#Cone Joint Tube

Text

Choosing Marijuana Packaging Polypropylene Cone Joint Tube

Polypropylene is a translucent material, allowing consumers to visually inspect the contents of the tube without opening it. This transparency is advantageous for both producers and consumers, as it enables quality control and product visibility. Many regions mandate child-resistant packaging for cannabis products. Polypropylene cone joint tubes can be manufactured with child-resistant features, such as push-and-turn caps or squeeze-and-pull mechanisms, ensuring compliance with safety regulations.

Maintaining the freshness of pre-rolled joints is crucial for customer satisfaction. Polypropylene cone joint tubes often come with airtight seals, preventing moisture and air from affecting the product's quality. This feature contributes to the longevity of the cannabis and its potency. Polypropylene is easily customizable, allowing manufacturers to print branding information, product details, and compliance labels directly on the tube. This enhances brand visibility and helps consumers make informed choices.

0 notes

Text

#pre roll packaging#pre roll boxes#pre roll tubes#pre roll bags#pre roll cone packaging#joint cone packaging#custom pre roll packaging#preroll packaging

1 note

·

View note

Text

blunts and parks

synopsis; you went to phoneix, arizona for your fifeteen brithday trip. being blown off by your so called bestfriend opens now doors and new friends.

pairing- madeline mcgraw, mason thames and miguel cazarez mora x gn reader.

____

here i am, currently waiting for my bestfriend, junior, to meet me at the park. it feels as if its 113 degrees but it was only 94 with no wind and straight sun. it probably wasnt the best idea to go phoneix in the middle of the summer. i look out to see if he is atleast at the park. instead of seeing him i see a group of 3 of familier faces walking around. its was 2 boys around the same height and a girl that looked no younger then 14. the buzzing from my phone snapped me out of my thought. i answered it already knowing a who would be on the other line.

"yo im staying with valerie for the rest of the day" i could hear a girls voice in the background talking about money to go somewhere. "what was the point of bringing you on my brithday trip" i mumbled. "we can hang out later. i gotta go." his usally loud voice was smaller. then there was slinence. groaning i look around again, im on the swings covered with some shade i found. i find the small group by the tables near me, their backs facing me. i started to rummage in my jackets pocket, knowing what to do to make me feel better.

pulling out the small tube i always carry around along with my lighter and airpods. putting in my right airpod and turning on whatever playlist that i was listening to last started to play. thinking about the group again before popping open the top. i slowly started to get up from the swings, i headed my way towards the small tables. the closer i got the more i was able to hear the voices. it started to mush with the song i was listening to. "sorry but do yall care if i light this? its a blunt" my voice a little raspy due to not having any water on me.

the trio looked at me then back at eachother before the girls nods speaking, "yeah we dont have a problem with it." giving them a small smile "thanks," i walked back to the swings. thinking about the group again, i had forgetton my glasses while packing so it was hard to see even if i was up close. i couldnt quite make it out but they looked familiar. the girl, who i mostly looked at reminded me of the actress Madeline mcgraw, the girl who played gwen in the black phone movie.

pushing whatever i was thinking about to the side so i could focus on the cone shape pre-roll. igniting the red lighter, i rotated the joint in the fire. i brought it up to my lips and took a hit. inhaling and then exhaling. i focused on the song that just started playing, pink + white by frank ocean. i started to inhale again only to be stopped seeing a shadow figure walking up to me. i grabbed my phone and turned it down a little, loooking up i was met with the same girl from before. "hi im maddy and me and my friends were wondering if you would like to join us? the suns getting a lil stronger." she pointed towards the table she was sitting at. "oh uh sure, and im (name)" as soon as i got up to stand i realized how hot it actually was, the heat was overwhelming. "should i put this out or do you guys wanna smoke it with me?" i asked as we both got closer to the park table. "if you teach us how, sure!" her smooth voice stayed upbeat.

i took the free seat next to the tan boy with long dark wavy hair. "mason, miguel this is (name), (name) this is mason and miguel." suddenly it snapped, they were the actors from the black phone. the 2 boys said lil hi's. i took another big hit, then tapping it so the ash falls off. i look at mason, since he was on my left infront of me. "well mason do you wanna hit this?" he thought about it for a moment then nodded his head.

"so how do i do this?" his brown eyes looked at me for help. "so you just suck on it till you get enough smoke and then you take another breathe to actually inhale it." i tried repeating what my older brother taught me a while back. seeing succesfull as he exhaled a cloud while coughing. he handed it to maddy while still trying to catch his breath. holding back my luaghter i remembered the first time i smoked. i look over at maddy and she seemed pretty hesitant, "its okay if you dont wanna," i told her she looked at me then at her hands. she brought it up to her lips and took a breath. she exhaled same as mason except she was able to control her breathing a bit better. she passed to miguel, and when he exhaled he was fine. i figured maddy and miguel did better since they were in some type of sport or exercise.

when i was passed the blunt they stared at me. i took a hit normally and exhaled normally. i started to feel a wash of an euphoric state take over me. i could already tell mason was high. his eyes were red and glossy. i hinted at him to take it but he nodded his head side to side. i did the same with maddy and she took it. "so are you from here?" miguel asked. "nah im here cause its my brithday trip. but im from las vegas," maddy raised her brow "why are you alone on your brithday trip?"

i was handed the joint again, "me and my friend, junior were supposed to hang out today but he bailed on me to stay with his girlfriend." shrugging while i spoke. "thats a dick move." mason snipped quickly. i agrred with him, i did pay for juniors ticket and hotel room. we stayed like that for a while. luaghing and coughing. "(name)!" our peaceful moment interrupted by a forgien voice.

i looked behind me to see a girl with curly brown skin and deep brown skin. valerie, juniors girl. i never officially met her, as she and junior were long distance. "valerie? what are you doing here?" as i got up to hug her. while i didnt know her face to face we have talked one in a while. "junior said we were meeting here today to hang out with you." her voice held some confusion while my head wasnt even processing. "he told me that he was hanging out with you for the rest of the day. you were there when he called me?" i became genuinely confused.

"i havent even seen him today, so hes spending a dat with someone he lied about being his girlfriend?" her voice was hurt while her face was stotic. "oh-" "i cant beilieve he's putting me through this agian" her usal confident voice gone, becoming bitter more as she spoke. she pulled out her phone and calling who i would imagine was junior. she stromed off into her car for some privacy.

"what the hell" i looked back at the intoxicated teens next to me and they laughed, i shrugged it off. "how old are you turning (name)?" mason asked his eyes werent red anymore, but still glossy. "fifteen" miguel turned his head towards me with a semi-shooked face. "i thought your were like eighteen, you look so much older" the other two nodding their head in agreement. my phone started to buzz again. answering it automatically i was greeted with junior yelling. "WHAT WERE YOU THINKING TELLING VALERIE THAT I WAS WITH ANOTHER GIRL?"

"its your own fault for using me as an excuse junior, plus its on you for cheating." he began to yell again but i didnt see the point of talking to him, so i hung up. "i should be leaving soon, it was nice meeting yall" giving them all a smile. "we should hang out again," maddy said. "here give me your number and ill send it to the boys" maddy extend her hand to me, her phone dail already open. swiftly putting my number in along with my name, i gave it back. "call me when yall wanna hang out" i gave a small wink and walked away.

#the black phone x reader#mason thames#miguel cazarez mora#madeleine mcgraw#maddy mcgraw#mason thames x you#mason x reader#miguel cora x reader#the black phone x you#platonic#fluff#x gender neutral reader#the black phone x gn reader

53 notes

·

View notes

Text

What are the 3 Basic Types of Brass Fittings?

Brass fittings play a crucial role in plumbing and industrial applications, providing a reliable and durable connection for various systems. As a leading manufacturer and supplier of brass fittings, it's essential to understand the basics of these essential components. In this blog post, we will explore the three basic types of brass fittings, their applications, and the advantages they offer.

Understanding Brass Fittings

Brass fittings are widely used in plumbing and industrial settings due to their excellent corrosion resistance and durability. They are typically made from brass, an alloy of copper and zinc, which provides strength and malleability. Brass fittings are available in various shapes and sizes, making them suitable for a wide range of applications.

The Three Basic Types of Brass Fittings

1. Compression Fittings

Compression fittings are a popular choice for connecting pipes and tubes in plumbing systems. They consist of a body, nut, and sleeve, which are used to create a tight seal around the pipe. Compression fittings are easy to install and disassemble, making them ideal for applications that require frequent maintenance or repairs.

2. Flare Fittings

Flare fittings are commonly used in gas and high-pressure fluid applications. They feature a cone-shaped connection that seals the fitting when tightened, ensuring a secure and leak-free joint. Flare fittings are known for their resistance to vibration and high pressure, making them suitable for demanding industrial environments.

3. Threaded Fittings

Threaded fittings, also known as pipe fittings, have threaded connections that allow them to be screwed onto pipes or other fittings. They are versatile and can be used in a wide range of applications, including water, gas, and oil systems. Threaded fittings are available in various configurations, such as elbows, tees, and couplings, providing flexibility in designing and assembling plumbing and industrial systems.

