#construction material science

Text

Can Weird Things be Used as Binder in Concrete?

In the quest to enhance the strength and durability of concrete, researchers and engineers often experiment with a myriad of unconventional materials. The idea is to explore whether these “weird” substances can function effectively as binders, the crucial ingredient that holds concrete together. This article delves into the fascinating realm of concrete science, examining the potential of various…

View On WordPress

#alternative concrete binders#binder performance in concrete#concrete additive research#construction innovation#construction material science#durability of weird concrete additives#eco-friendly construction practices#environmental impact of construction materials#green building trends#organic fiber reinforcement#recycled concrete materials#structural engineering advances#sustainable building materials#unconventional concrete binders#wool in concrete

0 notes

Text

The construction industry as a CO2 sink? Researchers at Empa's Concrete & Asphalt lab are working on this. By incorporating biochar into concrete, they are exploring the potential of CO2-neutral or even CO2-negative concrete. For optimal applicability, they process the biochar into pellets and use them to replace conventional aggregates.

To achieve the goal of a climate-neutral Switzerland by 2050, strategies and processes with a negative CO2 balance are necessary. These so-called negative emission technologies (NET) are intended to counterbalane the remaining "hard-to-avoid" emissions in 2050 and should help ensure that we eventually achieve net zero. As one of the main emitters, the construction sector has a particular obligation. Around eight percent of global greenhouse gas emissions are caused by cement production. At the same time, initial efforts are emerging to use the construction sector, with its massive consumption of resources, as a possible carbon sink. What sounds paradoxical will succeed if we start "building with CO2" -- or rather, using carbon to produce building materials and thus removing it from the atmosphere in the long term. For such visions to become reality, a great deal of research is needed -- such as is currently being done at Empa's Concrete & Asphalt lab. A team led by Pietro Lura is developing a process for integrating biochar into concrete.

Read more.

16 notes

·

View notes

Text

Nuclear Power Renaissance with Molten Salts - Technology Org

New Post has been published on https://thedigitalinsider.com/nuclear-power-renaissance-with-molten-salts-technology-org/

Nuclear Power Renaissance with Molten Salts - Technology Org

A science team is reinventing nuclear energy systems via molten salt technologies.

A retro wonder gleaming white in the sun, propelled by six rear-facing rotors and four jet engines affixed to the longest wings ever produced for a combat aircraft, the Convair B-36 Peacemaker looks like it flew right out of a 1950s science fiction magazine.

Frozen uranium containing fuel salt (NaF-BeF2-UF4), inside a glovebox in Raluca Scarlat’s SALT lab. Illustration by Sasha Kennedy/UC Berkeley

One of these bombers, which flew over the American Southwest from 1955 to 1957, was unique. It bore the fan-like symbol for ionizing radiation on its tail. The NB-36H prototype was designed to be powered by a molten salt nuclear reactor — a lightweight alternative to a water-cooled reactor.

Nuclear-propelled aircraft like the NB-36H were intended to fly for weeks or months without stopping, landing only when the crew ran short of food and supplies. So what happened? Why weren’t the skies filled with these fantastical aircraft?

“The problem was that nuclear-powered airplanes are absolutely crazy,” says Per F. Peterson, the William S. Floyd and Jean McCallum Floyd Chair in Nuclear Engineering. “The program was canceled, but the large thermal power to low-weight ratio in molten salt reactors is the reason that they remain interesting today.”

Because of numerous concerns, including possible radioactive contamination in the event of a crash, the idea of nuclear-powered aircraft never took off. But nuclear submarines, using water as coolant, completely replaced their combustion-powered predecessors. Civilian reactors were built on the success of submarine systems, and as a result, most nuclear reactors today are cooled with water.

Professor Per Peterson holds a single fuel pebble, which can produce enough electricity to power a Tesla Model 3 for 44,000 miles. Illustration by Adam Lau / Berkeley Engineering

While most water-cooled reactors can safely and reliably generate carbon-free electricity for decades, they do present numerous challenges in terms of upfront cost and efficiency.

Molten salt reactors, like those first designed for nuclear-powered aircraft, address many of the inherent challenges with water-cooled reactors. The high-temperature reaction of such reactors could potentially generate much more energy than water-cooled reactors, hastening efforts to phase out fossil fuels.

Now, at the Department of Nuclear Engineering, multiple researchers, including Peterson, are working to revisit and reinvent molten salt technologies, paving the way for advanced nuclear energy systems that are safer, more efficient and cost-effective — and may be a key for realizing a carbon-free future.

