#SmartManufacturing

Text

#SurfaceMetrology#PrecisionMeasurement#MetrologyTechnology#ManufacturingAdvancements#QualityControl#Industry4.0#TechnologyInnovation#RoughnessMeasurement#ContourMeasurement#ManufacturingIndustry#Automation#DigitalMeasurement#IndustryTrends#QualityAssurance#MetrologyStandards#EfficiencyImprovement#ManufacturingQuality#FutureTechnology#SurfaceProfiling#SmartManufacturing

2 notes

·

View notes

Text

Exploring The Applications And Advancements Of Vibration Sensors

Vibration sensors, also known as accelerometers, play a crucial role in various industries and applications, from automotive engineering to structural health monitoring. These devices detect and measure vibrations in machinery, structures, and other systems, providing valuable insights into their performance, condition, and safety. This article delves into the fundamentals of vibration sensors, their diverse applications, recent advancements, and prospects.

Fundamentals of Vibration Sensors:

They operate based on the principle of detecting changes in acceleration or velocity caused by vibrations. They typically consist of a mass suspended on a spring within a housing, with a piezoelectric crystal or capacitive element to measure the resulting displacement. When subjected to vibrations, the mass moves relative to the housing, generating a signal proportional to the acceleration or velocity experienced.

Applications in Industry:

Vibration sensors find extensive use in industrial machinery monitoring and predictive maintenance. By continuously monitoring vibrations in rotating equipment such as motors, pumps, and turbines, these sensors can detect anomalies indicative of impending failures, allowing for timely maintenance interventions to prevent costly downtime. Additionally, sensors are employed in automotive applications for vehicle health monitoring, engine diagnostics, and safety systems.

Structural Health Monitoring:

In civil engineering and infrastructure, sensors play a vital role in structural health monitoring (SHM). They are used to assess the dynamic behavior of bridges, buildings, dams, and other structures under various loads, including wind, seismic activity, and traffic. By monitoring vibrations, engineers can detect structural defects, assess integrity, and ensure the safety and longevity of critical infrastructure.

Advancements in Vibration Sensor Technology:

Recent advancements in vibration sensor technology have led to improved sensitivity, accuracy, and miniaturization. Micro-electro-mechanical systems (MEMS) technology has enabled the development of miniature vibration sensors with high performance and low power consumption, suitable for integration into portable devices and IoT applications. Additionally, advancements in signal processing algorithms and wireless connectivity have enhanced the capabilities of vibration monitoring systems for real-time data analysis and remote monitoring.

Wireless Vibration Monitoring Systems:

Wireless vibration monitoring systems offer several advantages over traditional wired systems, including ease of installation, flexibility, and cost-effectiveness. These systems consist of wireless sensors deployed throughout a facility or asset, transmitting data to a central monitoring system for analysis and decision-making. Wireless connectivity enables real-time monitoring of equipment health, allowing for proactive maintenance and improved operational efficiency.

Condition-Based Maintenance:

Condition-based maintenance (CBM) strategies leverage vibration sensors and other predictive maintenance technologies to monitor equipment health and perform maintenance tasks only when necessary. By monitoring vibration signatures and trend analysis, CBM systems can identify early signs of degradation or faults, enabling maintenance teams to schedule repairs during planned downtime, minimize unplanned outages, and extend equipment lifespan.

Challenges and Opportunities:

Despite their widespread adoption and benefits, sensors face certain challenges, including environmental factors, signal noise, and data interpretation complexities. Additionally, integrating vibration monitoring systems into existing infrastructure and workflows may require investments in equipment, training, and software integration. However, with ongoing advancements in sensor technology, data analytics, and connectivity, the potential for innovation and application of vibration sensors continues to expand across industries.

Future Trends and Outlook:

Looking ahead, the future of vibration sensors holds promise for further miniaturization, increased sensitivity, and enhanced integration with IoT and AI technologies. The advent of Industry 4.0 and the proliferation of smart sensors and connected devices are driving demand for advanced vibration monitoring solutions capable of delivering actionable insights in real time. As industries strive for greater efficiency, reliability, and safety, sensors will remain indispensable tools for monitoring equipment health and optimizing asset performance.

Emerging Applications:

In addition to traditional uses, vibration sensors are finding new applications in emerging fields such as wearable technology, healthcare, and environmental monitoring. In wearable devices, these sensors can track human motion, detect falls, and monitor physical activities, enhancing fitness tracking and healthcare monitoring capabilities. In healthcare, sensors are being explored for applications such as gait analysis, sleep monitoring, and prosthetic limb control. Furthermore, in environmental monitoring, sensors are used to detect seismic activity, monitor structural integrity, and assess the impact of human activities on ecosystems.