Applications and Advantages

Each type of brass fitting offers unique advantages and is suitable for specific applications. Compression fittings are commonly used in household plumbing systems, while flare fittings are preferred for gas and high-pressure fluid systems. Threaded fittings, on the other hand, are versatile and widely used in various industries.

Brass fittings are favored for their corrosion resistance, durability, and ease of installation. They can withstand high temperatures and pressures, making them suitable for demanding environments. Additionally, brass fittings are known for their aesthetic appeal, making them a popular choice for visible plumbing installations.

Conclusion

Brass fittings by Instrumxx Industries are essential components in plumbing and industrial systems, providing reliable connections and leak-free performance. Understanding the three basic types of brass fittings – compression fittings, flare fittings, and threaded fittings – is crucial for selecting the right components for specific applications. As a leading manufacturer and supplier of brass fittings, it's important to offer a diverse range of fittings to meet the needs of various industries and applications.

By providing high-quality brass fittings and expertise in their applications, manufacturers and suppliers can contribute to the efficiency and reliability of plumbing and industrial systems, ultimately benefiting their customers and end-users.

0 notes

Text

What Do You Need to Know About Hyperdontia?

Hyperdontia is a dental condition that involves the loss of teeth, often causing discomfort and difficulty in daily life. It can be diagnosed, treated, and managed to alleviate symptoms.

What is Hyperdontia?

Hyperdontia, also known as extra teeth, refers to overcrowding of teeth in the mouth, often referred to as extra teeth. This occurs in dental arches, where the first 20 primary teeth erupt during childhood, followed by 32 permanent teeth. Extra baby teeth are more common in cases of hyperdontia.

What are the symptoms of Hyperdontia?

An important indicator of hyperdontia is the emergence of supplementary teeth, which frequently erupt in close proximity to your natural adult or baby teeth. This typically affects adults, and it entails recognizing these supplementary teeth by their distinct forms and locations within your oral cavity.

In hyperdontia, supplementary teeth can take on a variety of forms, such as:

In addition. These teeth share an appearance with the teeth next to them.

Tuberculous teeth: These teeth have a barrel or tube form.

A complex odontoma is a tooth composed of numerous tiny growths that resemble teeth that are grouped together.

Compound odontoma: An region of tissue containing structures resembling teeth arises in place of a single tooth.

Teeth with a cone or rod shape are wider at the base and narrower at the tip.

Additionally, extra teeth can develop in a variety of places, including:

Premolars are additional teeth that erupt in the back of your mouth next to your molars.

What are the causes of Hyperdontia?

Although the precise etiology of hyperdontia is unknown, a number of hereditary or genetic disorders are frequently associated with it. These conditions include, among others:

Gardner Syndrome: An uncommon hereditary condition that can cause tumors to grow in the intestines and skull as well as skin cysts.

Ehlers-Danlos Syndrome: An genetic condition that can cause scoliosis, fragile skin, weak joints that dislocate easily, and pain in the muscles and joints.

Fabry's syndrome: This illness can result in an acrid or blue skin rash, painful limbs, abdominal pain, and a lack of perspiration.

Orofacial Clefts: These are disorders that cause openings in the roof of the mouth or the upper lip, such as cleft palates and lips. They may result in trouble speaking and eating, as well as a higher risk of ear infections.

Claviculocranial Dysplasia: Distinguished by abnormal growth of the collarbone and cranium.

At what age can supernumeraries be drawn?

The child's developmental stage determines the appropriate age for extraction of more teeth.

Extra teeth are usually extracted throughout adolescence, when the mouth and face have fully developed. But, if the extra teeth are interfering with function or appearance, the extraction may need to be done even earlier in certain circumstances.

When to intervene in the case of small children?

Monthly check-ups are recommended for children with delayed dental procedures. Consult a dentist for comprehensive evaluation of dental arches to determine the best course of action to prevent impacted teeth from affecting healthy teeth eruption and offer appropriate remedies. Contact your child's dentist for any dental issues.

Life with Hyperdontia

Hyperdontia can lead to normal life without treatment, but some individuals may need to remove extra teeth to prevent future issues. It's crucial to inform your dentist of any pain, discomfort, swelling, or oral concerns.

Hyperdontia is a rare dental disorder characterized by the presence of extra teeth in the mouth, often linked to inherited disorders. Diagnosis is straightforward, and treatment options range from no action to extraction. Regular check-ups and open dental contact are crucial for maintaining good oral health in hyperdontia patients.

To get full details, read the full blog : https://www.dramarnathansdentalcare.com/what-do-you-need-to-know-about-hyperdontia/

For More Tips & Details Visit

Website: https://www.dramarnathansdentalcare.com/

Facebook: https://www.facebook.com/people/DrAmarnathans-Dental-Care/100063667464980/

Twitter: https://twitter.com/dramarnathan

Instagram: https://www.instagram.com/dr_amarnathans_dental/

0 notes

Text

Session 14: Extinction Burst

Chapter 5 of A Life Alone, Rated M

CW: drug use, Geralt's persistent use of ableist and judgemental language around himself

“How are you doing, after last week? That was a lot.”

“I…don’t know,’ Geralt admits. “Off. Keyed up, distracted. I’m not sleeping well, and it’s making me…I’m really easily frustrated.” Angry, really. Even angrier than normal. The world seems like too much, too frustrating, too stupid and loud and constantly trying his last fucking nerve. The shaky, pent up energy in his limbs feels like it’s about to burst out of him in something awful.

“Hmm,” Nenneke nods sympathetically. “What kinds of things do you do for fun? How are you taking care of yourself?”

“Uhh,” he fumbles around for a moment. It probably shouldn’t be so hard to think of things that he enjoys doing. “I enjoy training, on my own at the gym and sparring. Riding, obviously.”

Sex, he doesn’t say. Not that he’s getting any, anyway. He honestly hasn’t wanted to seek out a new relationship or even a one night stand.

“Using your body can certainly help to still your mind, take you out of your spinning thoughts. How about meditation, listening to music, watching movies, trashy TV, jigsaw puzzles, model airplanes– what do you do to relax?”

Geralt snorts, glancing away with a wry smirk. Well.

Despite the cold Geralt stood barefoot on the tiny balcony of his apartment, determined to turn his brain off by whatever means necessary. In this case that meant stopping at one of the dispensaries that were suddenly everywhere and buying a pre-roll that he was sucking down with intense focus, methodically holding the smoke in his lungs as long as he could in between hits. It’d been many years since the last time he’d smoked, and the burn of it in his throat felt strange.

He didn’t notice at first just how restless he was, shuffling his weight ceaselessly back and forth on the ancient, crumbling concrete that stuck to the bottoms of his frozen feet in sharp little chunks of gravel and grit, fiddling with the lid of the bougie plastic tube that joints apparently came in now. He was bemused by the perfectly rolled, tight cone complete with a filter when it had fallen out into his palm. Had marveled at the label bearing more provenance and fiddly detail than a fucking wine bottle, remembering instead the half crushed, lumpy blunts in thin ziplock bags that his college friends used to buy from some guy down the dorm hall.

He felt old. Old and broken down, a nearly-forty year old man huddled in a ratty hoody standing on his balcony watching the curls of smoke and warm breath rise in front of his mouth and into the weird orange light of the streetlights, unable to deal with his own racing thoughts. Pathetic. He’d abandoned the plastic tube in his hoodie pocket at some point in favor of worrying his thumb over the greasy-sticky residue of the torn price sticker of his pilfered lighter. It was printed with palm trees on a sandy beach and he had no idea where it had come from.

Did anyone ever buy a new lighter? Did they choose one of these trashy, lurid designs because it spoke to them in some way? Surely someone had to, but in Geralt’s experience lighters were always picked up from some bar table, or left behind on your porch by some nicotine-addicted friend. Someone had to start the cycle, though, to set them circulating in that never ending loop of abandonment and retrieval.

He decided with relief that the fact he was wondering about this at all was a sign that the high was kicking in, and let himself relax into the floaty haze of it as he sucked down the last acrid lungful. He was still rubbing over the smooth, curved surface of the lighter, but it felt meditative now rather than twitchy. He rubbed his feet absently against his calves to get the concrete bits off and stepped back into the warmth of his apartment feeling hopeful he might actually find sleep tonight.

He should have known better. He was still awake to feel the last edges of the high fade away, watching the clock tick over 2 A.M. with bleary, bloodshot eyes, and didn’t do more than drift restlessly before his alarm woke him for good with a harsh buzzing at 6:00.

Continue on Ao3

#my fic#A Life Alone#Geralt had an intense breakthrough last session#but recovery isn't linear and sometimes things have to get worse#before they can get better

0 notes

Text

How to solder copper pipes

While there are many DIY or repair projects that are best left to trained and experienced professionals, soldering and replacing copper pipes in your home doesn't have to be one of them. The brazing process looks a bit intimidating as a DIY project for beginners, but it's a fairly simple process as long as you follow a few basic instructions.

Prepare the pipes and fittings

Before you begin this project, be sure to put on safety glasses.

Cut the pipes to length

Clamp the pipe between the cutting wheel and the guide wheel of the pipe cutter. For longer pipes, clamp the other end under your knee to keep it stable.

Rotate the pipe cutter to cut the pipe all the way around

Tighten the knob of the pipe cutter by a quarter turn. Score the pipe all around again; this will create a slightly deeper score line.

