#binder performance in concrete

Text

Can Weird Things be Used as Binder in Concrete?

In the quest to enhance the strength and durability of concrete, researchers and engineers often experiment with a myriad of unconventional materials. The idea is to explore whether these “weird” substances can function effectively as binders, the crucial ingredient that holds concrete together. This article delves into the fascinating realm of concrete science, examining the potential of various…

View On WordPress

#alternative concrete binders#binder performance in concrete#concrete additive research#construction innovation#construction material science#durability of weird concrete additives#eco-friendly construction practices#environmental impact of construction materials#green building trends#organic fiber reinforcement#recycled concrete materials#structural engineering advances#sustainable building materials#unconventional concrete binders#wool in concrete

0 notes

Text

🌊 Embrace Excellence with CERA CRYSTALLINE CRETE Waterproofing System! 🏆

💎 The Perfect Blend: Our unique mix of penetrative swellable salt, cementitious binders, and chemical additives ensures unrivaled performance.

🛡 Crystal Clear Protection: Watch as our active chemicals react with free lime to form insoluble crystals, safeguarding against moisture.

🏗 Built to Last: CERA CRYSTALLINE CRETE becomes an integral part of your concrete, ensuring long-lasting results and substantial savings in time and resources.

🌟 Endless Versatility: Ideal for both internal and external applications, offering resilience against chemical attacks, including sewage and industrial waste.

🚰 Seal Every Pore: Experience unmatched penetration and capillary tract sealing, creating a barrier against water intrusion.

💧 Potable Water Safe: Rest easy knowing our system is VOC-free and compatible with potable water.

📞 Transform Your Projects: Contact us now to protect your concrete structures with CERA CRYSTALLINE CRETE. Unlock the potential for exceptional waterproofing! 💦

#🌊 Embrace Excellence with CERA CRYSTALLINE CRETE Waterproofing System! 🏆#💎 The Perfect Blend: Our unique mix of penetrative swellable salt#cementitious binders#and chemical additives ensures unrivaled performance.#🛡 Crystal Clear Protection: Watch as our active chemicals react with free lime to form insoluble crystals#safeguarding against moisture.#🏗 Built to Last: CERA CRYSTALLINE CRETE becomes an integral part of your concrete#ensuring long-lasting results and substantial savings in time and resources.#🌟 Endless Versatility: Ideal for both internal and external applications#offering resilience against chemical attacks#including sewage and industrial waste.#🚰 Seal Every Pore: Experience unmatched penetration and capillary tract sealing#creating a barrier against water intrusion.#💧 Potable Water Safe: Rest easy knowing our system is VOC-free and compatible with potable water.#📞 Transform Your Projects: Contact us now to protect your concrete structures with CERA CRYSTALLINE CRETE. Unlock the potential for excepti#CERA#CrystallineCrete#WaterproofingSystem#ConcreteProtection#ChemicalReaction#SafeguardYourStructure#HighPerformance#VersatileSolutions#ChlorideFree#LongLastingResults#ConstructionSolutions#SealEveryPore#TransformYourSpace#InstaHome#QualityMatters

0 notes

Text

What are the sustainable building materials?

In the quest for eco-conscious construction, the choice of sustainable building materials plays a pivotal role in minimizing environmental impact and promoting long-term sustainability. From renewable resources to recycled materials, the selection of sustainable building materials encompasses a diverse array of options that prioritize ecological stewardship and resource efficiency.

One of the most widely recognized sustainable building materials is wood sourced from responsibly managed forests. Timber offers inherent sustainability benefits, as it is renewable, biodegradable, and has a lower carbon footprint compared to traditional building materials. Engineered wood products such as cross-laminated timber (CLT) and laminated veneer lumber (LVL) further enhance the sustainability credentials of wood by maximizing resource efficiency and structural performance.

Bamboo emerges as another eco-friendly alternative to conventional building materials, prized for its rapid growth rate and renewability. As a versatile and resilient material, bamboo finds applications in structural elements, flooring, and interior finishes, offering strength, durability, and aesthetic appeal while promoting biodiversity and carbon sequestration.

Recycled materials play a crucial role in sustainable construction, diverting waste from landfills and conserving natural resources. Recycled steel and aluminum, for example, retain the same structural properties as virgin materials but require significantly less energy and resources for production. Similarly, recycled glass, concrete, and plastic contribute to circular economy principles by closing the loop on material lifecycle and reducing environmental degradation.

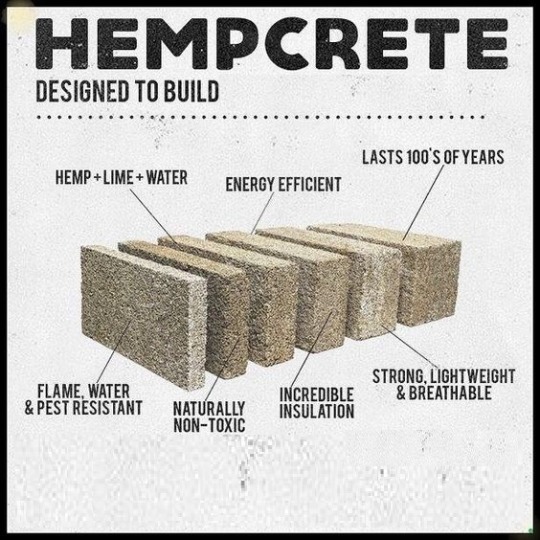

Innovative materials such as hempcrete, made from hemp fibers and lime-based binders, offer sustainable alternatives to traditional concrete for insulation and building envelope applications. Hempcrete boasts excellent thermal performance, moisture regulation, and carbon sequestration capabilities, making it an attractive choice for energy-efficient and environmentally friendly construction projects.

Sustainable building materials represent a fundamental shift towards greener, more responsible construction practices that prioritize environmental preservation and long-term resilience. By embracing renewable resources, recycled materials, and innovative solutions, builders and developers can create healthier, more sustainable built environments that minimize carbon emissions and ecological footprint. For access to a comprehensive range of sustainable building materials that meet the highest standards of quality and performance, consider Alugrow Trading as your trusted partner in sustainable construction initiatives.

Alugrow Trading

2 notes

·

View notes

Text

Hempcrete Finally Aproved by Building Code

More than three decades ago a radically new building material started gaining popularity - in Europe: The benefits of hempcrete (a.k.a. hemplime) include exceptional thermal performance, highly effective transmission of humidity, resistance to mould, and acoustic insulation. It is also fireproof, and sequesters more carbon than its industrial production requires. Given all these incredible benefits, it may sound surprising that until now hempcrete has been not been permitted in US building codes. This had to do with hemp being considered an illegal plant. With the legalization of cannabis for medical and even recreational use in many states, the US is finally ready to include hempcrete as a permitted material in its residential building codes.

image source

What is Hempcrete?

When separating the woody inner portion of the hemp stalk from the main fiber, we get what's called shives. They are also very fibrous, but unlike the main fiber, which is threaded into rope, shives are coarse, broken pieces. This material is what makes up the bulk of hempcrete. The other part is a limestone binder, using either hydrated or hydraulic lime. This is an industrial product, requiring the calcination of lime at very high temperatures in kilns, similar to the production of cement for concrete.

image source

After the hemp shives are mixed with the lime binder, and combined with the addition of water, the curing process starts. Depending on the type of binder, this could take up to a month. For this reason, the hempcrete is usually molded into blocks, similar to cinder blocks. In comparison, however, hempcrete tends to be lighter, and less brittle than concrete.

An Alternative to Concrete?

Before I continue comparing the characteristics of hempcrete to concrete, I want to get its most important drawback out of the way: Hempcrete has about 5% of the compressive strength of residential grade concrete. This means, it is never meant to be used as a structural material to bear great loads! However, excluding this main disadvantage, hempcrete outperforms concrete in so many other aspects, that it would be a waste dismissing this amazing material for its mere structural weakness.

image source

First of all, hempcrete is not only highly insulative, but it also has a good thermal mass. Normally these would be contradictory properties, since most other materials with plenty of thermal mass tend to be poor insulators, and vice versa. Hempcrete is a great exception to this rule, due to its efficient R value of between 0.67/cm (1.7/in) and 1.2/cm (3.0/in) and a specific heat capacity of between 1000 J/kg K to 1700 J/kg K. At the same time, hempcrete "breathes", meaning it is great at transmitting humidity, keeping the interior air dry, which creates a comfortable warm sensation.

