#Needle Manufacturers

Text

Why You Should Consider Switching to Low Dead Space Needles

Are you tired of dealing with messy injections and wasted medication? It may be time to consider making the switch to low dead space needles. In this blog post, we will explore the benefits of low dead space needle and why they are becoming increasingly popular among healthcare professionals.

What Exactly is Dead Space?

Dead space refers to the space within a needle or syringe where medication can get trapped and go to waste. Traditional needles have a larger dead space, leading to inaccurate dosing and potential medication waste. Low dead space needle aim to minimize this wasted space, providing a more efficient and effective injection experience.

What are Low Dead Space Injection Needle?

First off, let’s talk about what exactly low dead space needle are. These innovative needles are designed with a minimal amount of space between the needle and the syringe, reducing the amount of medication that gets trapped and wasted. This means more accurate dosing and less medication left behind in the needle.

Benefits of Low Dead Space Needle

So, why should you consider switching to low dead space needle? Well, for starters, they can improve injection practices by ensuring that patients receive the full dose of medication every time. This can lead to better treatment outcomes and reduced risk of infection or contamination.

Low dead space needle offer several benefits, especially in healthcare where precision and safety are paramount

Reduced Medication Waste: Low dead space needle minimize the amount of medication left in the needle hub after administration. This can be particularly significant with expensive or critical medications, reducing waste and potentially saving costs.

Lower Risk of Cross-Contamination: With less residual fluid left in the needle, the risk of cross-contamination between patients is reduce. This is particularly important in settings where needles are reuse or when dealing with infectious diseases.

Improved Accuracy in Dosage: Dead space in needles can hold a small amount of medication, affecting the accuracy of dosage delivery. Low dead space needle ensure that the intended dose is administered more accurately, which is crucial in treatments where precise dosing is required.

Enhanced Safety for Healthcare Workers: Reduced dead space means less exposure to blood or bodily fluids for healthcare workers during needle handling and disposal. This can help minimize the risk of accidental needlestick injuries and potential exposure to bloodborne pathogens.

Better Patient Experience: Zero dead space needles can contribute to a more comfortable injection experience for patients, as they may experience less pain and bruising due to more accurate delivery of medication.

Compliance with Needle Exchange Programs: In harm reduction programs such as needle exchange initiatives for intravenous users, zero dead space needles are prefer due to their reduced risk of transmitting bloodborne infections between users.

Environmental Impact: Minimizing medication waste not only saves costs but also reduces the environmental impact associated with the disposal of unused medications. This aligns with sustainability goals in healthcare.

How Low Dead Space Needles Can Improve Injection Practice

Low waste injection devices are also easier to handle and use, making them a preferred choice among healthcare professionals. Their design allows for more precise injections, reducing the risk of needle stick injuries and other complications. Additionally, they can help reduce medication waste, saving both time and resources in the long run.

Read More : The Ultimate Guide to IV Catheter Needle-Pen Type

Environmental Impact

In addition to their practical benefits, low dead space needles also have a positive environmental impact. By reducing medication waste, these needles help minimize the amount of pharmaceuticals that end up in landfills or waterways. This can contribute to a healthier and more sustainable healthcare system.

Cost-Effectiveness

Despite their many advantages, some may be concerned about the cost of switching to low dead space needles. However, the long-term benefits of these needles far outweigh the initial investment. By reducing medication waste and improving injection practices, low dead space needles can ultimately save money for healthcare facilities and providers.

Conclusion: Making the Switch to Low Dead Space Needle In conclusion, low dead space needles offer a range of benefits that can improve injection practices, reduce medication waste, and promote a more sustainable healthcare system. If you are looking to enhance your practice and provide the best possible care for your patients, consider making the switch to low dead space needles today. Your patients and the environment will thank you for it!

Source : Why Low Dead Space Needles is Best for Accurate Injection

#Low Dead Space Needles#Efficient Needles#Healthcare Improvement#Medical Devices#Medication#Needle Manufacturers#Medical Advancements#Medical Instrument

0 notes

Text

I need Sean Finnerty and Bucky Barnes to meet.

I don't care how.

