#Hardwood pallets for concrete block machine

Text

Pallets for Block Machines and Their Use

High-grade and advanced range of pallets is required for block machines and varied other purposes to streamline the process and keep everything in a systematic way. Being the integral components in block machine operations, pallets for block machines are known for their multifaceted role ranges from providing a stable base for block formation to aiding in curing and efficient movement. These structures enhance the quality, consistency, and productivity of concrete block manufacturing processes. It will be better to know about the critical functions of pallets in block machine operations so that you can make informed decisions to optimize their production lines and contribute to the construction industry's advancement.

What Are the Benefits of Using Pallets for Block Machines?

Pallets serve as the foundation for producing high-quality concrete blocks. They provide a stable platform on which the blocks are shaped, allowing for uniformity in size and shape. The pallet's flat surface and even dimensions ensure that the formed blocks are consistent, which is crucial for construction projects that demand precise measurements.

Pallets Ensure Easy Movement and Transport Operations

Pallets facilitate the easy movement of freshly molded blocks within the manufacturing facility. They provide a convenient base on which the blocks can be transported using forklifts or other handling equipment. This streamlines the production process, reducing the time and effort required to move the blocks from one phase of production to another.

Pallets Are the Right Sources of Efficient Curing

Curing is the process of maintaining adequate moisture and temperature levels for concrete blocks to set and strengthen. This is the right process that is greatly aided by pallets. The pallets support the blocks, allowing air to circulate around them during the curing process. This controlled environment enhances the quality and durability of the blocks, ensuring they meet the required standards.

No Need to Worry About the Breakage

Pallets play a pivotal role in preventing breakage during the de-molding process. Once the concrete blocks have set, they need to be removed from the molds. Pallets provide essential support during this delicate phase, ensuring that the blocks maintain their integrity and structural strength as they are released from the molds.

Enhanced Productivity of Block Machines

The utilization of pallets in block machine operations significantly boosts productivity. With the aid of pallets, multiple blocks can be molded simultaneously, optimizing the manufacturing process. Moreover, pallets enable the seamless stacking of blocks, preventing damage and facilitating efficient storage. Pallets for block machines are crafted from various materials, including wood, plastic, and metal. Wooden pallets are commonly used due to their cost-effectiveness and availability. Plastic pallets, on the other hand, are known for their durability and resistance to moisture, making them ideal for prolonged use and outdoor storage. You have to choose the best range and place your order accordingly.

0 notes

Text

Buy Production Boards for Concrete Pavers Online with Complete Guide

Concrete pavers need durability, strength, resistance to moisture and chemicals and above all accuracy in production. For them, the most crucial thing is selection of the best quality production boards that are in varied shapes, sizes and designs. Choosing the best range of boards is a crucial decision to make. For this, the best way is to search for the top manufacturers who are dealing in production boards for concrete pavers.

If you don’t have any idea about the production board for concrete pavers and you are spending more on internet searching for the best range of pavers, here is a better option to fulfill your requirement. Go online as it is counted as one of the convenient ways to enhance your experience There are a number of recognized manufacturers and wholesale suppliers bringing to you the best quality pavers and ensuring you will get them delivered to your address without any delay. All details are provided to you that will be a plus point.

GPE Pallets Has the Best Range of Production Boards for Concrete Pavers

GPE Pallets is a one stop trusted name, when it comes to choose the best range of production boards for concrete pavers. Different sizes of such boards are available in varied dimensions. All details are provided to you that will be a plus point to enhance your experience. You can contact from anywhere and anytime and get the best range delivered on time – right to your address. GPE Pallets has a broad range of pallets. A complete user guide is provided to you to ensure you are getting the best range. Place your order now and get delivery in timely manner.

#Hardwood pallets for concrete block machine#Timber Pallets For Concrete Block machine#Production boards for concrete pavers

0 notes

Text

Repairing Wood Pallets Has Many Advantages

Pallets that have been restored or made in part of used pallet material for re-use can be referred to as reconditioned, recycled, remanufactured, or combo.

All of the varieties are a less expensive alternative to new wooden pallets and can carry items of all shapes and sizes effectively. There are several other reasons to fix and reuse wood pallets, including the following:

Why Do You Reuse and Repair Wood Pallets?