Other beneficial attributes of hempcrete are that it is fireproof, resistant to moulds, and is highly effective at insulating against acoustic disturbances. Its most notable feature, however, has to do carbon sequestration, making it highly interesting for modern applications, as we are facing an overabundance of carbon in our atmosphere.

image source

Carbon-neutral... or Carbon-negative?

Even before it is turned into hempcrete, the hemp plant is already highly effective at taking up carbon from the atmosphere. At 15 tons of CO2 per hectare it does this much faster than any forest or commercial crop, while it is fast growing and doesn't require much care or delicate conditions. So growing hemp is already a great way to combat CO2, but hempcrete takes this carbon sequestration a step further.

In its natural cycle, the hemp plant stops taking up carbon once it dies. Sure, by that time it will likely have reproduced, and its offspring can continue the good work, but in the form of hempcrete even the dead hemp plant can continue this process thanks to the lime binder it is mixed with. Due to the carbonation process, the lime continues absorbing CO2, not only during its curing phase, but throughout its entire existence. The amount of this is estimated around -1.6 to -79 kg CO2e/m2.

image source

This means that even though the production of the lime binder involves a good amount of carbon emissions, it is all made up by the joint effects of growing hemp and converting it into hempcrete. So you could say that hempcrete is not only a carbon-neutral building material, but it is in fact carbon-negative, removing more carbon from the atmosphere than it has put into it.

Time to Start the Future?

Given its amazing properties, and time tested practicality in Europe, there are many ambitious projects related to hempcrete. One such proposed application are the Urban Sequoias, enormous high-rise buildings that are supposed to sequester 1,000 tons of CO2 per year, about the amount of 48,500 trees. Although no Urban Sequoia has been built so far, the technology is highly promising.

image source

Also, now that the United States has incorporated hempcrete as a permitted material in its 2024 International Residential Code, it can be expected that this it will find further appeal and acceptance among builders, architects, and engineers in far reaching applications.

Sources: 1, 2, 3, 4, 5, 6, 7

10 notes

·

View notes

Text

fill in the gaps

She first crosses path with him when she's running to her music theory class, trying with one hand to wrangle her books into her bag and with the other to keep her hat from flying right off her head. Koala looks down for one second to shove Music Theory and Composition: A Guide in as deep as it will go, and the crunch of an old granola bar wrapper is all she hears before she runs headlong into something warm, heavy, and which makes a shocked Oomf as they go crashing.

Shit, Koala thinks and her hands fly out to steady herself, anticipating the shock of hard concrete on her gloved palms, but all she manages to do is trip them up and she falls hard onto the sidewalk. Her side twinges in pain and Koala curses as her books and hat go flying, the wind gleefully picking up the covers and throwing them open to pages of text and notes.

"Shit!" she swears, out loud this time, and scrambles to pick everything up, shoving her hat into its rightful place and stashing her books away as fast as she can. "I'm so sorry, I really didn't mean to slam into you - "

In her haste, she fumbles with one of her binders and it slips loose from her grasp, only to be caught by a hand that isn't hers and handed back. Looking up, she realizes that accompanying the offered binder is a smile, and warm dark eyes, and a face framed by wavy locks of blond hair.

"It's alright," her accidental victim says with a small laugh, too cheerful for 7:56 on a Tuesday morning, when the sun is barely even up. "You're a music major , huh?"

"Yeah," Koala manages, wondering if she's winded from the crash or from the way he laughs, boyishly charming. "I am. Thanks."

Before she can make a fool of herself, she grabs her binder and pushes it into her bag. "Sorry for crashing into you again - I should have been watching where I was going - "

"Hey, no, it's fine!" he says. "Running late, huh?"

Oh, she really has to get going now. "Yeah," Koala says, starting to walk in the direction of her building, trying not to be rude with the speed of her pace. "My alarm ran out of battery and I forgot to put new ones in, so - "

"Ah, you don't have to worry," he laughs. "What's your first class? Anything except music history and you'll be just fine, the professors are all really laid-back."

"Music theory," she says. He's easily keeping up with her, despite the fact that she's halfway to jogging and considering a full-on sprint. Then again, he's a good bit taller than she is. "You?"

"I don't have a class this early, so I'm really just out wandering," he says, and the sheepish way he rubs at the back of his head makes her laugh despite herself. The moths in her stomach settle down a little. "It's cool that you're studying music, though! What instrument?"

The doors swing open with one shove. "You haven't even told me what you're studying," she rebukes, playful, and he laughs and something in her gut does a backflip.

"You got me. I'm a sociology major," he says. "I know, it sounds boring, but it's actually fascinating!"

She finds the lecture hall and makes her way inside with Sabo just behind her, on a passionate rant about class divisions and the urban consequences. He moves into a fervent whisper when he notices that they're no longer in a hallway and Koala finds herself entranced by the way he talks, gesturing as he does so, mapping out a world only he can see and that she could only dream of. Only when she picks out a random spot and sits down does he stop talking, for the sole purpose of saying,

"Wait, so what was your instrument again?"

Koala can't help it - she laughs, hiding it behind a hand, as she takes out her textbook and notebook and fishes a pen from somewhere in the depths of her bag. "I never told you," she says and he pouts at her, stupidly cute. "Violin. I'm majoring in strings performance."

"Woah, violin?" His eyes go adorably wide. "Wow. Can I watch you practice sometime?"

"It won't be interesting," she feels the need to warn. "80% of it is just scales and studies. I'm sure you don't want to watch me play double stops for an hour straight."

"I don't even know what those are," he tells her, sincere in his admission. Ten minutes into meeting him and she's already taken in. "Everything you do will be impressive to me, I'm sure."

"Don't you have a campus to wander around on?" she jokes. The professor is starting and Koala flips to a clean page on her notebook, clicking her pen.

"Is that a yes?"

Koala opens her textbook. In the corner of her page, she draws a checkmark and then a time and room in black ink. His answering grin is enough to make her smile in turn.

When he gets up to leave, she resists looking at him - then can't help it and Koala turns back at the perfect moment to catch him give her an exaggerated thumbs up and mouth something - I'll be there - before he vanishes out the door.

To her surprise, when she gets to the practice room at 1:00 with her case and bag in tow, he's there, leaning against the doorjamb, eyes closed and a backpack sitting by his feet. Koala sets down her case, wondering if he's sleeping - the sound of it doesn't elicit any reaction.

He probably is asleep, she reflects. She debates for a moment on whether or not to wake him, then decides that he did want to watch her practice and she may as well, so -

"Gah!"

Koala yanks her hand away as he tries to bat it out of the air, like a startled cat. "Good afternoon, sleepyhead," she teases. "Why were you napping outside the practice room?"

"Oh, you know. The usual," he says with a bashful smile. "You came!"

"I should be the one saying that," she says, opening the door. Picking up her case, she walks inside and starts to set up her violin. Behind her, she hears him follow, the door clicking shut. "You sure about this?"

"Oh, definitely. I like to listen to music when I do homework, so... "

"So I'm background noise," she says, tightening her bow, and can't hold back her laugh when he hurries to assure her that that's not what he meant. "I'm joking! I don't mind, though like I said - it's not very exciting."

"Ah, well, the music I listen to isn't very exciting either," he says, unzipping his bag and pulling out two textbooks. "It's just to help me concentrate, you know? What's that?"

"Oh, this? Rosin," Koala says, wrapping up the cake and dropping it back into her case. "It's to help the bow make a better sound."

"And that?"

"Shoulder-rest. Makes the violin easier to hold."

She's used to playing in front of a mirror, watching and correcting her posture. Thankfully, the practice room has one, so Koala drags a stand over and opens her book of scales. She sets her metronome onto the stand and turns it on, the rhythmic ticking filling their space. Through the mirror's reflection, she can see him opening a laptop and starting to type, soft clicks beneath the sounds of the metronome.