#Sad Soldiers#They just wanna protecc#Sean Finnerty#Bucky Barnes#Candela Obscura#Circle of Needle and Thread#Critical Role#Captain America#MCU#PTSD#Veterans#Maybe they can commiserate over a drink#Maybe they can toss a baseball around#idk#Working Class Manufactured Monsters#The Winter Soldier

12 notes

·

View notes

Text

Get To Know About the Cylindrical Needle Rollers

Compact cylindrical needle rollers with a length significantly longer than their diameter are known as cylindrical needle rollers. These rollers, which are typically constructed from ground and hardened steel, are available in a range of sizes and designs to accommodate a variety of uses. Cylindrical needle rollers are perfect for harsh situations because of their distinctive design, which offers…

View On WordPress

#Cylindrical Needle Rollers#Cylindrical Needle Rollers China#Cylindrical Needle Rollers Manufacturer#Cylindrical Needle Rollers Supplier

2 notes

·

View notes

Text

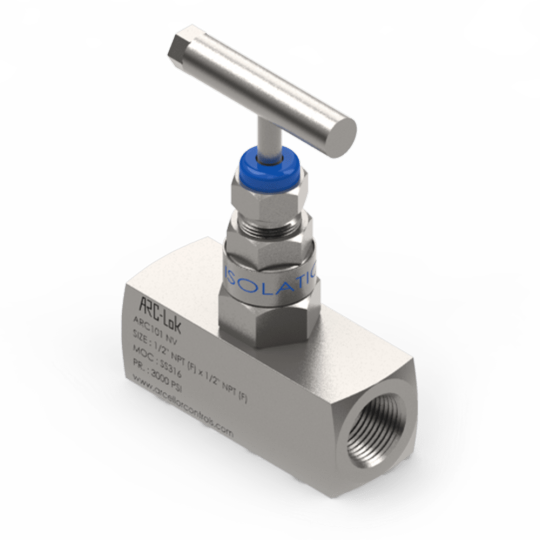

Introduction of Needle Valve Manufacturers

The needle valve is also known as a plunger valve. It helps to control pressure in the pipe and prevents the pipe from being damaged by the pressure. The needle valve is located at the end of the pipe and has a small hole in it. The Needle Valve Manufacturers in Mumbai are used to control the pressure in the pipe.

It is a small, dislike-like device that is inserted into a pipe to close it. The needle valve is better for small-diameter pipes, such as those found in a shower or a toilet, because it doesn't require any additional parts to work. It is also better for pipes that are already closed, like those found in a sink or a bath, because it doesn't require any additional work to open them.

This allows the builder to pre-pressurize a pipe before the plumber arrives, and then release the pre-pressurization when the plumber arrives. This helps to avoid the potential cost and inconvenience of a service call by the plumber, and also prevents damage to the pipes if the pre-pressurization is not released between customers. The valve manufacturer designedaneedle valve in India as per the requirement of customers, and industries needs.

Needle valves are a type of valve that is distinct from the other valves commonly used in plumbing and industrial applications. By using a long, threaded stem and a sharp, tapered needle, these valves can provide precise control over the flow of fluids, compared to the more binary actuation of typical valves. This needle valve is composed of a screw-in body that contains a perforated seat and a needle-shaped valve stem, which is usually made from stainless steel. The precision and accuracy of the valve make it popular for applications like controlling pressure and flow in chemical processing plants.

Needle valves are different from other valves, as they possess a long, slender cone-shaped disk that is used to regulate the flow of fluids. The disk is perforated with multiple holes which are used to control the rate of flow. This is why Needle Valve Manufacturers in Chennai are often used in industries where precise control is required over the flow rate of fluids. Needle valves are also known for their superior performance in high-temperature and pressurized applications, making them perfect for the extreme conditions found in many industrial settings.

There are few points to be considered:

The needle valve in the nozzle is shut off so that no fluid can leak out, and so that any extra fluid in the system is forced back into the system to help prevent contamination.

The needle valve is a small valve used to regulate the flow of fluid. It consists of a small steel disc with a hole (called a needle) through which fluid flows, and a spring-loaded valve stem that opens when the needle is pushed.

The operation of the needle valve is easy and simple. You only need to press the button and the valve will open. This makes it a great option for people who are not comfortable with traditional faucet valves. You can also adjust the flow of water with the needle valve, which is not possible with faucet valves.

The needle valve has a small size diameter and can be closed to control the flow of solution through it. The needle valve is of small size, it is available to customers as per requirement need to approach theNeedle valve manufacturer.

One while selecting a needle valve one should consider material, temperature & pressure rating, size of the valve, and many other criteria as per their requirement.

The role of the needle valve is flow control, pump start, pressure regulation, and turbine by pass, flow discharge, air regulation, reserve inlet, etc many other roles.

