Text

High-Grade Pallets for Concrete Blocks Online

Pallets have emerged as indispensable components in the realm of block machine operations, revolutionizing the efficiency and quality of the construction industry. These flat, often wooden or plastic structures provide crucial support during the manufacturing of concrete blocks, enhancing the overall production process. Depending on your requirement, you can choose the best range of pallets for concrete blocks to carry them easily and in safe way.

For the best range of pallets for concrete blocks, what all you have to do is search for the top manufacturers, go through the details of such pallets and then place your order accordingly. The best way is searching for the top companies online. There are a number of recognized names in this domain providing you with complete peace of mind. You can contact from anywhere and anytime.

Online search is an ideal way to save you time and provide you with some better option to fulfill your requirement. You can contact from anywhere and anytime and get the best range in secure way.

Composite Pallets for the Best Range of Pallets for Concrete Blocks

Among some of the top names in this domain, you will find name of Composite Pallets on top – offering you the best range of pallets and in fully secure way. You can contact from anywhere and anytime and get the best range delivered to your time. All details are provided to you with a complete guide. So, what you are waiting for, place your order now and get the best range of pallets for concrete blocks.

0 notes

Text

Pallets for Block Machines and Their Use

High-grade and advanced range of pallets is required for block machines and varied other purposes to streamline the process and keep everything in a systematic way. Being the integral components in block machine operations, pallets for block machines are known for their multifaceted role ranges from providing a stable base for block formation to aiding in curing and efficient movement. These structures enhance the quality, consistency, and productivity of concrete block manufacturing processes. It will be better to know about the critical functions of pallets in block machine operations so that you can make informed decisions to optimize their production lines and contribute to the construction industry's advancement.

What Are the Benefits of Using Pallets for Block Machines?

Pallets serve as the foundation for producing high-quality concrete blocks. They provide a stable platform on which the blocks are shaped, allowing for uniformity in size and shape. The pallet's flat surface and even dimensions ensure that the formed blocks are consistent, which is crucial for construction projects that demand precise measurements.

Pallets Ensure Easy Movement and Transport Operations

Pallets facilitate the easy movement of freshly molded blocks within the manufacturing facility. They provide a convenient base on which the blocks can be transported using forklifts or other handling equipment. This streamlines the production process, reducing the time and effort required to move the blocks from one phase of production to another.

Pallets Are the Right Sources of Efficient Curing

Curing is the process of maintaining adequate moisture and temperature levels for concrete blocks to set and strengthen. This is the right process that is greatly aided by pallets. The pallets support the blocks, allowing air to circulate around them during the curing process. This controlled environment enhances the quality and durability of the blocks, ensuring they meet the required standards.

No Need to Worry About the Breakage

Pallets play a pivotal role in preventing breakage during the de-molding process. Once the concrete blocks have set, they need to be removed from the molds. Pallets provide essential support during this delicate phase, ensuring that the blocks maintain their integrity and structural strength as they are released from the molds.

Enhanced Productivity of Block Machines

The utilization of pallets in block machine operations significantly boosts productivity. With the aid of pallets, multiple blocks can be molded simultaneously, optimizing the manufacturing process. Moreover, pallets enable the seamless stacking of blocks, preventing damage and facilitating efficient storage. Pallets for block machines are crafted from various materials, including wood, plastic, and metal. Wooden pallets are commonly used due to their cost-effectiveness and availability. Plastic pallets, on the other hand, are known for their durability and resistance to moisture, making them ideal for prolonged use and outdoor storage. You have to choose the best range and place your order accordingly.

0 notes

Text

Pallets for Block Machines for the Convenient Base to Carry Blocks

Pallets are the essential part of block machines to carry them easily and in safe way. You will also get amazing benefits of using such pallets. Talking more about the pallets, they serve as the foundation for producing high-quality concrete blocks. They provide a stable platform on which the blocks are shaped, allowing for uniformity in size and shape. Not to mention their flat surface and even dimensions ensure that the formed blocks are consistent, which is crucial for construction projects that demand precise measurements. In addition to this, they also facilitate the easy movement of freshly molded blocks within the manufacturing facility.

Pallets for block machines provide a convenient base on which the blocks can be transported using forklifts or other handling equipment. This streamlines the production process, reducing the time and effort required to move the blocks from one phase of production to another. Curing is the process of maintaining adequate moisture and temperature levels for concrete blocks to set and strengthen. This is the right process that is greatly aided by pallets.