Koala sets her violin on her shoulder, lifts her bow, and starts playing.

Arguably, scales are boring. Considering she's been playing for a good nine years, though, Koala can understand their importance. So she plays through all the major scales, then harmonic and melodic minor, then takes a minute or so to roll her shoulders before starting on chromatic.

Before, Koala used to play for hours on end, losing herself in repertoire. Now, she's learned to take breaks for important things, like water or schoolwork, and that much of practice is meant to be boring. So she stops after the major arpeggios to take a drink of water, then pulls out her binder and flips to a sheet of vibrato exercises.

"Wait," her companion says when she finishes the last one. "That song you just played."

Koala tilts her head, watching his reflection in the mirror. He's staring at her like she'd just started levitating. "What about it?"

"Is that - Is that Bink's Brew?"

"Oh, that's what it's called?" Koala says. "I never knew the name." Hachi in particular loved the song, as did much of Fisher Tiger's family - they would sing it after nights out, and it could often go on well past the moon's zenith.

"Wow," he laughs. "I was not expecting to feel so nostalgic today. Do you have any other songs?"

"I mean, yeah, but unless you grew up on a household in love with classical music I doubt you'll feel as nostalgic," she says. "I might be able to play the rest of the song, though, if I can remember how it goes."

"Please," he says and she laughs but obliges, closing her eyes to pull on those gold-tinted memories.

Her second family, because they'd been her family after she crawled out of the burnt remains of Saint Gregorius' mansion, hadn't been quite on the legal side of things. But they were good, caring people, and they took care of her. She remembers a seedy bar, with the bulbs cracked and flickering, but feeling perfectly at home with them - they never let her touch alcohol, but they somehow got her juice and she would sip on it and listen to their raucous song, Hachi's voice the loudest of them all. It was a simple song, one without much difficult technique; it was a song that rejoiced at being alive, and at being heard.

She ends the song on a flourish, adding an ornament just for the way the notes dance and linger - and for how her companion applauds, grinning from ear to ear.

"You play so well!" he gushes. "I really wanted to sing but I can never sing on-key. It'd sound horrible."

"Oh, don't say that," she laughs.

"No, trust me. My brothers tell me I sound like a goose being strangled to death," he informs her, all earnest eyes.

"Yeah, but it's not what matters," Koala says. "It's not exactly a performance song. It's just for fun."

He's quiet for a moment, absorbing what she just said. Then he tilts his head and smiles at her and something in Koala's chest flutters to and fro.

"I never did get your name," he says. "I'm Sabo."

"Koala," she says. "Nice to meet you, Sabo. Though, it's a few hours late."

He grins at that, carefree as the wind. "Nice to meet you too, Koala! Better late than never, right?"

She leaves the practice room that day with a new bounce her step and a new number in her phone. On her way out of the building, it vibrates and she pulls it out, swiping up to see -

From: Sabo

was really cool to meet you today

wanna chat again at some point?

To: Sabo

sure!

--

Sabo is, Koala finds out, the eldest sibling of three ("I mean, Ace is technically a month older, but he's also an idiot sometimes, so I think I get to be the oldest, you know?" "Sabo, that's not how ages work."); he's roommates with someone he calls Ivankov, who is in cosmetology school but is also a passionate activist and is frequently helped by Sabo ("See this scar? Yeah, a cop clipped me with a rubber bullet once." "You know you should run in zig-zags from bullets, not directly away, right?" "I'll keep that in mind for the future, then."); he boxes, and is taught by someone he calls Dragon ("He's got this wicked tattoo on his face and he hits like a damn truck. I swear he can teleport." "He's called Dragon? I think I've heard of him before." "Oh, really? You should come with me sometime!").

The last point is one Koala takes in with interest. "I should!" she agrees. "I do kickboxing, actually, in my spare time. It'll be fun."

"Ooh, then we definitely don't need to teach you," he says. "It makes sense that you do kickboxing. You need the reach."

She flicks him in the forehead for that, which he accepts chortling like a loon all the while. "Shut up."

"You'd have to reach my face to make me do that!" he grins and hurriedly ducks away when she leans over to pinch at his cheeks.

"You're a dumbass."

"I've been told it's one of my charms."

Sabo is also, Koala finds out, passionate, intelligent, and impulsive. He texted her once if i mix together coffee, sleeping pills, and yogurt will it cancel out into just yogurt? with a blurry picture of his kitchen counter and she'd run over to stop him in the middle of the night, knocking the cursed concoction out of his hands when he opened the door. That same night she met Ivankov, who took a liking to her immediately for managing to stop one of Sabo's horrific, sleep-deprivation fueled plans.

He's top of his class and she could (and has, before) go for hours listening to him talk about his interests, whether over phone call or in-person as they work. Everything about how he speaks, from the way he skips over syllables when he gets excited to the gesturing of his hands to the clear zeal in his voice - she thinks of it when she plays, sometimes, trying to translate that same fervour into her pieces.

He's also a right idiot sometimes, but it's so easy to relax around him, to let herself come free. She thinks of that when she plays too, sometimes, letting his laughter drift through her head and hearing her notes bounce to a similar rhythm, clear and joyous.

And he's a good boxer. He does bring her to meet Dragon at one point, and she wraps her hands and accepts the gloves and gets in the ring against him, and they trade blows until she knows she'll feel the bruises the next day but so will he, until he gets out between heavy breaths that she's packing a lot of muscle in your tiny arms, damn and she finds the strength between panted laughter to (gently, of course) whack him on the head, which he ducks to let her do, snickering all the while. It's the same day that she meets Sabo's brothers - Dragon, apparently, is Luffy's father, though none of them refer to him as such ("It's complicated," Sabo says, and leaves it at that) - and Hack.

Put short, he's a good friend. He's -

"Anyone ever tell you you look like that one fairytale prince?"

"Ew, princes," Sabo says, wrinkling his nose, before she can even register what she just blurted out and feel embarrassed, at all. "I don't want to be a part of oppressive nobility. C'mon, Koala, can't I be like - a cool rogue, or something?"

She elbows him. "Fine, fine. You're a cool rogue."

"With a top hat." He grins down at her, conspiratorial, and she thinks a top hat would suit him - would look dashing on him, even.

"With a top hat," she indulges and lets herself believe, for a moment, that her comment had been forgotten.

"So, what's that fairytale with a prince?"

Shit. "It's just an old story my family used to tell me," she says. Sabo's aware already that the people Koala grew up with were perhaps not quite always on the right side of the law, and his only reaction was just Cool, can I meet them? To which she'd had to say No, and didn't elaborate.

"Yeah?" Sabo says. He leans on her shoulder, a steady weight as she studies for her upcoming music history test. His voice is no demand but is an invitation, letting her decide, and she doesn't think she can't be any more grateful for his friendship.

"There's a girl," Koala says. "She lives by the ocean and she makes a living there, when an injured bird washes up on her shore. She takes in the bird and nurses it to full health, whereupon it promises her that if she keeps it with her it will grant her riches beyond measure. But she doesn't want to keep an innocent animal trapped, so she declines and goes to release it. When she sets it on the sand, it transforms into a prince, who tells her that she has freed him from his curse and they fall in love and marry. The end."

"Riveting storytelling."

"Oh, shush."

Just a story, just a memory shared first by firelight and now underneath the lamplight. He is kind of like that prince, the sort of boy she would have dreamed of as a naive child, whether curled up in their stifling room in the servant's quarters or watching the stars through the crooked window lying on Hachi's back.

Sabo shifts a little closer. He says, "When I was a kid, my brothers and I got it into our heads that there was a monster stalking our home. So we found old pipes and went to hunt it down."

"That does sound like a you thing to do."

"Hey, what does that mean?"

Koala snickers at his mock-offended expression and lightly pokes his cheek. "Did you succeed?"

"Nah, we were kids. But our grandfather came and beat it up for us, then taught us how to use those pipes." He spins a pen between his fingers, and she watches the clever bend and flick of them. He could be a pianist, with his nimble hands. "Fun times."