A needle valve is used to regulate water pressure, flow rate, reservoirs, power plant, and water distribution and by many industries as per their requirement.

Yakshita Engineering is the leading needle valve manufacturer and has great experience in manufacturing of valves in India.

#Needle valve manufacturers in Mumbai#Needle valve manufacturer in Chennai#Needle valve manufacturer in India

2 notes

·

View notes

Text

StandBuilding is like WorldBuilding but for jojo stands. anyway missed opportunity for standbuilding is that every piece of metal on risotto's design should be silver instead of gold because then it could be implied that he created his outfit with the help of metallica

#because that ''jojo outfits are so crazy bc theyre all handmade'' post is DEFINITELY canon#and ive been thinking about the possible practical application of metallica so much#do you realize how practical a stand that can forge things by pulling iron out of the environment is#risotto could literally buy bulk iron powder and manufacture shit from it. i dont see why not!!!#if girl can create scissors and sewing needles and razor blades and scalpels#those youtube channels who make crazy stuff with molten metals have got nothing on risotto

3 notes

·

View notes

Text

Just broke a bamboo knitting needle for the first time in my life. I’m so upset.

#knitting#i am so mad#kill me#i set my project down on the couch. scrolled for a bit. then decided to stand up.#i put my hand down on the cushion next to me to push myself upwards. and i realized i was on my project#and sure enough. with my luck. i had pressed onto the needle and bent it.#then i screamed#i am so upset. i guess steel needles it is. but i've preferred bamboo over the years.#but these were part of an interchangeable needle set and luckily if i order from the manufacturer i can get just the single size#rather than a whole new set. so i'll get this size in steel instead of bamboo#and get a few more chords since i need a longer length and a shorter length too. but UGH. i am so mad

4 notes

·

View notes

Text

0 notes

Text

The Top Valve Fittings Manufacturers,Supplier & Exporter in USA - Mcneil Instruments

Mcneil Instruments stands as the leading valve fittings manufacturer, supplier, and exporter in the USA, specialising in a wide array of valve fittings. With a focus on quality and precision, we offer tube fittings, needle valves, ball valves, check valves, and more, ensuring adherence to industry standards. Valves play a critical role in fluid and gas pipe networks, regulating flow effectively. As top industrial valve manufacturers, we provide the best instrumentation valves to meet diverse industry needs. Manifold valve, needle valve, ball valve, check valve, globe instrumentation valve, gate instrumentation valve, huge cock valve, and block bleed valve, our products are engineered to deliver optimal performance and reliability, making us the preferred choice among valve suppliers in the USA.

#valve fittings#manufacturer#USA#Manifold valve#needle valve#ball valve#check valve#globe instrumentation valve#gate instrumentation valve#Gauge cock valve#block bleed valve

0 notes

Text

It's t-shot Tuesday, y'all! Woo!

#I do wish I could figure out the trick to consistent shot administration#by that I mean every week is a Russian Roulette on the spectrum of “is this gonna hurt like a mfer or am I not gonna feel it at all”#today was closer to the hurt like a mfer but not all the way there#Everything was against me taking the shot this morning#first I ended up with a bit of the vial gasket in my syringe#which meant disposing of the whole thing#T and all#which was hard AF to do but it's not like I could strain and resterilize#and then#After applying the thinner needle to my syringe and uncapping it#I noticed there was some odd fucking white plastic or something attached to the side#some kind of manufacturing issue I guess#so all in all I used twice as many supplies for a single shot today

0 notes

Text

What is Needle Valve? Uses and Working, Types

Needle valves are fundamental additives in various industries where precision glide control is crucial. Renowned for his or her excellent-tuning abilties, needle valves play a essential function in regulating fluid drift with extraordinary accuracy. In this complete manual, we'll delve into the intricacies of needle valves, exploring their uses, running standards, and different types.

What is a Needle Valve?

A needle valve is a sort of valve designed to manipulate the drift of fluids with excessive precision. Its distinguishing function is the slender, tapered factor on the give up of the valve stem, reminiscent of a needle, for this reason the call. This needle-like shape lets in for sluggish adjustment of go with the flow quotes, making needle valves ideal for applications that call for particular manage over fluid flow.

Uses of Needle Valves:

Needle valves discover packages across a huge variety of industries wherein precision flow control is paramount. Some common uses include:

Instrumentation: Needle valves are notably utilized in instrumentation structures, along with strain gauges and glide meters, wherein correct control of fluid float is important for particular measurements.