By stopping used pallets from ending up in a landfill, the organization will demonstrate its contribution to the environment. Recycled pallet material is drier than new wood, which helps to reinforce the pallet and make it almost as sturdy as new wood.

Used pallet material may be used to make custom-sized pallets (or pallets that require particular equipment compatibility specifications) for up to 25% less than a custom-built new pallet. This is suitable for manufacturing and food and beverage sectors.

One-way delivery is suitable for broken pallets that have been fixed. However, if a mixture of materials is used during remanufacturing, they may be ideal for several shipments. For the critical load measurements, we recommend new material, and for the surrounding region, we recommend recycled material.

Pallets that have been restored or reconstructed with used pallet material, like the new type, are ideal for foreign shipping after heat treatment.

So don't give up on your used pallets because of bent boards, missing nails, or twisted or warped wood. Repairing and reusing used pallets, as well as recycling all or portions of the pallet, will give them a new lease on life. Hardwood Pallets for Concrete Blocks will determine your pallet supply and assist you in making decisions on whether to restore, recycle, or use a combination of the two. We can also deliver an empty trailer to your location for you to unload all of your wood pallet waste into. We will drop/switch the trailers and remove the scrap or waste for recycling when you call to report a complete trailer.

0 notes

Text

Achieve Superior Results with Hardwood Pallets for Concrete Block Machines

In the construction industry, precision and durability are key factors for success. Concrete block machines play a crucial role in creating sturdy and reliable blocks. However, the quality of the pallets used in these machines is equally important. Hardwood pallets for concrete block machines are the best source offering unparalleled strength and durability, making them an ideal choice for concrete block machines. These pallets are engineered to withstand the heavy weight and intense pressure exerted during the block-making process. By using hardwood pallets, you can ensure that your blocks are produced with utmost precision and resilience.

Stability of the Pallets in Concrete Block Machines

The stability of the pallets used in concrete block machines is crucial for maintaining consistent quality. Hardwood pallets provide excellent stability due to their robust construction. They offer a flat and level surface, ensuring that the blocks are formed with accuracy and uniformity. This stability translates into high-quality blocks that meet industry standards and exceed customer expectations.

GPE Pallets Offers The Best Range of Hardwood Pallets for Concrete Block Machines

Investing in hardwood pallets for your concrete block machine is a wise decision in terms of longevity and cost-effectiveness. Hardwood is known for its resistance to wear and tear, making these pallets a durable and long-lasting option. By using hardwood pallets, you can minimize the need for frequent replacements, saving you both time and money in the long run. When it comes to concrete block production, the quality of the pallets used in your machines can significantly impact the final results. Opting for hardwood pallets from trusted suppliers like GPE Pallets ensures superior strength, enhanced stability, and long-term cost-effectiveness.

0 notes

Text

Pallets for Block Machines In Varied Sizes – Durable and Strong Enough

Pallets for Block machines are in varied shapes, sizes and design that are sure to enhance your experience of keeping the blocks safe and secure. You can choose the best range with a user guide. They are frequently used in block and brick making industry. When the delivery of bricks and concrete blocks is done to another place, pallets are required to keep blocks unite together. Depending on your requirement, you can choose the best range of pallets for block machines and get them delivered with a complete guide. For this, the best way is to search for the top manufacturers or suppliers.

Online search will save you time and money and provide you with more options of choosing the best one. Check all details and get the best range of pallets that are durable and made of strong wooden pieces and other materials. They are safe and secure to use and come with different added features.

You can place your order for pallets for block machines and get delivery on time.

Composite Pallets Offers the Best Range of Pallets for Block Machines

Among some of the top names in this domain from where you will get the best range of pallets for block machines, you will find name of Composite Pallets on top – offering you the best range of pallets for block machines. You can place your order from anywhere and anytime and get delivery on time. So, what you are waiting for, place your order now and get delivery on time.

0 notes

Text

Why do you need Timber Pallets For the Concrete Block machine?

During the production of concrete block machines, timber pallets are often used as it provides many profits and benefits as compared to any other materials. In this post, why you require Timber Pallets For Concrete Block machine is well explained.

Cost-effective

It has been found that timber pallets are quite costly compared to other materials like plastic and steel. They can be easily sourced and readily available, which makes them a cost-effective option for manufacturers of concrete block machines.