She recognizes it as the offering it is - story for a story, memory for a memory. Their own little bargain, their own little trade.

She lets herself relax into his shoulder and turns a page in her notebook.

--

From: 'dashing' rogue

so how'd it go?

To: 'dashing' rogue

how'd what go?

From: 'dashing' rogue

your test

you were studying for it right?

saw your textbook

To: 'dashing' rogue

better than expected

what about your presentation? you were stressed when you were rehearsing

From: 'dashing' rogue

i may or may not have gone over the time limit

:)

To: 'dashing' rogue

sabo

From: 'dashing' rogue

hey it was only by like two minutes

it's fine... probably :) :)

To: 'dashing' rogue

don't smiley face at me >:((

--

Okay, so maybe the butterflies in her stomach haven't been digested yet. Maybe they're still there.

That's life. Koala has other things to focus on - like her upcoming recital, where she's managed to earn the chance to play solo and not just in the orchestra.

--

"With passion!" her teacher says, spinning about in the room. It should look ridiculous, one full-grown adult doing pirouettes with a (comically shorter) girl playing violin in the center, the metronome ticking in the background. "With love, Koala! Pour all your heart into it!"

Professor Brook has been deemed eccentric by many, but he's a damn good teacher. Some of the student body rumour that he's immortal, based on the pictures they've seen in his office. Whether or not those rumours hold any truth to it is another matter (though, privately, she thinks they may be accurate - no mortal person would talk so personally about some of history's greatest composers).

"And steady now - let that note take its time! Let it ring! The audience needs to feel its full weight!"

She finishes the piece on a dying chord, the sound fading delicately away like morning mist evaporated by the sun, melancholic and wistful as the piece demands. Professor Brook wipes a fake tear and claps.

"Bravo, dear! You've improved much since you started this piece!"

"Thanks, professor!" Koala says, rolling her left shoulder.

"But, something is missing," Brook says, voice becoming more serious as he pulls up a chair and sits in front of her. "Not that your playing isn't beautiful! Your technique - stunning. Your vibrato is marvelous. That double-stop passage in the midsection so many have trouble with - your intonation there is nigh perfect. Yes, yes, you would wow every audience."

He looks at her, serious, and she abruptly remembers her first time visiting Brook's office and seeing the bookshelf of awards, every single shelf absolutely filled - one he'd waved off as 'unimportant' when she asked about it, instead pushing tea into her hands and imploring her to sit. If there was something lacking about her playing, he of all people would certainly know.

"Music can have no uncertainties, dear," Brook tells her. "Even pieces like the Autumn Suite - ah, such a lovely work of art, a shame about Ellis cheating on his wife or perhaps we would have the complete version - must be played by a violinist who knows perfectly well their purpose." He taps her forehead with a cool finger. "You need to be confident, Koala. You are showing your best self, through your music. What is making you hesitate?"

She looks - not at Brook, but past Brook, to the girl she sees watching in the mirror. She's played for Sabo more times after their first meeting, but each time has grown more nervous, with more wish to impress. And it's impressed him, alright, when she's shown him some of her flashier caprices and concertos, when she's dipped into her repertoire of fugues and sonatas. But this will be the first time she plays as a performer, onstage beneath the searing spotlights, the crowd expectant and him in it.

"Someone is going to be there," she admits. "I don't want to mess up in front of him, not when they want my best."

"Ah. A lover?"

"What - no!" she shrieks. "He's not that! He's a friend."

"Young love," Brook sighs wistfully. "You make me nostalgic for my own days - then again, those were only forty years ago!"

"I thought they were fifty?"

"Ah, forty-five. Nonetheless!" Brook says, waving a hand. "This is the one you think of? This is your focus? Your muse?"

She really wishes he wouldn't say it like that. Still - "I.. guess?"

"No uncertainties, dear. Do you think of him?"

I do, Koala knows in her heart, and she says, "I do."

Too much, maybe.

"Then you will go up on that stage," Brook announces. "You will bow and you will find him in the audience. And you will close your eyes, and think of him. Do it now, in fact! Let's run it through one more time."

She raises her violin to her shoulder and lifts her bow to the strings. She can hear Brook stepping over to the piano, and the mellow notes ringing through the room, bouncing off the walls, off the glass of the mirror. Koala knows this piece by heart, inside and out - she's tapped it against tables, against her palm, against armrests. She's hummed it in the shower and when studying ("You have a nice voice!" "Thanks!).

"And close your eyes," Brook calls, over the piano's introduction. "There is nothing there but you. You are alone, and the only person you are playing for, Koala - "

--

- the only person in the audience who matters, the only person she can picture at that moment as the white lights hit her eyelashes and overtake most of her vision and for a second she panics, she thinks I can't find him, where is he? There's just so many people.

But then. Blond hair, sandwiched between two other people she can recognize as Sabo's brothers. Ivankov is there, too. Dragon, as well. But most of all is Sabo, his attention fixed on her. The whole room, fixed on her, watching her, and he is all that she cares about as her cue approaches.

Koala shuts her eyes. Squeezes them tight, blocking out the harsh glare, and thinks of lamplight and warmth. Affection snuck between them, shoulders pressed and legs tangling. Tenderness.

This is why she loves music, she thinks - it is her, in every way possible, and it will say everything she does not dare put to words. Her breaths rise and fall with the beat, inexplicably steady. Tenderness. This is what she fell in love with, this feeling of total synchrony, of total unification. Nothing but her, and her muse, that matters.

A love confession, she thinks with some irony - can Sabo even tell? There is a knowledge needed, to decipher music. But it won't matter, because this is as much for her as it is for him, and when she gets off the stage she will feel lighter than she has in months, all her longing poured into her notes and disseminated into the air.

She opens her eyes on a moment of stillness, people spellbound and entranced. Koala lets her bow hover, allowing the silence to run its natural course. She doesn't try to find Sabo in the audience, this time.

Then she allows her bow to come down, and her violin too, and she waits for the pianist to join her before they both bow and then leave, heralded by raucous applause.

--

Sabo is the first one who gets to her after the recital. Koala can see some of her fellow music students receiving bouquets and hugs, but Sabo pulls out a gathered bunch of dandelions, columbine, and daisies with a flourish and presents them to her with a smile that she would dare call nervous.

"You played amazingly," he declares. "I can't ever stop being impressed by you, can I?"

"Flatterer," she laughs, certain that her cheeks are a red to match the columbine petals, and accepts. They are beautiful and vibrant, and the gold of the dandelions calls back to Sabo's hair. "Did you pick these?"

"They're small but stubborn, like you," he teases and she elbows him but this time he catches her elbow, draws her in close and wraps his arm around her shoulders in a hug, the flowers pressed between them like a secret.

"You really were beautiful," he murmurs into her hair, and she wonders if she's hearing the hammering of his heart or her own.

"Thanks," she whispers, into the daisy petals, and wonders if what's left unsaid by her will ever come out in the open or if it will haunt them between late nights and punches.

All he does is squeeze her tight, and Koala holds to him with the same strength and her hopes flutter like the flower petals in the wind.

-----------------------------------------------------------------------------------------------------------

Wordcount: 4333

3 notes

·

View notes

Text

All about Asphalt Surfacing

Elshadhai Civils

All about Asphalt Surfacing

https://elshadhaicivils.co.zw +263 78 028 9132

https://elshadhaicivils.co.za +27 82 712 6571

Asphalt surfacing is a mixture of aggregates, binder and filler, used for constructing and maintaining roads, parking areas, railway tracks, ports, airport runways, bicycle lanes, sidewalks and also play- and sport areas.

Aggregates used for asphalt mixtures could be crushed rock, sand, gravel or slags. Nowadays, certain waste and by-products, such as construction and demolition debris, are being used as aggregates, which increases the sustainability of asphalt.

In order to bind the aggregates into a cohesive mixture a binder is used. Most commonly, bitumen is used as a binder, although nowadays, a series of bio-based binders are also under development with the aim of minimising the environmental impact of the roads.

Asphalt Surfacing / Road Construction Process

What is Asphalt concrete?

