#hmi

Text

peugeot fractal 2015

#transport#auto#car#concept car#black#hmi#full black#detail#technical#grain#technical grain#lines#stripes

7 notes

·

View notes

Photo

85 notes

·

View notes

Text

Unlock the Power of Employee Automation Control Training

At BIN95, we understand the importance of equipping your team with the skills they need to excel in today's fast-paced world. That's why we offer an unbeatable deal - half off of our comprehensive training program and unlimited user and installation licenses.

Imagine the possibilities when every member of your organization (company or School) has access to cutting-edge training materials and resources. Our program covers everything from basic concepts to advanced techniques, ensuring that your team is well-equipped to handle any automation challenge that comes their way.

But time is running out! Don't let this opportunity slip through your fingers. Visit https://bin95.com/educational-site-licenses/ for more details and secure your purchase order today.

Invest in the future of your business or institution with Automation Control Training. Together, let's unlock a world of endless possibilities!

#automation control software#automation training#plc training#training solutions#tech school#STEM education#corporate training#community colleges#vocational training#plc#Motor Controls#hmi#vfd

2 notes

·

View notes

Text

#plcprogramming#plc#automation#programming#industrialautomation#scada#automationengineering#s#hmi#siemens#electricalengineering#plcsiemens#controlsystem#siemensplc#plctraining#instrumentation#electrical#automationsolutions#tiaportal#robotics#industrialcontrol#factoryautomation#training#competitiveprogramming#engineering#programmingart#industrial#programmingclass#programmer#automatizacion

5 notes

·

View notes

Text

Visualizing Success: The Role of HMI in Industrial Automation

In the realm of industrial automation, success is often measured by efficiency, productivity, and safety. One crucial element in achieving these goals is Human-Machine Interface (HMI). HMI serves as the bridge between human operators and automated systems, enabling intuitive control, monitoring, and visualization of industrial processes. In this blog, we'll look into the significance of HMI in industrial settings, its key components, benefits, applications, and future trends.

Understanding HMI

Human-Machine Interface (HMI) refers to the technology that allows interaction between humans and machines. In industrial automation, HMI typically involves touch screens, graphical displays, and control panels that provide operators with real-time data and control over machinery and processes. The primary goal of HMI is to facilitate efficient communication and decision-making, ultimately enhancing productivity and safety in industrial environments.

Key Components of HMI

User Interface (UI): The UI of an HMI system encompasses the visual elements and controls that users interact with. This includes buttons, sliders, gauges, and graphical representations of process variables.

Control System: The control system is the backbone of HMI, responsible for processing user inputs and controlling industrial processes accordingly. It integrates with sensors, actuators, and other hardware components to execute commands and monitor system status.

Data Visualization: HMI enables the visualization of complex data in a user-friendly format. This may include trend graphs, alarm notifications, process diagrams, and other visual aids to help operators understand system behavior and make informed decisions.

Benefits of HMI in Industrial Automation

Improved Efficiency: HMI systems streamline operation workflows by providing insightful controls and real-time feedback. Operators can quickly identify issues, adjust parameters, and optimize processes for maximum efficiency.

Enhanced Safety: With HMI, operators have better visibility into industrial processes, allowing them to detect potential hazards and respond promptly to safety concerns. Alarms and notifications can alert operators to abnormal conditions, preventing accidents and minimizing downtime.

Reduced Downtime: The predictive maintenance capabilities of HMI systems enable proactive monitoring of equipment health and performance. By detecting issues early on, maintenance activities can be scheduled strategically, reducing unplanned downtime and optimizing asset utilization.

Data-driven Decision Making: HMI systems collect and analyze vast amounts of data from sensors and equipment. This data can be used to identify trends, diagnose problems, and make data-driven decisions to improve overall system performance.

Applications of HMI in Industrial Settings

Manufacturing: In manufacturing plants, HMI systems are used to control production processes, monitor equipment status, and track production metrics. Operators can adjust machine settings, track inventory levels, and schedule production runs through intuitive touchscreen interfaces.

Oil & Gas: In the oil and gas industry, HMI plays a critical role in monitoring drilling operations, managing pipeline networks, and controlling refinery processes. Operators can visualize well data, monitor flow rates, and remotely control valves and pumps for optimal production efficiency.

Utilities: HMI systems are widely employed in utility plants for monitoring and controlling power generation, water treatment, and distribution systems. Operators can visualize energy consumption, monitor equipment performance, and respond to grid disturbances in real-time to ensure reliable service delivery.

Future Trends in HMI

Integration with IIoT: The integration of HMI with the Industrial Internet of Things (IIoT) enables seamless connectivity between devices and systems. This allows for real-time data exchange, remote monitoring, and predictive analytics to optimize industrial processes further.

