#tensile architecture

Text

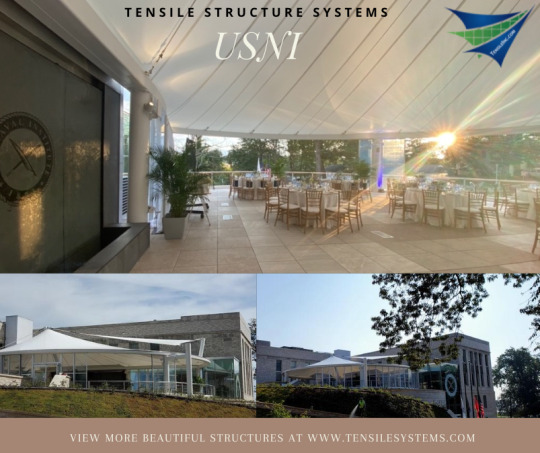

This custom-designed #tensile #canopy at the US Naval Academy creates a beautiful space on the patio for major events and receptions. The #structure is climate controlled and has removable custom side panels that allow year-round comfort and convenience for patrons.

Contact us to learn more about the endless possibilities that come with #tensilestructure: tensilesystems.com / 410.814.7525

1 note

·

View note

Text

"I'm your arch's nemesis"

Normal people: what? that doesn't sound right, don't you mean-

Architects: HAVE AT THEE, FUCKING BUTTRESS

#tumblr wants me to add tags#uuuh#architecture#here you go#I guess the actual nemesis of arches would be orthogonal horizontal pressure though?#since then an arch would (I presume) be less stable to that than a wall of similar length#that's just what I expect though I know literally nothing about architecture#At least if the arch doesn't support anything#If it does support something good luck felling it#I know that much#because obviously it's hard to push stuff out if there's stable weight on it#I wonder how that holds up to an architect's expertise#do architects do whole calculations of materials like how ductile they are and friction index and tensile strength and lots of stuff like#that so nothing bad happens#or do we have that stuff figured out and they just pull out a table with all the data and they just know by heart the important stuff#like 'don't use stucco as your foundation; it is brittle and sad'

4 notes

·

View notes

Text

Best Tensile Car Parking in Delhi

Tired of the Delhi heat baking your car? We've got the answer! Our tensile car parking structures are like high-tech carports. Imagine a sturdy metal frame holding up a special fabric that creates a cool, shaded spot for your car. MS Tensile offers the best tensile car parking for car owners in Delhi. Not only will it protect your car from the sun's harsh rays, but it'll also keep it dry from rain and shielded from dust and dirt.

The best part? These shelters look fantastic! They're modern and stylish, adding a touch of class to your home or business. Plus, at MS Tensile, we offer:

Unbeatable Strength: Our shelters are built to last, using top-quality materials that can handle anything Delhi weather throws at them.

Just Your Style: We can design a car shelter that perfectly fits your space, whether you need a single spot or a canopy for multiple cars.

Expert Setup: Our experienced team will get your shelter installed quickly and efficiently, with minimal disruption.

Great Prices: We offer top-notch tensile car parking at affordable prices.

Contact MS Tensile today for a free consultation and quote to get the perfect car parking tensile structure for your needs.

#tensile structure#tensile car parking#tensile manufacturer#tensile structure manufacturer#architecture

0 notes

Text

Auditorium Tensile Structure

An "Auditorium Tensile Structure" typically refers to a tensile structure designed and constructed to cover the auditorium. An auditorium is a dedicated space for performances, presentations, lectures, or other events, and combining a tensile structure into its design can provide several benefits. Here's a breakdown of key aspects:

Advantages of Tensile Structures for Auditoriums:

Large Span Coverage: Tensile structures can cover large spans without the need for extensive internal support, creating unobstructed views within the auditorium.

Natural Lighting: Translucent fabric membranes can allow natural light to filter through, creating a well-lit and comfortable environment.

Customization: Tensile structures can be customized to fit the specific design requirements of the auditorium and provide a distinctive architectural identity.

Weather Protection: The tensile covering protects against the elements, ensuring that events can be held even in harsh weather.

Applications:

Outdoor Auditoriums: Tensile structures are often used in outdoor auditoriums to create a covered space for performances and events.