The pallets support the blocks, allowing air to circulate around them during the curing process. This controlled environment enhances the quality and durability of the blocks, ensuring they meet the required standards.

You have to go through the details, know about their specialties, choose the right size and design and place your order.

0 notes

Text

What Are The Benefits Of Using Wooden Pallets For Concrete Block Machines?

Concrete block machines are vital in producing durable and high-quality building materials in the construction industry. These machines' essential components are the pallet, which provides support and stability during concrete block manufacturing. While various pallet materials are available, wooden pallets have emerged as a popular choice due to their numerous benefits. In this blog, we will explore the advantages of using Wooden Pallets for Concrete Block Machine.

Durability and Strength

Wooden pallets exhibit exceptional durability and strength, making them ideal for the demanding requirements of concrete block production. Wood possesses natural properties that allow it to withstand heavy loads and constant impacts, ensuring the longevity of the pallet. Additionally, Wooden Pallets for Concrete Block Machine cracking and deformation over time, maintaining their structural integrity.

Cost-effectiveness and Availability

Another significant advantage of Wooden Pallets for Concrete Block Machine is their cost-effectiveness and widespread availability. Compared to alternative pallet materials, such as plastic or metal, wooden pallets are more affordable. Additionally, wood is a renewable resource, making it readily accessible for manufacturing purposes. The availability of wooden pallets in the market ensures businesses can acquire them easily without excessive lead times or high costs.

Conclusion:

Wooden pallets offer several benefits when used in concrete block machines. Their durability and strength guarantee reliable support throughout manufacturing, resulting in high-quality concrete blocks. Moreover, wooden pallets are cost-effective and readily available, making them a practical choice for businesses seeking efficient and sustainable solutions. Construction companies can enhance productivity and reduce operational expenses by opting for wooden pallets. To explore further options and learn more about wooden pallets for concrete block machines, consult reputable suppliers and manufacturers in the industry.

0 notes

Text

Unlock the Power of Block Machines: A Comprehensive Guide

Block machines have revolutionized the construction industry, offering efficient and cost-effective solutions for producing high-quality concrete blocks. Pallets for block machine are widely used for various applications, including building construction, landscaping, and road paving. In this comprehensive guide, we will explore the power of block machines and provide valuable insights into their operation, benefits, and potential applications.

Understanding Block Machines

Pallets for block machine, or brick-making machines, are mechanical devices designed to produce concrete blocks or bricks. They consist of a mold, which shapes the concrete mixture into the desired block shape, and a hydraulic or mechanical system that applies pressure to harden the blocks. These machines come in various sizes and configurations, catering to different production requirements.

The Benefits and Applications

Block machines offer numerous benefits to construction projects:

1. They enhance productivity by automating block-making, reducing labor costs, and increasing output.

2. These machines produce uniform blocks with precise dimensions, ensuring consistency and quality in construction.

3. They enable the use of various raw materials, such as concrete, cement, or fly ash, making them versatile and environmentally friendly.

Conclusion

Unlocking the Pallets for block machine can significantly benefit the construction industry. Their ability to automate and streamline block-making processes enhances productivity and ensures consistent quality. By using block machines, construction projects can achieve cost savings, reduce labor requirements, and easily produce high-quality blocks. Whether it's a small-scale construction project or a large infrastructure development, block machines are versatile tools that offer a range of applications. To explore further, consider reputable companies that provide block machine solutions, where you can find innovative products and solutions tailored to your specific needs.

0 notes

Text

Exploring the Benefits of Pallets for Concrete Blocks

When it comes to the transportation and storage of concrete blocks, the use of pallets can offer numerous advantages. Pallets for Concrete Blocks are sturdy platforms that provide a stable base for stacking and moving heavy loads. This blog will delve into the benefits of using pallets for concrete blocks, highlighting their efficiency, cost-effectiveness, and sustainability.

Enhanced Efficiency

Pallets for Concrete Blocks provide a standardized and uniform base for stacking concrete blocks, ensuring efficient use of space during transportation and storage. Their design allows for easy and secure stacking, minimizing the risk of damage and improving the overall workflow. Pallets can be easily handled using forklifts or pallet jacks, saving time and effort in loading and unloading concrete blocks.

Cost-Effectiveness and Sustainability

Using Pallets for Concrete Blocks can lead to significant cost savings in the long run. Pallets are reusable and durable, reducing the need for constant replacements. They are often made from sustainable materials like wood or composite materials, minimizing the environmental impact. Additionally, pallets allow for efficient use of transport space, reducing the number of trips required and lowering fuel consumption, further contributing to cost savings and environmental benefits.