Smaller, safer reactors

In the basement of Etcheverry Hall, there’s a two-inch-thick steel door that looks like it might belong on a bank vault. These days, the door is mostly left open, but for two decades it was the portal between the university and the Berkeley Research Reactor, used mainly for training. In 1966, the reactor first achieved a steady-state of nuclear fission.

Fission occurs when the nucleus of an atom absorbs a neutron and breaks apart, transforming itself into lighter elements. Radioactive elements like uranium naturally release neutrons, and a nuclear reactor harnesses that process.

Concentrated radioactive elements interact with neutrons, splitting themselves apart, shooting more neutrons around and splitting more atoms. This self-sustaining chain reaction releases immense amounts of energy in the form of radiation and heat. The heat is transferred to water that propels steam turbines that generate electricity.

The reactor in Etcheverry Hall is long gone, but the gymnasium-sized room now houses experiments designed to test cooling and control systems for molten salt reactors. Peterson demonstrated one of these experiments in August. The Compact Integral Effects Test (CIET) is a 30-foot-tall steel tower packed with twisting pipes.

The apparatus uses heat transfer oil to model the circulation of molten salt coolant between a reactor core and its heat exchange system. CIET is contributing extensively to the development of passive safety systems for nuclear reactors.

After a fission reaction is shut down, such systems allow for the removal of residual heat caused by radioactive decay of fission products without any electrical power — one of the main safety features of molten salt reactors.

The first molten salt reactor tested at Oak Ridge National Laboratory in the 1950s was small enough to fit in an airplane, and the new designs being developed today are not much larger.

Conventional water-cooled reactors are comparatively immense — the energy-generating portion of the Diablo Canyon Power Plant in San Luis Obispo County occupies approximately 12 acres, and containment of feedwater is not the only reason why.

The core temperature in this type of reactor is usually kept at some 300 degrees Celsius, which requires 140 atmospheres of pressure to keep the water liquid. This need to pressurize the coolant means that the reactor must be built with robust, thick-walled materials, increasing both size and cost. Molten salts don’t require pressurization because they boil at much higher temperatures.

In conventional reactors, water coolant can boil away in an accident, potentially causing the nuclear fuel to meltdown and damage the reactor. Because the boiling point of molten salts are higher than the operational temperature of the reactor, meltdowns are extremely unlikely.

Even in the event of an accident, the molten salt would continue to remove heat without any need for electrical power to cycle the coolant — a requirement in conventional reactors.

“Molten salts, because they can’t boil away, are intrinsically appealing, which is why they’re emerging as one of the most important technologies in the field of nuclear energy,” says Peterson.

The big prize: efficiency

Assistant professor Raluca Scarlat uses a glovebox in her Etcheverry Hall lab. Illustration by Adam Lau / Berkeley Engineering

To fully grasp the potential benefits of molten salts, one has to visit the labs of the SALT Research Group. Raluca O. Scarlat, assistant professor of nuclear engineering, is the principal investigator for the group’s many molten salt studies.

Scarlat’s lab is filled with transparent gloveboxes filled with argon gas. Inside these gloveboxes, Scarlat works with many types of molten salts, including FLiBe, a mixture of beryllium and lithium fluoride. Her team aims to understand exactly how this variety of salt might be altered by exposure to a nuclear reactor core.

On the same day that Peterson demonstrated the CIET test, researchers in the SALT lab were investigating how much tritium (a byproduct of fission) beryllium fluoride could absorb.

Salts are ionic compounds, meaning that they contain elements that have lost electrons and other elements that have gained electrons, resulting in a substance that carries no net electric charge. Ionic compounds are very complex and very stable. They can absorb a large range of radioactive elements.

This changes considerations around nuclear waste, especially if the radioactive fuel is dissolved into the molten salt. Waste products could be electrochemically separated from the molten salts, reducing waste volumes and conditioning the waste for geologic disposal.

Waste might not even be the proper term for some of these byproducts, as many are useful for other applications — like tritium, which is a fuel for fusion reactors.

Salts can also absorb a lot of heat. FLiBe remains liquid between approximately 460 degrees and 1460 degrees Celsius. The higher operating temperature of molten salt coolant means more steam generation and more electricity, greatly increasing the efficiency of the reactor, and for Scarlat, efficiency is the big prize.

“If we filled the Campanile with coal and burned it to create electricity, a corresponding volume of uranium fuel would be the size of a tennis ball,” says Scarlat. “Having hope that we can decarbonize and decrease some of the geopolitical issues that come from fossil fuel exploration is very exciting.”

“Finding good compromises”

Thermal efficiency refers to the amount of useful energy produced by a system as compared with the heat put into it. A combustion engine achieves about 20% thermal efficiency. A conventional water-cooled nuclear reactor generally achieves about 32%.