Entrance Canopies: Tensile structures can also be used as entrance canopies for auditoriums, providing a welcoming and aesthetically pleasing feature.

If you're searching for a reliable and trustworthy company for high-quality Auditorium Tensile Structures look no further than Royal Tensile Structure Pvt. Ltd.!

#tensile manufacturer#tensile structure manufacturer#tensile structure#tensile car parking#architecture#tensile auditorium

0 notes

Photo

Contact us 0565019032 https://parkingshades.weebly.com #parkingshades #architecture #landscape #garden #tensile #carparkingpergola #sharjah #uae #people #design #Alnouf https://g.page/r/CXorswe6WLtiEAE (at Nouf, Sharjah) https://www.instagram.com/p/Cp0OhPoJrtO/?igshid=NGJjMDIxMWI=

#parkingshades#architecture#landscape#garden#tensile#carparkingpergola#sharjah#uae#people#design#alnouf

1 note

·

View note

Link

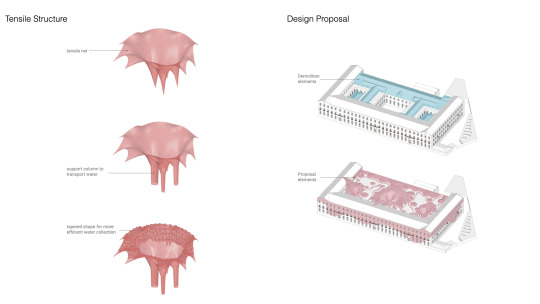

Biomimetic Water Harvesting

Architecture’s Emergent Role in Climate Change

Dessau Institute of Architecture Masters Programme

Studio Peter Ruge - #0000FF- Too Little, Too Much

Stanislava Kungurova - Biomimetic Water Harvesting

Climate change leads to changes in precipitation patterns, which provokes two opposite extremes: floods and droughts. Climate scientists predict that much of the world will experience a significant water loss. The effects of climate change should be seen as a challenge for designers to mitigate water scarcity through architecture. Understanding and responding to the effects of environmental change requires a focus on both immediate and long-term solutions. One response to the water crisis is rainwater harvesting, which is already widely used. However, today's water scarcity problems require alternative water management solutions where buildings can receive, store, and transport water more efficiently.

Existing water scarcity problems are increasing the demand for improved water management strategies. Effective water management solutions can be derived from strategies found in nature. Many similar problems have already been solved by organisms that have had to adapt to environments where water is scarce, intermittent, or excessive. Some species have developed ways to harvest water from the air in deserts or store it for periods of scarcity. The purpose of this study is to consider the methods of applying biomimetics to architecture, particularly water management, to propose a more efficient concept of water harvesting through design. Elements based on a biomimetic approach such as a water harvesting façade, a tensile net structure and a green roof are considered within the project.

Since the project is expected to focus more on biomimicry- inspired water harvesting stratagies, choosing the existing building for renovation is relevant. Within Spain, a former factory, the Tabacalera, in Madrid, has been chosen as the appropriate design area. The construction took place between 1780 and 1792. From 1809 it was a tobacco and rapeseed factory until the end of the 20th century. Nowadays, after it was declared the National Center of Fine Arts in 2007, Tabacalera Promotion of Art is managed by the General Directorate of State Museums of the Ministry of Culture and Sports, develops a permanent program of temporary exhibitions and events dedicated to photography, contemporary art and fine arts (Ministerio de Cultura y Deporte n.d.).

#dessau institute of architecture#Dessau Institute of Architecture Masters Programme#Master Thesis#Studio Peter Ruge#sustainability#0000ff#biomimicry#sustainable#dia#DIA Masters Programme#water harvesting#tensile#Architecture#rain water harvesting#climate change

1 note

·

View note

Text

'the inflatable sprach pavilion by veech media architecture outlines a new niche for tensile architectonic materials' in ultra materials: how materials innovation is changing the world - bradley quinn (2007)

40 notes

·

View notes

Photo

What are the main materials used in the construction of the Brooklyn Bridge?