Integration with Artificial Intelligence:

The integration of sensors with artificial intelligence (AI) and machine learning (ML) algorithms is revolutionizing predictive maintenance and fault diagnosis. AI-driven vibration analysis can identify subtle patterns and anomalies in vibration data, enabling predictive maintenance models to predict equipment failures with greater accuracy and reliability. By continuously learning from historical data and real-time sensor inputs, AI-powered systems can adapt to changing operating conditions and optimize maintenance schedules for maximum efficiency and cost savings.

Remote Monitoring and Diagnostics:

Remote monitoring capabilities offered by sensors enable real-time monitoring of equipment health and performance from anywhere in the world. By transmitting vibration data wirelessly to cloud-based platforms, maintenance teams can remotely monitor the condition of critical assets, diagnose potential issues, and prioritize maintenance activities. This remote monitoring approach minimizes the need for on-site inspections, reduces travel costs, and enables proactive maintenance interventions, ultimately improving asset reliability and uptime.

Interdisciplinary Collaboration:

The interdisciplinary nature of vibration sensor technology fosters collaboration between engineers, data scientists, and domain experts from various fields. Cross-disciplinary collaboration facilitates the development of innovative solutions and applications that address complex challenges in diverse industries. By leveraging expertise from multiple disciplines, teams can design customized vibration monitoring systems tailored to specific use cases, optimize sensor placement and configuration, and enhance data analysis techniques for improved predictive maintenance and performance optimization.

Conclusion:

Vibration sensors play a critical role in monitoring machinery, structures, and systems across various industries, enabling predictive maintenance, structural health monitoring, and condition-based maintenance strategies. Recent advancements in sensor technology, wireless connectivity, and data analytics are driving innovation and expanding the applications of vibration sensors. As industries embrace digital transformation and the era of smart manufacturing, the importance of sensors in ensuring operational efficiency, safety, and reliability will continue to grow.

0 notes

Text

DIGITAL TWINS: ENHANCING MANUFACTURING THROUGH VIRTUAL SIMULATION

0 notes

Photo

(Exploring the Top 10 Emerging Trends in Robotics and Automation)

🤖✨ Unlocking the Future: Discover the Top 10 Emerging Trends in Robotics and Automation shaping industries worldwide ✨🤖

Buckle up, fellow tech enthusiasts! 🚀 The future is knocking, and it's dressed in circuits and algorithms. Let's dive into the exciting world of robotics and automation, where innovation knows no bounds! Here are the top 10 emerging trends that are revolutionizing industries across the globe:

1. Collaborative Robots (Cobots): Say hello to your new work buddies! Cobots are designed to work alongside humans, boosting efficiency and safety in manufacturing and beyond.

2. AI-Powered Automation: Artificial Intelligence isn't just a buzzword; it's the brains behind the operation. From predictive maintenance to autonomous decision-making, AI is transforming how robots interact with the world.

3. Internet of Things (IoT) Integration: Everything's connected! IoT allows robots to communicate with each other and with other devices, creating seamless, efficient workflows.

4. 3D Printing Revolution: Imagine printing your own robot parts on demand! 3D printing is democratizing manufacturing and enabling rapid prototyping like never before.

5. Exoskeletons and Wearable Robotics: Superhuman strength, anyone? Exoskeletons are enhancing human abilities in industries like healthcare, construction, and logistics.

6. Autonomous Vehicles: From self-driving cars to drones, autonomous vehicles are reshaping transportation and logistics, making deliveries faster, safer, and more efficient.

7. Robotics in Healthcare: Robots aren't just for assembly lines anymore. From surgical assistants to caregiving companions, robotics is revolutionizing healthcare delivery.

8. Agile Manufacturing: Flexibility is the name of the game! Agile manufacturing systems are enabling rapid adaptation to changing market demands, keeping industries competitive in a fast-paced world.

9. Sustainability in Robotics: Green is the new black! Sustainable practices, from energy-efficient designs to recyclable materials, are shaping the future of robotics and automation.

10. Human-Robot Interaction: It's all about harmony! Designing robots that understand and respond to human behavior is key to creating a future where man and machine coexist peacefully.

So there you have it, folks! The future of robotics and automation is bright, bold, and brimming with possibilities. Whether you're a tech aficionado or simply curious about what lies ahead, one thing's for sure: the age of robots is upon us, and it's going to be one heck of a ride! 🤖✨

1 note

·

View note

Text

Streamline Your Industrial Automation with the GE Fanuc IC660BBA021 I/O Block

In the world of industrial automation, having the right equipment is essential for smooth operations. Today, we're excited to introduce the GE Fanuc IC660BBA021 I/O Block, a high-performance solution designed to enhance your industrial control systems. With its exceptional functionality and reliability, this I/O Block is an invaluable asset for any manufacturing or processing facility.

1. Versatile Connectivity: The GE Fanuc IC660BBA021 I/O Block offers a wide range of connectivity options, allowing seamless integration with various devices. Whether you're connecting sensors, switches, or other control devices, this I/O Block provides the flexibility you need to build a robust automation system.