Conclusion

In conclusion, using Pallets for Concrete Blocks offers a range of benefits that enhance efficiency, reduce costs, and promote sustainability. Pallets optimize space utilization and streamline workflows by providing a standardized base for stacking and moving concrete blocks. Their reusability and durability make them a cost-effective choice while contributing to environmental conservation. When considering transportation and storage solutions for concrete blocks, utilizing pallets proves wise and practical.

0 notes

Text

Here's What People Are Saying About Pallets For Concrete Blocks?

Pallets for Concrete Blocks are gaining popularity in the construction industry due to their numerous benefits and advantages. These specially designed pallets provide an efficient, cost-effective solution for handling, storing, and transporting concrete blocks. In this article, we will explore what people say about pallets for concrete blocks and how they are revolutionizing the construction process. In this blog, we will look at some people's perspectives on pallets for concrete blocks.

Enhanced Durability and Stability

These pallets for concrete blocks are a very useful tool for industries. Pallets for Concrete Blocks are revolutionizing the construction industry by offering enhanced durability, stability, efficiency, productivity, and environmental sustainability. One of the key advantages of pallets for concrete blocks is their exceptional durability and stability. These are constructed from high-quality steel.

These pallets, such as composite plastics or reinforced steel, are designed to withstand heavy loads and harsh environmental conditions. This durability ensures that the concrete blocks remain secure and protected during storage and transportation, reducing the risk of damage and ensuring consistent product quality.

Increased Efficiency and Productivity

Pallets for Concrete Blocks are known for their ability to streamline the construction process and increase overall efficiency. The standardized dimensions of these pallets allow for easy stacking and handling, optimizing space utilization and reducing labor costs. Moreover, their lightweight design facilitates quick and convenient transportation, enabling construction teams to complete projects more efficiently. By utilizing these pallets, construction companies can significantly enhance their productivity and meet project deadlines more effectively.

Environmental Sustainability

Pallets for concrete blocks are highly environmentally friendly, and this section will talk about some features of environmental sustainability shown by pallets for concrete blocks. Another aspect that people appreciate about pallets for concrete blocks is their contribution to environmental sustainability. These pallets are often constructed from recycled materials, such as composite plastics or reclaimed wood, reducing the demand for new resources. By opting for these eco-friendly pallets, construction companies can minimize their carbon footprint and promote a more sustainable construction process.

Conclusion

In conclusion, Pallets for Concrete Blocks are revolutionizing the construction industry by offering enhanced durability, stability, efficiency, productivity, and environmental sustainability. These specially designed pallets provide a reliable and cost-effective solution for handling and transporting concrete blocks, reducing the risk of damage and improving overall project timelines. As more construction companies recognize the benefits of using pallets for concrete blocks, they become integral to the construction process.

0 notes

Text

High-Grade Concrete Block Machine Pallets in Varied Sizes

Pallets for concrete block machines or high-grade concrete block machine pallets are designed in varied shapes, sizes and designs that you can get according to your specific needs and type of machines to use them properly. All quality standards are followed for the duration of making such machines. It will be better to check all details and get the best solutions according to your needs for the best range of concrete block machine pallets.

• These high-grade concrete block machine pallets are manufactured with different varieties of surfaces to cater individual requirements of concrete block manufacturers around the world

• Surfaces are crucial and made of using synthetic film, industrial fabric or glass fibre to offer different levels of resistance to the abrasive nature of concrete products

• Concrete block machine pallets are known for having high density in comparison to hardwood, softwood and plastic production boards for concrete blocks that ensures efficient transmission of vibration to the concrete.

There is a lot more associated with the best quality concrete block machine pallets. Choosing the best range of such machines is a crucial decision to make. There are a number of recognized names in this domain offering you the best quality pallets. Check all details and get the best range delivered to your address.

Composite Pallets is a one stop trusted name in this domain offering you the best solutions to choose high-grade pallets. You can place your order according to your specific needs and get delivery on time.