The Brooklyn Bridge stands as an iconic symbol of engineering prowess and architectural marvel, connecting the boroughs of Manhattan and Brooklyn in New York City. Its construction, which began in 1869 and was completed in 1883, marked a significant leap forward in bridge engineering during the 19th century. At the heart of this magnificent structure lie a variety of materials that were carefully selected to withstand the test of time and provide the strength and stability needed to support the bridge's massive weight and endure the forces of nature.

Foundations and Substructure:

The foundations of the Brooklyn Bridge are built upon a series of caissons—watertight chambers that were sunk to the bedrock below the East River. These caissons served as the base upon which the towers of the bridge would rise. Constructed using timber and brick, the caissons were then filled with compressed air to keep water out, allowing workers to excavate the riverbed and lay the bridge's foundations. Granite blocks were used to create the towers' outer layer, providing a sturdy and enduring base.

Superstructure:

The superstructure of the Brooklyn Bridge, including its towers and main span, is primarily composed of limestone, granite, and Rosendale cement. The limestone and granite provide the necessary strength and durability, while the Rosendale cement—a type of natural cement produced in Rosendale, New York—acted as the binding agent in the construction of the bridge's arches and towers.

Suspension Cables:

The most distinctive feature of the Brooklyn Bridge is its elegant web of suspension cables. These cables are made of high-tensile strength steel, a revolutionary material for the time. The steel cables were galvanized to protect against corrosion, ensuring the long-term stability of the bridge. The cables were meticulously woven and anchored into the bridge's towers and anchorages, distributing the load and supporting the immense weight of the bridge deck.

Decking and Walkways:

The decking and walkways of the Brooklyn Bridge were constructed using wooden planks. Originally made from longleaf yellow pine, the wooden decking has undergone various replacements and renovations over the years, adapting to the evolving demands of modern traffic. Today, the bridge features a reinforced concrete deck topped with asphalt, providing a smooth surface for vehicles and pedestrians alike.

Decorative Elements:

The Brooklyn Bridge's towers and other decorative elements showcase an array of materials, including granite, limestone, and limestone blocks. The neo-Gothic arches and intricate details that adorn the towers contribute to the bridge's aesthetic appeal and make it a true work of art.

Conclusion:

The construction of the Brooklyn Bridge stands as a testament to the innovation and engineering prowess of the 19th century. A careful selection of materials, combining strength, durability, and aesthetic appeal, was crucial to the success of this historic structure. Today, as the Brooklyn Bridge continues to serve as a vital link between two bustling boroughs, its enduring legacy serves as a reminder of the importance of thoughtful material selection in the world of civil engineering and architecture.

#New York City#new york#newyork#New-York#nyc#NY#manhattan#urban#city#USA#buildings#visit-new-york.tumblr.com#Bridge#Brooklyn Bridge

118 notes

·

View notes

Text

With #tensilestructures we are leading the way into the architectural future and providing creative and dynamic solutions with every new project. #Tensilefabric offers distinct advantages over traditional materials while also being cost-effective, easy to install, and are 95% recyclable.

There are so many opportunities that come with tensile structures!

Please contact us if you are interested in opening up or expanding your space to provide a beautiful outdoor environment: tensilesystems.com / 410.814.7525

#tensile architecture#tensile desing#tensile design#architecture#fabric architecture#architecture design#ptfe fabric membrane#design build specialty contractor fabric architecture

0 notes

Photo

Manta Rays by Vincent Callebaut Architectures @vincentcallebautarchitectures, A Sustainable Cluster of Ecolodges in Organic Tensile Membrane Structures, #Bali, Indonesia Read more: Link in bio! Vincent Callebaut Architectures: For the project “Manta Rays’, a sustainable cluster of ecolodges in Tensile Membrane Structures (TMS), form-finding was the first step in the design process, in which the structure has adopted a unique equilibrium shape based on the initial configuration of the structure and the applied initial prestress… #indonesia #sustainable #архитектура www.amazingarchitecture.com ✔ A collection of the best contemporary architecture to inspire you. #design #architecture #amazingarchitecture #architect #arquitectura #luxury #realestate #life #cute #architettura #interiordesign #photooftheday #love #travel #construction #furniture #instagood #fashion #beautiful #archilovers #home #house #amazing #picoftheday #architecturephotography #معماری (at Bali, Indonesia) https://www.instagram.com/p/CpItTtJOAM6/?igshid=NGJjMDIxMWI=