Tighten the cutter knob another quarter turn and score the pipe a third time. Continue tightening and scoring the tube until it breaks off; this takes about eight turns.

Clean and flux the pipes and fittings

Use the deburring tool or wire brush to deburr the inside of the pipe. A burr is a small copper bulge that forms when the pipe is cut and pressed into the pipe. If you do not remove it, it can impede the flow of water through the pipe or cause leaks.

Use emery cloth, sandpaper or steel wool to clean the outside of the pipe and the part of the fitting that connects to the pipe. When clean, the pipe should be shiny. Once this is done, do not touch the pipe with your bare hands so that you do not leave body oils on the surface. This can interfere with the curing of the solder and cause leaks.

Solder pipes and fittings together

Put on the heavy gloves before you start these steps, and make sure you are still wearing eye protection.

Cover all flammable surfaces near your work area with a fire blanket.

Light the propane torch with the built-in igniter.

Hold the torch so that the tip of the blue flame cone just touches the fitting. Move it back and forth to heat the fitting evenly. You don't need to heat the pipe with the torch; the heat from the fitting will take care of that. You should hear the hiss of the flux as the metal heats up.

Place the end of the solder wire at the joint, on the opposite side of the terminal from the torch flame. As the metal gets hot, the wire will liquefy and flow into the joint to fill the space.

Call the Emergency Plumber in Luton. We are your right contact partner. Call us whenever you want, 01582323084.