According to Massimiliano Fratoni, Xenel Distinguished Associate Professor in the Department of Nuclear Engineering, a high-temperature, molten salt reactor might achieve 45% thermal efficiency.

So, with all the potential benefits of molten salt reactors, why weren’t they widely adopted years ago? According to Peter Hosemann, Professor and Ernest S. Kuh Chair in Engineering, there’s a significant challenge inherent in molten salt reactors: identifying materials that can withstand contact with the salt.

Anyone who’s driven regularly in a region with icy roads has probably seen trucks and cars with ragged holes eaten in the metal around the wheel wells. Salt spread on roads to melt ice is highly corrosive to metal. A small amount of moisture in the salt coolant of a nuclear reactor could cause similar corrosion, and when combined with extreme heat and high radiation, getting the salt’s chemistry right is even more critical.

Hosemann, a materials scientist, uses electron microscopes to magnify metal samples by about a million times. The samples have been corroded and or irradiated, and Hosemann studies how such damage alters their structures and properties. These experiments may help reactor designers estimate how much corrosion to expect every year in a molten salt reactor housing.

Hosemann says molten salt reactors present special engineering challenges because the salt coolant freezes well above room-temperatures, meaning that repairs must either be done at high temperatures, or the coolant must first be drained.

Commercially successful molten salt reactors then will have to be very reliable, and that won’t be simple. For example, molten salt reactors with liquid fuel may be appealing in terms of waste management, but they also add impurities into the salt that make it more corrosive.

Liquid fuel designs will need to be more robust to counter corrosion, resulting in higher costs, and the radioactive coolant presents further maintenance challenges.

Nuclear engineering graduate students Sasha Kennedy and Nathanael Gardner, from left, work with molten salt. Illustration by Adam Lau/Berkeley Engineering

“Good engineering is always a process of finding good compromises. Even the molten salt reactor, as beautiful as it is, has to make compromises,” says Hosemann.

Peterson thinks the compromise is in making molten salt reactors modular. He was the principal investigator on the Department of Energy-funded Integrated Research Project that conducted molten salt reactor experiments from 2012 to 2018.

His research was spun off into Kairos Power, which he co-founded with Berkeley Engineering alums Edward Blandford (Ph.D.’10 NE) and Mike Laufer (Ph.D.’13 NE), and where Peterson serves as Chief Nuclear Officer.

The U.S. Nuclear Regulatory Commission just completed a review of Kairos Power’s application for a demonstration reactor, Hermes, as a proof of concept. Peterson says that high-temperature parts of Kairos Power’s reactors would likely last for 15 to 25 years before they’d need to be replaced, and because the replacement parts will be lighter than those of conventional reactors, they’ll consume fewer resources.

“As soon as you’re forced to make these high-temperature components replaceable, you’re systematically able to improve them. You’re building improvements, replacing the old parts

and testing the new ones, iteratively getting better and better,” says Peterson.

Lowering energy costs

California is committed to reaching net zero carbon emissions by 2045. It’s tempting to assume that this goal can be reached with renewables alone, but electricity demand doesn’t follow peak energy generating times for renewables.

Natural gas power surges in the evenings as renewable energy wanes. Even optimistic studies on swift renewable energy adoption in California still assume that some 10% of energy requirements won’t be achieved with renewables and storage alone.

Considering the increasing risks to infrastructure in California from wildfires and intensifying storms, it’s likely that non-renewable energy sources will still be needed to meet the state’s energy needs.

Engineers in the Department of Nuclear Engineering expect that nuclear reactors will make more sense than natural gas for future non-renewable energy needs because they produce carbon-free energy at a lower cost. In 2022, the price of natural gas in the United States fluctuated from around $2 to $9 per million BTUs.

Peterson notes that energy from nuclear fuel currently costs about 50 cents per million BTUs. If new reactors can be designed with high intrinsic safety and lower construction and operating costs, nuclear energy might be even more affordable.

Molten salt sits on a microscope stage in professor Raluca Scarlat’s lab. Illustration by Adam Lau/Berkeley Engineering

Even if molten salt reactors do not end up replacing natural gas, Hosemann says the research will still prove valuable. He points to other large-scale scientific and engineering endeavors like fusion reactors, which in 60 years of development have never been used commercially but have led to other breakthroughs.

“Do I think we’ll have fusion-generated power in our homes in the next five years? Absolutely not. But it’s still valuable because it drives development of superconductors, plasmas and our understanding of materials in extreme environments, which today get used in MRI systems and semiconductor manufacturing,” says Hosemann. “Who knows what we’ll find as we study molten salt reactors?”

Source: UC Berkeley

You can offer your link to a page which is relevant to the topic of this post.