0 notes

Text

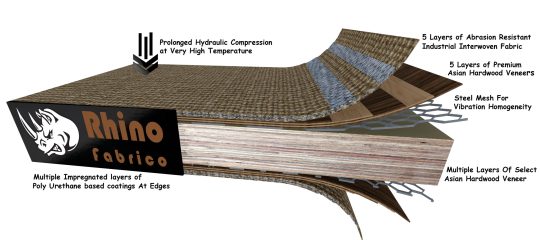

High-Grade Pallets for Concrete Blocks and Their Making Procedure

Pallets for concrete blocks are made of using plantation hardwood timber that is chosen from plantation timbers around the world with the way to ensure perpetual recurrence of vegetation. The plantation timber is grown in conducive geographical regions – ensuring that the forests are not destroyed for increasing requirement of wood.

Plantation trees are selected to ensure physical parameters of logs that go through the process of de-barking. The logs are fed into veneering machines to produce extremely thin layer of timber.

• Hardwood veneers forms the core of pallets for concrete blocks that are made by focusing on the highest quality standards. These pallets are cross laid to increase the core strength.

• Humidity optimization is next crucial point to consider in the final step of the entire process. They are stored in controlled humidifying before proceeding to next level of manufacturing.

• Waterproof synthetic resin and resin saturated fibers are other steps in the process.

• Hydraulic compression and pallet core formation are next key points to make strong pallets

Each and every step in the process is completed successfully and by paying attention to varied key points. The most crucial thing is to choose the best pallets according to your requirements and place your order directly to the top manufacturers.

Go online as it is counted as one of the convenient ways to find top manufacturers and place your order for the best range of pallets for block machines. You will find a number of top names in this domain offering the best range of pallets with a complete guide. Check all details and you will get delivery on time and right to your address.

0 notes

Text

High-Grade Pallets for Concrete Blocks in Varied Sizes and Thickness

Concrete blocks are used in the construction domain in different ways to make any structure strong and give stability to the building for long term. These blocks are designed in different patterns, styles, shapes and sizes. Choosing the best range of concrete blocks can be far easier than carry them from one place to another in convenient way. For such blocks, you need something durable, strong and in the shape to carry them easily and in convenient way. Choosing the right type of pallets for concrete blocks will be the right option to enhance your experience. Depending on your requirement, you can choose the right type of pallets for concrete blocks that are designed by keeping in mind their weight, type and size.

High-grade pallets for concrete blocks machines are designed to give them stability. These pallets are designed to last through harsh and abrasive working conditions for production of concrete blocks, pavers, and other concrete products in all types of block machines.

Pallets Are Manufactured with Different Surfaces to Cater Individual Needs

These high-grade pallets are manufactured with different varieties of surfaces to cater individual requirements of concrete block manufacturers around the world. Not to mention the surface of synthetic film, industrial fabric or glass fibre – known for offering different levels of resistance to the abrasive nature of concrete products. These high-grade pallets for concrete blocks are known for having high density in comparison to hardwood, softwood and plastic production boards for concrete blocks that ensures efficient transmission of vibration to the concrete.

They are available in all sizes with thickness up to 70mm and sometimes in other thicknesses. These pallets are manufactured in state-of-the-art hydraulic press and exclusive use of tropical plantation hardwood. Not to mention the use of fibers in manufacturing that ensures consistent quality. In this way, they outlast ordinary softwood and hardwood pallets for concrete block manufacturing. Different types of engineered surfaces are offered that ensure long life of trouble free services by the pallets.

Find Top Manufacturer of Pallets for Concrete Blocks

Depending on your requirement, you can choose the best range of pallets for concrete blocks machines and for other purposes. Pricing depends on the type of pallets you are using and getting their delivery will be far easier to your address without any delay.

For the best range of pallets for concrete blocks and machines, you need to reach the top manufacturer. Go online and it is counted as one of the convenient ways to provide you with some of the best options to choose the best one. You can place your from anywhere and get delivery to your address without any delay. Check all details and get the best range of pallets for concrete blocks.

0 notes

Text

Pallets for Block Machines and Their Benefits of Using

Pallets for block machines are designed in varied sizes and thickness to ensure strong blocks are designed. These pallets are made by following all quality standards and to make them able to stay stronger. Some of the added benefits that you will get from pallets for concrete machines include, but not limited to:

• Strong and Homogeneous with faster cycle times

• Excellent vibration transmission with minimum deflection

• One solid piece with no gapes or joints and less power consumption

• No moisture problems (even if chipped) made to regrind and refurbish

• High block density with less wear to machines and modules

In addition to the aforementioned benefits, pallets for Block machines are known for vibration stress compatibility with quick and consistent compaction and perfect plain surface with long life and hardwood fibre fortification.