0 notes

Text

Brasil XCMG SPARE PARTS wheel loader road roller motor grader excavator

380901027 SILENCIADO GR1803

803360084 BRAKE CABLE SELENOIDE DE PARADA LW180

803690790 BRAKE SWITCH BOTÃO DE PARADA

803666709 KEY IGNITION CHAVE DE IGNICAÇÃO

803543240 STARTING BUTTON BOTÃO

380601513 JOINT BALL JUNTA ESFERICAS

380901141 CIRCULAR BOX REDUÇÃO GIR DE LAMINA

380501086 FRONT NEXT

380501088 REAR COXIM

380900920 BOTTLE

380900921 RING

860101074 RING

380900925 FLANGE

380905147 PORK

380905025 FRONT AXLE BOTTLE LD

380905026 FRONT AXLE GARFO LE

380901130 FRONT WHEEL CUBE

380901930 FRONT WHEEL

800106653 WHEEL TAMBOR

800107316 DRY TANDEM AXIS

380901118 DRUNK

800356298 Axle

800554584 ROLLING

275400006 Axle

803196026 RING

275400079 DOUBLE ENGINEERING

801139890 SEAL RING

801138397 SEAL

801138308 RETENTOR

275301382 CJ AXIS REDUCTION

275301406 BRAKE PISTON

275301407 MOLA

228300680 ALAVANCA

803686635 ARROW INTERUPTOR

228700567 HYDRAULIC RESERVATION

803683104 CONTROL SOLENOID

803004448 MOTRIZ BOMB

803004378 GLASS PUMP

803080674 Shock absorber

803548383 COMPREESOR

803587085 CONDENSATOR

800101668 HELICE XS122

801737245 AMOTORCEMENT

312701595 FRONT NEXT

312602008 CENTRAL COXIM

800154217 Silent

310712002 POINT

800151253 ASSEMBLY

803080548 HELICE

800162880 ECM MODULE

803098254 BRINCIPAL PUMP

860159506 SAFETY VALVE

860159507 SAFETY VALVE

860159508 CONTROL PILOT

860159512 CUTTING VALVE

860159513 FOOD VALVE

803403439 JOINT GIRATORY

414104964 STICKER REPAIR

800305441 ASSEMBLY

800155641 Silent

310503332 SEAL BOTTLE

801971215 SEAL

414100958 DRIVER ARO

414105012 REPARO KIT

803403467 JOINT GIRATORY

860514811 RING

860514812 RING

860514813 RING

860514814 RING

860515477 RING

910301900 CONNECTION

910300397 ABRAÇADIRA

801095542 COXIM

860159389 SOLENOID

329900940 PARAFUSO

860152945 Silent

860152824 VARTATE LEVEL

860115772 CJ ROAD RETUDOR

803045250 HYDRAULIC PUMP

252100847 JOINT BOMB

803070678 REPAIR CIL CENTRAL

803070679 Lateral CIL REPAIR

860102757 REPAIR CIL DIRECTION

860145867 SAFETY VALVE

860145869 VALVE

860145868 VALVE

860146620 SAFETY VALVE

800901161 AUXILIAR CYLINDER

800901158 Brake pedal

801701502 Shock absorber

860143195 CONDENSATOR

860142671 SELLER

252611078 Silent

252611075 SILENT TUBE

252608114 BLOCK CONTROL

860152907 POLIA

860142253 Silenciador Lw180

860142294 ALTERNATOR LW500BR

860142302 UNDERSTANDER COMPRESSOR DE AR LW180

272200526 BRAKE LW180

272200527 FLANGE

803043388 PUMP TRANSMISSION

860141919 BRAKE PATTERN

860141921 PISTON

860141922 RETENTOR

860141920 RING

800354589 CARDAN

800354603 CARDAN

800354605 CARDAN

800360553 CARDAN

860141928 CRUISE

803043375 MAIN BOMB

803043439 PRIORITY VALVE

803079886 ORBITROL

860142738 SAFETY VALVE

860141144 REPAIR OF COMMAND

860142018 CONDENSATOR

860147164 TURBO

860140353 ALTERNATOR

860166481 ENGINE ECU

860132919 PUMP TRANSMISSION

402207432 Silent

801902798 TAMBOR COXIM XS123PDBR/XS122PDBR - 84314929 - PARALELA

819947638 XT870 WITH BRAKE - ORIGINAL

251702785 RESPIRE - ORIGINAL

329900857 POWDER RETENTOR - ORIGINAL

28562 Brake Ring XT870 - PARALELA

28500 O-PARALLEL

800340255 PARAFUSO SAPATA XE215 - 73181500 - PARALELA

143874 BRAKE DISC - PARALELA

381600469 MOTORCYCLE LAMP - 84314200 - PARALELA

350669 BARRA S/ TERMINAL - ORIGINAL

402205546 SEAL RING - ORIGINAL

310600273 O-Ring Ring - 40169300 - ORIGINAL

803172436 SEAL RING - 40169300 - ORIGINAL

329900858 Dust Retainer - 40169300 - ORIGINAL

251900441 O-RING - ORIGINAL

860140383 BRONZINE - ORIGINAL

860145658 ANEL CONE - ORIGINAL

329900654 ADJUSTMENT PANTS - ORIGINAL

803172437 SEAL RING - 40169300 - ORIGINAL

860101377 BOBBY PANTS - ORIGINAL

802103356 FOR BRISA XE215 - 70072100 - ORIGINAL

803548423 GLASS PORTA LE - 70071100 - ORIGINAL

800901152X LIQUID PUMP - ORIGINAL

803548025 SENSOR LEVEL - ORIGINAL

329900661 ADJUSTMENT PANTS - PARALLEL

329900666 WINNIL ADJUSTMENT PANTS - PARALELA

801968378 Rubber Shock Absorber - Original

228302284 DRYED GLOVE FOR VIBRATION ENGINE - ORIGINAL

402204848 BOTTLE TUBE - 40093100 - ORIGINAL

800145136 DRIVE 3289930 - PARALELA

402100811 ANNEX ARRUELA - 73182200 - ORIGINAL

800511349 ROLLING - 84828000 - ORIGINAL

800515216 NEEDLE ROLLING - ORIGINAL

803172505 SEAL RING - ORIGINAL

803548424 GLASS PORTA LD - ORIGINAL

860147448 GLASS MACANETA - 83012000 - ORIGINAL

380901068 DIRECTION TERMINAL LE - 84314929 - ORIGINAL

860140384 BRONZINE - ORIGINAL

402201160 TRANSMISSION OIL VARTET XT870 - BR-I - ORIGINAL

402205547 ABRAÇADEIRA - 73182200 - ORIGINAL

800302307 CORREIA AIR CONDITIONADO XS123 - 40103200 - PARALELA

803670694 SENSOR - 85364100 - ORIGINAL

380901101 DIRECTION TERMINAL LD - ORIGINAL

802138566 SEPARATE PLATE XT870 - 84314929 - PARALELA

380901112 HASTE STRIPATOR - ORIGINAL

329900704 VINYL ADJUSTMENT PANTS - 73182200 - ORIGINAL

800105353 COXIM DE RURRACHA - 40169990 - ORIGINAL

803593386 CONDITIONAL AIR COMPRESSOR - ORIGINAL

226803402 TEMPERATED GLASS ROLL - ORIGINAL

803590105 AIR CONDITIONING CORNER (CAN USE 803548362 OR 803593416) - (CAN USE 803548362 OR 803593416) - ORIGIN

803608668 STARTING ASSISTANCE RELE - ORIGINAL

228700310 FITTING CHAP - ORIGINAL

252100222 COXIM - ORIGINAL

380900928 RING - 84314929 - ORIGINAL

380900929 ROTULA - PARALELA

800107361 BRAKE SHOE - 84314929 - ORIGINAL

800305382 HYDRAULIC PUMP ACOPLAMENTO - 84836090 - ORIGINAL

800341137 LOWER ROLLET - 87089990 - PARALELA

801140276 OIL SEAL - 40169300 - ORIGINAL

801937939 COXIM MOTOR MWM - ORIGINAL

803202249A ARM SEAL KIT - 40169300 - PARALELA

803687892 PRESSOSTATE - 85365090 - ORIGINAL

805400029 RETENTION RING - 73182900 - ORIGINAL

860514391 ASSEMBLY SF-125K-195 - PARALLEL

819909125 ALTERNADOR CORREIA XE150 - 40103900 - ORIGINAL

227000326 PARABRISA XS123BR - ORIGINAL

252700253 INTERCOOLER HOSE ZL30BR - ORIGINAL

800154207 OIL LEVEL INDICATOR - 90261029 - ORIGINAL

801905482 CABIN COXIM - 84314929 - ORIGINAL

803611915 STARTING RELEASE - 85364100 - ORIGINAL

803678323 GENERAL INTERRUPTER - 85365090 - ORIGINAL

860141484 REPAIR KIT XY150GDG - 40169990 - ORIGINAL

275400044 MOTOR AXIS - 84314929 - ORIGINAL

801737166 GAS MOLA - 87082999 - ORIGINAL

802133931 DOOR CLOSE XE150BR, XE215BR - 84314929 - ORIGINAL

803302709 MANGUEIRA - 40092210 - ORIGINAL

803684468 ELECTROMECHANICAL TYPE RELEASE - ORIGINAL

860140886 TRANSMISSION BOX CONTROL DEVICE - MODEL - 6009010001 - ORIGINAL

860145652 ARRANGE ENGINE - ORIGINAL

910602739 REPARO DO GIRO - 40169300 - PARALELA

226803403 GLASS PORTA LD - ORIGINAL

228300469 228300469 - ORIGINAL

381600374 DISPLAY - 73181900 - PARALELA

402205066 EXHAUST TUBE - 84314929 - ORIGINAL

402205545 ARRUELA - ORIGINAL

414100960 MOLA TENSORA - ORIGINAL

414102489 CURRENT - PARALELA

801736972 Shock Absorber - ORIGINAL

803090243 BRAKE PUMP XT870BR - ORIGINAL

803202248 KIT REPARO LEVANTE - 40169300 - PARALELA

803202249 ARM REPAIR KIT - 40169300 - ORIGINAL

803370253 OIL LEVEL INDICATOR - 90261029 - ORIGINAL

803504812 CONDENSATOR - 84314929 - ORIGINAL

803544182 PRESSOSTATE FOR REGULATION - 90262090 - ORIGINAL

803604579 BATTERY INTERRUPTER - 85365090 - ORIGINAL

803611303 POTENCIOMETER 24V - 85333910 - ORIGINAL

803611480 RELE SET - ORIGINAL

803682401 WORK HEADLAMP - ORIGINAL

860132747 BOX ROLLING - PARALLEL

860141485 REPAIR KIT XY150GCD - 40169990 - ORIGINAL

914901387 REPARO ESTABLIZADOR XT870 - 40169300 - PARALELA

252611022 PARKING BRAKE SYSTEM - 87083090 - ORIGINAL

252802726 SILENCER SET - 400K(DC)IV 1.2 - ORIGINAL

860140408 WATER PUMP RING - ORIGINAL

226802493 FRONT GLASS LATERAL LD - ORIGINAL

226802495 BACK GLASS - ORIGINAL

227000331 GLASS DA PORTA LD - PARALELA

227000336 RIGHT SIDE GLASS XS123 - ORIGINAL

227000337 LEFT SIDE GLASS XS123 - PARALEL

228300740 SUPPORT - PARALLEL

228300804 MANGUEIRA - 40093100 - ORIGINAL

228302658 RADIATOR PROTECTOR - ORIGINAL

228302890 EXCENTRAL AXIS RIGHT - ORIGINAL

228700356 Exhaust exit junction joint - 40169300 - PARALELA

228900625 BATTERY BOX - 73043910 - PARALELA

251900192 ORBITROL 4 WAYS ZL30BR/XT870BR/XS122PDBR - ORIGINAL

252900681 FRONT FRONT GLASS - ORIGINAL

252910807 RIGHT SIDE SUPERIOR GLASS - ORIGINAL

380602032 GLASS DOOR GR1803BR - 70071100 - PARALELA

380900930 GR1803BR MOTOR WHEEL SET - ORIGINAL

402204850 RETRO WASHER WASHER XT870BR - 40092290 - ORIGINAL

402204851 RETRO WASHER WASHER XT870BR - 40092290 - ORIGINAL

402206247 LOWER DOOR GLASS LD - 70071100 - ORIGINAL

800105314 SELLER XE150BR - 84149020 - ORIGINAL

800154340 HELICE - 84145990 - ORIGINAL

800160250 HELICE XT870BRI DEUTZ - 84314929 - ORIGINAL

800302267 TRANSMISSION ZL30H - 84834010 - ORIGINAL

800358167 CJ ACCELERATOR CABLE - 84314929 - ORIGINAL

800511343 ROLLING - 84825010 - ORIGINAL

800546516 CROWN OF GIRO - ORIGINAL

801138731 OIL LEVEL INDICATOR - 90261029 - ORIGINAL

802103364 GLASS LATERAL LD - PARALELA

802138348 LEFT BACK GLASS - PARALLEL