#bali#indonesia#sustainable#архитектура#design#architecture#amazingarchitecture#architect#arquitectura#luxury#realestate#life#cute#architettura#interiordesign#photooftheday#love#travel#construction#furniture#instagood#fashion#beautiful#archilovers#home#house#amazing#picoftheday#architecturephotography#معماری

57 notes

·

View notes

Text

#tensile structure#tensile car parking#tensile manufacturer#tensile structure manufacturer#architecture

0 notes

Text

0 notes

Text

Are space elevators possible? Physicist says they could transform humanity into a 'spacefaring civilization'

Humanity's quest to explore—and, perhaps eventually, colonize—outer space has prompted a great many ideas about how precisely to go about it.

While conventional wisdom suggests that space launch via rockets is the best way to send human beings into orbit, other "non-rocket" methods have been proposed, including a futuristic "space elevator."

The concept of a space elevator—essentially a sky-high cable that would let humans climb into space—has been championed by some industry experts as a way to overcome the astronomical costs associated with sending people and cargo into space by rocket, says Alberto de la Torre, assistant professor of physics at Northeastern.

"Current launch systems are predominantly single-use and typically exceed $10,000 per kilogram of payload, totaling around $60 million per launch," de la Torre says. "Here's where space elevators are appealing."

First imagined by Russian rocket scientist Konstantin Tsiolkovsky in the late 19th century, the space elevator would extend from the ground through the atmosphere, then past "geostationary orbit," an altitude where objects in space—pulled in by the Earth's gravity—orbit more or less in tandem with its rotation. Geostationary orbit is roughly 22,236 miles above the Earth's surface.

Effectively, a cable would descend from a satellite structure anchored in geostationary orbit that would act as a "counterweight" down to Earth.

Theoretically, a satellite positioned beyond geostationary orbit would act to stabilize the cable through a combination of forces: the Earth's gravitational pull, which would exert a downward force on it from the ground, and the centrifugal force of its rotation, which would exert an upward force on the cable from space. The interaction of forces would create an ideal tension—a tautness—necessary to sustain a cable of such length, de la Torre says.

"The key element of a space elevator is its cable, positioned at the Earth's equator and synchronized with the Earth's rotation," de la Torre says.

No proof of concept exists for a space elevator. While there have been several attempts at architectural designs, including an award-winning design by a British architect that recently bore a six-figure prize, numerous technical obstacles have kept the space elevator decades out of reach.

"A cable of such length [more than 22,236 miles above the Earth] isn't feasible with standard materials," de la Torre says. "If made of steel, the maximal tension it faces at geostationary orbit exceeds its tensile strength rating by over 60 times."

For an Earth-based space elevator, strategies to reduce tensile forces, or the ability of a material to withstand tension, are crucial, he says.

But there are some materials that carry promise. Boron nitride nanotubes, diamond nano threads and graphene—all materials with "low density and high tensile strengths"—could fit the bill, de la Torre says.

"Carbon nanotubes are proposed as an ideal material due to their high tensile strength," he says. "Recent research has raised concerns about the feasibility of translating their nano-scale properties to megastructures."

In the long-run, the space elevator's promise lies in its potential to make trips to outer space significantly more economical. "The cost of putting a payload beyond a geostationary orbit can be cut to just a few hundred dollars per kilogram," de la Torre says.

"While the initial investment in a space elevator might be substantial—akin to the expense of developing and launching the James Webb Space Telescope into orbit, the costs could be recouped after successfully launching a mere few tons of payload," he says.

"With the continuous evolution of materials sciences, space technology and engineering, the concept of space elevators shouldn't be ruled out in the not-so-distant future," de la Torre says.

Until those breakthroughs in materials science arrive, the space elevator may only continue to serve as fodder for science fiction enthusiasts.

"Space elevators, in essence, hold the promise of transforming humanity into a spacefaring civilization," de la Torre says. "They could present a safe, cost-efficient avenue to bring into orbit the heavy payloads needed for hypothetical space stations, asteroid mining or developing extraterrestrial habitats."