There are a number of benefits and features of the pallets for block machines. They are commercially available and for uses directly from the top manufacturers. Go online and you will find a number of top names in this domain offering you the best range of pallets for block machines. Choose the best one, check all details and get the best solutions according to your needs.

You have to find the top manufacturer, know about the making procedure and leave rest of the work on experts working there. Prices are competitive and backed by some additional services.

0 notes

Text

Pallets for Block Machines In Varied Sizes – Durable and Strong Enough

Pallets for Block machines are in varied shapes, sizes and design that are sure to enhance your experience of keeping the blocks safe and secure. You can choose the best range with a user guide. They are frequently used in block and brick making industry. When the delivery of bricks and concrete blocks is done to another place, pallets are required to keep blocks unite together. Depending on your requirement, you can choose the best range of pallets for block machines and get them delivered with a complete guide. For this, the best way is to search for the top manufacturers or suppliers.

Online search will save you time and money and provide you with more options of choosing the best one. Check all details and get the best range of pallets that are durable and made of strong wooden pieces and other materials. They are safe and secure to use and come with different added features.

You can place your order for pallets for block machines and get delivery on time.

Composite Pallets Offers the Best Range of Pallets for Block Machines

Among some of the top names in this domain from where you will get the best range of pallets for block machines, you will find name of Composite Pallets on top – offering you the best range of pallets for block machines. You can place your order from anywhere and anytime and get delivery on time. So, what you are waiting for, place your order now and get delivery on time.

0 notes

Text

Heavy-Duty Concrete Block Machine Pallets Online At Discounted Rates

Concrete block machines pallets are in different sizes, design and types that you can get delivered to your address in time and right to your address. Check all details and get the best range delivered on time and in fully secure way. Online search is counted as one of the convenient ways to enhance your experience to help you in getting what exactly you are looking for.

Concrete block machine pallets are the right options to enhance your experience. You can place your order and get the best range delivered in timely manner.

Find Top Manufacturers of Concrete Block Machine Pallets

There are a number of recognized names in this domain offering you the best range of such products. They are of premium quality and come with a number of added features. All details are provided to you about the concrete block machine pallets.

Composite Pallets Offers the Best Range of Concrete Block Machine Pallets

Among some of the top names in this domain from where you can buy the best range of concrete block machine pallets, you will find name of Composite Panels on top – a one stop trusted name in this domain offering the best range of pallets for concrete block machines for their delivery in fully secure way. All details are provided to you that will be a plus point. A complete guide is provided to you so that you can understand well the use of concrete block machine pallets.

0 notes

Text

Know About the Making Process of Pallets for Concrete Blocks

Pallets for concrete blocks are the basic need required to keep blocks in a set and packed for the duration of shifting from one place to another. There are a number of benefits of using pallets. The most crucial thing is to choose the durable and strong pallets. It will be better to know about their making process.

Plantation of Hardwood Timber

Pallets for concrete blocks are designed by using hardwood sourced from varied places and transformed through a process.

Plantation for hardwood timber is done to select the best hardwood and ensuring perpetual recurrence of vegetation. Plantation timber is scientifically grown in conducive geographical regions to ensure that the forests are not destroyed for want of wood.

How Veneers Are Made

Not to mention the log processing as plantation trees are selected to ensure physical parameters of logs. The logs go through the process of de-barking and fed into veneering machines where hydraulically operated sharp bladed produce extremely thin layers of timber.

How to Form the Core of Composite Pallets

Hardwood veneers are known for forming the core of composite pallets. They must be absolutely of highest quality. Out of the veneers produced in the factory, ones with highest parameters are selected for composite pallets. They are cross laid to increase the core strength.

Not to mention the humidity of veneers that plays a very important part in the final quality of the pallets for concrete blocks. Veneers are stored in controlled humidifying chambers to achieve the desired levels of humidity before preceding the next level of manufacturing. They maintain optimum moisture during the whole process.

Waterproof Synthetic Resin Process

Waterproof synthetic resin is done to ensure consistent quality and availability of all grades of required resins for different applications. On the other side, the wooden pallets for concrete blocks use the highest grade of waterproof synthetic. Resin is the way to ensure long and trouble free life of pallets.

The resin process is done to get veneer sheets and to ensure complete fiber saturation. There are different other steps required to complete in the making process of Pallets for concrete blocks. Here, the most crucial thing is to search for the right manufacturers and place your order accordingly for the best range of pallets. Go online and it will surely save you time and money and provide you with more options to choose the best range of pallets. You can place your order from anywhere and anytime.