803009438 DRIVER PUMP - ORIGINAL

803073165 VALVULA DE ALIVIO - 84814000 - ORIGINAL

803074804 PILOT BOMB - PARALELA

803201536 ZL30 LOAD PILOT OIL SUPPLY BLOCK - ORIGINAL

860118574 MARCH SELECTOR - ORIGINAL

860141465 REPAIR KIT - 40169990 - ORIGINAL

860147412 HELICE LW 300 KV - 84145990 - ORIGINAL

860148276 KIT REPAIR CYLINDER - 40169990 - ORIGINAL

860167740 TURBINA DEUTZ - ORIGINAL

380900977 MANGUEIRA

380900979 MANGUEIRA

860143082 CONDENSADOR

380501362 LUZ TRASEIRA ESQUERDA

380501361 LUZ TRASEIRA DIREITA

801541034 ESPELHO RETROVISOR

380602062 ESPELHO INTERNO

803545918 PAINEL DE CONTROLE

801535996 MANOPLA DE TRAVA DA COLUNA

800347389 EIXO

380501176 ESCADA

803543267 FAROL DIREITO

803543266 FAROL ESQUERDO

803546714 LUZ DE TRABALHO INFERIOR DA CABINE

801504198 MANOPLA

800346773 FLANGE

275400005 RESPIRO DO DIFERENCIAL

860143078 EVAPORADORA

803084013 REDUTOR ROTATIVO - MOTOR HIDRÁULICO DE GIRO

860162453 VÁLVULA DE SEGURANÇA - SOLENÓIDE

802138294 MAÇANETA EXTERNA DA PORTA

803079963 MANOPLA DO JOYSTICK - CONJUNTO DE ALAVANCA

803084012 BOMBA PRINCIPAL

803544198 LUZ DA LANÇA

803588822 MONITOR ELETRÔNICO

819954002 COMPRESSOR DE AR CONDICIONADO

803011945 MOTOR DE VIAGEM

310503515 MANGUEIRA DE BORRACHA

310503512 TUBO DE ÁGUA DO MOTOR

310503511 TUBO DE ÁGUA DE ENTRADA DO MOTOR

310503513 MANGUEIRA DE BORRACHA

310503516 TUBO DE ÁGUA

800105346 MANGUEIRA DE BORRACHA

800158738 TURBOCOMPRESSOR

800158730 BOMBA DE ÁGUA

310604937 VALVULA DE PILOTO DIREITA - JOYSTICK COMPLETO

802138312 BRAÇO DE LIMPADOR DE PARABRISA

310706112 PEDAL

310604094 BOMBA PRINCIPAL

310706997 ESPAÇADOR DA HÉLICE

860514451 JUNTA DA TAMPA DE VÁLVULA

800146949 JUNTA DO CABEÇOTE

860514452 MEDIDOR DE NÍVEL DE ÓLEO

800153513 MOTOR DE ARRANQUE

803546768 COMPRESSOR

800146099 TERMOSTATO

800153515 BOMBA DE ÁGUA

800147172 BOMBA DE COMBUSTÍVEL

803504810 EVAPORADORA

803504814 PAINEL AR CONDICIONADO

801905564 ARRUELA DE AJUSTE

803173452 VEDAÇÃO

803176607 ANEL ORING

312600236 PLACA DE FRICÇÃO

312600230 ESPAÇADOR

312600235 PRATO

803172462 ANEL ANTI POEIRA

819908697 ARRUELA DE AJUSTE

819908698 ARRUELA DE AJUSTE

801905558 ARRUELA DE AJUSTE

803172590 ANEL ANTI POEIRA

801905474 ESPELHO

803504605 LUZ DA LANÇA

803504741 LUZ DE TRABALHO

819908611 TUBO

312600292 TUBO

819908612 TUBO

819908614 MANGUEIRA

312600293 TUBO

819908615 TUBO

819908610 TUBO

819908613 MANGUEIRA

819909396 COMPRESSOR DO AR CONDICIONADO

800104253 CORREIA DO AR CONDICIONADO

252611012 MANGUEIRA

252611011 MANGUEIRA

252611016 MANGUEIRA

252611005 MANGUEIRA

252611007 MANGUEIRA

252611010 MANGUEIRA

860140371 JUNTA DO CABEÇOTE

860140390 JUNTA DA TAMPA DE VÁLVULA

860140393 TENSOR DA CORREIA

860152918 BOMBA DE ÓLEO

800359448 CARDAN TRASEIRO

860115535 SEMI EIXO

803086379 JOYSTICK

252611020 PEDAL DE FREIO

802138058 LIMPADOR DO PARABRISA

252806534 RESERVATÓRIO DE AR

252610747 TUBO DE AÇO

252806629 TUBO DE CONEXÃO

252610725 TUBO DE ÁGUA INFERIOR

860139765 TURBOCOMPRESSOR

13026703 ANEL DO PISTÃO

13022349 ANEL CÔNICO

13026702 ANEL

13032095 PISTÃO

13066058 MOTOR DE PARTIDA

1000087783 ALTERNADOR

400405423 TUBO DE ÁGUA INFERIOR

800158137 HÉLICE DO MOTOR

400405425 TUBO DE ÁGUA SUPERIOR

B3L.050002 PRIMEIRO ANEL DO PISTÃO

B3L.050003 SEGUNDO ANEL DO PISTÃO

B3L.050200 TERCEIRO ANEL DO PISTÃO

B3L.050001A PISTÃO

Q43038 ANEL DE RETENÇÃO

6N5L.410000 BOMBA DE ÓLEO

R.410001 ANEL HERMÉTICO

1039-76-S VÁLVULA TERMOSTÁTICA

QDJ277E MOTOR DE PARTIDA

ECU1841-T-00 CONTROLADOR ECU

400405907 EIXO CARDAN TRASEIRO

400405230 EIXO CARDAN DIANTEIRO

400404784 EIXO CARDAN INTERMEDIÁRIO

400402949 PLACA DE BLOQUEIO SUPERIOR

800511367 ROLAMENTO DE ARTICULAÇÃO

400402950 PLACA DE BLOQUEIO INFERIOR

252800192 COXIM

860142699 MANIPULADOR

860142718 ALAVANCA DE ALÇA

400402851 ANEL DE RETENÇÃO

803164084 ANEL DE JUNTA

400404740 CONJUNTO CONTROLADOR DE FREIO

803546474 FAROL ESQUERDO

803546475 FAROL DIANTEIRO

802140661 RASPADOR DE CHUVA

802138059 RASPADOR DE CHUVA

252911064 TUBO DE BORRACHA

252910176 TUBO DE ENTRADA DO MOTOR

252910625 MANGUEIRA

252910172 TUBO DE ADMISSÃO DO REFRIGERADOR INTERMEDIÁRIO

252910173 TUBO DE SAÍDA DO REFRIGERADOR INTERMEDIÁRIO

252910175 TUBO DE SAÍDA DO MOTOR

252804236 TUBO DE BORRACHA

800355971 EIXO CARDAN INTERMEDIÁRIO

252113974 EIXO CARDAN TRASEIRO

860115231 PASTILHA DE FREIO

860115233 PISTÃO DE FREIO

275102044 ANEL DE VEDAÇÃO DO FREIO

275102045 TAMPA A PROVA DE POEIRA

275102285 ANEL HERMÉTICO EM FORMA DE O

275102284 ANEL HERMÉTICO EM FORMA DE O

275101688 COROA DO EIXO TRASEIRO

275100111 SEMI EIXO

275100142 ENGRENAGEM PLANETÁRIA

275100138 RODA SOLAR

275100122 EIXO PLANETÁRIO

275100116 ANEL HERMEÉTICO

275100141 PLACA DE RETENÇÃO

252914231 CALÇO DE AJUSTE

252914229 CALÇO DE AJUSTE

252914230 CALÇO DE AJUSTE

800500278 ROLAMENTO

803164083 RETENTOR

805047263 PARAFUSO

252100574 CILINDRO

252900387 CILINDRO DE DESPEJO

252910995 VÁLVULA DE FREIO

252908163 RESERVAATÓRIO DE AR

252115191 CILINDRO DE FREIO

800158459 HELICE

275000416 CUBO TRASEIRO

275000287 SEMI EIXO

402205748 TUBO DE ARREFECIMENTO

860153486 SUPORTE DO ALTERNADOR

860149635 BOMBA DE ALTA

275000199 TIRANTE/ BARRA DE DIREÇÃO

800362331 ALAVANCA DO FREIO DE MÃO

404202337 SELETORA ESQUERDA

803644318 SELETORA DE LUZES

803502568 TACÔMETRO DO HORÍMETRO

860147826 LIMPADOR DO PARABRISA

800362849 DISCO DE FREIO CARRARO

800362810 COROA E PINHÃO

800154295 HÉLICE DO MOTOR

252608877 ESPAÇADOR

252608883 TUBO DE AÇO

252608878 TUBO

252608873 TUBO

252607980 TUBO

252608866 MANGUEIRA

252608867 TUBO DE ÁGUA

252608859 TUBO DE AR

252608857 TUBO DE AR

252608858 MANGUEIRA

PAINEL (RASTREAR PART NUMBER CORRETO)

381600373 PIN

380900923 PIN ARTICULATION

380900922 PIN COVER

380905146 ARTICULATION PINE

805601794 PIN

860141916 BRAKE PINK

819948373 PINO BRAVA - ORIGINAL

819948380 PINO TRAVA DENTE XE215 - ORIGINAL

402205548 PINE BUCK - ORIGINAL

396366 PINHÃO RETENTOR - PARALELA

380901115 ARTICULATION PIN - ORIGINAL

402205263 ARTICULATION PIN - ORIGINAL

402205260 PIN - ORIGINAL

402205251 ARTICULATION PIN - ORIGINAL

402205265 PIN - ORIGINAL

819908991 PINO ESTEIRA - 84314929 - PARALELA

310700016 PIN - ORIGINAL

252600341 PIN - ORIGINAL

310500070 PINO CONCHA XE150BR - ORIGINAL

310504765 CONCHA PINE XE150 - ORIGINAL

310503387 PINO - 73182900 - ORIGINAL

310600283 PIN - ORIGINAL

310600286 PIN - 84314929 - ORIGINAL

252600344 PIN - ORIGINAL

310503378 LOWER H PIN OF CONCHA - ORIGINAL

310503492 PINO COM CHAPA - 73182900 - ORIGINAL

310600284 PIN - 84314929 - ORIGINAL

310600285 PIN - ORIGINAL

402205223 ARTICULATION PIN - ORIGINAL

310500095 PINO CONCHA XE150BR - 84314929 - ORIGINAL

310500067 PIN - 84314929 - ORIGINAL

310503381 PINO DO H DA CONHA - 84314929 - ORIGINAL

310503386 PIN - 84314929 - ORIGINAL

310503390 STEEL PIN - 73182900 - ORIGINAL

310600268 PIN - ORIGINAL

310600289 PIN - ORIGINAL

381601225 PINO DA CELA - 84314929 - ORIGINAL

819908899 PINO DO DENTE

312600229 PINO

312600234 PINO

312600237 PINO

312600232 PINO

312600220 PINO

312600214 PINO

12152378 PINO DO PISTÃO

12151395 TRAVA DO PINO

RAZL.050004

Read the full article

0 notes

Text

The largest share is made up

Tin ore crusher There are generally a lot of useful minerals associated in tin ore which are as follows: ferrous metals like iron, manganese minerals; copper, lead, zinc, bismuth, tungsten, antimony and other non-ferrous minerals; titanium, zirconium, tantalum, niobium, beryllium, indium, germanium, gallium, cerium, lanthanum, thorium and other rare minerals and rare China OEM Brake Pads Manufacturer earth minerals; and non-metallic minerals such as sulfur, arsenic, fluorite. Thus, in the tin ore dressing, we must use a variety of joint methods for prehensive recovery of these associated useful minerals. Design Absorber System The use of heat pumps has been increasing for many years. Growing environmental awareness and significant increases in oil and gas prices give rise to rethinking on the part of consumers.

The largest share is made up of brine heat pumps with the heat source of geothermal heat due to the fact that these systems have proved to be extremely reliable and cost-effective. Often, however, it is not possible to develop the usual heat source for the use of geothermal heat; the reasons may be a property that is too small, too expensive drilling operations, prohibitions in water conservation areas, etc. Aggregate Ball Mill Ball mills are large or small tubes used in grinding and mixing materials such as ceramic materials, ores, chemicals and paints etc. Ball mills rotate, partially filled with the material to be ground and the grinding medium (flint pebbles, ceramic balls or stainless steel balls Ball mills can make your material into a fine powder. Ball mills are often used in the alloying process to producing alloys from powders.