· Durability

You can get high durability with timber pallets that can withstand the pressure and heavy weight of the wet concrete mix in the concrete block manufacturing process. It has resistance to moisture as well as resists decaying and rotting that helps to endure its lifespan.

· Customizable

These pallets involve different manufacturing processes and customization options that help to meet the specific needs of the manufacturers. It allows the manufacturers to cut to size and shape to produce concrete blocks of various dimensions and sizes.

· Environmentally friendly

Timber pallets are known as renewable resources, which can be repurposed or recycled after ending their lifespan. The biodegradable nature of this pallet makes them an environmentally friendly option.

· Good insulation

Good insulation properties are associated with the timber pallets that help to maintain the wet concrete mix temperature during the manufacturing process.

Conclusion

Many advantages are associated with the timber pallets, like offering good insulation, customizable, cost-effective, durability, etc., which makes them more attractive to many manufacturers. Thus, choose the right Timber Pallets For Concrete Block machine based on your specific needs.

#Timber Pallets For Concrete Block machine#Production boards for concrete pavers#Hardwood pallets for concrete block machine

0 notes

Text

Why Hardwood Pallets for Concrete Block Machine Is Useful

The process of moulding blocks using a concrete block manufacturing machine or a big, fully automated concrete block production line, using a pallet as a carrier for loading the wet blocks once the block is demoulded. Pallets are also extensively utilised during the block curing process. Many different types of block machine pallets have been developed by our Hardwood pallets for concrete block machine through decades of innovative research and development, and among the best are the wooden pallet, PVC plastic pallet, bamboo pallet, bamboo-PVC surface and edge covered pallet, and glass fiber pallet.

Block machine wooden pallet

The boards are the primary components of wooden pallets. The wooden block machine pallet has the qualities of bending strength and lower density and this kind of wood block pallet is lightweight and liked by buyers of block machines.

In the production of wooden pallets, we use special methods and techniques. Three or four pieces of fastening screws and rods are placed for reinforcement of the pallet between each lath of the wood board using male and female slot joints. The wooden block pallet also has channel steel covering and protection at both ends. With the aforementioned unique design, the wood pallet achieves exceptional strength and endurance throughout the manufacture of concrete.

A typical pallet's opening glue and losing edges is broken by the core layer of the pallet, which is made of bamboo chips and particles. Our pallet performs well when it comes to bonding. The tested average bonding strength of the new generation which is more than twice that of the industry standard. Compared to other pallet materials, it has a significantly higher strength. Additionally, the pallets are developed and manufactured in strict agreement with the concrete block manufacturing industry in terms of their longitudinal and transverse static bending strength and elastic modulus.

#Hardwood pallets for concrete block machine#Pallets for Concrete Blocks#Concrete Block Machine Pallets

0 notes

Text

Which is better to choose: the hardwood pallet or the software pallet?

Warehouse management requires that operations are completed efficiently and productively. As a result of their useful design and longevity, pallets are a dependable staple in warehouses. Pallets are classified into steel pallets, plastic pallets, and Hardwood pallets for concrete block machine. Choosing the proper sort of pallet for one's business ensures that resources are used optimally. In this blog, we’ll talk about which pallet you should choose.

Facts softwood pallet

Softwood pallets are frequently treated to eliminate mold and fungal hazards and to dry off excess moisture. Softwood is often utilized to manufacture windows, doors, paper goods, and wooden furniture. Because of the huge availability of softwood, the pallets constructed from this material quickly compensated for the lack of supply in hardwood pallets. Softwood pallets offer two major advantages. Softwood is significantly less expensive than hardwood since it produces and propagates more quickly. Softwood is less dense than hardwood, implying that it is lighter.

Facts about Hardwood pallet

The Hardwood pallets for concrete block machines are well renowned for their sturdiness and resilience. It's also far less expensive than steel and plastic pallets. Hardwood is recognized as a material used for furniture, building, and other long-lasting tasks. It is less vulnerable to humidity difficulties and minimizes the indications of degradation or decay. The hardwood pallet is stronger and longer-lasting than the softwood pallet; thus, if operational longevity is important to a company, the hardwood pallet is the best option.