4 notes

·

View notes

Text

Exploring Different Types of Square Pipes and Their Uses

Square pipes have become essential components in various industries due to their unique shape and strong qualities. The amalgamation of their geometric configuration and remarkable durability makes them well-suited for a diverse range of applications. This blog post provides a complete analysis of the many square pipes that are currently accessible in the market. It examines their distinct properties and the wide array of industries in which they are utilised. Elevate your structures with reliable square pipes by Tube Trading Co., your trusted partner and Square pipes supplier in Gujarat!

Mild Steel Square Pipes:

Mild steel square pipes, also known as MS square pipes, hold a significant presence within the construction and industrial sectors. The reasons for their widespread acceptance can be ascribed to their cost-effectiveness, durability, and simplicity in production. These pipes are widely utilised in the fabrication of frames, supports, and diverse structural components.

In addition to their application in construction, MS square pipes are commonly employed in the fabrication of furniture, racks, and fences owing to their notable pliability and corrosion resistance. Due to their wide range of applications, these entities are considered vital assets in various initiatives, spanning from architectural ventures to industrial infrastructure development.

Stainless Steel Square Pipes:

Stainless steel square pipes are widely recognised for their remarkable resistance to corrosion and their pleasing visual characteristics. These pipes have been utilised in architectural contexts, namely for embellishing handrails, balustrades, and other ornamental components. The exceptional capacity to withstand adverse weather conditions and exhibit resistance to corrosion renders them a very suitable option for outdoor applications.

In addition, sectors such as food processing and pharmaceuticals exhibit a preference for stainless steel square pipes owing to their hygienic characteristics and convenient maintenance. The integration of performance and aesthetics in these pipes renders them a highly desirable choice for applications that prioritise both endurance and visual appeal.

Aluminum Square Pipes:

Aluminium square pipes have emerged as a prominent choice due to their ability to achieve a harmonious equilibrium between strength, weight, and resistance to corrosion. The utilisation of these pipes holds considerable influence in sectors such as aerospace and automotive, where their favourable high strength-to-weight ratio is evident. The utilisation of aluminium square pipes in the construction industry yields advantages, as they facilitate the creation of structures and frames that are characterised by their lightweight nature.

Furthermore, their influence is evident within the renewable energy industry, specifically in the production of frameworks for solar panels. The inherent inertness of aluminium guarantees the durability of these structures, hence enhancing the sustainability of solar energy installations. Don't compromise on quality and strength, experience the difference with quality square pipes offered by Tube Trading Co. - an excellent Square pipe distributor in Vadodara!

PVC Square Pipes:

PVC square pipes have dominated the plumbing, irrigation, and drainage industries due to their low cost and high durability. These pipes are essential in water management systems and subterranean pipelines where corrosion is a major concern. PVC square pipes can be used as electrical conduits due to their insulating characteristics. Their importance in do-it-yourself (DIY) endeavours and the development of modular furniture is also not to be underestimated. PVC pipes are ubiquitous in the arts because of their adaptability and portability.

Carbon Steel Square Pipes:

Carbon steel square pipes are the go-to option when extreme durability and tensile strength are required. The oil and gas industry, among others, relies heavily on high-pressure applications, making these pipes an absolute necessity. Because of their high resistance to wear, they are particularly effective at transporting fluids and are also able to deal with abrasive materials. Carbon steel square pipes can be counted on for years to come, making them ideal for use in the production of long-lasting industrial machinery and equipment.

Galvanized Square Pipes:

When the primary issue is corrosion resistance, galvanised square pipes, which are strengthened by a zinc coating, become the focal point. These pipes are commonly utilised in external structures such as fences, handrails, and signage. In areas with elevated humidity levels or frequent contact with seawater, the galvanised coating serves as a defensive barrier, preventing corrosion and extending the durability of the pipes. The cost-effectiveness of their endurance results in a reduction in maintenance requirements and enhances the structural integrity of buildings.

Final Thoughts:

The realm of square pipes offers a wide range of possibilities, accommodating the unique requirements of different sectors. The diverse range of materials, such as mild steel with its utilitarian strength, stainless steel with its elegant properties, aluminium with its lightweight appeal, and PVC with its corrosion-resistant utility, each possess distinct characteristics that contribute to their individual merits.

