#mold manufacturing

Text

Contactor base injection mold design

1 Base analysis

Base is similar to a semi-enclosed box-shaped piece. Coil is installed inside box surrounded by vertical ribs. Outer side where vertical ribs are located and B and C surfaces are exterior surfaces. No push rod marks or obvious parting lines are allowed. End surface where height of vertical rib is located is mating surface with upper shell. Try to avoid setting flat push rods.…

View On WordPress

#core-pulling molding#Core-pulling Structure#injection mold design#injection molding pressure#mold design#mold manufacturing#mold structure#molded plastic parts#plastic part#plastic parts

0 notes

Text

Mahalaxmi Industries: Noida's Premier Mold Manufacturing Company

Noida, a thriving industrial hub in northern India, is home to Mahalaxmi Industries, a name synonymous with excellence in mold manufacturing. With a rich legacy of delivering precision and quality, Mahalaxmi Industries has established itself as the foremost mold manufacturing company in Noida. In this article, we will explore the remarkable journey and the unparalleled expertise that define Mahalaxmi Industries.

A Legacy of Excellence

For over two decades, Mahalaxmi Industries has been a stalwart in the manufacturing industry, consistently setting the bar for quality and innovation. The company's journey, marked by unwavering commitment and relentless pursuit of perfection, underscores its reputation as a trailblazer in mold manufacturing.

Cutting-Edge Infrastructure

Mahalaxmi Industries owes its success to a state-of-the-art infrastructure. Their modern manufacturing facility is equipped with advanced CNC machines, CAD/CAM software, and staffed by a highly skilled workforce. This cutting-edge infrastructure empowers the company to offer a comprehensive array of mold manufacturing services, including injection molds and die-casting molds.

A Commitment to Quality

Quality is at the heart of Mahalaxmi Industries' operations. The company adheres to strict quality control measures, ensuring that every mold they produce is a paragon of precision and durability. Rigorous quality assurance protocols, encompassing meticulous inspections, rigorous testing, and thorough validation processes, are the hallmarks of their manufacturing process.

Customized Solutions

Mahalaxmi Industries sets itself apart with its ability to provide tailor-made solutions. Their team of seasoned engineers and designers collaborates closely with clients to comprehend their unique requirements, resulting in bespoke mold manufacturing solutions. This customer-centric approach ensures that every project is a resounding success.

Serving Diverse Industries

Mahalaxmi Industries caters to a wide spectrum of industries, including automotive, aerospace, electronics, and consumer goods. Their molds play a pivotal role in the production of a wide range of products, from intricate automotive components to high-precision medical devices. The company's diverse industry portfolio attests to the versatility and reliability of their offerings.

A Global Footprint

Mahalaxmi Industries has extended its reach far beyond Noida, serving clients not just in India but worldwide. Their commitment to adhering to international standards, swift turnaround times, and competitive pricing has positioned them as a trusted partner on the global stage.

Sustainability and Responsibility

In addition to their unwavering commitment to quality, Mahalaxmi Industries prioritizes sustainability and corporate responsibility. They employ eco-friendly manufacturing practices and continually invest in minimizing their environmental footprint. This responsible approach to business resonates with clients who value ethical and sustainable partnerships.

0 notes

Text

Mold manufacturing company for switchgear, defense systems, automotive, and toys. Compression moulding and injection moulding for all plastic productsThriam, an ISO 9001-2015 certified company was started in 1989 by our founder Mr. Madhukumar. Thriam works with companies like ABB, Legrand, Crompton, and Cochin Shipyard Limited for OEM needs.We are an expert multi-engineering solution provider in the industry for more than three decades.

0 notes

Text

In the selection of mold materials, in addition to the accuracy and quality of the products, we should also consider the actual processing and heat treatment capabilities of the mold factory to give a correct choice. In addition, in order to shorten the manufacturing cycle, the existing standard parts shall be used as much as possible.

In addition to the best structure and reasonable tolerance fit in the design, the precision of the mold is very important for the part processing and mold assembly. Therefore, the choice of processing precision and processing method plays an absolutely dominant role in mold manufacturing.