The following are the distinctions between hardwood & softwood pallets. If you have any additional concerns about which type of pallet is best for your business, you can choose one.

#Timber Pallets For Concrete Block machine#Production boards for concrete pavers#Hardwood pallets for concrete block machine

0 notes

Text

Our Best Quality Machine for Pallet Blocks

Wood blocks are produced using a pallet block machine, also known as a pressed wood block machine. We provide three different models of this machine, including single-head, double-head, and triple-head models, all with different specs.

What kinds of materials are suitable for manufacturing pallet blocks?

Our Pallets for block machine items left over from the creation of pallet factories or woodworking product processing plants, including sawdust, residual scraps, waste wood, shavings, waste pallets, and building templates.

Pallets for block machine characteristics

• strengthened framework, temperature gauge.

• Non-fumigation - Fumigation is not necessary because the pallet block is manufactured at a high temperature.

• simple process - Three machines can be operated simultaneously by one employee with the innovative PLC system and a touch panel.

• cutting costs - The pallet block machine is effective in recycling waste wood.

• elevated loading capacity -The loading capacity of the block can support up to 1-3 tons, and the block's density can range from the standard size.

• Block size is flexible - Depending on the needs, the block's specs can be altered between the ranges

This machine can produce blocks for two different types of standard pallets: solid and blocks with holes inside.

How is the pallet block machine operated?

The block is used to create the base of the wood pallet, which serves as a storage or transit pallet. The finished item might receive an E1 grade. You can view to see a solid pallet block without a hole in the middle as well as a hollow pallet block.

• In order to extrude and mould the materials, the hydraulic cylinder pushes the piston under high pressure.

• The solidification and moulding of urea-formaldehyde glue are encouraged by heating the heating plate at a high temperature.

• Using a specific length while cutting usually around 1.2 m.

• Once the items have cooled, trim the long wood strips to the desired size.

#Pallets for block machine#Concrete Block Machine Pallets#Hardwood pallets for concrete block machine

0 notes

Text

Production Boards for Concrete Pavers – Choose the Best Units

Different types of machines and accessories are required for concrete blocks and pavers. Production boards for concrete pavers are the most popular type used in concrete blocks and pavers manufacturing – designed especially for the applications. These boards are made from specific species of timber that offers high strength, durability, resistance to vagaries of nature and a lot more. There is a lot more associated with the advanced range of production boards for concrete pavers. Check all details, know about the process, and leave rest of the work on experts working here.

If you don’t have any idea about production boards for concrete pavers, you will find varied big names in this domain offering you the best range. Check all details, know about the specialties and place your order accordingly. There are a number of big names in this domain providing you with the right solutions. Check all details and you will get the best solutions. Their main motive is to help you at every step.

Among some of the top names in this domain from where you will get the best range of

production boards for concrete pavers

, you will find name of GPE Pallets on top – providing you with the best quality boards in varied sizes. The leading manufacturer and supplier has become the trusted name for the best range of production boards. Place your order now and get them delivered on time in fully secure way.

#Production boards for concrete pavers#Timber Pallets For Concrete Block machine#Hardwood pallets for concrete block machine

0 notes

Text

Production Boards for Concrete Pavers with Assured Durable Life and High Performance

Production boards for concrete pavers are required for different purposes and available in varied designs and shapes that you can get according to your application types and specific needs.

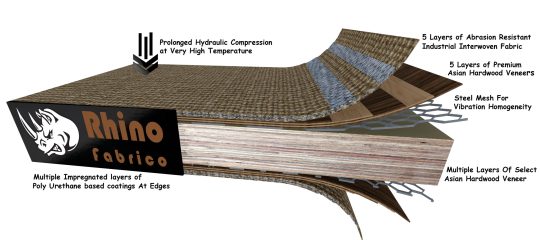

Production boards for concrete pavers or pallets are manufactured from high quality densified plywood. They are pressed under high temperature after the treatment with waterproof resins mainly to create extremely durable pallets for concrete pavers. They are for concrete blocks that are known as production pallets for concrete pavers – single solid pieces with no joints or gaps. You will also get a lot more from the production boards for concrete pavers that come with different added features. You have to go through the details, know about the applications in which they are used and leave rest of the work on experts working there.