0 notes

Text

Buy the Best Range of Pallets for Concrete Blocks

Stock of concrete blocks needs proper care and attention to keep them free from the unexpected falling from anywhere and from varied other issues. Choosing the best range of blocks depends on varied key points. You have to search for the right type of pallets in the required sizes, shapes, and types. For this the best way is to go online and search for the top manufacturer or a supplier that is convenient for you and bringing to you the best range of pallets.

If you don’t have any knowledge or idea about the pallets for concrete blocks, you can go online and search for the top names in this domain. There are a number of recognized names in this domain offering you the best range of pallets and with a complete guide in your desired shape, size and type. Check all details and get the best range delivered to your address.

Composite Pallets Offers the Best Range of Pallets

Composite Pallets is a one stop trusted name in this domain offering you the best range of pallets for concrete blocks. Check all details and you will get the best range delivered on time and right to your address. Prices are competitive and backed by discounts; while you will get delivery on time. You can place your order from anywhere and get them delivered on time.

0 notes

Text

How Our Wooden Pallets for Concrete Block Machine Are the Best

Our Pallet blocks are free from fumigation because they are created by hot pressing. The wood waste might be recycled effectively with a pallet block machine. Our Wooden Pallets for Concrete Block Machine Pallets are very simple to use. An individual here might operate three machines.

While it is within the range, we could customize if you have certain needs. Furthermore, a single machine could produce blocks in two distinct sizes.

• How is the pallet block machine operated?

• In order to extrude and mould the materials, the hydraulic cylinder pushes the piston under high pressure.

• The solidification and moulding of urea-formaldehyde glue are encouraged by heating the heating plate at a high temperature.

• Using a specific length while cutting.

• Once the items have cooled, trim the long wood strips to the desired size.

Modern technology is used by our completely automatic pallet-free block building machines to reliably and quickly make high-quality pavers and blocks. This machine is capable of producing a variety of items, including concrete blocks, I-shaped pavers, hollow blocks, curved pavers, and block pavers. To lessen the hydraulic shock and noise and to increase overall production stability and efficiency, flexible automatic control is used throughout the entire process. Call us to learn how to expand your business with this automatic block maker in a simple and effective way.

Vibration system technical data

Servo motors power eccentric devices. The vibration force is applied to the vibration table evenly and at an extremely high rotating speed and vibration force. It guarantees the completed items' high intensity and compactness.

System of hydraulics

This system employs proportional control and Starts quickly and stops right away while feeding, moving moulds up, shifting mould boxes, etc. To lessen the hydraulic shock and noise and to increase overall production stability and efficiency, flexible automatic control is used throughout the entire process.

0 notes

Text

Why Hardwood Pallets for Concrete Block Machine Is Useful

The process of moulding blocks using a concrete block manufacturing machine or a big, fully automated concrete block production line, using a pallet as a carrier for loading the wet blocks once the block is demoulded. Pallets are also extensively utilised during the block curing process. Many different types of block machine pallets have been developed by our Hardwood pallets for concrete block machine through decades of innovative research and development, and among the best are the wooden pallet, PVC plastic pallet, bamboo pallet, bamboo-PVC surface and edge covered pallet, and glass fiber pallet.

Block machine wooden pallet

The boards are the primary components of wooden pallets. The wooden block machine pallet has the qualities of bending strength and lower density and this kind of wood block pallet is lightweight and liked by buyers of block machines.

In the production of wooden pallets, we use special methods and techniques. Three or four pieces of fastening screws and rods are placed for reinforcement of the pallet between each lath of the wood board using male and female slot joints. The wooden block pallet also has channel steel covering and protection at both ends. With the aforementioned unique design, the wood pallet achieves exceptional strength and endurance throughout the manufacture of concrete.

A typical pallet's opening glue and losing edges is broken by the core layer of the pallet, which is made of bamboo chips and particles. Our pallet performs well when it comes to bonding. The tested average bonding strength of the new generation which is more than twice that of the industry standard. Compared to other pallet materials, it has a significantly higher strength. Additionally, the pallets are developed and manufactured in strict agreement with the concrete block manufacturing industry in terms of their longitudinal and transverse static bending strength and elastic modulus.

#Hardwood pallets for concrete block machine#Pallets for Concrete Blocks#Concrete Block Machine Pallets

0 notes