Augmented Reality (AR) Interfaces: AR technology is poised to revolutionize HMI by overlaying digital information onto the physical environment. AR interfaces provide operators with contextual information, interactive guides, and immersive visualizations for enhanced situational awareness and decision-making.

Voice and Gesture Control: The adoption of voice and gesture recognition technologies in HMI systems offers hands-free operation and greater accessibility for operators. Voice commands and gestures can be used to execute commands, navigate menus, and interact with HMI interfaces in a natural and intuitive manner.

Conclusion

In conclusion, Human-Machine Interface (HMI) plays a crucial role in visualizing success in industrial automation. By providing intuitive controls, real-time data visualization, and predictive analytics, HMI systems empower operators to optimize processes, enhance safety, and drive efficiency in industrial environments. As technology continues to evolve, the future of HMI holds exciting possibilities for enhanced connectivity, augmented reality, and seamless interaction between humans and machines, paving the way for a new era of industrial automation.

#industrial automation#auto2mation#industrial equipment#industrial spare parts#industrial automation equipment#industrial and marine automation equipment#industrial and marine automation#hmi#automation#industrial

0 notes

Text

Merlan Siap Support Intermediate Training HMI

Hargo.co.id, GORONTALO – Bupati Bone Bolango, Merlan Uloli menegaskan dirinya siap untuk mensupoort kegiatan Intermediate Training skala nasional yang akan dilaksanakan Himpunan Mahasiswa Islam (HMI) cabang persiapan Bone Bolango.

Memberikan support kegiatan itu, Merlan bukan tanpa dasar. Bagi dia, tema dari kegiatan tersebut, yakni pengelolaan sumber daya alam (SDA) khususnya dari sektor…

View On WordPress

#Bupati Bone bolango#Himpunan Mahasiswa Islam#HMI#HMI Bone Bolango#Intermediate Trainig#Kabupaten Bone Bolango#Merlan Uloli#Pemkab Bone Bolango#Support

0 notes

Text

Forlinx Embedded AM62x SoM, Empowering a New Generation of HMI

HMI (Human-Machine Interface) is a medium for interaction and information exchange between systems and users. It is essential in fields involving human-machine communication, and can be seen in many industries. As technology advances, HMI continues to evolve. In addition to data collection, control, and display, future HMI will incorporate new interactive forms to enable machines to operate more intelligently and interact more efficiently with humans.

The increasing demand for more intelligent human-machine interactions also raises higher requirements for processors used in HMI applications. In order to assist engineers with terminal development requirements in selecting the main controller, in this article, the author will provide a detailed explanation of the three key elements that will influence the next generation of HMI.

Smarter Interaction

AI support will help the new generation of HMI achieve more powerful functions. For example, AI face recognition can be used to realize human access to devices, and AI gesture recognition can also be used to realize contactless control between people and devices. At the same time, it also allows the equipment to monitor and analyze the current system status more accurately. For example, in the medical field, intelligent HMI systems can allow doctors to interact with medical devices through gestures.

Balance of Power Consumption And Performance

AI function support puts forward higher requirements for the performance of processors, and the high integration and performance improvement of chips will inevitably increase power consumption and generate more heat. In order for devices with limited size to be able to adapt to a more diverse and complex environment, it is very important to have multiple power consumption mode options - the freedom to choose between high power consumption, low power consumption, and ultra-low power consumption modes. This not only allows performance to be properly optimized, but also helps to better control costs, achieving a balance between power consumption and performance.

Enhanced Communication Capabilities

The increase in real-time industrial communication protocols has also brought new challenges to the new generation of HMI applications. For example, the HMI applied in the smart factory not only needs to carry the task of exchanging information between people and equipment, but also needs to complete the function of communicating with other machines and equipments, which means that the HMI needs to have a stronger connection and control function.

FET6254-C SoM launched by Forlinx Embedded not only meets the traditional HMI's human-computer interaction needs but also can realize the three key elements mentioned above, empowering the new generation of HMI.

FET6254-C System on module is built on the TI Sitara™ AM6254 industrial-grade processor, featuring a quad-core Arm Cortex-A53 architecture with a maximum frequency of up to 1.4GHz. It enables edge AI capabilities, making the HMI smarter and more intelligent. During the development process, rigorous environmental temperature testing, pressure testing, and long-term stability testing were conducted to ensure that it can operate stably in harsh environments.

Not only the performance is guaranteed, but also the power consumption can be very low. Through a simplified power architecture design, the AM62x processor exhibits extremely low power consumption performance, with power as low as 5mW in deep sleep mode. With a core voltage of 0.75V, the operating power can be kept below 1.5W, greatly reducing system power consumption.