#000#2022#aircraft#airplanes#applications#atom#atoms#boiling#bombers#Building#carbon#carbon emissions#Cars#challenge#chemistry#Chemistry & materials science news#coal#construction#contamination#control systems#cooling#corrosion#crash#designers#development#effects#efficiency#electrical power#electricity#electron

3 notes

·

View notes

Text

the urge to become a video essayist just so i have an excuse to research my special interests/jump into things i KNOW im going to eventually hyperfixate on and infodump for like an hour straight uninterrupted

#autistic moment#so what if i like the science of vampires#and spiderman#and zombies#and stars#and werewolves#and (non-religious) magic#and astrophysics#and fursuit engineering#(for like protogens because PROTOGENS /pos)#and maybe even being trans#definitely being trans#and gay#and aspec#yknow what maybe even just making regular fursuits from scratch#maybe i want to film myself doing that#maybe i want to make a multi-part series where some videos are me talking about all of my research into the projects and the others are#collecting/building the materials and constructing whatever#what then neurotypicals#what then#sorry for long tags#im being silly#probably delete later#idk#ramblesfrombones

4 notes

·

View notes

Text

The 7 Most Simplified Explorations Of Wood Vs UPVC Vs Aluminum In Construction: Choosing Right Material For Your Project

Please visit blogs section in our website, for regular updates like this

Link:- https://kaaryadesigns.co.in/wood-vs-upvc-vs-aluminum/

#civilengineering #bloggerofinstagram #blogoftheday #materialscience #sustainability #sustainableliving #woodvsupvcvsaluminum

#interiordecor#interiorinspiration#sustainability#sustainableliving#sustainablelifestyle#civil engineering#home interior#construction#material science

1 note

·

View note

Text

Self-Healing Materials Market is Led by the Polymers Category

The self-healing materials market is experiencing significant growth and it will continue this trend in the years to come.

The growth of the industry is primarily attributed to the continuous inventions in the advanced material field intended for self-healing; surging acceptance of these materials in the healthcare, electronics, and automotive sectors; and their greater long-term financial advantages over conventional materials.

Self-healing materials assist in boosting the lifespan of systems, as they restore the damages and further lessen the growing entropy. The most substantial utilizations of such materials are in the aerospace, automotive, oil & gas, and building & construction sectors. The utilizations in the automotive sector comprise self-healing elastomers-based anti-scratch polyurethane coatings for vehicle bodies.

Moreover, the major application in the construction sector is self-healing asphalt. Capsules comprising oil are embedded in the bituminous binder to boost the asphalt roof covering lifespan. Therefore, the expansion in these sectors is resulting in the advancement of the industry.

Various innovations in self-healing materials have been observed, in the past few years, in the domain of advanced material. This advancement in technology has resulted in quicker healing and boosted the repair of the performance of these materials. This would cause a new era of environmental management and infrastructure preservation technologies. Therefore, research & development in cutting-edge materials has become a key trend in the industry.

In the past few years, the polymers category, based on material, accounted for the largest self-healing materials market share, and it will further advance at a considerable rate in the years to come. This is mainly because polymers imitate biological healing and heal themselves without requiring any external interference when they endure damage.

In the past few years, the building & construction category, based on application, accounted for the largest share of the self-healing materials industry. This is mainly because of the surging utilization of such materials in non-residential construction. These materials can restore early-stage damage, which, if unchecked, might result in material failure.

The European self-healing materials industry accounted for the largest share in the past few years, and it is likely to further advance at a substantial rate in the years to come.

#Self-Healing Materials market#materials science#market trends#global market outlook#innovative technologies#market dynamics#research and development#structural applications#market growth factors#construction materials#regulatory landscape#quality assurance#automotive coatings#biomimicry