2. Expandable and Scalable: As your business grows, your automation requirements may evolve. The IC660BBA021 I/O Block is designed to accommodate future expansions and scalability needs. With modular expansion capabilities, you can easily add more I/O modules to support additional devices and functions, ensuring that your automation system can adapt to changing demands.

3. Superior Reliability: Industrial environments can be harsh, and reliability is crucial for uninterrupted operations. The GE Fanuc IC660BBA021 I/O Block is built to withstand demanding conditions, with rugged construction and advanced protective features. Rest assured that this I/O Block will deliver consistent performance, even in challenging industrial settings.

4. Easy Configuration and Maintenance: Simplifying the configuration and maintenance process is an important aspect of any industrial automation solution. The IC660BBA021 I/O Block offers user-friendly tools and interfaces, making it easy for technicians to set up, monitor, and troubleshoot the system. Minimize downtime and optimize efficiency with the intuitive design of this I/O Block.

5. Rugged Construction: Built to withstand the rigors of industrial environments, the GE Fanuc IC660BBA021 I/O Block features a robust construction that ensures long-term reliability and durability.

Features:

- High-performance connectivity: This I/O block offers multiple connectivity options, making it easy for you to connect switches, sensors, and other devices required for automation.

- Easy expansion: With its modular design, the IC660BBA021 I/O Block can be easily expanded by integrating additional I/O modules to support new devices or functions.

- Durability: Built for industrial environments, this I/O block is rugged and durable, capable of withstanding extreme conditions.

- Streamlined operation and maintenance: The user-friendly interface of the I/O block makes it easy for operators to configure, monitor, and troubleshoot the system with minimal downtime.

Benefits:

- Enhances operational efficiency: With its high-performance connectivity and streamlined operation and maintenance, the IC660BBA021 I/O Block improves the efficiency of your automation system, delivering consistent and reliable results.

- Future-proof scalability: The modular design of the I/O block enables you to scale your system as your business grows, ensuring that your investment is future-proof.

- Reduces downtime: The easy-to-use interface and modular design make maintenance and troubleshooting of the system a breeze, minimizing downtime and enhancing productivity.

- Provides an edge in the market: By investing in the GE Fanuc IC660BBA021 I/O Block, you're giving your organization a competitive edge by streamlining your automation system, enhancing operational efficiency, and minimizing downtime.

Applications:

The GE Fanuc IC660BBA021 I/O Block is suitable for a wide range of industrial control applications, including manufacturing, energy management, process automation, and more. Its precision engineering and reliable performance make it an essential component in optimizing efficiency and productivity across various industries.

Enhance the efficiency and control of your industrial automation system with the GE Fanuc IC660BBA021 I/O Block. This cutting-edge module is designed to optimize connectivity, expandability, and performance, allowing you to take your operations to the next level. With its rugged construction and user-friendly interface, this I/O Block is a reliable and efficient solution for a wide range of industrial applications.

Seamless Connectivity:

The IC660BBA021 I/O Block offers seamless connectivity with a variety of devices, including switches, sensors, actuators, and more. It provides a robust and reliable interface for integrating these devices into your automation system, ensuring smooth communication and coordination between different components. Say goodbye to compatibility issues and streamline your workflow with this versatile I/O Block.

Modular Design for Scalability:

Whether your operations require a small-scale automation setup or a complex system, the IC660BBA021 I/O Block has got you covered. Its modular design allows for easy expansion, enabling you to add additional I/O modules as needed. This scalability ensures that your automation system can grow alongside your business requirements, saving you time and money on future upgrades.

Durable and Reliable:

Operating in harsh industrial environments can pose challenges for electronic equipment. However, the GE Fanuc IC660BBA021 I/O Block is built to withstand these conditions. Its rugged construction ensures durability and reliability even in demanding environments, minimizing downtime and maximizing productivity. Rest easy knowing that this I/O Block will keep your operations running smoothly.

User-Friendly Interface:

Configuring and managing your automation system should be a hassle-free experience, and the IC660BBA021 I/O Block delivers just that. Its intuitive user interface allows for easy setup, monitoring, and troubleshooting, empowering your team to operate the system efficiently. Reduce training time and enhance productivity with this user-friendly I/O Block.

Boost Efficiency and Productivity:

By incorporating the IC660BBA021 I/O Block into your industrial automation system, you're investing in increased efficiency and productivity. Optimized connectivity, seamless scalability, durability, and a user-friendly interface all work together to streamline your operations. Stay ahead of the competition and achieve new levels of success with this high-performance I/O Block.

Conclusion:

Upgrade your industrial automation system with the GE Fanuc IC660BBA021 I/O Block. Experience enhanced connectivity, scalability, durability, and ease of use that will take your operations to new heights. Visit our website to unlock the full potential of your automation system with this innovative I/O Block. Order now and revolutionize your industrial automation control.