Laboratory Equipment: In laboratories, needle valves are hired in diverse analytical devices and experimental setups to regulate the float of gases and liquids with utmost precision.

Hydraulic Systems: Needle valves are crucial components in hydraulic structures, in which they assist adjust the waft of hydraulic fluid to control the rate and course of hydraulic actuators.

Chemical Processing: In chemical processing plant life, needle valves are utilized to govern the go with the flow of corrosive or unsafe fluids, ensuring secure and green operation of the method.

Oil and Gas Industry: Needle valves play a important role in the oil and gas enterprise, where they are utilized in wellhead control systems, pressure alleviation structures, and other essential packages that demand unique flow manipulate.

Working Principle of Needle Valves:

The running precept of a needle valve revolves round the precise adjustment of go with the flow via the narrowing passage created with the aid of the tapered needle and the valve seat. When the valve is inside the closed function, the tapered needle tightly seals towards the valve seat, preventing the waft of fluid. As the valve is gradually opened by means of turning the handle or actuator, the space among the needle and the seat increases, allowing the fluid to go with the flow through the valve. By precisely adjusting the position of the needle, the glide charge may be managed with exquisite accuracy.

Types of Needle Valves:

Needle valves are available in numerous configurations to suit one of a kind packages. Some common kinds encompass:

Straight Needle Valves: Straight needle valves feature a linear float path, making them suitable for programs wherein a immediately flow trajectory is preferred.

Angle Needle Valves: Angle needle valves are designed with a bent or angled flow path, taking into account easier installation in tight areas or packages where area constraints are a issue.

Integral Bonnet Needle Valves: Integral bonnet needle valves have the bonnet and frame cast together as a single piece, providing stronger electricity and sturdiness, making them suitable for excessive-pressure packages.

Screwed Bonnet Needle Valves: Screwed bonnet needle valves feature a separate bonnet this is screwed onto the frame, taking into account easy preservation and repair.

Packing Needle Valves: Packing needle valves are ready with packing material around the valve stem to prevent leakage, making them appropriate for packages in which sealing integrity is crucial.

In end, needle valves are critical components in industries in which unique glide manipulate is vital. Their ability to modify fluid waft with fantastic accuracy makes them worthwhile in a wide range of programs, from instrumentation and laboratory system to hydraulic systems and chemical processing plants.

For pinnacle-first-class needle valves and expert steerage on tube clamps and dairy pharma fittings, look no similarly than Bu-Lok. As a main Needle Valve manufacturer within the enterprise, Bu-Lok offers a complete variety of tube clamps, inclusive of hydraulic pipe tube clamps, heavy-obligation tube clamps, and light-duty tube clamps. With their know-how and dedication to excellence, Bu-Lok is your trusted companion for all your tube clamp needs.

0 notes

Text

Top Uses of Chiba Needles in the Medical Field

Chiba needles, also known as Chiba biopsy needles, are thin and sharp medical instruments commonly used in various procedures within the medical field. These specialized needles have become an essential tool for physicians and healthcare professionals due to their versatility and effectiveness in a wide range of medical applications.

From diagnostic biopsies to therapeutic injections, Chiba needles have revolutionize the way medical procedures are perform, providing accurate and efficient results. In this article, we will discuss the top uses of Chiba needles in the medical field, highlighting their importance and impact on patient care.

What are chiba needles?

Chiba needles are thin, flexible needle that are use in various medical procedures to access specific areas of the body with precision. They are named after the Japanese radiologist who first introduced them, Dr. Chiba. These needles come in different lengths and gauges, making them versatile tools for healthcare professionals.

Top chiba needle applications in the medical field

1.Diagnostic Procedures

One of the primary use of Chiba needle is in diagnostic procedures such as biopsies and aspirations. These needles allow doctors to obtain tissue or fluid samples from deep within the body with minimal trauma to the patient. This is crucial in diagnosing conditions such as cancer or infections.

2.Pain Management

Chiba needle are also use in pain management procedures such as nerve blocks and epidural injections. By delivering medication directly to the source of pain, these needles can provide targeted relief for patients suffering from chronic pain conditions.

3.Biopsy Procedures

When it comes to performing biopsies, Chiba needle are essential tools for obtaining tissue samples from organs such as the liver, kidneys, or lungs. These needles are design to penetrate deep tissues safely and accurately, making them invaluable in the diagnosis of various diseases.