0 notes

Text

Just kinda... putting this out into the universe for right now, but I've been thinking really hard about getting my old enamel pin collections back in circulation, as well as maybe releasing them as stickers as well (for a budget option and also for things you can't put enamel pins on). I had to throw out basically all my remaining stock when I moved (which... oouugh it still hurts), so I might essentially run a "reboot" kickstarter to get another batch of Dire Hounds made and then try again to get the full Grimalkins set funded. A few things this would let me do:

update the templates for slightly cleaner manufacturing, and update the backer cards with accurate artist info because man that was really bothering me

like I said, hopefully get the second half of the Grimalkins produced so they're a proper six-pin collection like the first one

network! Now that I'm in a big city I think I honestly might have better luck with consignment stores and craft fairs than I ever did with only an online shop, and more visibility can only mean good things.

I'm also still definitely planning to make idog merch, and beyond that I'd potentially love to lean even further into the cyberpunk and y2k aesthetics to really hone my Brand™, but obviously that requires original thought and creative effort while getting the dogs and cats remade just requires pulling the old AI files off my poor aging iMac.

#if possible I'd love to find a (more) local manufacturer instead of the one in the UK I was using before#unfortunately that means they'll cost a bit more up front since they won't have the molds already#which I guess would have possibly been a non-issue anyway if I was gonna tweak the art#but also the lower shipping costs without going through customs.....#anyway just thinking..... on a conceptual level I really miss ~designing merch~ even though I never really excelled at it lmao#a lot of you probably have no fucking clue what I'm talking about because the pins were before your time :/#just take my word for it they were all really really cool and you want them#I wish I made the kind of art that people want on their walls lmao prints seem like easy money for a lot of people#but it just doesn't mesh with what I make. All I can offer to The People is Little Guys For Your Bag Or Jacket

20 notes

·

View notes

Note

could you do the queer angel with short hair?

Here's a quick edit for you Anon

#I'm not planning to manufacture this one since it would require a new mold#but I'll put it on Redbubble#pride angels#don't expect this to be a regular thing I generally don't like making edits to my designs once I've finished them

75 notes

·

View notes

Text

ok doll shelf update AGAIN... sorry abt all the naked plastic ladies i am still in the process of washing/acquiring/making clothes for them rn. but i needed them off my desk!!! im not super happy with my little fashion queen pedestal centerpiece rn but im sure ill get it figured out esp after she has.. you know... CLOTHES ON. i might end up trying to diy her original outfit or smth close to it bc i really dont want to be leaving her wigs on long term those bitches melt.

#if anyone is insane and knows which plat blonde superstar mold barbie i have please let me know i have been scouring websites and cant quite#find her. her earrings are captive in her head and she doesnt have bangs unless someone managed to completely pull them out or smth#i can find REALLY CLOSE dolls but the eye color will be off or smth... but idk how much variation there was between manufacturing locations#the main site i was using did have some dolls with location differences but i didnt see her there

8 notes

·

View notes

Text

…How do we feel about the environmental implications of certain very tiktok-friendly Small Business Crafts such as resin work and polymer clay jewelry. I know that I feel and think things about them but I don’t really know what those things are

#like are they yet another expression of first world consumerist luxury?#is it irresponsible to create with what is essentially a lot of plastic?#is it stupid to shame people for this when their impacts are negligible compared to manufacturers and industry?#or is it something to be more concerned about?#how is the ‘accessible low-entry level craft -> small business on tiktok’ pipeline affecting artists?#in what ways do these crafts intersect w privilege or lack thereof?#what makes them different from things like beading/embroidery/pottery/painting/metalwork/sewing/other arts and crafts?#are they different at all?#idk I just feel like on the one hand yay creativity on the other hand i feel like it’s trendifying/yassifying/commodifying certain aspects#of creativity#like most amateur like ‘small business’ tiktok girlies are just making things that follow trends and often copies of whatever is popular atm#(at least in my experience)#like do you know what I mean. like all the resin girlies with their molds they bought on aliexpress#and the polymer clay earring girlies where they make the clay look like marble/stone in a ‘satisfying’ grammable process#of chopping up teeny bits of clay and mixing it with acrylic paint and gold leaf and rolling it all out#and it’s ‘satisfying’ and just the ~perfect~ vehicle for ~trending audios~

