is essential to ensure compliance with regulations and standards.

In conclusion, meticulous consideration of fasteners used in building construction is essential for fire safety and building code compliance. Employing fire-resistant materials, proper installation, and adherence to guidelines ensure that fasteners play their part in creating safer environments for building occupants.

Stud Bolts and Nuts

0 notes

Text

Why People Love to Hate 316 Stainless Fasteners

Marine fasteners play a crucial duty worldwide of seafaring, ensuring the security and reliability of ships, watercrafts, offshore frameworks, as well as aquatic equipment. These essential components safe different components of vessels, offering a durable connection that can withstand the extreme conditions of the open sea. In this post, we look into the relevance of marine bolts, their various types, materials, as well as applications, in addition to the obstacles encountered in ensuring their efficiency in maritime environments.

The Significance of Marine Fasteners

Marine bolts serve as the anchors of the maritime market. They are accountable for holding with each Copper Nails other important parts such as hulls, decks, masts, rigging, and different mechanical systems on board ships and also boats. Provided the extreme problems dealt with mixed-up, including saltwater exposure, high humidity, consistent resonances, and considerable mechanical anxiety, marine fasteners have to be highly long lasting, corrosion-resistant, and reliable.

Types of Marine Fasteners

Screws and Nuts: Bolts and also nuts are amongst the most commonly utilized fasteners in marine applications. They are created to supply a solid, detachable connection and also can be found safeguarding equipment, frameworks, and equipment aboard ships.

Screws: Screws are used when a solid long-term connection is required. They are frequently used to fasten wood, steel, or composite products in various aquatic applications.

Rivets: Rivets are fasteners that develop an irreversible connection between two or even more components by flawing the tail end of the rivet after installation. They are commonly made use of in shipbuilding and also fixing.

Washers: Washers are utilized with bolts and nuts to distribute the stress and stop damage to the connected materials.

Pins and Clips: These bolts are used to safeguard setting up and also other elements that need frequent disassembly and reassembly.

Products Used in Marine Fasteners

Marine bolts are produced from materials that exhibit phenomenal resistance to rust and also deterioration in marine environments. Some typical products consist of:

Stainless-steel: Marine-grade stainless-steel, such as 316 or 316L, is widely utilized because of its exceptional deterioration resistance, stamina, as well as resilience.

Brass: Brass bolts are prominent for their corrosion resistance and also aesthetic charm, making them appropriate for sure aquatic applications.

Silicon Bronze: Silicon bronze fasteners are known for their remarkable deterioration resistance, making them ideal for aquatic hardware like cleats, hatches, and port lights.

Monel: Monel fasteners provide excellent resistance to saltwater deterioration as well as are frequently used in marine applications where high toughness is required.

Obstacles in Marine Fasteners

The aquatic environment presents unique challenges for bolts, requiring mindful style as well as choice. Several of the major obstacles include:

Rust: The most substantial challenge encountered by aquatic fasteners is corrosion because of exposure to deep sea, leading to galvanic deterioration, crevice deterioration, as well as pitting. Selecting the ideal corrosion-resistant product is essential.

Load and also Vibration: Ships as well as watercrafts experience continuous lots and resonances throughout procedure, which can trigger bolts to loosen over time. Appropriate tightening methods and also lock nuts are employed to combat these effects.

Temperature Level Extremes: Marine fasteners need to hold up against a vast array of temperature levels, from cold conditions in polar regions to scorching heat in tropical locations.

UV Exposure: Fasteners on the outside parts of a vessel are revealed to hazardous UV radiation, which can deteriorate specific products over time.

The option of suitable materials and styles is crucial to battle corrosion and mechanical tensions, ensuring that marine bolts proceed to fulfill their essential duty in the seafaring sector. As modern technology and material science breakthrough, aquatic bolts will most certainly end up being also more resistant, additional boosting the safety and efficiency of vessels around the globe.

0 notes

Text

Anchor custom bolts | Roll Fast

This Anchor custom bolts enables builders to embed items in concrete. We manufactured ½” to 4” / M12 to M100 dia. Bolts. We supply custom bolts & nuts to various industries. We provide custom bolts for telecommunication industry, mining industry, construction, transportation, automotive, wind firms etc. We have wide range of customised products, we can also customise fasteners as per the customers need. We manufacture Bolts in Alloy steel, Carbon steel, Stainless steel, Aluminium, Brass, Duplex steel etc. We are your one-stop source for non-standard fasteners cut to length and threaded to your exact application specifications. Our extensive inventory includes blanks in many grades of steel. We can forge Bolts up to 4" / M100 in diameter and 48" long, as well as Heavy Hex Nuts up to 4" / M100 in diameter.

0 notes

Text

https://www.kaizenmetals.com

1 note

·

View note

Text

The Advantages of Aluminum Eyelets in Tarpaulins: Durability and Versatility

Tarpaulins are widely used for various purposes, ranging from outdoor protection to temporary shelters. One crucial component of a tarpaulin is the eyelet, which enables secure fastening and anchoring. While eyelets can be made from different materials, aluminum eyelets have gained significant popularity due to their unique advantages. In this blog post, we will explore the benefits of using aluminum eyelets in tarpaulins.