Read More : How to Choose the Right Biopsy Needle for Your Practice

4.Interventional Radiology

In the field of interventional radiology, chiba needle play a crucial role in procedures such as percutaneous drainage or ablation. These needles allow radiologists to access and treat tumors or fluid collections under imaging guidance, offering minimally invasive alternatives to traditional surgery.

5.Drainage Procedures

Chiba needles are commonly employ for various drainage procedures, including thoracentesis (draining fluid from the pleural space), paracentesis (draining fluid from the abdominal cavity), and pericardiocentesis (draining fluid from the pericardial sac). The sharpness and flexibility of Chiba needles facilitate smooth insertion and effective drainage, crucial for managing conditions such as pleural effusion and ascites.

6.Minimally Invasive Surgery

In minimally invasive surgical techniques such as laparoscopy and percutaneous procedures, Chiba needles find application in tasks such as tissue sampling, vessel cannulation, and suture placement. Their slender profile and precise control make them invaluable instruments for surgeons performing complex procedures through small incisions.

Conclusion: The Versatility of Chiba Needles

In conclusion, chiba needle are versatile instruments that have revolutionized the way medical procedures are performed. From diagnostic biopsies to pain management interventions, these needles continue to be indispensable tools in the medical field. So, the next time you hear about Chiba needle, remember their significant impact on patient care and the advancement of medical technology.

Source : Top Uses of Chiba Needles in the Medical Field

#Chiba Needles#Chiba biopsy needles#medical instruments#medical procedures#biopsies injections#Medical Device#Medication#Healthcare#Needle Manufacturers#Needle Suppliers

0 notes

Text

does anyone know if they make gloves to protect your hands when you're pressing down on the plunger of the syringe barrel? like that has padding in the thumb? testosterone is really thick, esp if ur pushing it thru a sub-q needle !!!

IM injections are out the window bc they tend to make me react (ex: my skin gets all hard and really itchy, and ill scratch it to the point of tearing skin!! and we've tried benadryl to subvert that reaction, but it doesn't seem to be helping @.@... subcutaneous is all i have... )

#reggie speaks#theres auto injectors but theyre for insulin which is significantly less thick! and takes fixed needles which arent luer-slip/lock..#were not sure if the spring load will work if its as thick as testosterone either... so all i can think of is gloves#testosterone#hrt#transgender#< tags 4 ppl to find this#we did find a video of an auto injector designed for t but we have questions that i dont think the uploader will have answers for...#it was an auto injector for people with erectile dysfunction but the needle was also fixed.#and trying to draw up t with such a small gauge is bad for our hands.#so we would need one that allows your own needles and not just special ones you can only get straight from the manufacturer of the injector.

0 notes

Text

Key features of cylindrical needle rollers produced in China

Cylindrical needle rollers China is a precision-engineered component used in various mechanical systems to facilitate smooth motion and support high radial loads. These rollers are commonly employed in needle roller bearings, which are essential in automotive, aerospace, industrial machinery, and other applications where space-saving and high-load capacity are critical.

Key features of cylindrical needle rollers produced in China include:

High-Quality Materials: Manufacturers in China often utilize high-grade materials such as bearing steel (e.g., GCr15) or stainless steel to ensure durability, strength, and resistance to wear and corrosion.

Precision Machining: Chinese manufacturers employ advanced machining techniques and equipment to produce cylindrical needle rollers with precise dimensions and tolerances, ensuring consistent performance and compatibility with bearing assemblies.

Customization Options: Customers can often request customization of dimensions, materials, surface finishes, and coatings to suit specific application requirements. This flexibility allows for optimal performance in diverse operating conditions.

Cost-Effective Solutions: China's manufacturing capabilities and economies of scale often result in competitive pricing for cylindrical needle rollers without compromising quality.

International Standards Compliance: Reputable Chinese manufacturers adhere to stringent quality control processes and often comply with international standards such as ISO and ANSI to ensure product reliability and consistency.

Cylindrical needle rollers China play a crucial role in needle roller bearings, where they provide efficient load distribution, reduced friction, and increased rigidity. These bearings are widely used in transmissions, engines, gearboxes, steering systems, and other machinery where space constraints and high radial loads are prevalent. Manufacturers in China contribute significantly to the global supply of cylindrical needle rollers, offering reliable solutions for a wide range of industrial applications.