Asphalt concrete, also referred to as black cementing agent has been used for road construction for centuries. Asphalt is a combination of aggregates, binder, and filler, used for constructing and maintaining roads.

Aggregates used in asphalt mixture can be crushed rock, sand, gravel, or slags. In present times, to increase the sustainability of the asphalt, certain waste and by-products are used, such as materials resulting from the alteration, construction, destruction, rehabilitation, or repair of any manmade physical structure includes houses, buildings, industrial or commercial facilities, and roadways. To bind or put together aggregates into a cohesive mixture a binder is used. Bitumen is used as a binder.

What is Bitumen?

Bitumen is the liquid binder that holds asphalt together and is produced from petroleum. Bitumen is produced through the distillation of crude oil that is recognized for its waterproofing and adhesive properties. This process removes lighter crude oil components, such as gasoline and diesel, leaving the “heavier” bitumen behind. Although nowadays, to minimize the environmental impact of the roads, bio-based binders are also under development.

Asphalt Surfacing Mixture

Asphalt surfacing is a mixture of 2 primary ingredients:

1) Aggregates

2) Asphalt binder

The aggregates have around 95% of the total mixture by weight. Aggregates are mixed with 5% of asphalt binder to produce asphalt pavement. The aggregates and asphalt are heated to an appropriate temperature and mixed in a processing plant capable of producing specified materials. Asphalt pavement is transported by truck to the paving site, it is then spread to a uniform thickness with a paving or finishing machine.

The material is then compacted to the required degree by heavy, self-propelled rollers, producing a smooth pavement course. Depending on the factors such as ambient conditions, to achieve adequate density, care is been taken that mix temperature does not fall below optimum compaction temperature while the material is compacted.

Asphalt Surfacing Laying Temperature Classification

1) Hot mix asphalt

2) Warm mix asphalt

3) Half-warm mix asphalt

4) cold mix asphalt

Hot mix asphalt (HMA) has a laying temperature above 150˚C, it is one of the traditional paving methods used. Warm mix asphalt (WMA) has a lower temperature compared to hot mix asphalt, between 110˚C to 140˚C. The third concept is half-warm mix asphalt (HWMA), it has a lower temperature compared to HMA and WMA, i.e., below 100˚C. While Cold mix asphalt (CMA) is least suitable for paving, having a paving temperature below 60˚C, also cold mix asphalt is the most environment-friendly among all, but due to lack of performance, it is not used as paving temperature.

Anciently, HMA was the most preferred asphalt surfacing temperature but in recent years development, WMA has been performing very close to that of HMA. WMA has a 30% lower production temperature compared to HMA. WMA has advantages such as less power consumption, better performance, decrease emission and lower fuel consumption. Benefits are also seen on-site due to a reduction in emission leading to keep better health of people working on sites. WMA can be used in strictly air polluted areas as well as the site of paving can be opened earlier due to less time for cooling asphalt surfacing so that transportation can easily access it again. HWMA and WMA consume less energy i.e., 50% and 10to30%.

Asphalt Surfacing Process

It consists of the 5 layers mentioned below (From bottom to top)

1) Sub-Grade (150-300mm)

The subgrade is a layer of natural soil prepared to receive the layers of the pavement and is a base of all the payment layers. All the stress of the above pavement layers is transferred to Sub-grade. Hence, it is essential to ensure that the sub-grade is not overstressed. The subgrade should be strong enough to take up the stresses Imposed due to loads without shear failure or excessive deformation.

2) Sub-base (100-300mm)

It is the layer of the material between the Sub-Grade course and Base-Course. The sub-base is also known as soling. The primary functions of the sub-base are to provide structural support, improve drainage, and reduce the intrusion of fines from the sub-grade in the pavement structure. This course provides a medium to spread the wheel loads to the subgrade. In the case of the base course, the course is open-graded or has a large air void, the sub-base course with more fine material can be utilized as filler between sub-grade and the base course. The course usually consists of broken stones, bricks, or aggregates. As the stresses in a sub-base are much lower than those in the base, the material used is inferior to those in the base course. A sub-base course is not mandatory needed or used.

3) Asphalt Surfacing base Course (100-300mm)

The base course layer is above the sub-base layer and immediately beneath the surface of the binder course. The base course is considered an important structural layer of the pavement, it is planned to effectively distribute traffic and environmental loading that underlying unbound layers are not exposed to excessive stresses and strains. The base course also provides additional load distribution and contribution to the sub-surface drainage. Crushed stone, crushed slag, emulsified asphalt, and other untreated or stabilized material are used for the base course.

2 notes

·

View notes

Photo

Building on the moon or Mars? You'll need extraterrestrial cement for that Sustained space exploration will require infrastructure that doesn’t currently exist: buildings, housing, rocket landing pads. So, where do you turn for construction materials when they are too big to fit in your carry-on and there’s no Home Depot in outer space? “If we’re going to live and work on another planet like Mars or the moon, we need to make concrete. But we can’t take bags of concrete with us — we need to use local resources,” said Norman Wagner, Unidel Robert L. Pigford Chair of Chemical and Biomolecular Engineering at the University of Delaware. Researchers are exploring ways to use clay-like topsoil materials from the moon or Mars as the basis for extraterrestrial cement. To succeed will require a binder to glue the extraterrestrial starting materials together through chemistry. One requirement for this out-of-this-world construction material is that it must be durable enough for the vertical launch pads needed to protect man-made rockets from swirling rocks, dust and other debris during liftoff or landing. Most conventional construction materials, such as ordinary cement, are not suitable under space conditions. UD’s Wagner and colleagues are working on this problem and successfully converted simulated lunar and Martian soils into geopolymer cement, which is considered a good substitute for conventional cement. The research team also created a framework to compare different types of geopolymer cements and their characteristics and reported the results in Advances in Space Research. The work was highlighted recently in Advances in Engineering. Geopolymer cement Geopolymers are inorganic polymers formed from aluminosilicate minerals found in common clays everywhere from Newark, Delaware’s White Clay Creek to Africa. When mixed with a solvent that has a high pH, such as sodium silicate, the clay can be dissolved, freeing the aluminum and silicon inside to react with other materials and form new structures — like cement. Soils on the moon and Mars contain common clays, too. This made Maria Katzarova, a former associate scientist and member of Wagner’s lab at UD, wonder if it was possible to activate simulated moon and Martian soils to become concrete-like building materials using geopolymer chemistry. She proposed the idea to NASA and obtained funding via the Delaware Space Grant Consortium to try with the help and expertise of then-UD doctoral student Jennifer Mills, who studied terrestrial geopolymers for her doctoral dissertation. The researchers systematically prepared geopolymer binders from a variety of known simulated soils in the same exact way and compared the materials’ performance, which hadn’t been done before. “This is not a trivial thing. You can’t just say give me any old clay, and I’ll make it work. There are metrics to it, chemistry that you have to worry about,” Wagner said. The researchers mixed various simulated soils with sodium silicate then cast the geopolymer mixture into ice-cube-like molds and waited for the reaction to occur. After seven days, they measured each cube’s size and weight, then crushed it to understand how the material behaves under load. Specifically, they wanted to know if slight differences in chemistry between simulated soils affected the material’s strength. “When a rocket takes off there's a lot of weight pushing down on the landing pad and the concrete needs to hold, so the material’s compressive strength becomes an important metric,” Wagner said. “At least on Earth, we were able to make materials in little cubes that had the compressive strength necessary to do the job.” The researchers also calculated how much terrestrial material astronauts would need to take with them to build a landing pad on the surface of the moon or Mars. Turns out, the estimated amount is well within the payload range of a rocket, anywhere from hundreds to thousands of kilograms. Simulating space conditions The research team also subjected the samples to different environments present in space, including vacuum and low and high temperatures. What they found was informative. Under vacuum, some of the material samples did form cement, while others were only partially successful. However, overall, the geopolymer cement’s compressive strength decreased under vacuum, compared to geopolymer cubes cured at room temperature and pressure. This raises new considerations depending on the material’s purpose. “There's going to be a tradeoff between whether we need to cast these materials in a pressurized environment to ensure the reaction forms the strongest material or whether can we get away with forming them under vacuum, the normal environment on the moon or Mars, and achieve something that's good enough,” said Mills, who earned her doctoral degree in chemical engineering at UD in May 2022 and now works at Dow Chemical Company. Meanwhile, under low temperatures of about -80 degrees Celsius, the geopolymer materials didn’t react at all. “This tells us that we might need to use some sort of accelerant to achieve the strength we see at room temperature,” Mills said. “Maybe the geopolymer needs to be heated, or maybe we need to add something else to the mix to kickstart the reaction for certain applications or environments.” At high temperatures, about 600 degrees Celsius, the researchers found that every moon-like sample got stronger. This was not surprising, Mills said, given how the kinetics were hindered at low temperatures. The research team also saw changes in the physical nature of the geopolymer cement under heat. “The geopolymer bricks became much more brittle when we heated them up, shattering as opposed to becoming compressed or breaking in two,” Mills said. “That could be important if the material is going to be subjected to any type of external pressure.” Based on their results, the researchers said that chemical composition and particle size may play an important role in material strength. For example, smaller particles increase the available surface area, making them easier to react and potentially leading to greater overall material strength. Another possible factor: the amount of aluminosilicate content in the starting materials, which can be tricky to estimate when added solutions may also contain small concentrations of these materials and contribute to material performance. What does it all mean? Well, Amazon doesn’t offer two-day delivery to space, so designing the right formulation of starting materials to take matters. Understanding what affects material strength is important, too, since astronauts will be sourcing our topsoil materials from different places on planets — and maybe even different planets altogether. These results also can be used to make geopolymer cements on Earth that are better for the environment and can be sourced from a wider variety of local materials. Geopolymer cements require less water than is needed to make traditional cement, too, because the water itself is not consumed in the reaction. Instead, the water can be recovered and reused, a plus in water-limited environments from arid earthly landscapes to outer space. Today, two of Wagner’s current graduate students are exploring ways to use geopolymer cements to 3D-print houses and to activate geopolymer materials using microwave technology. The work is a collaborative project, funded by the National Science Foundation, with researchers at Northeastern and Georgetown universities. Similar to the microwaves you use to reheat your morning coffee, microwave heating can accelerate geopolymer curing and may one day provide a way for terrestrial builders — or astronauts — to cure geopolymer concrete in a targeted way. IMAGE....University of Delaware researchers mixed simulated lunar and Martian soils with a high-pH solution to create geopolymer bricks, then crushed the bricks to see how strong they were. The experiments are helping them work on ways for astronauts to create building materials in space. CREDIT Photo illustrations by Jeffrey C. Chase/ University of Delaware