#IndustrialAutomation#AutomationTechnology#EfficiencyBoost#Productivity#IndustrialControl#Manufacturing#SmartManufacturing#Innovation#IndustrialEngineering#EfficientProcesses#AutomationSolutions

0 notes

Text

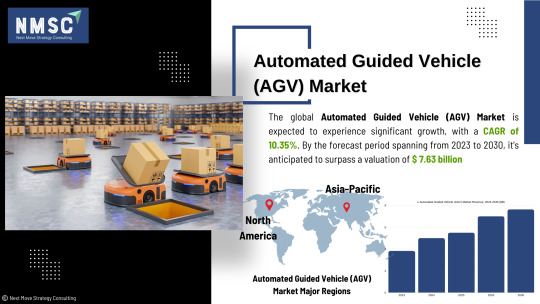

𝐓𝐡𝐞 𝐀𝐮𝐭𝐨𝐦𝐚𝐭𝐞𝐝 𝐆𝐮𝐢𝐝𝐞𝐝 𝐕𝐞𝐡𝐢𝐜𝐥𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐢𝐬 𝐨𝐧 𝐭𝐡𝐞 𝐑𝐢𝐬𝐞!

𝐆𝐞𝐭 𝐚 𝐟𝐫𝐞𝐞 𝐬𝐚𝐦𝐩𝐥𝐞 𝐏𝐃𝐅 𝐫𝐞𝐩𝐨𝐫𝐭 @ https://www.nextmsc.com/automated-guided-vehicle-market/request-sample?utm_source=debashree_linkedin&utm_medium=debashree_ip&utm_campaign=debashree_agv&utm_id=debashree_mar&utm_term=debashree_ip&utm_content=debashree_ip

The global 𝐀𝐮𝐭𝐨𝐦𝐚𝐭𝐞𝐝 𝐆𝐮𝐢𝐝𝐞𝐝 𝐕𝐞𝐡𝐢𝐜𝐥𝐞 (𝐀𝐆𝐕) 𝐌𝐚𝐫𝐤𝐞𝐭 is experiencing remarkable growth to a staggering USD 7.63 billion by 2030, boasting a robust CAGR of 10.35% from 2024 to 2030.

𝐖𝐡𝐚𝐭 𝐞𝐱𝐚𝐜𝐭𝐥𝐲 𝐢𝐬 𝐚𝐧 𝐀𝐆𝐕, 𝐲𝐨𝐮 𝐚𝐬𝐤?

These are self-propelled, computer-controlled mobile robots designed to autonomously transport materials, products, or goods within facilities or along predefined paths, eliminating the need for human intervention.

𝐇𝐞𝐫𝐞'𝐬 𝐰𝐡𝐲 𝐲𝐨𝐮 𝐬𝐡𝐨𝐮𝐥𝐝 𝐩𝐚𝐲 𝐚𝐭𝐭𝐞𝐧𝐭𝐢𝐨𝐧 𝐭𝐨 𝐭𝐡𝐢𝐬 𝐛𝐨𝐨𝐦𝐢𝐧𝐠 𝐦𝐚𝐫𝐤𝐞𝐭:

𝐆𝐫𝐨𝐰𝐢𝐧𝐠 𝐀𝐝𝐨𝐩𝐭𝐢𝐨𝐧 𝐢𝐧 𝐌𝐢𝐥𝐢𝐭𝐚𝐫𝐲 𝐚𝐧𝐝 𝐃𝐞𝐟𝐞𝐧𝐬𝐞: The military and defense sectors are increasingly turning to robotics, including AGVs, to enhance their logistical and material handling operations. The precision and efficiency these robots offer are revolutionizing how these facilities operate.

𝐑𝐢𝐬𝐞 𝐢𝐧 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲 𝟒.𝟎 𝐀𝐝𝐨𝐩𝐭𝐢𝐨𝐧 𝐚𝐧𝐝 𝐒𝐦𝐚𝐫𝐭 𝐌𝐚𝐧𝐮𝐟𝐚𝐜𝐭𝐮𝐫𝐢𝐧𝐠: The demand for Industry 4.0 adoption and smart manufacturing practices is skyrocketing as companies strive for heightened efficiency and productivity. By integrating technologies such as IoT, automation, and data analytics, businesses are creating interconnected systems that optimize production processes like never before.

𝐀𝐜𝐜𝐞𝐬𝐬 𝐟𝐮𝐥𝐥 𝐫𝐞𝐩𝐨𝐫𝐭 @ https://www.nextmsc.com/report/automated-guided-vehicle-market?utm_source=debashree_linkedin&utm_medium=debashree_ip&utm_campaign=debashree_agv&utm_id=debashree_mar&utm_term=debashree_ip&utm_content=debashree_ip

0 notes

Text

Elevate industrial automation with #PLC and #SCADA solutions! 🏭✨ Discover how our cutting-edge technologies enhance efficiency and control in manufacturing processes.