Gulin is the experienced, leading support manufacturer of Peak Performing Ball Mill Gearing for the Major Mill Suppliers and End Users. Gulin has long been a predominant mill gear supplier as a result of our track record with the development and manufacture of Large Critical Gears. Gulin's World Class Manufacturing Facility is home to unparalleled Machine Tools, Inspection Technology and Critical Welding Capabilities. Our unsurpassed Quality sets Gulin's reputation above and beyond peting Ball Mill Gear manufacturers. Stone crushing plant is used to crush stone with less than 350mm,such as hard limestone,granite,basalt,pebble.Product with various sizes can be made according to customers'special requirements in hydroelectric station,building materials,highway,railway,urban construction,etc. Impact crusher can be replaced by cone crusher according to customers'requirement or hardness of stone.Tin ore crusher, Design Absorber System, Aggregate Ball Mill

0 notes

Text

Paper Pangolin Pandemonium

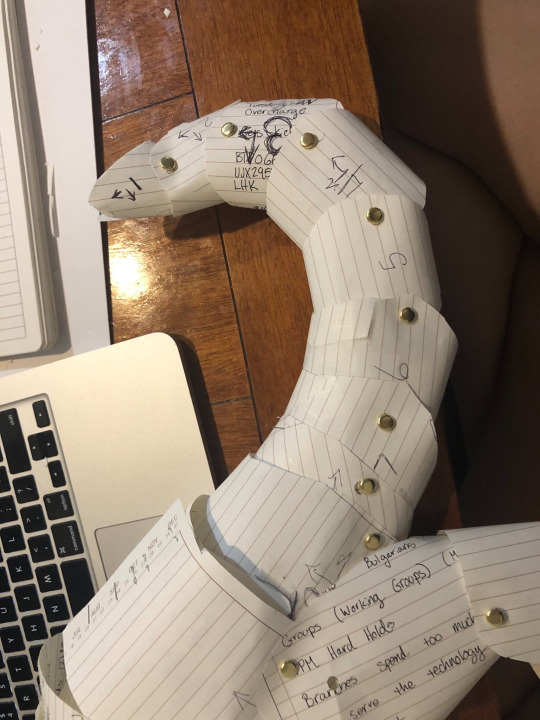

For this project, I chose the Chinese Pangolin. I was originally drawn to the pangolin because of its unique form. The pangolin rolls up into a ball as an act of self defense.

I thought their scales would be an interesting thing to recreate with cardboard. Oddly enough, their scales are also the reason they are endangered. Just like our fingernails, pangolin scales made of keratin. Unlike our fingernails, pangolin scales are believed to have medicinal properties. The demand for these scales have made pangolins the most trafficked mammal in the world.

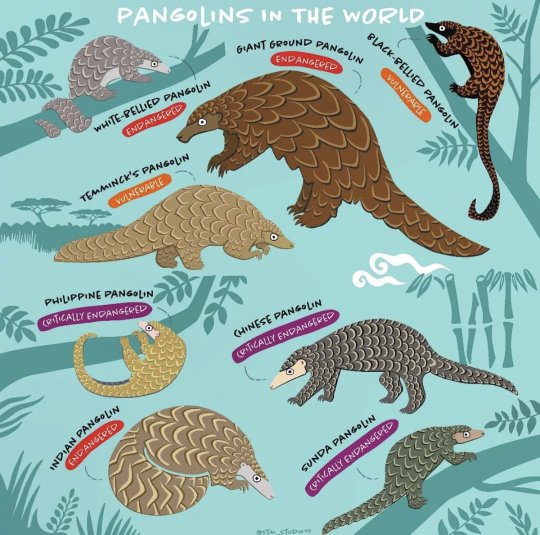

There are eight species of pangolin, all of which are threatened.

The rate at which pangolin scales are sold implies that pangolins are reproducing at a rate that would allow populations to recover if we could eliminate the demand for their scales. However, pangolins can be difficult to track, so it’s hard to know for sure.

Pangolins have a unique tongue that connects to their sternum, instead of their lower jaw. They use this tongue to eat roughly 70 million ants or termites annually.

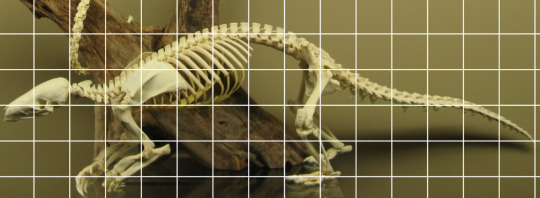

Chinese pangolins are about 15 in long. To help retain portions, I started by overlaying a 15 square wide grid over a photo of a pangolin skeleton.

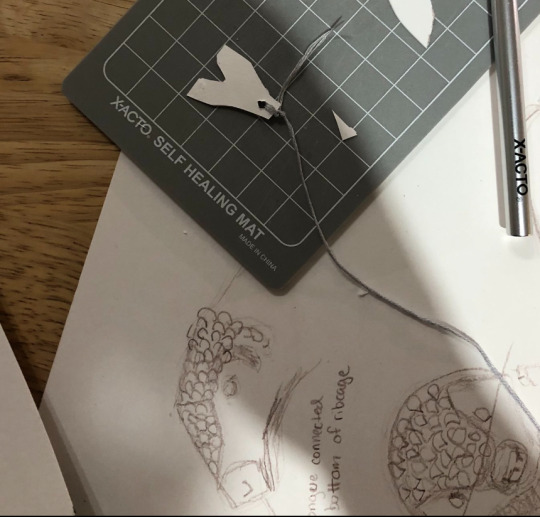

I had also drawn out this skeleton, as a way of studying the structure. Unfortunately, I accidentally threw away my pangolin study paper during anchovy clean up. Here is the only evidence remaining of that study. :(

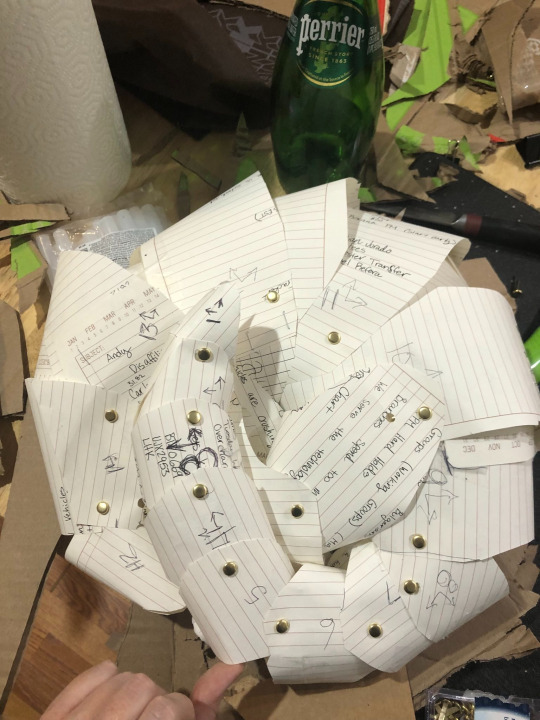

The good news is I learned a lot either way. Next, I drew out a mock up. I didn’t think I could really call it a pangolin if it didn’t move, so I decided to construct the pangolin using cones/tubes. This was similar to what I did for one of my anchovies. However, I didn’t want it to just move around, I wanted it to roll up. The video on cardboard attachments explained how to using brass fasteners to create a joint in cardboard, and I though this would be a great use for that technique.

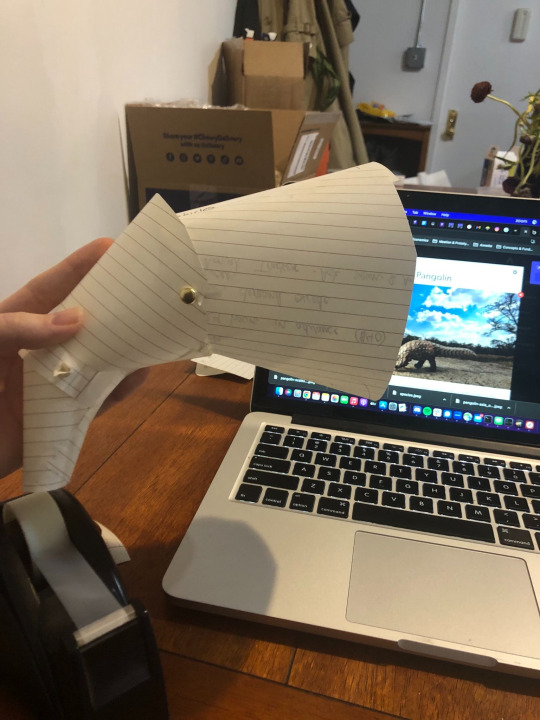

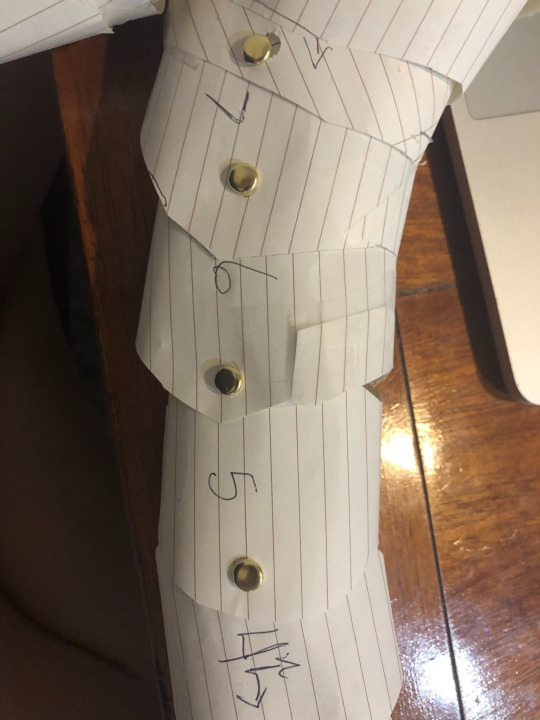

I set about making an initial prototype with paper from notebooks from my old job. I don’t have any use for the notes, and I figured it would be a good way to get rid of the paper.