0 notes

Text

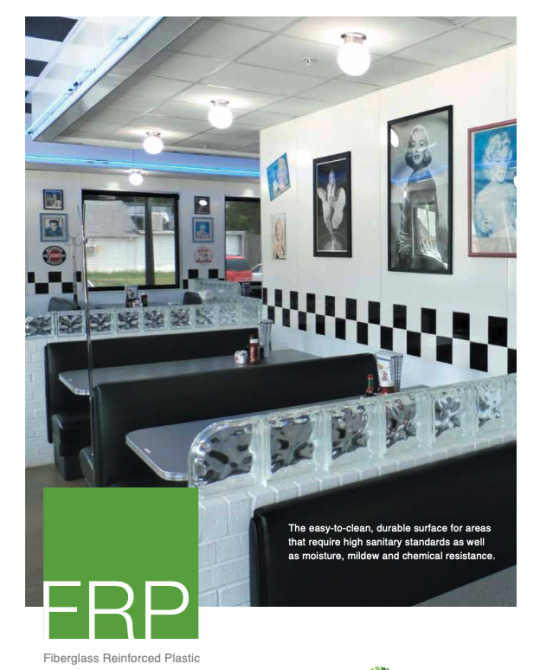

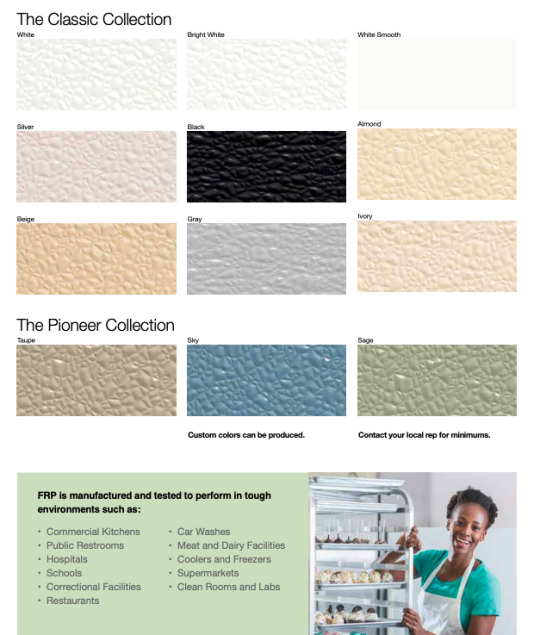

Controlling rising construction costs

In the current landscape of escalating taxes, soaring utility expenses, manufacturing and shipping costs along with the general upkeep of buildings, the construction industry is grappling with a significant surge in material prices. Suppliers, in an attempt to offset their mounting overheads, are passing on the burden to consumers, resulting in an undeniable hike in construction costs. Amidst these challenges, the need for a more streamlined and cost-effective approach becomes increasingly apparent.

Enter www.commwall.ca, a pioneering force reshaping the dynamics of the construction and building materials sector. Recognizing the urgency of the hour, www.commwall.ca is committed to offering a comprehensive range of building materials, tools, and apparel at direct pricing. The platform goes a step further, extending exclusive discounts to registered installation companies and dealers, with even greater incentives for full pallet orders.

Unlike traditional norms that often required bulk truckload purchases for substantial discounts, www.commwall.ca breaks the mold by negotiating smaller quantity bulk deals. This revolutionary approach allows businesses to invest less capital, maintain minimal standing inventory, and simultaneously enhance profit margins. The result is a win-win scenario, where contractors not only optimize their returns but also pass on the savings to clients, making their project bids more competitive.

www.commwall.ca stands out as a leader in the Canadian building materials industry with an ever-expanding array of manufacturers and products. This diversity ensures that Canadian contractors have access to a wide selection, meeting the demands of today's dynamic construction environment. By embracing www.commwall.ca, industry professionals can navigate the challenges of rising costs, ultimately fostering a more efficient and economically viable construction landscape.

In a world where direct shipping and bulk purchases have become essential for cost-conscious construction projects, www.commwall.ca emerges as the clear choice for Canadian contractors. Visit their website to explore the extensive offerings and revolutionize the way you approach construction material procurement.

#business#entrepreneur#economy#construction#building materials#healthcare#startup#ecommerce#hygienic#contractor#project managers#construction estimating services#tools#installation#jack of all trades#commercial#prevention#antimicrobial#cleanroom#mortuary science#veterinary#dental#clinic#safety#food safety#agriculture#cannabis

1 note

·

View note

Text

In another installment of

Slow On the Uptake Hot-Take

I wish there was a final installment to the "Lock In" series by John Scalzi. It's three books, one of which is a prequel (kinda), and I just want the arc to finish. Except it is finished because each book is a stand-alone, but a third fourth book would round it out and I would like that to happen.

It won't happen and I'll get over it (again. I'm rereading the series via the audiobooks narrated by @wilwheaton). Since it's been around about 10 years since Unlocked (the companion novella/kind-of-sequel) was published and if Scalzi wanted to write a fourth installment, he would. I dont blame him for not. He's moved onto other projects (read the "Interdependency" series, it's so good).

I'm just a fangirl who likes androids, floating consciouses, and literal liminal spaces, who is just kvetching. I know I could write some fanfiction, but police procedurals and noirs are well far my particular afield and the things in my afield are struggling to take root as it is.