Reach Us: 8807148869

PLC SCADA

#PLC#SCADA#AutomationTech#ControlSystems#PLCProgramming#IndustrialAutomation#SCADASystems#SmartFactory#Industry40#ProcessControl#PLCSCADA#AutomationEngineer#IoTinIndustry#SmartManufacturing#FactoryAutomation#PLCTechnology#DigitalTransformation#SCADAControl#AutomationSolutions#TechInnovation

0 notes

Text

Industrial Robotics Market Business Summation, Industry Examination, Standpoint 2024 to 2030

The qualitative report published by Exactitude Consultancy research on the “Industrial Robotics Market offers an in-depth examination of the current trends, latest expansions, conditions, market size, various drivers, limitations, and key players along with their profile details. The Industrial Robotics market report offers the historical data for 2018 to 2023 and also makes available the forecast data from the year 2024 to 2030 which is based on revenue. With the help of all this information research report helps the Market contributors to expand their market positions. With the benefit of all these explanations, this market research report recommends a business strategy for present market participants to strengthen their role in the market. This report analyzes the impact of the Covid 19 pandemic on the Industrial Robotics Market from a Global and Regional perspective.

The global industrial robotics market was valued at 15.8 billion in 2022, and is projected to reach USD 40.22 billion by 2029, growing at a CAGR of 14.3% from 2022 to 2029.

For The Full Report Click here:

https://exactitudeconsultancy.com/reports/17446/industrial-robotics-market/

#IndustrialRobotics#RoboticsTechnology#FactoryAutomation#ManufacturingAutomation#RoboticAutomation#IndustrialAutomation#RoboticsIndustry#Industry40#AutomationTechnology#RoboticSystems#SmartManufacturing#RoboticsEngineering#RoboticsInnovation#RoboticSolutions#AutomationEngineering#RoboticManufacturing#RoboticsDevelopment#RoboticAssembly#RoboticArm#RoboticsResearch

0 notes

Text

Digital Twin Market, Overview, Growth, Demand and Forecast to 2024-2030

The global digital twin market is a dynamic and innovative landscape situated at the intersection of technology and industry. This technology involves the creation of virtual replicas or models of physical assets, systems, or processes, allowing for real-time simulations, monitoring, and analysis. Its remarkable growth stems from its widespread applications across sectors like manufacturing, healthcare, automotive, aerospace, and smart cities. Digital twins provide valuable insights into the performance, behavior, and predictive analytics of physical assets, thus enhancing operational efficiency and facilitating data-driven decision-making.

North America, particularly the United States, spearheaded the digital twin market, buoyed by substantial investments in technology and innovation. Key industries such as manufacturing, healthcare, and aerospace embraced digital twin technology for predictive maintenance, product development, and operational enhancement. The region's advanced technological infrastructure and a thriving ecosystem of tech companies played pivotal roles in its market dominance.

In Europe, countries like the United Kingdom, Germany, and France showcased active adoption of digital twin technology across diverse sectors including manufacturing, automotive, and smart infrastructure. Europe's focus on Industry 4.0 initiatives, coupled with its robust manufacturing foundation, drove the widespread adoption of digital twins for streamlining production processes and enhancing operational efficiency.

To Know Global Scope and Demand of Veterinary Video Endoscopy Market.Request for Sample PDF:

*𝗕𝘆 𝗧𝘆𝗽𝗲:

System Twin

Process Twin

Asset Twin

*𝗕𝘆 𝗔𝗽𝗽𝗹𝗶𝗰𝗮𝘁𝗶𝗼𝗻:

Aerospace and Defense

Automotive and Transportation

Machine Manufacturing

Energy and Utilities

Others

*𝗕𝘆 𝗥𝗲𝗴𝗶𝗼𝗻: North America, Europe, Asia-Pacific, South America, Middle East & Africa

*𝗕𝘆 𝗞𝗲𝘆 𝗣𝗹𝗮𝘆𝗲𝗿𝘀: General Electric, PTC, Siemens, Dassault Systèmes, IBM Corporation, ANSYS, Microsoft Corporation, Oracle Corporation, Accenture (Mackevision), SAP, AVEVA Group

0 notes

Text

Industry 4.0

🏭✨ Exploring the fascinating world of smart manufacturing with Industry 4.0! From AI-powered robots to IoT sensors, these innovations are reshaping the way products are made. Imagine factories that are not just efficient but also smarter than ever! 🌐🤖

#smartmanufacturing#industry4.0#techinnovation#techsolutions#technology#manufacturer#future#innovation

0 notes

Text

Industrial IoT: Transforming Manufacturing through Connected Intelligence

The convergence of industrial processes with cutting-edge technology has given rise to the Industrial Internet of Things (IIoT), revolutionizing the landscape of manufacturing and industrial operations. This comprehensive exploration delves into the intricacies of Industrial IoT, examining its definition, key components, applications, benefits, and the transformative impact it has on optimizing efficiency, enabling predictive maintenance, and ushering in a new era of connected intelligence within the industrial sector.