The process reminded me a lot of pattern making and I used similar techniques to adjust my pieces. I felt it would be easier to work with paper first, and then I could cut the pieces in cardboard to make a final version. Below, I cut open the tube and extended it with another piece of paper.

I carved away any portion that prohibited the piece from rotating inward. I quickly realized that it needed to have a chevron pattern on the bottom to allow for this movement.

Once I got down to the tail, I made the pieces more of a diamond shape, to allow movement in both directions.

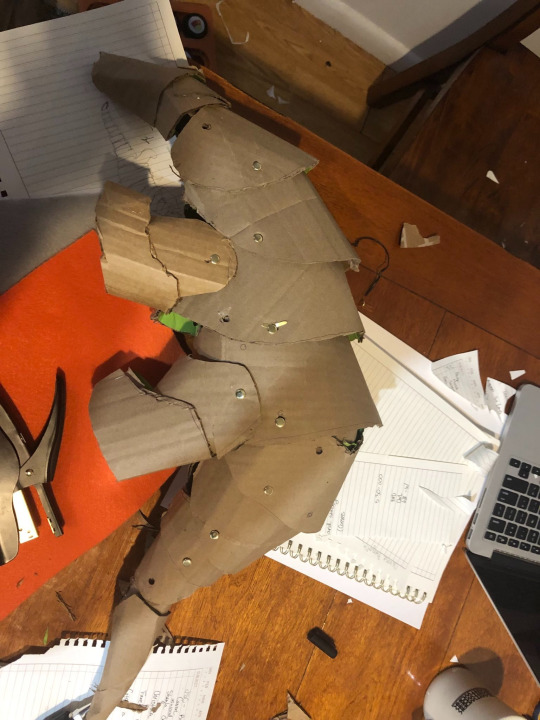

Once I was happy with my paper prototype, I numbered each piece and disassembled it so I could trace it onto cardboard. Cardboard proved to be much more difficult to work with. I used corrugated cardboard, and the bulkiness didn’t work well with my pattern. I had to adjust a few pieces, and shorten the tail a lot.

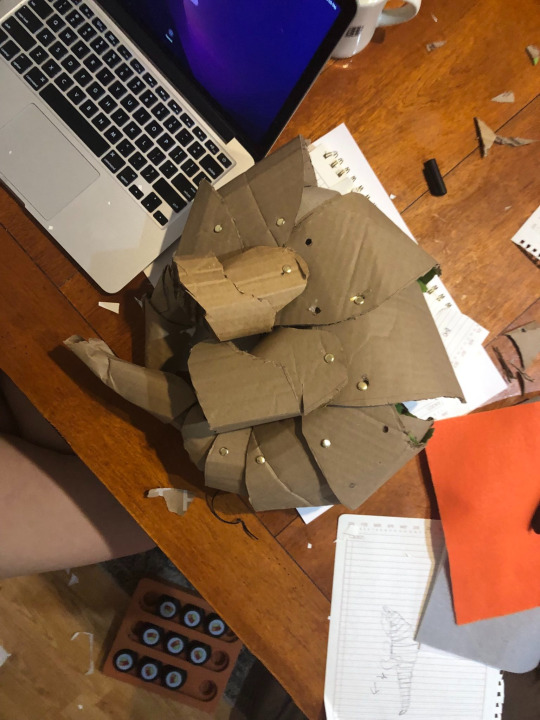

The stiffness also meant it didn’t roll up nearly as well.

I think part of the issue is that the brass fasteners were being pushed to their limit. Since the cardboard was much thicker, the brass fasteners were tighter. Additionally, it meant there was less space to move.

I was so bummed by the result that I went back and reassembled the first one.

I think I was so caught up by the idea of using cardboard, that I wasn’t noticing how well paper was working. I mean look at this roll! (and the mess I made with the cardboard, yikes.)

And now to compare...

youtube

World Pangolin day is celebrated on the 3rd Saturday of February, meaning this Saturday (February 18th, 2023) is World Pangolin Day!

I had a great time on this project and was really happy to learn more about pangolins. I’ll leave you with this photo of a pangolin who looks like he really needs to ask you something but doesn’t want to interrupt.

0 notes

Text

ASTM A234 Gr WPB carbon steel fittings is used in various industries like power plants, petroleum industries, fabrication industries, oil and gas industries, construction and chemical industries, etc. It is known to deliver exceptional performance. ASTM A234 WPB Elbow process manufacturing is called "wrought" which means it could be forged or casted. They are divided into two categories which defines the distance over which they alter heading. They are the centerline of one conclusion to the inverse confront. Carbon steel ASTM A234 Gr WPB cap is using pipe caps is to waterproof the connections and also useful to close the ends of hydraulic or pneumatic tubes and pipes. It is a protective device and are used to protect pipe ends of various shapes.

Tee ASTM A234 Gr WPB is manufactured from plate, pressed in two halves with three weld seams. It is carbon steel fittings which is used for piping connection in industrial plants such as Oil & Gas, Petrochemical etc. ASTM A234 Gr WPB concentric reducer is used to join pipe sections or tube sections on the same axis. They are manufactured from plate with one weld seam or with two weld seams on the bases of the size requirement. concentric reducer is in cone-shaped which is used when there is a shift in diameter between pipes.

Specification Schedule of ASTM A234 Gr WPB Carbon Steel Pipe Fittings

A234 Grade WPB Pipe Fittings sizeCS ASTM A234 Seamless Butt Weld Fittings: 1/2" - 10"

CS ASTM A234 gr WPB Welded Butt Weld Fittings: 1/2" - 48"ASTM A234 Gr WPB Pipe Fittings DimensionsASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10CS ASTM A234 Pipe fittings ThicknessSCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75Carbon Steel sch 40 A234 Fittings

CS ASTM A234 gr WPB Butt Weld Fitting

CS A234 Seamless Fittings

Carbon Steel ASTM A234 WPB ERW Fittings

ASTM A234 Gr WPB Welded Fittings

A234 Grade WPB Fabricated Pipe Fittings

CS ASTM A234 gr WPB Bevel Ends Pipe Fittings

CS ASTM A234 gr WPB Forged Fittings

ASTM A234 WPB Carbon Steel Fittings TypeDN15-DN1200Carbon Steel A234 WPB Buttweld Fitting ConnectionWeldingSize Range½" NB to 120" NB

CS ASTM A234 Seamless Butt Weld Fittings: 1/2" - 24"

CS ASTM A234 gr WPB Welded Butt Weld Fittings: 1/2" - 120"

CS ASTM A234 Two Joint / Two Halve Fittings 6" to 48"SA234 Grade WPB fittingsAngle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D, 5D, 6D, 7D-40D .

Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISOCS ASTM A234 Fittings Manufacturing processPush, Press, Forge, Cast, etc.Surface treatmentSand blasting, Sand Rolling, Sand BlastingASTM A234 WPB Carbon Steel Buttweld Pipe Fittings Test CertificatesEN 10204/3.1B

Raw Materials Certificate

100% Radiography Test Report

Third Party Inspection Report, etc

0 notes

Text

Considerations To Know About Indoor termination kits

Tubes employed only Crepe Crepe Electric powered, designed in one hundred% electric powered kraft paper. Also in the whole process of creping only deionized drinking water is used to maintain the most electric powered purity.

EPDM is largely good in all features and much less high priced, due to the fact EPDM used for lessen Charge polymer that provides the very best top quality processing ability.

Automatic strip reducing machineAutomatic cable crimping machineAutomatic feeding machineAutomatic tying machineAutomatic tube Slice machineAutomatic Labeling machineAutomatic Tape wrapping machine1 Subscribe

One particular disadvantage of tubular skylights is their tendency to heat for the duration of notably sizzling and humid seasons or climates.

Incorporates access to our preferred JOINTERS Web site with contributions from utility gurus, linesmen and cable jointers engaged on MV HV EHV cables and overhead traces usually at 11kV, 33kV, 66kV and as many as 132kV. fifteen,000+ Subscribers.

Switching accounts in the midst of an buy will crystal clear your present cart. Have you been absolutely sure you ought to swap accounts?

An MS3454 fashion jam nut receptacle encompasses a one mounting gap for increased environmental defense. The integrated silicone O-ring seals the mounting area to maintain environmental integrity. Addresses are proposed to safeguard contacts.

There are the HVAC seals and gaskets for obvious explanations. Nitrile gloves will also be preferred solutions of PVC Nitrile Foam. They may be really puncture-resistant and delicate. Also, as expected, tend to be a great match for your arms and proof against chemical assaults.

Cost: 2150/- USD

Raychem RPG caters to your infrastructure segment of many enterprise industries. For many decades, the corporate has worked with several industries, offering a host of engineering options for their techniques and programs.