1. Durability:

One of the most significant advantages of aluminum eyelets is their exceptional durability. Aluminum is a lightweight yet robust material that exhibits excellent resistance to corrosion, rust, and general wear and tear. Unlike traditional eyelets made of steel or brass, aluminum eyelets do not rust when exposed to moisture or harsh weather conditions. This durability ensures a longer lifespan for tarpaulins, making them a cost-effective choice in the long run.

2. Lightweight and Easy Handling:

Aluminum eyelets are lightweight, which makes them easy to handle during installation or any repositioning of tarpaulins. This characteristic is particularly beneficial when dealing with large or heavy-duty tarpaulins that require multiple eyelets. The lightweight nature of aluminum eyelets reduces the overall weight of the tarpaulin without compromising its structural integrity.

3. Versatility:

Aluminum eyelets offer excellent versatility in terms of compatibility with various materials. They can be easily installed on different types of tarpaulins, including polyethylene, canvas, vinyl, and mesh fabrics. Whether you are using a tarpaulin for camping, gardening, construction, or any other application, aluminum eyelets provide a reliable and versatile attachment point.

4. Resistance to Extreme Temperatures:

Tarpaulins often face extreme temperature variations, ranging from scorching heat to freezing cold. Aluminum eyelets excel in such conditions due to their high melting point and thermal stability. They can withstand intense heat without deforming or losing their structural integrity, ensuring that the tarpaulin remains securely anchored. Additionally, tarpaulin eyelets do not become brittle in freezing temperatures, making them suitable for use in colder climates.

5. Aesthetically Pleasing and Professional Finish:

Aluminum eyelets add a touch of sophistication to tarpaulins with their sleek and polished appearance. They provide a professional finish, enhancing the overall aesthetics of the tarpaulin. Whether you're using a tarpaulin for promotional purposes, outdoor events, or trade shows, aluminum eyelets contribute to a more visually appealing presentation.

6. Ease of Installation:

Installing aluminum eyelets is relatively straightforward, even for individuals with minimal experience. They can be easily installed using basic tools, such as eyelet setting tools or grommet machines, allowing for efficient and hassle-free installation. The simplicity of installation makes aluminum eyelets a practical choice for both DIY enthusiasts and professionals.

Conclusion:

Aluminum eyelets offer numerous advantages when it comes to tarpaulins. Their durability, lightweight nature, versatility, resistance to extreme temperatures, aesthetic appeal, and ease of installation make them a reliable and cost-effective choice. By opting for aluminum eyelets, you can ensure that your tarpaulin remains securely fastened and protected for an extended period, even under challenging environmental conditions. Whether you're using tarpaulins for personal or commercial purposes, considering aluminum eyelets is a wise decision.

1 note

·

View note

Text

What Fastener Is Commonly Used With

Fasteners are essential hardware components used to join or secure objects together. They come in various forms, each designed for specific applications based on factors such as the type of materials being joined, the load-bearing requirements, and the desired level of strength and durability.

In this article We will explore some of the commonly used fasteners across different industries and applications.

Screws:

Screws are versatile fasteners that are commonly used in woodworking, construction, and general assembly applications.

They consist of a threaded shaft with a head, allowing them to be easily inserted and tightened using a screwdriver or a drill.

Different types of screws are available, including wood screws, machine screws, self-tapping screws, and sheet metal screws, each designed for specific materials and applications.

Screws provide a strong and secure connection and can be easily removed if needed.

Bolts:

Bolts are robust fasteners used for applications that require high strength and load-bearing capabilities.

They consist of a threaded shaft with a head and require a nut to secure the joint.

Bolts are commonly used in the construction, automotive, and machinery industries.

They are available in various grades and types, such as hex bolts, carriage bolts, and eye bolts, each suitable for specific applications.

Nuts:

Nuts are paired with bolts to create a secure fastening system.

They are typically hexagonal in shape and have internal threads that match the bolt's external threads.

Nuts are available in different materials, such as steel, stainless steel, and brass, to suit various application requirements.

They are widely used in construction, machinery, and automotive industries.

Washers:

Washers are flat, disc-shaped fasteners that are placed between the fastener and the surface being fastened.

They distribute the load evenly, provide stability, and prevent damage to the surface.

Common types of washers include flat washers, lock washers, and spring washers.

They are used in various industries, including construction, automotive, and electrical.

Rivets:

Rivets are permanent fasteners used to join two or more materials together, especially in applications where disassembly is not required.

They consist of a cylindrical shaft with a head that is inserted into pre-drilled holes and then deformed to secure the joint.

Rivets are commonly used in the aerospace, automotive, and construction industries.

They provide excellent shear and tensile strength.

Nails:

Nails are widely used in woodworking, carpentry, and construction applications.

They have a sharp point and a flat head and are driven into the material using a hammer or nail gun.

Nails come in various lengths, sizes, and materials, such as steel or stainless steel, to suit different applications.

They provide a quick and efficient means of securing materials together.

Anchors:

Anchors are fasteners used to provide secure attachments to surfaces that cannot support the load directly.

They are commonly used in masonry, concrete, and drywall applications.

Different types of anchors are available, including expansion anchors, screw anchors, and toggle anchors, each designed for specific materials and load requirements.

Anchors provide stability and strength in applications where the material alone cannot provide sufficient support.

Clips and Clamps:

Clips and clamps are fasteners used to hold objects together or secure them in place.

They are commonly used in automotive, HVAC, and industrial applications.

Examples include hose clamps, spring clips, and panel fasteners.

They provide a secure and adjustable

Fasteners Manufacturers