Gif unrelated, I just like it

#john scalzi#me just bitching don't worry about it#gif warning#science fiction#I'm more inclined to think of the threeps as cyborgs more than as androids because one's consciousness is a kind of organic material#imo#threeps are the robotic constructs humans with hadens syndrome use to live in the 'real world'#hadens syndrome is a disease that resulted in a chunk of the earth's population locked in their bodies#not comatose or sleeping because one's consciousness is independent of their physical body#ppl with hadens are colloquially referred to as being 'locked in' hence the title of the first book#lock in#wil wheaton does a good job nareating btw which isn't surprising it's just good to note

0 notes

Text

Unbreakable Future: Exploring the Self-Healing Materials Market

The self-healing materials market is growing rapidly around the world. The major reasons that are credited to the growth of this industry are, increasing acceptance of these materials in the automotive, electronics and healthcare sectors, and their better long-term results.

On the basis of product, the industry is divided into concrete, metal, ceramic, fiber-reinforced composites, asphalt…

View On WordPress

#advanced materials#aerospace industry#automotive applications#construction materials#durability#Electronics#engineered materials#Healthcare#industry trends#infrastructure#innovative technology#materials science#protective coatings#self-healing materials#self-regenerating#self-repairing#smart coatings#smart materials#sustainability

0 notes

Text

0 notes

Text

#neural networks#robotics research; engineering; civil engineering; engineering and construction; robotics; artificial intelligence; neural interfaces; comp#materials science; spintronics; civil engineering; optics; spintronics research; artificial intelligence; photography; neural interfaces

0 notes

Text

Researchers at UBC Okanagan are revisiting old building practices -- the use of by-products and cast-offs -- as a way to improve building materials and sustainability of the trade.

A technique known as rammed earth construction uses materials that are alternatives to cement and are often more readily available in the environment. One such alternative is wood fly ash, a by-product of pulp mills and coal-fired power plants, explains Dr. Sumi Siddiqua, with UBC Okanagan's School of Engineering.

Industry has been trying to find a use for materials like fly ash that predominantly end up in landfills, she explains. Better described as a fine powder, fly ash shares the same strength and texture characteristics as cement, which is often added to concrete to enhance its strength.

Read more.

7 notes

·

View notes

Text

Breakthrough to Circular and Emission-Free Building - Technology Org

New Post has been published on https://thedigitalinsider.com/breakthrough-to-circular-and-emission-free-building-technology-org/

Breakthrough to Circular and Emission-Free Building - Technology Org

The building industry faces enormous challenges. By 2050, the built environment must not only be emission-free, but also circular.

Within the NWA programme titled ‘Transition to a circular and emission-free building industry’, UT is contributing to research to facilitate the transition required to meet these challenges. UT researcher Marc van den Berg (Faculty of Engineering Technology) and colleagues are focusing on the digital aspects of supporting material reuse and recycling processes as part of this research.

Building – illustrative photo. Image credit: Pixabay (Free Pixabay license)

Renovation projects are complex challenges characterised by intensive decision-making and organisational activities. Such projects connect a variety of otherwise fragmented disciplines, including designers, builders and demolition companies.

Crucial for fostering more circular renovation practices with lower emissions is the availability of information on reusable materials and design strategies which factor in the preservation of existing value.

Collaborative, Digitised and Integral Processes to Achieve Circular and Emission-Free Renovation (PACER)

The PACER (Collaborative, Digitised and Integral Processes to Achieve Circular and Emission-Free Renovation) project, in which UT is represented, aims to provide collaborative, digitised, integral processes, tools, and legal and economic frameworks to achieve circular and emission-free renovation practices.

Dutch Research Agenda (NWA)

This programme of the Dutch Research Agenda (NWA) focuses on existing buildings and invites interdisciplinary consortia to investigate how buildings can be renovated in a circular and emission-free manner by studying a concrete case at the street or neighbourhood level. Societal and technical perspectives of circular and emission-free construction are jointly included.

Transition of the construction sector

The aim of the thematic NWA programme titled ‘Transition to a circular and emission-free building industry’ is to achieve breakthroughs and develop action perspectives that contribute to the transition of the building industry, primarily in relation to renovation projects. The NWA programme is organised in association with the Ministry of the Interior and Kingdom Relations, NWO and the Taskforce for Applied Research SIA.

Within the NWA programme, two broad multidisciplinary consortia will spend the next five years carrying out research to advance the transition to circular and emission-free building, with significant involvement of professional experts in the sector. The total funding awarded under the programme is approximately €2,865,000.

Read also the press release accompanying Marc van den Berg’s PhD research titled: ‘UT provides tools for circular demolition and design of buildings (utwente.nl)’

Source: University of Twente

You can offer your link to a page which is relevant to the topic of this post.