11 notes

·

View notes

Text

once again i am realizing the ramifications of my decision re: clarissa in the AU

like "oh, you tried to kill a guy because he put your father in prison, and then actually met him and decided 'well shit, he's just a little guy, just a birthday boy, i can't do this'. only part of that that's remotely weird is the 'in prison' part. otherwise that's regular mechwarrior shit, you're free to go. no we're not seizing all of your family's assets, again, Regular MechWarrior Shit. go sell it all and start a merc company or something."

meaning she's still filthy fucking rich, still has a noble title, and has high society connections, and also fuckall to do other than sign on with said birthday boy's pathetically small but disproportionately effective mercenary outfit (convenient, since otherwise i'd have to find an excuse for her to run into amos later)

#expanse battletech au#i'm putting it down to holden's 'magnetic hero'-ism and bobbie's ass as to why she joins up#that said she does liquidate most of her house's assets and sell the manufacturing stuff to tycho#but that's just because an ex-solaris gladiator who's now a mercenary doesn't have much use for scrooge mcduck-level assets#clarissa: another case for judge moneybag i see#holden: when are you going to run out of money. i'm curious.#clarissa: probably uh in a few centuries. it kind of grows just sitting there. hate that. it's like mold.

2 notes

·

View notes

Text

#Injection Molding#Ultrasonic Welding#electronics manufacturing services#electronic manufacturing services#electronic manufacturing services companies#electronics manufacturing services India#electronics manufacturing services chennai#top Ems companies in India#bestEmscompanies in India#EMS

2 notes

·

View notes

Text

Material expansion: At present, the types of materials for 3D printing are relatively limited. In the future, more types of materials can be explored, including new polymer materials, metal materials, ceramic materials, etc., to meet the needs of different fields.

Technological progress: At present, the speed, accuracy and quality of 3D printing technology still need to be improved. In the future, new printing technologies can be developed to increase printing speed, reduce printing errors and improve printing quality.

Diversified applications: At present, the application fields of 3D printing technology are still relatively limited. In the future, applications in more fields can be explored, such as applications in construction, medical, aerospace, automobile manufacturing and other fields, and its unique technical advantages can be exerted.

Intelligent development: In the future, artificial intelligence, machine learning and other technologies can be combined with 3D printing technology to realize intelligent design, optimization and production, and improve production efficiency and product quality.

Green development: At present, the waste and environmental protection problems generated by 3D printing technology still need to be solved. In the future, we can explore the path of green development, such as developing recyclable materials, reducing waste generation, etc., while paying attention to the impact on human body and environment .

Interdisciplinary cooperation: In the future, cooperation and innovation between different disciplines can be promoted, such as combining biology, chemistry, physics and other disciplines with material science, mechanical engineering, electronic information and other disciplines to jointly promote the development and application of 3D printing technology .

Cost reduction: At present, the cost of 3D printing technology is still relatively high. In the future, technological progress and large-scale production can be used to reduce costs and increase the penetration rate and application range.

2 notes

·

View notes

Text

Causes and Countermeasures for Deformation of Injection Molded Parts - 7

Serial No. 7 (Friends who are interested can follow Gud Mould to view previous series in historical news)

3) Mold inlay design

Usually when moldmakers consider inlay design, their starting points are: ease of processing, lower material costs, reduce tendency of mold core deformation, and improve exhaust. However, few mold designers can proactively consider mold core inlays from perspective of…

View On WordPress

#Causes and countermeasures for deformation of injection molded parts#clamping force#cooling design#Deformation of Injection Molded Parts#design of exhaust#Exhaust system design#injection molded parts#injection molding production#injection pressure#Mold designer#Mold ejection design#mold factories#Mold inlay design#mold manufacturing#product design#Strength of mold structure

0 notes

Text

Here are three easy plastic orders.

I will continue to update the post related to injection molding machine processing.

Please stay tuned~

#injection molding#cncmachining#Prototool#rapid prototyping#injection molding machine#mold#custom manufacturing

2 notes

·

View notes

Text

Custom Molded Rubber Parts Manufacturers in Chennai India USA | K R Industries

#Custom Molded Rubber Parts Manufacturers in Chennai India USA | K R Industries#krindustry#vehiclerubbermanufacturing#manufacturing#rubbermanufacturing#qualityrubbermanufacturingindustryinchennai

2 notes

·

View notes

Text

chair

Wlecome to visit our factory and negotiate business.