Rhino Composite Pallets Offers the Best Range of Production Boards for Concrete Pavers

Rhino Composite Pallets is a one stop trusted name in this domain offering you the best range of pallets and production boards for concrete pavers. All details are provided to you that will be a plus point to enhance your experience. You can contact from anywhere and anytime and get the best quality production boards for concrete pavers. They are packed in safe boxes and delivery is done to your address. So, what you are waiting for, place your order according to your requirement and get the best range delivered on time.

#Production boards for concrete pavers#Hardwood pallets for concrete block machine#Timber Pallets For Concrete Block machine

1 note

·

View note

Text

High-Grade Concrete Block Machine Pallets in Varied Sizes

Pallets for concrete block machines or high-grade concrete block machine pallets are designed in varied shapes, sizes and designs that you can get according to your specific needs and type of machines to use them properly. All quality standards are followed for the duration of making such machines. It will be better to check all details and get the best solutions according to your needs for the best range of concrete block machine pallets.

• These high-grade concrete block machine pallets are manufactured with different varieties of surfaces to cater individual requirements of concrete block manufacturers around the world

• Surfaces are crucial and made of using synthetic film, industrial fabric or glass fibre to offer different levels of resistance to the abrasive nature of concrete products

• Concrete block machine pallets are known for having high density in comparison to hardwood, softwood and plastic production boards for concrete blocks that ensures efficient transmission of vibration to the concrete.

There is a lot more associated with the best quality concrete block machine pallets. Choosing the best range of such machines is a crucial decision to make. There are a number of recognized names in this domain offering you the best quality pallets. Check all details and get the best range delivered to your address.

Composite Pallets is a one stop trusted name in this domain offering you the best solutions to choose high-grade pallets. You can place your order according to your specific needs and get delivery on time.

0 notes

Text

High-Grade Pallets for Concrete Blocks and Their Making Procedure

Pallets for concrete blocks are made of using plantation hardwood timber that is chosen from plantation timbers around the world with the way to ensure perpetual recurrence of vegetation. The plantation timber is grown in conducive geographical regions – ensuring that the forests are not destroyed for increasing requirement of wood.

Plantation trees are selected to ensure physical parameters of logs that go through the process of de-barking. The logs are fed into veneering machines to produce extremely thin layer of timber.

• Hardwood veneers forms the core of pallets for concrete blocks that are made by focusing on the highest quality standards. These pallets are cross laid to increase the core strength.

• Humidity optimization is next crucial point to consider in the final step of the entire process. They are stored in controlled humidifying before proceeding to next level of manufacturing.

• Waterproof synthetic resin and resin saturated fibers are other steps in the process.

• Hydraulic compression and pallet core formation are next key points to make strong pallets

Each and every step in the process is completed successfully and by paying attention to varied key points. The most crucial thing is to choose the best pallets according to your requirements and place your order directly to the top manufacturers.

Go online as it is counted as one of the convenient ways to find top manufacturers and place your order for the best range of pallets for block machines. You will find a number of top names in this domain offering the best range of pallets with a complete guide. Check all details and you will get delivery on time and right to your address.

0 notes

Text

High-Grade Pallets for Concrete Blocks in Varied Sizes and Thickness

Concrete blocks are used in the construction domain in different ways to make any structure strong and give stability to the building for long term. These blocks are designed in different patterns, styles, shapes and sizes. Choosing the best range of concrete blocks can be far easier than carry them from one place to another in convenient way. For such blocks, you need something durable, strong and in the shape to carry them easily and in convenient way. Choosing the right type of pallets for concrete blocks will be the right option to enhance your experience. Depending on your requirement, you can choose the right type of pallets for concrete blocks that are designed by keeping in mind their weight, type and size.

High-grade pallets for concrete blocks machines are designed to give them stability. These pallets are designed to last through harsh and abrasive working conditions for production of concrete blocks, pavers, and other concrete products in all types of block machines.

Pallets Are Manufactured with Different Surfaces to Cater Individual Needs

These high-grade pallets are manufactured with different varieties of surfaces to cater individual requirements of concrete block manufacturers around the world. Not to mention the surface of synthetic film, industrial fabric or glass fibre – known for offering different levels of resistance to the abrasive nature of concrete products. These high-grade pallets for concrete blocks are known for having high density in comparison to hardwood, softwood and plastic production boards for concrete blocks that ensures efficient transmission of vibration to the concrete.