2 notes

·

View notes

Text

How to Conserve Asphalt Driveways? Tips for Longevity and Beauty

An asphalt driveway is highly sought-after among homeowners due to its longevity, affordability, and smooth driving surface. However, like any outdoor texture, it needs routine care to maintain its appearance and structural integrity. We'll explore various tips and techniques to help you preserve your asphalt driveways for years to come.

Understanding Asphalt Driveways

Before delving into preservation techniques, it's crucial to understand the composition of asphalt driveways. Asphalt includes a bitumen blend (a petroleum-based binder) and aggregate materials such as sand, gravel, and stone. This mixture is warmed, poured, and compressed to form a solid surface appropriate for vehicle traffic.

1. Regular Cleaning

Routine cleaning is vital for maintaining the appearance of asphalt driveways. Use a broom or leaf blower to remove debris such as leaves, dirt, and gravel.

For stubborn stains or dirt buildup, use a pressure washer or hose to thoroughly clean the surface. Regular cleaning by professionals prevents debris from accumulating and causing damage to the asphalt.

2. Fill Cracks and Potholes

Cracks and potholes are common issues that can develop on asphalt driveways over time, especially in regions with harsh weather conditions. Promptly fill any cracks or potholes using an asphalt patching compound.

Clean the affected area, apply the patching compound according to the manufacturer's instructions, and compact it using a tamper or hand tool. Repairing cracks and potholes prevents water infiltration and further deterioration of the asphalt.

3. Sealcoating

Sealcoating is a crucial step in preserving asphalt driveways. A seal coat is a protective layer applied to the surface of the asphalt to shield it from UV rays, water damage, and oil spills. The sealing coats your driveway every two to three years to conserve its integrity and appearance.

Before using the seal coat, thoroughly clean the driveway and allow it to dry completely. Apply the seal coat evenly using a squeegee or roller and allow it to cure according to the manufacturer's instructions.

4. Avoid Heavy Loads

Decrease heavy vehicle traffic and avoid parking heavy vehicles in the same spot on your driveway for extended periods. Heavy loads can cause indentation and deterioration of the asphalt surface over time.

Consider installing additional support, like a strengthened base or driveway pavers, to distribute the weight more evenly and reduce the risk of damage.

5. Proper Drainage

Ensure your asphalt driveways have proper drainage to prevent water from pooling on the surface. Poor drainage can accelerate asphalt deterioration and lead to cracks and potholes. Clear any debris or obstructions from drainage channels and consider installing a drainage system or adding slopes to divert water from the driveway.

6. Avoid Chemical Spills

Avoid dribbling gasoline, oil, or other chemicals on your asphalt driveways, as these substances can tarnish the asphalt and cause staining.

If a spill occurs, clean it up promptly using porous materials such as kitty litter or sand, followed by a detergent solution. Avoid using intense chemicals that may further damage the asphalt surface.

7. Protect Edges

Install edging materials such as bricks, concrete, or landscape timbers to protect the edges of your asphalt driveways from pulverizing and erosion. Edging helps maintain the driveway's structural integrity and prevents grass or weeds from intruding onto the surface.

8. Regular Inspections

Perform regular inspections of your asphalt driveways to recognize any signs of damage or wear. Look for cracks, potholes, or areas of surface wear and manage them promptly to control further damage. Early detection and repair can extend the lifespan of your driveway and save you from costly repairs down the road.

Conclusion

Conserving your asphalt driveways requires assertive maintenance and routine care. Following the tips outlined in this guide, you can protect your driveway from the elements and ensure its longevity and beauty for years to come. Remember to clean regularly, fill cracks and potholes, seal coat periodically, avoid heavy loads and chemical spills, maintain proper drainage, protect edges, and conduct regular inspections. Take professional assistance from A&C Contractor for installation, repairs, and maintenance of an asphalt driveway. With proper maintenance by the contractors, your driveway will continue to provide a smooth and durable surface.

0 notes

Text

Maintaining the Beauty of Quartz Carpet Stone Overlay - Tips for Long-Term Durability

Quartz Carpet Stone Overlay is renowned for its seamless, durable, and visually stunning finish. Whether adorning commercial spaces, educational institutions, or residential homes, this innovative surfacing solution offers both aesthetic appeal and practicality. However, to ensure its longevity and retain its pristine appearance over time, proper maintenance is essential. In this comprehensive guide, we delve into the intricacies of maintaining the beauty of Quartz Carpet Stone Overlay, providing invaluable tips for long-term durability.

Understanding Quartz Carpet Stone Overlay

Before delving into maintenance tips, let's first grasp the fundamentals of Quartz Carpet Stone Overlay. This surfacing solution comprises colored quartz stones sourced from Belgium, meticulously combined with an epoxy binder. This unique blend results in a resilient, textured, and seamless finish that can be applied over various substrates, including concrete, tiles, and compressed sheeting. Its versatility, coupled with its durability, makes it a preferred choice for both indoor and outdoor applications.

Routine Maintenance Practices

Regular Cleaning: Establish a routine cleaning schedule to remove dirt, dust, and debris from the surface. Use a soft-bristled broom or vacuum cleaner to gently sweep away loose particles. For more stubborn stains, a mild detergent solution and soft cloth can be employed.

Avoid Abrasive Cleaners: While Quartz Carpet Stone Overlay is resilient, abrasive cleaners and harsh chemicals can compromise its integrity. Opt for pH-neutral cleaners specifically formulated for use on stone surfaces. Avoid bleach, ammonia, and acidic substances, as they can cause discoloration and deterioration.