#Cylindrical Needle Rollers China#Cylindrical Needle Rollers Supplier#Cylindrical Needle Rollers Manufacturer#Cylindrical Needle Rollers

1 note

·

View note

Text

#SS Needle Valve Manufacturer Ahmedabad#SS Needle Valve Manufacturer in Mumbai#SS Needle Valve Manufacturer in Chennai#SS Needle Valve Manufacturer in Gujarat#SS Needle Valve Manufacturer in Vadodara#SS Needle Valve Manufacturer in Rajasthan#SS Needle Valve Manufacturer in Ghaziabad#SS Needle Valve Manufacturer in Delhi#SS Needle Valve Manufacturer in Bangalore

0 notes

Text

Discover the key factors to consider when searching for reliable needle roller manufacturers. Our guide provides valuable insights and tips to help you navigate the market, ensuring you find trustworthy suppliers for high-quality needle roller products.

0 notes

Text

Top Needle Valve Manufacturers in India for 2024

Needle valves play a crucial role in the dynamic world of commercial systems. These precision equipment play a pivotal position in regulating and controlling fluid go with the flow within various structures. As we embark on the adventure of 2024, staying nicely informed becomes paramount, particularly concerning the Best Needle Valves and their manufacturers. For those in search of pinnacle-notch first-rate, it is critical to explore the leading needle valves manufacturer in India. These innovators aren't most effective in shaping the industry however additionally setting up new benchmarks, making them key gamers within the evolution of the needle valves era.

In this weblog submit, we're going to delve into the top needle valve manufacturers shaping the enterprise in 2024.

Understanding the Significance of Needle Valves:

Needle valves are fundamental additives in fluid management structures, imparting exceptional management over go with the flow charges. Their layout, providing a slim, tapered point at the end of the valve stem, allows for unique adjustment of drift, making them perfect for programs wherein accuracy is paramount. Industries inclusive of oil and gas, petrochemicals, prescription drugs, and manufacturing depend heavily on needle valves for their operations.

Top 5 Needle Valve Manufacturers in India for 2024:

Arcellor Controls India: Setting the Standard

At the leading edge of the needle valve manufacturing enterprise, Arcellor Controls India stands out as the Best Needle Valves Manufacturer, continually turning in pinnacle-notch merchandise that meets and exceeds the expectancies of customers internationally. Specializing in a wide range of needle valve types, inclusive of High-Pressure Needle Valves, Integral Bonnet Needle Valves, MXM Angle Type Needle Valves, and more, we cater to numerous industries with precision and quality craftsmanship. As a main needle valves supplier in India, we take delight in presenting the best needle valves, ensuring unheard-of overall performance for our customers across the globe in numerous countries like India, Oman, Qatar, USA, Germany, UK, Brazil, Turkey, UAE, Indonesia, and Saudi Arabia on the most competitive in the marketplace.

Why Choose us for Needle Valves?

Unmatched product range and customization alternatives

Adherence to global requirements and specs

Global supply chain ensuring well-timed deliveries

Competitive pricing without compromising on fine

Instrumxx Industries: A Noteworthy Competitor

While numerous needle valve producers in India show off prowess, Instrumxx Industries sticks out as a high-quality competitor. With a focal point on technological innovation and reliable overall performance, Instrumxx Industries has carved a gap for itself in the marketplace.

Doshi Impex India: Crafting Excellence in Needle Valves

Doshi Impex India has earned its recognition as a dependable needle valve provider with the aid of continually turning in merchandise that adheres to stringent first-class requirements. Their commitment to excellence and client pride makes them a key participant within the enterprise.

Hilton Forge India: A Name Synonymous with Quality

Known for his or her dedication to best and sturdiness, Hilton Forge India has made a mark inside the needle valve manufacturing zone. With a various product variety and a consumer-centric approach, Hilton Forge India competes strongly inside the market.

Hayward Flow Control: Innovating Fluid Solutions

Completing the top five listings is Hayward Flow Control, a producer recognized for its innovation in fluid control solutions. While no longer completely centered on needle valves, Hayward Flow Control's contribution to the industry can't be left out.

Final Words!

As needle valve manufacturing continues to evolve through 2024, Arcellor Controls India stands proudly as the ultimate destination for those looking for precision, reliability, and customization in needle valve solutions. Renowned as a leading Needle Valves Manufacturer, we've mounted ourselves as an international benchmark for high quality, with a dedication that remains unwavering. Operating on a global scale, we preserve to shape the trajectory of fluid manipulate solutions, consistently putting industry standards that others aspire to emulate. When it comes to pleasurable your needle valve requirements, pick out us, the epitome of excellence in every side of valve performance.

0 notes