They are available in all sizes with thickness up to 70mm and sometimes in other thicknesses. These pallets are manufactured in state-of-the-art hydraulic press and exclusive use of tropical plantation hardwood. Not to mention the use of fibers in manufacturing that ensures consistent quality. In this way, they outlast ordinary softwood and hardwood pallets for concrete block manufacturing. Different types of engineered surfaces are offered that ensure long life of trouble free services by the pallets.

Find Top Manufacturer of Pallets for Concrete Blocks

Depending on your requirement, you can choose the best range of pallets for concrete blocks machines and for other purposes. Pricing depends on the type of pallets you are using and getting their delivery will be far easier to your address without any delay.

For the best range of pallets for concrete blocks and machines, you need to reach the top manufacturer. Go online and it is counted as one of the convenient ways to provide you with some of the best options to choose the best one. You can place your from anywhere and get delivery to your address without any delay. Check all details and get the best range of pallets for concrete blocks.

0 notes

Text

Pallets for Block Machines and Their Benefits of Using

Pallets for block machines are designed in varied sizes and thickness to ensure strong blocks are designed. These pallets are made by following all quality standards and to make them able to stay stronger. Some of the added benefits that you will get from pallets for concrete machines include, but not limited to:

• Strong and Homogeneous with faster cycle times

• Excellent vibration transmission with minimum deflection

• One solid piece with no gapes or joints and less power consumption

• No moisture problems (even if chipped) made to regrind and refurbish

• High block density with less wear to machines and modules

In addition to the aforementioned benefits, pallets for Block machines are known for vibration stress compatibility with quick and consistent compaction and perfect plain surface with long life and hardwood fibre fortification.

There are a number of benefits and features of the pallets for block machines. They are commercially available and for uses directly from the top manufacturers. Go online and you will find a number of top names in this domain offering you the best range of pallets for block machines. Choose the best one, check all details and get the best solutions according to your needs.

You have to find the top manufacturer, know about the making procedure and leave rest of the work on experts working there. Prices are competitive and backed by some additional services.

0 notes

Text

Know About the Making Process of Pallets for Concrete Blocks

Pallets for concrete blocks are the basic need required to keep blocks in a set and packed for the duration of shifting from one place to another. There are a number of benefits of using pallets. The most crucial thing is to choose the durable and strong pallets. It will be better to know about their making process.

Plantation of Hardwood Timber

Pallets for concrete blocks are designed by using hardwood sourced from varied places and transformed through a process.

Plantation for hardwood timber is done to select the best hardwood and ensuring perpetual recurrence of vegetation. Plantation timber is scientifically grown in conducive geographical regions to ensure that the forests are not destroyed for want of wood.

How Veneers Are Made

Not to mention the log processing as plantation trees are selected to ensure physical parameters of logs. The logs go through the process of de-barking and fed into veneering machines where hydraulically operated sharp bladed produce extremely thin layers of timber.

How to Form the Core of Composite Pallets

Hardwood veneers are known for forming the core of composite pallets. They must be absolutely of highest quality. Out of the veneers produced in the factory, ones with highest parameters are selected for composite pallets. They are cross laid to increase the core strength.

Not to mention the humidity of veneers that plays a very important part in the final quality of the pallets for concrete blocks. Veneers are stored in controlled humidifying chambers to achieve the desired levels of humidity before preceding the next level of manufacturing. They maintain optimum moisture during the whole process.

Waterproof Synthetic Resin Process

Waterproof synthetic resin is done to ensure consistent quality and availability of all grades of required resins for different applications. On the other side, the wooden pallets for concrete blocks use the highest grade of waterproof synthetic. Resin is the way to ensure long and trouble free life of pallets.

The resin process is done to get veneer sheets and to ensure complete fiber saturation. There are different other steps required to complete in the making process of Pallets for concrete blocks. Here, the most crucial thing is to search for the right manufacturers and place your order accordingly for the best range of pallets. Go online and it will surely save you time and money and provide you with more options to choose the best range of pallets. You can place your order from anywhere and anytime.

0 notes