In addition, carbon steel and galvanised pipes are designed to meet specific needs, hence improving the performance and durability of various buildings and systems. The examination of square pipes elucidates not only their tangible achievements but also their vital role in the advancement of contemporary infrastructure and architecture on a global scale. Crafting Gujarat's infrastructure with excellence. Choose Tube Trading Co. – a renowned Square pipe dealer in Vadodara as your square pipes partner!

#Square pipes Supplier in Vadodara#Square pipes Supplier in Gujarat#Square pipe distributor in Vadodara#Square pipe dealer in Vadodara#Business#Supplier#Distributor#Jindal pipes#Steel industry#Steel company#Construction structure

8 notes

·

View notes

Text

Your Guide To Understanding The Differences Between Concrete vs. Steel Structures

Undoubtedly, concrete and steel take center stage in real estate as they help them focus on diverse solutions. Each material offers distinct advantages and characteristics, making it suitable for various projects depending on design requirements, budget constraints, and environmental considerations.

At Apollo Formwork, we specialize in providing high-performance formwork panel systems that cater to the unique needs of both concrete and steel structures. Whether you need information about concrete wall panels or other structures, you must focus on several options before moving ahead.

In this blog post, we focus on the differences between concrete and steel structures, shedding light on their respective attributes and highlighting our company's role in facilitating efficient and reliable construction processes.

Understanding Concrete Structures

Concrete structures have long been a staple in the construction industry, prized for their durability, versatility, and cost-effectiveness. Constructing a concrete structure involves pouring liquid concrete into formwork molds, allowing it to harden and form a solid mass. This method enables the creation of a wide range of shapes and sizes, making concrete an ideal choice for buildings, bridges, dams, and other infrastructure projects.

One of the key advantages of concrete structures is their inherent strength and durability. Concrete has excellent compressive strength, allowing it to bear heavy loads without deformation or failure. Concrete structures exhibit good resistance to fire, corrosion, and weathering, ensuring long-term structural integrity and minimal maintenance requirements.

Differentiating Steel Structures

In contrast to concrete, steel structures rely on steel components such as beams, columns, and frames to support the building's weight and resist external forces. Steel offers several advantages over concrete, including a higher strength-to-weight ratio, faster construction times, and greater design flexibility. Steel structures are often preferred for high-rise buildings, industrial facilities, and infrastructure projects where large spans and open floor plans are desired.

One of the primary benefits of steel structures is their exceptional strength and flexibility. Steel boasts high tensile strength, allowing it to withstand tension forces and bending without undergoing significant deformation or failure. This property enables engineers to design slender, lightweight structures without compromising safety or performance.

If you wish to know more about construction equipment for rental, explore a series of options.

The Role of Apollo Formwork

At Apollo Formwork, our core business focus revolves around developing high-performance formwork panel systems tailored to the specific needs of concrete and steel structures. Our innovative formwork solutions enable contractors and construction firms to streamline the building process, enhance productivity, and achieve superior results.

For concrete structures, our formwork panels provide a robust and reliable framework for pouring and shaping liquid concrete, ensuring precise alignment and finish quality. Our advanced formwork systems are designed to accommodate diverse project requirements, from simple foundations to complex architectural elements, allowing contractors to optimize efficiency and meet tight deadlines.

Similarly, our formwork solutions for steel structures offer unmatched versatility and adaptability, facilitating the rapid assembly and erection of steel components with minimal labor and material waste. By leveraging our expertise in formwork technology, contractors can overcome logistical challenges, reduce construction time frames, and deliver projects on schedule and within budget.

Conclusion

In summary, concrete and steel structures represent two distinct construction approaches, each with advantages and applications. While concrete offers durability, versatility, and cost-effectiveness, steel provides strength, speed, and design flexibility. At Apollo Formwork, we are committed to supporting construction professionals with innovative formwork solutions that enhance productivity, efficiency, and performance.

Footnotes

By understanding the differences between concrete and steel structures and leveraging suitable formwork systems, contractors can succeed in their projects while meeting the evolving demands of the construction industry.

To know more about concrete and steel structures, it will help if you explore a series of options before you make the final decision.

2 notes

·

View notes