Preventative Measures: Place doormats at entry points to minimize the ingress of dirt and moisture onto the surface. Additionally, use furniture pads or coasters to prevent scratching and indentation from heavy objects.

Prompt Spill Cleanup: Accidental spills should be promptly addressed to prevent staining. Blot liquid spills with a clean, absorbent cloth, avoiding excessive rubbing. For oil-based stains, a mild solvent may be necessary, but test it on a small, inconspicuous area first to ensure compatibility.

Periodic Maintenance Procedures

Sealing: Periodically inspect the surface for signs of wear and tear, particularly in high-traffic areas. Consider resealing the overlay every few years to maintain its protective barrier against moisture and contaminants. Consult with a professional applicator for guidance on the appropriate sealing products and application techniques.

Deep Cleaning: Over time, Quartz Carpet Stone Overlay may accumulate embedded dirt and grime that require deeper cleaning. Utilize a commercial stone cleaner or a diluted solution of white vinegar and water to effectively remove stubborn stains. Scrub the surface gently with a soft-bristled brush or a non-abrasive pad, followed by thorough rinsing with clean water.

Repair Minor Imperfections: Address minor imperfections such as scratches, chips, or cracks promptly to prevent them from escalating into larger issues. Consult with a qualified installer or technician to assess the damage and perform necessary repairs using compatible materials and techniques.

Professional Maintenance Services: Periodically enlist the services of professional maintenance providers experienced in caring for Quartz Carpet Stone Overlay. They possess the expertise and specialized equipment to conduct thorough cleaning, resealing, and repair procedures, ensuring optimal performance and longevity.

Conclusion

Maintaining the beauty of Quartz Carpet Stone Overlay requires diligence, care, and adherence to proper maintenance practices. By implementing routine cleaning routines, employing preventative measures, and periodically conducting deep cleaning and sealing procedures, you can preserve its aesthetic appeal and structural integrity for years to come. Remember to seek guidance from qualified professionals for comprehensive maintenance solutions tailored to your specific needs. With the right approach, your Quartz Carpet Stone Overlay will continue to adorn your space with timeless elegance and durability.

0 notes

Text

Anthony Lyons - Film project Critical Essay

LMD09126

40496618

Anything For You

Team and roles:

Mark-Antony Marini – Writer/Director

• Anthony Lyons – Producer

• Fionntan Mccaughey – DOP

• Max Brodbeck – 1 st AC

• Jason Binder – Lighting Assistant

• Aisling Keane - Production Designer

• India Marshall - Art Department Assistant

• Melanie Nava Urribarri – Editor

• Michael Hood – Sound Design

• Yat-hin Lee - Sound Recordist/Design

• Sean Dinwoodie – Boom Operator

Proposal Intentions

I was initially drawn to this project having worked with Mark-Antony before. I trust him as a screenwriter and also a collaborator. I think he’s very forward with his ideas and articulates them very well. At the same time, he’s very open to other ideas and establishes open communication to produce the best project possible. I was also drawn to the idea of working on another genre film after having worked on documentaries and drama and I thought this would be an exciting challenge. The film being an allegory for borderline personality disorder and the way in which mental health affects a person and the relationships that they have with the people close to them really resonated with me deeply and I wanted to try and develop this idea further. I felt the genre fit well with the synopsis. The vampirism that Damian struggles with reflects how people with BPD and other mental health issues can often view themselves as a ‘monster’. They can feel undeserving of love and the love they receive they can sometimes reject. This was a relatively unique approach to portraying mental health which has often suffered from poor portrayals within the media.

Critique of Process

Producing is a role I’ve never really had before. There were things I was happy with but there were many moments where I felt disappointed in my performance. My biggest weakness as a producer was definitely my difficulty with communication. Communication has always been a problem for me however, the issues became more prominent with this role.

It meant that progress was probably slower than it should have been. We did not have a concrete crew until close to the shoot, which to be fair was partially due to our original crew having other commitments but there was the issue with the make-up artist. She did a wonderful job but we only managed to recruit her just a week before the shoot which meant that the vampire make-up was not as immersive as it could have been. We were originally planning for the make-up to include prosthetics and a bald cap but we ended up not having the time. This in turn affected other aspects of the film like the overall visual look. In general, I believe that every aspect could have been improved with a stronger producer. If I had spent more time with Aisling then we could have tested out different methods for both the make-up and the set design. I should have looked for help in areas I was having difficulty with, e.g. locations, etc.

I definitely was more focused as the semester began. I reached out to companies in Edinburgh that offered filming space for hire and I looked into other rental websites, however, unfortunately many of our options were beyond our price range. I also enquired with anyone I had the contact details of but unfortunately, with the premise of our film, I don’t think many people were keen. I sent out casting calls to as many places as possible. I posted notices on facebook, Backstage and I also printed off posters to hang in various locations. This led to a surprising amount of actors expressing interest which was great in the long term as it meant that we could audition the actors and choose the actors that best suited the roles rather than having to settle for a particular actor.

I am comfortably happy with my input on set during the shooting days. I ensured that the cast and crew were comfortable and I believe I did a sufficient job keeping the cast and crew organised. I essentially acted as a runner, helping out in almost every technical area. The shooting days both ended ahead of schedule and it was a fairly simple process to turn over to the next shooting day.

Critique of Final Work

I think overall, it was a successful film. Mark-Antony brought a script that was both touching and engaging. However, viewing the final project, I think some of the issues that presented themselves in pre-production and the production itself are apparent in the final work.

The performances were probably the strongest aspect of the film. Despite not having much experience in directing, Mark-Antony did an extremely good job rehearsing with the actors.

I do wish we had a few more rehearsal sessions but unfortunately, organising rehearsal time can be a complicated procedure.I think Mark-Antony had a very strong vision on where he wanted to take these characters. Despite the horror aspect of the film initially seeming so prominent due to the concept, Mark-Antony wanted to make it very clear that this was a romance first. While watching the film, I never lost focus on the character’s emotional connection to each other. The horror aspect adds more depth to the film but it never distracts from the romantic focus. I feel as though the chemistry between actors was also portrayed surprisingly well on-screen. I’m glad that myself and Mark-Antony pushed for getting through auditions as early as possible as this meant we could get to know the actors and it gave the actors the opportunity to grow more comfortable with each other. The dialogue that Mark-Antony has written has fulfilled the initial idea in the sense that it does display this damaged relationship and the struggling mental health of Damian’s character. The gothic horror aspect could very easily be altered and it would still be an adequate portrayal of mental health due to the way the script has been written.

What Aisling and India managed to do with the space. I think there are a lot of nice touches in the latter scene where some of the set dressing is broken to give the impression that Damian attempted to rejuvenate the space with what he had available to him. Also the posters gave some nice insight into Damian’s character even if it were background dressing.

My only regret is that I did not either find a more suitable location or push for production design tests. I felt at times that we were restricted in terms of production design by the location and I think it shows in the final film. This is something that can be credited to my ability as a producer. I struggled to source a location that would fit the initial plan. However, I think it still works for the film. It meant that we had complete control over the location and could set dress it in any way we desired.

I think that the lack of coverage in some areas is slightly off putting. I made the decision to complete the shoot within two days instead of the initial three we had planned. This was due to the fact we were ahead of schedule and would only end up with about two or three shots left for the final day. I should have maintained the original plan as it would have meant that we could have reviewed the footage to ensure that we had covered everything. That one shot of ‘Damian’ rising is an example of this that I believe could have fit in something to make the action seem less static.

Fiontiann did a good job with the cinematography, there are many shots that I really admire and I think he was a great addition to the team. The shots that followed Damian’s shadow creeping along the wall and the shot of Damian’s eyes were especially commendable. I’m glad that we spent the time with fiontiann to have a test shoot that was focused on nailing the more complicated shots separate from blocking. This meant that for all the problems that arose during pre-production, the shooting days both went fairly smoothly without any real problems. We managed to capture anything more complicated with ease as we had already prepared.