Defining Industrial IoT

1. Overview of Industrial IoT

The Industrial Internet of Things (IIoT), also known as Industrial IoT, refers to the integration of internet-connected devices, sensors, and smart technologies into industrial and manufacturing processes. It leverages data analytics, machine learning, and real-time connectivity to enhance operational efficiency, monitor equipment health, and enable intelligent decision-making in industrial settings.

2. Key Components of Industrial IoT:

Sensors and Actuators: These devices capture real-time data from industrial equipment and processes, providing valuable insights into performance, conditions, and anomalies.

Connectivity Solutions: IIoT relies on robust communication protocols and networks to ensure seamless connectivity between devices and systems, enabling data transmission and analysis.

Edge Computing: Edge computing processes data locally near the source, reducing latency and enabling quick decision-making without relying solely on centralized cloud servers.

Cloud Platforms: Cloud-based platforms store and analyze vast amounts of data generated by IIoT devices, offering scalable and accessible solutions for data storage, analytics, and management.

Analytics and Machine Learning: Advanced analytics and machine learning algorithms interpret the collected data, providing actionable insights, predictive maintenance predictions, and optimization recommendations.

Applications of Industrial IoT

1. Predictive Maintenance

IIoT enables predictive maintenance by continuously monitoring equipment conditions. By analyzing data from sensors, manufacturers can predict when machinery is likely to fail, allowing for proactive maintenance and minimizing downtime.

2. Asset Tracking and Management

Tracking the location and status of assets within a manufacturing facility becomes efficient with IIoT. RFID tags and sensors provide real-time visibility, optimizing inventory management and reducing the risk of asset misplacement.

3. Supply Chain Optimization

IIoT facilitates end-to-end visibility in the supply chain. From raw material sourcing to product delivery, manufacturers can track and optimize each step, reducing lead times, minimizing disruptions, and improving overall supply chain efficiency.

4. Energy Management

Smart sensors and meters integrated with IIoT systems help monitor energy consumption in real time. Manufacturers can identify energy inefficiencies, implement energy-saving measures, and reduce operational costs.

5. Quality Control and Monitoring

IIoT enhances quality control by continuously monitoring production processes. Real-time data analysis ensures that products meet quality standards, reducing defects, and improving overall product quality.

6. Worker Safety and Health

Wearable devices equipped with IIoT capabilities enhance worker safety by monitoring environmental conditions, detecting potential hazards, and providing real-time alerts. This contributes to a safer working environment.

Benefits of Industrial IoT

1. Improved Operational Efficiency

IIoT optimizes operational processes by providing real-time insights into equipment performance, production efficiency, and resource utilization. This leads to streamlined operations, reduced waste, and increased overall efficiency.

2. Cost Reduction

Predictive maintenance, energy optimization, and efficient resource management enabled by IIoT contribute to significant cost reductions. Manufacturers can minimize downtime, extend equipment lifespan, and make informed decisions to optimize spending.

3. Enhanced Productivity

IIoT empowers manufacturers to make data-driven decisions that positively impact productivity. Automation, real-time monitoring, and predictive analytics contribute to smoother production processes and higher output.

4. Strategic Decision-Making

The data generated by IIoT devices provides valuable insights for strategic decision-making. Manufacturers can make informed choices regarding production schedules, resource allocation, and overall business strategies.

5. Innovation and Agility

The adoption of IIoT fosters innovation within the industrial sector. Companies that embrace connected technologies can quickly adapt to changing market demands, introduce new products, and stay ahead of the competition.

6. Customer Satisfaction

By optimizing production processes, ensuring product quality, and minimizing delays, IIoT contributes to higher customer satisfaction. Timely delivery of high-quality products enhances the reputation of manufacturers in the market.

Challenges and Considerations in Industrial IoT Implementation

1. Security Concerns

The interconnected nature of IIoT devices raises cybersecurity concerns. Safeguarding sensitive data, protecting against cyber threats, and ensuring secure communication between devices are critical considerations.

2. Interoperability Issues

Compatibility between different IIoT devices and systems can be a challenge. Establishing industry standards and protocols is essential to ensure seamless integration and interoperability.

3. Data Privacy and Compliance

With the vast amount of data generated by IIoT, ensuring compliance with data privacy regulations and standards is crucial. Manufacturers must implement robust data governance practices to protect customer and operational data.

4. Initial Investment Costs

The upfront costs associated with implementing IIoT infrastructure, including sensors, connectivity solutions, and analytics platforms, can be a barrier for some organizations. However, the long-term benefits often outweigh the initial investment.

Future Trends in Industrial IoT

1. 5G Integration

The rollout of 5G networks will enhance connectivity and enable faster data transmission for IIoT devices. This will further improve real-time monitoring, decision-making, and overall efficiency in industrial settings.