AM62x processor, as the next-generation MPU product in the TI Sitara™ product line, offers richer resource interfaces compared to the previous generation classic processor, the AM335x. It includes features such as 2 x Gigabit Ethernet with TSN support, 3 x CAN-FD, 9 x UART, 2 x USB 2.0 , 2 x LVDS interfaces, RGB, camera, audio, and more. This enhances the product's scalability and flexibility for various applications.

In addition to the advantages mentioned above, Forlinx Embedded has also ported a Chinese input method for the Linux system on the FET6254-C SoM. This makes it more convenient to invoke applications and helps users simplify their development workload. Moreover, the FET6254-C embedded board supports system burning via USB flash drive or TF card and can replace Uboot, Kernel, and device tree in the operating system, making it easy to achieve remote updates for products and helping users save on-site maintenance costs.

The combination of stable quality and rich functionality allows Forlinx Embedded's FET6254-C core board to demonstrate unique advantages in next-generation HMI applications, empowering HMI across industries such as industrial control, power, transportation, and healthcare. This enables machines to operate more intelligently and interact more efficiently with humans. The above is the HMI solution recommendation based on the Forlinx Embedded FET6254-C SoM. We hope it can be helpful for your product design.

Originally published at www.forlinx.net.

#HMI#Human Machine Interface#AI support#processor performance#communication capabilities#Forlinx Embedded

0 notes

Text

Ratusan Marbot Masjid Di Brebes Dapat Perlindungan Sosial Dari Badan Amil Zakat

Beritalidik.com ( Brebes )

Ratusan Marbot Masjid di Kabupaten Brebes, Jawa Tengah, mendapatkan perlindungan sosial dari Badan Amil Zakat Nasional (Baznas) Kabupaten Brebes. Perlindungan sosial tersebut, berupa kepesertaan Marbot di BPJS Ketenagakerjaan. Dengan diikutsertakannya kedalam BPJS Ketenagakerjaan diharapkan mereka bisa menikmati pekerjaan sebagai marbot dengan penuh keceriaan,…

View On WordPress

#Banjir#BPJS#Brebes#Bupati#Bupati Brebes#Camat#HMI#IKM#Jawa Tengah#Kabupaten#Kabupaten Brebes#Kecamatan#Kepala#Marbot#Masjid#Masyarakat#Pekerja#Pemerintah#Pj Bupati#RSU#Rumah#Sekolah#Sosial#Stunting#Tegal

0 notes

Text

Guía de programación de WINCC unified TIA PORTAL

Si estas empezando con la programación de HMI de siemens TIA PORTAL te recomiendo que empieces a ver WinCC unified, la tendencia es ir a ese tipo de programación debido a la escalabilidad y facilidad para implementar el tamaño en diferentes pantallas.

SIMATIC WinCC Unified es una herramienta universal para crear y gestionar configuraciones de PC y SIMATIC HMI Unified Comfort Panels. Esta basado…

View On WordPress

0 notes

Text

Daniel Lepik

6 notes

·

View notes

Text

استفاده از اچ ام آی دلتا در اتوماسیون صنعتی

مقدمه:

امروزه، اتوماسیون صنعتی نقشی حیاتی در ارتقای راندمان، کیفیت و ایمنی فرآیندهای تولیدی ایفا میکند. در این میان، رابط کاربری انسان و ماشین (HMI) به عنوان پل ارتباطی بین اپراتور و سیستمهای اتوماسیون، از اهمیت بالایی برخوردار است.

مزایای استفاده از اچ ام آی دلتا در اتوماسیون صنعتی:

نمایش اطلاعات بصری: اچ ام آی دلتا با نمایش اطلاعات بصری مانند نمودار، گراف و تصاویر، به اپراتور در درک سریع و آسان وضعیت فرآیند کمک میکند.

کنترل فرآیند: اپراتور میتواند از طریق اچ ام آی دلتا، پارامترهای فرآیند را تنظیم و دستورات لازم را به سیستم اتوماسیون ارسال کند.

عیب یابی: اچ ام آی دلتا با نمایش آلارم ها و هشدارها، اپراتور را از بروز خطا در سیستم اتوماسیون آگاه میکند.

ثبت اطلاعات: اچ ام آی دلتا میتواند اطلاعات مربوط به فرآیند را ذخیره و به منظور تجزیه و تحلیل و گزارش دهی، به رایانه یا سایر دستگاه ها منتقل کند.

کاربردهای اچ ام آی دلتا در اتوماسیون صنعتی:

کنترل خطوط تولید: اچ ام آی دلتا برای نمایش وضعیت و کنترل خطوط تولید در صنایع مختلف مانند نساجی، خودروسازی، مواد غذایی و … کاربرد دارد.

کنترل ماشین آلات: اچ ام آی دلتا برای کنترل و مانیتورینگ ماشین آلات صنعتی مانند ربات ها، CNC ها، پرس ها و … بکار میرود.