I’m especially happy with how vastly different the two scenes look from each other. Booking out as much lighting equipment as possible ended up being incredibly beneficial even though we did not use all of it. It allowed the first half of the film to feel successfully atmospheric and combined with the sound design, I think successfully presents itself as tense and suitable for a ‘horror’ experience. The second half of the film has a very different atmosphere. There’s almost a dreamlike quality to the scene, reflecting the mending of this strained relationship.

The sound design really provides an unsettling backdrop for the film. I especially believe it is strong for the first half of the film. The wind gradually grows more intense as the scene continues which increases this tension as the scene plays out. The chains sound appropriately heavy which really expresses the chain’s weight. During the second half, the audio can be slightly inconsistent. The background noise seems to get louder and can cut out depending on what audio track is being used which unfortunately is noticeable. However, I am very happy with the rest of the sound design.

I wish I had been more forward in the editing process. There are certain things that I possibly would have changed. There was one shot in particular that was cut in slightly early, that being the close up of Damian reacting to Gabriel entering the room. The shot of Damian’s shadow took priority. Overall, Mel did a good job with editing the film together, especially since she does not have much editing experience.

Overall, while I am happy with the final outcome, I am disappointed with my performance as a producer. I do think most of this was all down to my lack of experience and confidence. I think if I wanted to attempt a producing role it should not have been at this stage in the course, especially since my peers are settling into their preferred roles. While I do not think I would ever choose to produce again, this has significantly developed my organisational and social skills. Since acting as a producer I have more fully understood the connections between each department and the vital importance of constant communication and preparation.

I am interested to see how the film progresses going forward. We plan to take another look at the picture edit and refine certain things and we also plan to infuse an original score to prepare it for festivals.

0 notes

Text

[ad_1]

Asphalt pavements are among the most typical ones around the globe. A typical asphalt driveway, car parking zone, or different pavement ought to final over twenty years. Nevertheless, correct upkeep and restore work is required to make your pavements final this lengthy. Excessive-quality paving installations make properties look neat, considerably boosting curb attraction and worth.Nevertheless, many questions proceed to come up about asphalt pavements. Folks examine asphalt to different supplies like gravel and concrete. A pavement funding will all the time be a long-term one. So, exploring asphalt pavements intimately is sensible earlier than investing in a single. Beneath, we have now answered among the most typical asphalt pavement questions. Learn by means of to search out out extra:1. What's asphalt pavement product of?Asphalt pavement, also called blacktop, sometimes contains mixture stone, asphalt, and cement. Some further components improve sturdiness, flexibility, and resistance to climate and visitors. The combination materials gives boosted structural assist whereas performing as a binder, protecting the floor collectively. Excessive-grade adhesives are additionally used for extra energy.2. How lengthy do asphalt pavements final?A well-constructed asphalt pavement ought to final anyplace from 15 to 25 years. Nevertheless, various factors similar to local weather, visitors quantity, and upkeep impression the general lifespan of a typical asphalt pavement. Asphalt pavements are robust surfaces designed to final lengthy. Nevertheless, common upkeep, together with seal coating, crack sealing, and pothole filling, can considerably lengthen its lifespan.3. What causes cracks in asphalt pavement?Various factors could cause the asphalt floor to develop cracks. These components embody age, temperature fluctuations, moisture infiltration, and heavy visitors masses. In some circumstances, pure disasters can even trigger floor cracks in asphalt pavements. Over time, publicity to daylight and rain or snow water could cause the asphalt to oxidize and grow to be brittle, resulting in cracks. Moreover, repeated freeze-thaw cycles can exacerbate cracking by increasing current fissures.4. How can cracks in asphalt pavement be repaired?Asphalt cracks shouldn't be ignored in any respect, and immediate restore work will hold the floor intact for longer. Relying on the kind and severity of the cracks, crack sealing, patching, or infrared asphalt restore might be the chosen strategies. Crack sealing includes filling the cracks with a sizzling rubberized sealant to stop moisture infiltration. Patching includes eradicating and changing the broken asphalt.5. Why does asphalt pavement should be seal coated?Over time, asphalt surfaces are likely to lose their energy and binding potential. This makes them come aside. Additionally, continued publicity to components can fade the floor making it look uninteresting. Seal coating is the answer to all of those issues. It helps forestall oxidation and moisture infiltration, which may trigger the asphalt to deteriorate prematurely. Seal coating additionally restores the looks and darkish end.6. How usually ought to asphalt pavement be seal coated?Various factors like local weather, visitors quantity and measurement, pavement situation, and others will impression seal coating scheduling. Usually, asphalt pavement needs to be seal coated each two to a few years. This helps keep optimum safety and delay its lifespan. Nevertheless, extra frequent seal (sometimes yearly) coating could also be mandatory in high-traffic areas or harsh climates.7. Can asphalt pavement be recycled?Sure, asphalt pavements are among the most recycled supplies globally. Whenever you want a brand new asphalt driveway or pavement, many of the current supplies on the previous pavement shall be recycled. Recycling asphalt pavement conserves pure assets and reduces the environmental impression of paving initiatives. Additionally,

this helps in minimizing the necessity for virgin supplies for brand spanking new initiatives.8. How is asphalt pavement maintained in winter?If it snows quite a bit in your space, immediate snow elimination is all the time the primary issue. Additionally, protecting water runoffs unclogged always will allow melting snow water to be cleared away rapidly. De-icing brokers similar to rock salt or calcium chloride can soften ice and snow. Nevertheless, harsh chemical substances is likely to be dangerous. Repairing cracks or potholes earlier than the winter is all the time a beneficial approach. Additionally, seal coating earlier than the beginning of the winter will assist soften snow quicker and hold the pavement stronger.9. Can asphalt pavement face up to heavy visitors masses?Asphalt pavements are designed by skilled asphalt driveway corporations to deal with all types of visitors volumes and masses. This issue makes it supreme for highways, airports, and industrial areas. Correct design and building strategies, similar to enough thickness and compaction, make sure the asphalt pavement can deal with the required visitors quantity and weight with none harm. Common upkeep, together with crack sealing and patching, helps mitigate the results of heavy visitors on asphalt pavement.10. How can I keep my asphalt driveway?Correct upkeep is vital to prolonging the lifespan of an asphalt driveway. Good upkeep measures embody protecting it clear by sweeping off any overseas supplies, immediate crack and pothole filling, and common seal coating. You wish to decrease harm and management it earlier than it extends. Avoiding heavy or sharp objects on the driveway floor and eradicating any oil or mulch stains will hold it contemporary for longer. Additionally, hold the water runoffs clear always. Porous asphalt is the best way to go for a lot of initiatives.And LastlyUsually, asphalt driveways and pavements are very sturdy surfaces. Nevertheless, common upkeep is vital to creating them final lengthy. Asphalt driveways are a lot better choices in comparison with concrete pavements and gravel. Their potential to keep up their seems to be and performance for an extended length sustainably and affordably makes them the perfect alternative for residential and industrial initiatives.

[ad_2]

Supply hyperlink

0 notes

Text

Whiter Shades of Construction: Top White Cement Picks

The importance of cement cannot be overstated. It's the fundamental ingredient that binds together the bricks, stones, and sands to create structures that stand the test of time. Among the plethora of cement types available in the market, white cement stands out for its versatility and aesthetic appeal. Renowned for its purity and brightness, white cement is the preferred choice for projects where a pristine finish is desired. In India, where construction is booming, the demand for the best white cement is on the rise. Let's explore some top picks for white cement, including where to buy them and why they stand out in the market.

Best Cement in India: When it comes to selecting the best white cement in India, several brands deserve recognition. One such brand is UltraTech Cement, known for its high quality and reliability. With a strong presence in the market, UltraTech offers a range of white cement products suitable for various applications. Whether it's for flooring, plastering, or decorative purposes, UltraTech Cement is a trusted choice among builders and contractors across the country.

Buy White Cement: Purchasing white cement can sometimes be a daunting task, especially for those unfamiliar with the construction industry. However, with the advent of online platforms and specialized construction stores, buying white cement has never been easier. Brands like Birla White Cement have made their products readily available through online retailers, making it convenient for customers to purchase white cement with just a few clicks. Additionally, local hardware stores and construction suppliers also stock white cement, catering to the needs of DIY enthusiasts and professionals alike.