2. Edge Computing Advancements

Continued advancements in edge computing technologies will enable more processing capabilities at the device level. This reduces reliance on centralized cloud servers and enhances the speed of data analysis for critical applications.

3. AI and Machine Learning Integration

The integration of artificial intelligence (AI) and machine learning (ML) with IIoT will enable more advanced predictive analytics, anomaly detection, and optimization capabilities, further enhancing the intelligence of industrial processes.

4. Digital Twins for Simulation

The use of digital twins – virtual replicas of physical assets or systems – will become more prevalent. Manufacturers can simulate and analyze the behavior of assets in a virtual environment before implementing changes in the physical world.

Conclusion

The Industrial Internet of Things stands at the forefront of a transformative wave, reshaping the manufacturing and industrial landscape. As organizations continue to embrace connected intelligence, the benefits of IIoT in terms of efficiency, productivity, and innovation become increasingly evident. While challenges such as security and interoperability must be addressed, the potential for optimized operations, predictive maintenance, and enhanced decision-making positions IIoT as a cornerstone of the fourth industrial revolution. The ongoing evolution of IIoT promises not only to connect machines but also to empower industries with the intelligence needed to thrive in an ever-evolving, interconnected world.

Read More: Smart Manufacturing: A Revolution in Industry 4.0

#IIoT#industrialiot#connectedintelligence#manufacturing#predictivemaintenance#iotapplications#SmartManufacturing

0 notes

Text

Empowering Industry 4.0: Reconcify's Innovative Solutions

Enter the future of manufacturing and automation with Reconcify's cutting-edge solutions for Industry 4.0. Our advanced technology and expertise are revolutionizing industries, optimizing operations, and boosting productivity.

As the fourth industrial revolution unfolds, Reconcify is at the forefront, providing tailored solutions to meet the unique challenges of Industry 4.0. Whether you're in manufacturing, logistics, or any Industry 4.0-related sector, our innovative tools and services will help you thrive in this rapidly evolving landscape.

Don't get left behind in the era of smart factories and digital transformation. Partner with Reconcify to harness the power of Industry 4.0 and secure your competitive edge.

Elevate Your Industry 4.0 Game with Reconcify! Learn More at Reconcify.

0 notes

Text

Enhance Industrial Automation Efficiency with Precision Amplifiers Collection

Industrial automation processes require accurate and efficient measurement and control systems. High-quality amplifiers are an excellent solution to improve the accuracy and efficiency of industrial automation processes. By enhancing the performance of sensors and transducers, our amplifiers collection provides reliable and accurate readings in a wide range of applications.

Amplifiers are built with high-quality components and advanced signal processing technologies that ensure precise and stable measurements even in challenging environments. The amplifiers enable better control and monitoring of industrial processes, improving their efficiency and reducing costs.

Amplifiers are available in various configurations, including voltage amplifiers, current amplifiers, signal conditioning amplifiers, and more. We offer amplifiers with different input and output ranges and universal power supply options, making them ideal for integration into diverse industrial systems.

Moreover, we provide excellent technical support and customer service for all our products, ensuring that our clients get the best experience when using our amplifiers. With our high-quality amplifiers, you can enhance the performance of your industrial automation processes, achieve greater efficiency, and optimize your operations.

Industrial automation is a crucial aspect of modern manufacturing, and accuracy and efficiency are vital components of any such system. High-quality amplifiers can play a significant role in improving the accuracy and efficiency of your industrial automation processes. Our amplifiers are specifically designed to enhance the performance of your sensors and transducers, ensuring that they provide reliable and accurate readings in a wide spectrum of applications.

Amplifiers collection: boasts advanced signal processing technologies and high-quality components that guarantee precise and stable measurements even in challenging environments. With our amplifiers, you can get better control and monitoring of your industrial processes, resulting in improved efficiency and reduced costs.

Range of configurations: including voltage amplifiers, current amplifiers, signal conditioning amplifiers, and more, and are compatible with different input and output ranges. This diversity ensures that they can be easily integrated into a broad range of industrial systems, no matter what your requirements are.

We pride ourselves on providing excellent technical support and customer service to all our customers. When you choose our amplifiers, you can be sure that you're getting a high-quality product that is backed by exceptional support. By investing in our amplifiers, you can improve the accuracy and efficiency of your industrial automation processes, optimize your operations, and achieve better results.

Our collection of amplifiers is designed to enhance the performance and accuracy of sensors and transducers, ensuring reliable and precise readings in industrial automation processes.

1. Voltage Amplifiers: Our voltage amplifiers are designed to amplify low voltage signals from sensors or transducers to a higher voltage level for improved accuracy and sensitivity. They provide excellent signal conditioning and can be easily integrated into existing systems.

2. Current Amplifiers: Our current amplifiers are ideal for applications that require amplification of low current signals. They accurately amplify the current signals from sensors or transducers, ensuring reliable measurements and enhancing the overall performance of your industrial processes.