#000#Building#buildings#cellular recycling#Chemistry & materials science news#circular building#collaborative#Companies#concrete#construction#Design#designers#economic#emission-free#Emissions#engineering#Environment#factor#Faculty#Featured technology news#Funding#how#Industry#Legal#Link#material#material reuse#materials#Perspectives#photo

2 notes

·

View notes

Text

Lab creates first heat-tolerant, stable fibers from wet-spinning process -- ScienceDaily

Lab creates first heat-tolerant, stable fibers from wet-spinning process — ScienceDaily

Boron nitride nanotubes used to be hard to process, according to Rice University researchers. Not anymore.

A Rice team led by professors Matteo Pasquali and Angel Martí has simplified handling of the highly valuable nanotubes to make them more suitable for large-scale applications, including aerospace, electronics and energy-efficient materials.

The researchers reported in Nature Communications…

View On WordPress

#creates#fibers#Graphene; Nanotechnology; Materials Science; Nature of Water; Chemistry; Engineering and Construction; Aerospace; Engineering#heattolerant#Lab#process#ScienceDaily#stable#wetspinning

0 notes

Text

Alessandro Volta's Electric Eels

Okay so, it turns out that your cell phone battery is a basically a homunculus of an electric fish.

These are the same thing. Let me explain.

@fishteriously, a paleoichthyologist, told me that Alessandro Volta invented the electric battery after studying electric eels and rays. This sounded like a fun science factoid! I wanted to know more! I saw the claim repeated on any number of pop science articles from the last century or so, but none that quoted from primary sources.

The voltaic pile is one of the most important inventions, ever, of all time. Before Volta, electricity could be stored in Leyden jar capacitors, which would discharge in a single, brief burst. Volta's pile was the first method of producing a continuous electric current, which launched the modern era of electricity as we know it. His explanation for how it worked was incorrect, but it was still a massive breakthrough.

Batteries use the same principle to this day, just with different materials (e.g. cobalt oxide, graphite, and lithium salts rather than silver, zinc, and brine).

But is it a fish?

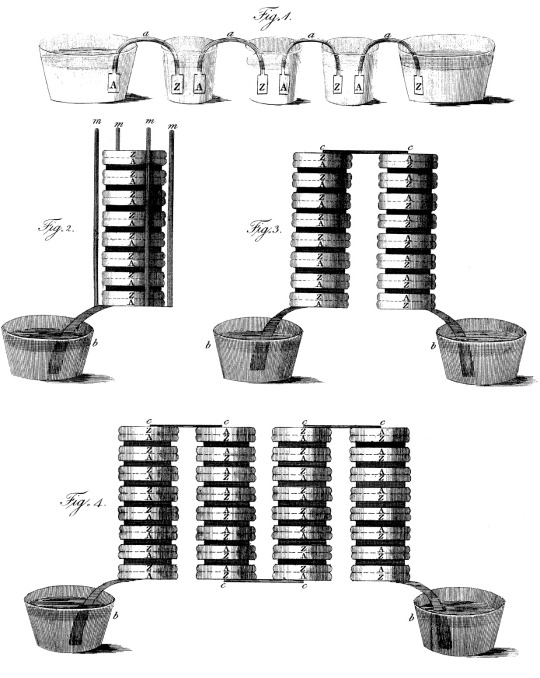

This is Volta's first schematic of a battery, or "voltaic pile" – at the time, "battery" referred to a bunch of Leyden jars linked in series, the term wouldn't come to refer to piles until later. "Z" and "A" stand for zinc and silver ("argentum"), with brine-soaked paper disks between. It does look a bit like an eel?

But is it truly?

Surely, if Volta modeled the pile after electric fishes, I’d be able to find a citation! Wikipedia is usually a good place to start when hunting primary sources, but no luck. No mention of fish at all. I trust fishteriously more than wikipedia, however, so I went digging. Looks like Volta first reported his discovery in a Letter to the Royal Society in 1800.

Found the letter!

Aw beans, it’s in French. I haven’t studied French since high school.

BUT WAIT. WHAT WAS THAT.

Une commotion électrique? A trembling eel???

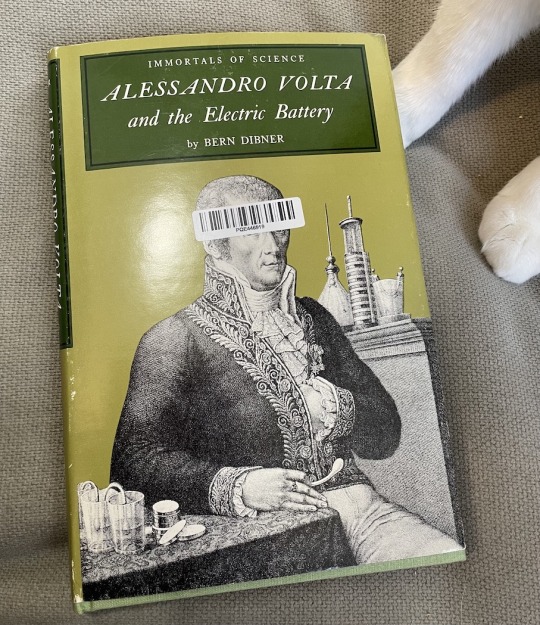

Okay so now I NEEDED to read the letter in English. I found an English-language summary published by the Royal Society, but it looks like the only English translation of the full letter was in the appendix of an out-of-print book called “Alessandro Volta and the Electric Battery.”