سیستم های مانیتورینگ: اچ ام آی دلتا برای نمایش اطلاعات مربوط به سنسورها، تجهیزات و سیستم های مختلف در صنایع مختلف مانند پتروشیمی، نیروگاه ها، تصفیه خانه ها و … کاربرد دارد.

تابلوهای برق: اچ ام آی دلتا برای نمایش اطلاعات و کنترل تجهیزات داخل تابلوهای برق بکار میرود.

نکاتی در انتخاب اچ ام آی دلتا برای اتوماسیون صنعتی:

اندازه صفحه نمایش: انتخاب اچ ام آی با اندازه مناسب، به فضای موجود و نیاز اپراتور بستگی دارد.

نوع صفحه نمایش: اچ ام آی دلتا با صفحه نمایش های لمسی و غیر لمسی در بازار موجود است.

قابلیت های ارتباطی: اچ ام آی دلتا با پورت های مختلف ارتباطی مانند RS-232، RS-485 و Ethernet ارائه میشود.

توان پردازش: اچ ام آی دلتا با پردازنده های مختلف در بازار موجود است که انتخاب آن به نوع و پیچیدگی فرآیند بستگی دارد.

قیمت: قیمت اچ ام آی دلتا به عوامل مختلفی مانند اندازه صفحه نمایش، نوع صفحه نمایش، قابلیت های ارتباطی و توان پردازش بستگی دارد.

نتیجه:

استفاده از اچ ام آی دلتا در اتوماسیون صنعتی، مزایای متعددی مانند افزایش راندمان، کیفیت و ایمنی فرآیندها، سهولت در کنترل و مانیتورینگ سیستم ها و کاهش هزینه های تولید را به همراه دارد.

0 notes

Text

PLC SCADA, your gateway to seamless industrial automation! 🤖💡 Perfect for engineers, tech enthusiasts, and anyone passionate about optimizing processes. Dive into the world of Programmable Logic Controllers (PLC) and Supervisory Control and Data Acquisition (SCADA) systems. Elevate your skills and transform industries with cutting-edge automation technology.

Read more: https://livewirecoimbatore.com/plc-scada/

Reach Us: 8807148869

PLC Scada

#PLC#SCADA#Automation#IndustrialTech#ControlSystems#SmartFactory#PLCProgramming#SCADASystems#AutomationEngineer#Industry40#IoT#SmartManufacturing#ProcessAutomation#DigitalTransformation#ControlEngineering#HMI#Robotics#IIoT#PLCControl#SCADATech

0 notes

Text

1BADHMI

#1badhmi#bad#hmi#bad hmi#ohio#dodge#vanity license plate#vanity license plates#vanity plates#vanity plate#custom license plate

0 notes

Text

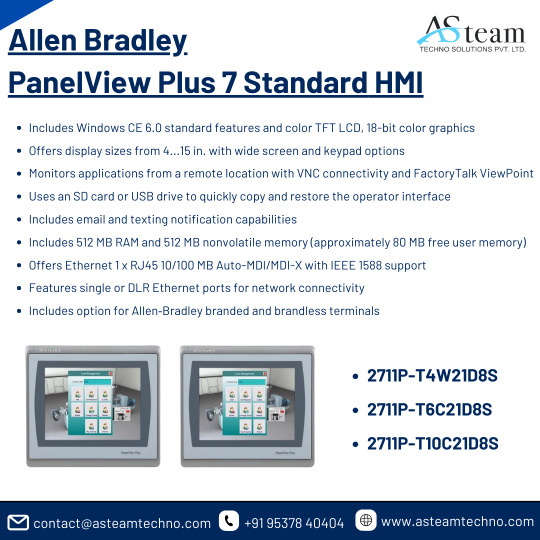

Allen Bradley PanelView Plus 7 Standard HMI

Allen Bradley PanelView Plus 7 Standard HMI :-

2711P-T4W21D8S |PanelView Plus 7 Standard Model

2711P-T6C21D8S | PanelView Plus 7 Standard Model

2711P-T10C21D8S | PanelView Plus 7 Standard Model

🌐Website :- https://asteamtechno.com

👉Contact us :- +91 95372 40404

📧Email :- [email protected]

#automation#trending#tumblr trends#viral#trendingnow#viralpost#bestdeals#allen bradley#rockwell automation#plc#HMI#panelview

1 note

·

View note

Text

#humanmachineinterface#hmi#automation#industrialautomation#hmitouchscreen#hmitouchpanel#plc#iot#engineering#scada#touchscreen#inverter#siemens#visionsensor#areasensor#doorsensor#manufacturing#towerlight#mechanicalelectrical#abb#pressuresensor#allenbradley#iiot#ipc#autonics#porsche#photoelectricsensor#rotaryencoder#proximity#proximitysensor

0 notes