3. Signal Conditioning Amplifiers: Our signal conditioning amplifiers are versatile devices that offer amplification, filtering, and other signal conditioning features. They can be customized to meet specific application requirements, such as providing precise calibration or compensating for signal fluctuations.

4. Power Amplifiers: For applications that require high-power amplification, our power amplifiers deliver excellent performance. They are capable of amplifying signals to high voltage and current levels, providing the necessary power for driving actuators, motors, or other heavy-duty industrial components.

5. Universal Amplifiers: Our universal amplifiers are designed to be highly versatile and adaptable. They can be easily configured to amplify various types of signals, making them suitable for a wide range of industrial applications. They offer flexibility and ease of integration, allowing for seamless integration into existing systems.

Amplifiers are built with high-quality components, ensuring durability and reliability in demanding industrial environments. They undergo rigorous testing and quality control procedures to meet stringent industry standards.

At Aeliya Marine Tech, we prioritize customer satisfaction and provide exceptional technical support to ensure that our customers can maximize the benefits of our amplifiers. Visit our website to explore our collection of amplifiers and find the perfect solution to enhance the accuracy and efficiency of your industrial automation processes.

Unleash the Power of Sound with Amplifiers - In the realm of marine audio systems, the amplifier reigns supreme as the heartbeat of your sound setup. It’s the component that takes the audio signal and amplifies it, ensuring that your music is not just heard but felt, even amidst the roaring waves and windswept decks.

Marine-Grade Durability - When you’re out on the water, your audio equipment faces a barrage of challenges – from saltwater corrosion to extreme temperatures and constant vibrations. Our amplifiers are engineered with marine-grade materials and construction techniques, ensuring they can withstand the harshest marine conditions without compromising on performance. Whether you’re cruising through rough seas or enjoying a leisurely day on the lake, our amplifiers are built to last.

Versatility and Compatibility - Whether you’re upgrading an existing audio system or building one from scratch, our amplifiers offer unmatched versatility and compatibility. With a range of input and output options, including RCA, speaker-level, and Bluetooth connectivity, our amplifiers seamlessly integrate with a variety of audio sources and components.

Conclusion: Amplifiers collection is a top-of-the-line option for anyone looking to enhance the accuracy and efficiency of their industrial automation processes. Our range of amplifiers is built with high-quality components, ensuring that they can endure even the toughest conditions. If you're looking for a reliable and high-performing amplifier collection, then Aeliya Marine Tech is the right choice.

#IndustrialAutomation#EfficiencyBoost#PrecisionAmplifiers#AutomationTechnology#IndustrialProductivity#SmartManufacturing#HighAccuracy#ReliablePerformance#AeliyaMarineTech#Amplifiers#EfficientAutomation

0 notes

Text

Revving Up Industry: The #Metaverse Takes Manufacturing to the Next Level

With industry giants predicting a skyrocketing market of $170.12 billion by 2030, the question isn't if, but how, businesses can leverage this game-changer.

The #industrialmetaverse creates virtual replicas of entire production lines, from machinery to workflows. This opens a door to unparalleled insights and control. #BlockchainAppsDeveloper integrate #metaversetechnologies into existing industrial software solutions,

Ready to dive in? Dive deeper into the article to explore practical implementation strategies for various industries with BlockchainAppsDeveloper. >>> https://www.blockchainappsdeveloper.com/metaverse-in-manufacturing

#industrialvr#digitaltwin#technology#futureofwork#smartmanufacturing#innovation#techrevolution#metaversemanufacturing#business#startups#manufacturingindustry#trendingtech#metaversenews#metaversecommunity#startupcommunity#usa#dubai#singapore#canada

0 notes

Text

Laser Cleaning Machine

#CleaningInnovation#EfficientCleaning#AdvancedTechnology#IndustrialCleaners#CleaningSolutions#TechCleaning#PrecisionCleaning#SmartCleaning#InnovativeDesign#IndustrialMachines#CleaningEfficiency#TechSolutions#CleaningTech#YourCompanyName#IndustrialMaintenance#MachineCleaners#SmartManufacturing#FactoryCleanliness#CleaningAdvancements#InnovationInMaintenance

0 notes

Text

Dive into the world of Industrial Automation with our comprehensive coverage of key topics! From data allocation to the intricacies of the design process, we've got you covered. Get ready to elevate your skills in PLC hardware, SCADA, and the art of wiring. 🌐🔧

Read more: https://livewirecoimbatore.com/plc-scada/

Reach Us: 8807148869

Key Topics Covered

#DataAllocation#DesignProcess#IndustrialAutomation#PLCHardware#SCADA#WiringSolutions#AutomationInsights#TechInIndustry#ProcessDesign#SmartManufacturing#DataEfficiency#PLCProgramming#IndustryTechTalk#SCADATechnology#WiringDesign#AutomationEducation#IndustrialEngineering#SmartFactory#DataManagement#ManufacturingTech

0 notes