So I bought a used copy. Let's see what Volta has to say about this:

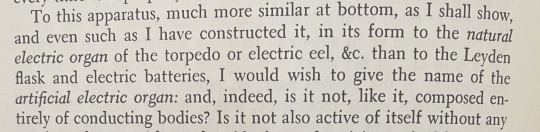

"To this apparatus ... I have constructed it, in its form to the natural electric organ of the torpedo or electric eel, &c, than to the Leyden flask and electric batteries [battery = linked Leyden flasks], I would wish to give the name of artificial electric organ."

Yes! The voltaic pile was explicitly modeled after electric fishes – torpedo rays and electric eels. Fishteriously was 100% correct. Volta never even calls it a "pile," it is always "artificial electric organ." A significant portion of the letter is devoted to electric eels and torpedo rays, in fact.

But also, the rest of the letter is bonkers.

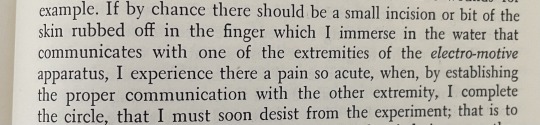

He wrote pages on painful experiments with the artificial electric organ – touching it, poking it into his eyes and ears, making other people touch it, generally just shocking the ever loving hell out of himself over and over. He routinely shocks himself so hard that he has to take breaks. And of course, he licks it.

But that's not the best part:

He says that the artificial electric organ can be turned sideways and submerged in liquid...

"...by which means these cylinders would have a pretty good resemblance to the electric eel ... they might be joined together by pliable metallic wires or screw springs, and then covered with a skin terminated by a head and tail properly formed, &c."

There you have it. One of the most important scientific discoveries of all time, and it includes a crafts project for building an authentic electric eel puppet.

In summary, next time you charge your phone, take a moment to thank the soul of the electric fish inside of it.

2K notes

·

View notes

Text

Elastic Innovations: Navigating the Synthetic Rubber Market

The global synthetic rubber market is experiencing growth, according to P&S Intelligence. This growth can be credited to the growing replacement of automotive tires, the rising requirement for long-lasting rubber, the growing manufacturing capacity of rubber builders and capital expenditure by them, and the rising automotive sector.

Additionally, numerous government steps for financial development, growing personal income, and constant industrialization efforts are driving industry development.

In recent years, the styrene-butadiene rubber (SBR) category, had the largest share in the synthetic rubber industry, and the category is also projected to experience substantial development in the future as well, on the basis of product type.

This can be credited to the cost-efficiency of SBR and its strong abrasion resistance, which brands it extremely useful in sectors like footwear, building and construction, and healthcare.

In the past few years, the tire category led the synthetic rubber market, and the category is projected to be dominant in the future as well. This can be credited to the growing requirement for replacement tires due to the growing sales of two-wheeled and four-wheeled vehicles among the rising populace.

In recent years, in terms of both value and volume, the APAC region dominated the synthetic rubber market, credited to the growing demand for synthetic rubber in the tire and construction sector.

Furthermore, automobile manufacturers are spending in APAC nations to create their production plants, to improve their market existence in the region. The robust emphasis on the growth of new-energy vehicles, to decrease the carbon footprint, is boosting auto manufacturing in China, which will further advance the demand for synthetic rubber during the forecast period in the region.

Companies in the industry of synthetic rubber are concentrating on joint ventures and purchases to grow progressive items and increase their reach. For example, in 2021, Goodyear Tire and Rubber Company acquired Cooper Tire and Rubber Company.

The deal, esteemed at USD 2.5 billion, would join the two manufacturers in order to fortify their existence, worldwide. Likewise, in 2019, Sibur Holding PAO and Sinopec Corp. arrived into a joint venture to make nitrile rubber in Russia, to fulfill the local demand.

#Synthetic Rubber Market#Rubber industry trends#Market analysis#Rubber innovations#Automotive applications#Construction materials#Synthetic rubber demand#Market dynamics#Industrial rubber products#Material science advancements#Sustainable materials#Synthetic rubber manufacturers#Consumer goods

0 notes