High quality surface blasting finished rotational aluminum mold factory and exporter

Dongguan Yuanyuhe Mould Co.,Ltd, produce rotomolding aluminum molds and rotationally-moulded products for the marine, medical, construction, leisure and sanitation industries etc.

High quality molds and products

LDPE HDPE XDPE plastic rotomolded products

7 notes

·

View notes

Text

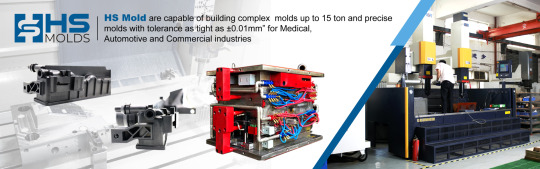

Application of 3+2 CNC Machining in Mold Making Factory

Plastic injection mold manufacturers have long embraced simultaneous multiple-axis machining on machine tools with five or more axes, but more and more China injection mold makers have begun machining mold components on multiaxis platforms in the past few years, said Charlie Chan, engineering manager HS Mold & Die Co.,LTD

He mentioned, however, that the common approach for machining mold parts in houses is 3+2, or 5-axis positional machining. According to his estimate, about 80% to875% of the multi-axis work is performed via 3+2 rather than simultaneous when cutting up to five sides of a prismatic metal workpiece in one fixturing.

What is 3+2 CNC Machining

3+2 (5 axis) CNC machining, also called “positional five-axis machining”, is a technique whereby a three-axis milling program is executed with the cutting tool locked in a tilted position using the 5-axis machine’s two rotational axes, hence the name, 3+2 machining. During the machining process, the fourth and fifth axes are used to rotate the cutting tool in a fixed position rather than to manipulate the tool continuously. On a standard three-axis machine, the only part face that the CNC machine could cut with a cutting tool in its normal position is the horizontal face that faces directly at the spindle.

3+2 CNC Machining Advantages

Compared to conventional three-axis machining, the main advantage of 3+2 CNC machining is the reduction of setup time. According to data from our mold making shop, we could save easily 20% to 25% in setup time because we don’t have to handle that part multiple times.”

Another big benefit of 3+2 CNC Machining is that it allows for the use of a shorter, more rigid cutting tool. With 3+2 machining, the spindle head can be lowered closer to the work piece with the tool angled toward the part surface. This means that a good surface finish and more accurate dimensional results can be achieved .This helps to improve part accuracy by being able to position a work piece so that short, rigid cutting tools are applied, such as when producing undercuts in mold cavities and steep wall inserts in addition, with 3+2 machining, we can use standard, off-the-shelf tools

Rather than using some custom, extra-long tool or holder and risk vibration, this helps to save money easily by 10% to 15% in injection mold costs because there is no need to use special tools for mold manufacturers in china, 3+2 Machining is an ideal option because they can use more off-the-shelf, standard catalog tooling. They have the freedom to reach into my part at different angles without using an especially long tool or special to make that feature on that part.

Application of 3+2 CNC Machining

Where applicable, 3+2 machining will save time and improve operations.This technique is more and more popular with mold making company because it offers great convenience while deep cavities or inserts in complex plastic molds that would otherwise have to be machined with long, slender tools or with tool extensions. Long, slender tools increase the risk of deflection or chatter and tool extensions can create clearance problems. Using 3+2 machining also allows undercuts in cavities and steep walls on standing mold cores to be machined directly. This technique might reduce or eliminate operations for electrical discharge machining (EDM).Relatively few parts are not suitable for 3+2 machining, including complex components. 3+2 CNC Machining is usually used to machine below parts:

deep cavities or inserts in complex plastic molds

certain types of parts from the solid rather than from a complex casting

Drilling holes of metal parts at compound angles such as aluminum brake cylinders in a single setup

We are a China injection mold maker and our CNC machining center has both 3+2 and full 5 axis machining capability, capable of making prototypes and production parts as fast as one day. Reach out HS Mold and see how we could benefit your next CNC rapid prototyping or low-volume manufacturing project.

4 notes

·

View notes