Busbar Heat Shrink Sleeve Tubing 35kV substantial voltage busbar heat shrink tubing is commonly Utilized in the insulation defense of substantial-voltage switchgear busbars, as a result of its superb insulation overall performance and adaptability, successfully blocking the chance of mishaps due to uncovered Dwell wires.

The electric area of chilly-shrinkable cable joints is taken care of by geometric process, which adjustments the electric subject distribution from the strain cone. It can be solved with a certain geometric condition and also a precise R angle. This method is simpler to regulate and exam. It could be ensured and realized in the factory. The electric subject therapy method of the indoor termination kits head is to change the electrical area distribution because of the linear parameter technique.

Computerized Handle and insulation in the event the set temperature is attained. Various layers of defense are blended to make sure the security and dependability of use.

There’s a rationale tubular skylights are among the most well-liked artificial lighting forms today. That’s for the reason that Qualified installation conveniently solutions their drawbacks.

0 notes

Text

HEMP.gg : Hempacco and Sonora Paper Company Disclose New Joint Venture to Manufacture and Market Hemp Paper Smoking Products Including Hemp Blunts, Hemp Cones, and Hemp Tubes - StreetInsider.com

Hempacco and Sonora Paper Company Disclose New Joint Venture to Manufacture and Market Hemp Paper Smoking Products Including Hemp Blunts, Hemp Cones, and Hemp Tubes StreetInsider.com

source https://news.google.com/__i/rss/rd/articles/CBMi3QFodHRwczovL3d3dy5zdHJlZXRpbnNpZGVyLmNvbS9OZXdzZmlsZS9IZW1wYWNjbythbmQrU29ub3JhK1BhcGVyK0NvbXBhbnkrRGlzY2xvc2UrTmV3K0pvaW50K1ZlbnR1cmUrdG8rTWFudWZhY3R1cmUrYW5kK01hcmtldCtIZW1wK1BhcGVyK1Ntb2tpbmcrUHJvZHVjdHMrSW5jbHVkaW5nK0hlbXArQmx1bnRzJTJDK0hlbXArQ29uZXMlMkMrYW5kK0hlbXArVHViZXMvMjA4OTk0MDguaHRtbNIBAA?oc=5

0 notes

Text

A rotary dryer for drying and mixing particulate material

A rotary dryer for drying and mixing particulate material, incorporates a shell having a pair of conical portions and supplied with a jacket to which a hot fluid may possibly be fed, the shell defining a chamber for the content to get dried and blended. A feeder pipe is air-tightly inserted inside the rotary tube shaft, sheathing and evacuating pipe to talk having a vacuum dryerline and an air supply pipe connected to said air nozzle.. The pre-mixed bulk resources or liquids for being dried enter by way of a charge/discharge opening in the side wall with the drying chamber, along with the dried goods are discharged by means of exactly the same opening.A double cone sort rotary vacuum dryer furnished with a double wall structure, in between whose double partitions a heating medium flows to dry the contents, has become conventionally used being a dryer of pvd coating machine for sale bulk components. An air nozzle is disposed along the internal wall in the shell plus a stirrer which includes a rotational mixing blade can be found within the shell to agitate the materials, the stirrer being supported through the wall in the shell.

The present creation may be created to cope with the aforesaid down sides, as well as the object of this creation is always to present a rotating barrel dryer which performs vacuum drying of bulk materials, stopping them from sticking to your internal wall surface area, and which yields stable superior products by lower temperature vacuum drying without any thermal decomposition or any thermal degradation. It just rotates the drying chamber to conduct drying. Nonetheless, this type of rotary vacuum dryer only serves for your drying operation and it&39;s got no mixing purpose (the term "mixing" used right here implies the systems for blending different kinds of bulk substance, for coating on particles, and for granulation). The rotary tube shaft is offered using a plurality of communication paths which communicate with charge/discharge ports found about the rotary joint pipe during rotation of the rotary tube shaft from the rotary joint pipe, the communication paths connecting the jackets in the shell as well as the closure for feeding the scorching fluid. An air-tight closure for your chamber is supplied which has a jacket to which sizzling fluid may be fed and through which the materials is charged and discharged.A rotary tube shaft extends horizontally from one end from the shell and along the horizontal axis from the shell, the rotary tube shaft currently being sheathed by a rotary joint pipe equipped which has a bearing rotatably supporting the rotary tube shaft

0 notes

Text

Types of Tube Fittings and Applications

What is the difference between Tubes and Pipes? Pipes are majorly round, and Tubes are rugged and come in plenty of shapes. Tube fittings are the essential part of the tubes that need to add or curve the tube to specific directions. There are plenty of tube fittings that are used to connect and fix two or more tubes.

Tube fittings are applied in plenty of industries. Tube fittings are an essential part that functions in significant parts. Tube fittings are implied to connect tubes. The fittings must be specific, and component selection is a must. Tube fittings have plenty of applications, prominently in hydraulic and pneumatic systems. Here are some applications of tube fittings.

Hydraulic Application:

It is where the liquid is transferred, like water or chemicals. Tight sealing is required in fittings to prevent leakage and better material to avoid corrosion.

Pneumatic Application:

It is where gasses are transferred in tubes. The tube fittings must be tightly installed to prevent any leakage. The fitting must be resistant to the corrosive nature of the gas.

Types of Tube Fitting.

Various types of Tube Fittings are crucial in numerous industries. The attachment of tubes with two leading types, Compression fitting, and Threaded Fitting.

Compression Fittings

Compression fittings connect tubes by using a gasket, ring, or ferrule. Compression is used to tighten the grip and have a fixed hold between two types securing the lines. The standard reduction doesn't require additional fittings, but they are very susceptible to high pressure. Contraction also defies heated substances, and proper tube fittings are required.

Bite-type fitting:

Bite-type fittings are compression-based fittings with a sharpened ferrule that presses the tube like a bite. When compressed a seal is created to secure the tube components to flow flawlessly. No unique tool is used to fix the joint, and this fitting is not sturdy and better for high-pressure connection.

Mechanical Grip Fittings:

Mechanical grip fittings have two ferrule assemblies, one in front and another behind. The back ferrule holds the tub while putting pressure against the front ferrule. The spring-loaded front ferrule creates a seal between the tubing and the fitting body. The mechanical grip can be attained multiple times and is not permanent.

Flare Fitting:

Flare fitting has a body with a coned end. A unique flaring tool is used to fit the tube in the tapered end. The small coned end tightens the seal and handles pressure with a broad range than standard compression fitting.

Threaded Fitting.

Threaded fittings have screw heads on both sides for connecting both tubes. It is a simple yet effective connection with no sealing. The treads intertwine with each other to provide a robust grip. Sealing can be added with an external coating over the threaded joint. Threaded tube fittings are highly operated in multiple industries.

Male and Female Connectors:

Male connectors have a threaded exterior, and female connectors have a threaded interior. The male connector is attached to one tube and the female to the other. A male connector is fitted into the female connectors to join the tubes.

Unions:

Unions are couplings with both ends threaded to connect the two ends of the tube. They can be disconnected without needing to cut them. A reducer union minimizes the flow of the substance present in the lines.

Couplings:

A coupling is used to connect two tubes by welding them together. It created a strong bond with no leakages of fluids or gasses. Couplings don't perform with pressured content and are permanent.

Elbow Fittings:

Elbow fittings are utilized to change the course of tubes to different angles. Both ends are threaded and stable materials are used to handle the extreme pressure on the bends. The elbow fittings are made in multiple angles, like 45 degrees and 90 degrees. Male Elbow fittings have outer threads that go in the joining pipe. Female elbow fittings have the connecting pipe go over it to join the line.

Tee Fittings:

Tee fittings allow three tube connections. It has a male thread and two female threads to ensure the leading pipe has a secure fit. To connect the prominent tube with the other two lines with a sturdy grip. The material used to construct tee fittings is better compared to others as it handles higher pressure from the pipe contents.

Union Cross:

Union cross is similar to a tee but with one additional joint. It offers four connections of equal connections. It is used to mix two fluids, and the construction is solid. The center is exceptionally solid and made to sustain high pressure and more corrosion.

Tub Caps:

Tube caps don't connect two lines, but restrict one. It is used to seal off the end of a line to stop its contents from flowing. Caps are made of higher-quality stainless steel tube fitting to withstand the pressure to stop the flow of tube fluids or gasses.

Tube Plug:

A tube plug is similar to a cap, but the only difference is the way it is attached. A plug is a male thread inserted into the tube with a threaded interior. The grip is better, and is also welded firmly to secure its position.

Instrumxx Industries is the leading tube fittings manufacturer in India. They excel in tube fittings and valve supply throughout the countries and foreign land. One benefit of their fittings is the variation in products and the materials used to construct them. Unlike the others, Instrumxx Industries has better personalization as they manufacture the products. So clients can avail of a personalized size with standard dimensions to attain the best tube fittings and more.

Here is the list of products Instrumxx Industries manufactures, exports and supplies.

● Double Compression Tube Fittings

● Precisionand Forged Pipe Fittings

● Air Header

● Condensate Pot

● Syphon,Snubber, and Flanges

● Seamless Pipes and Tubes

● Valves

● Manifolds

● BrassFittings, Clamps, Gaskets, Bolts, and more.

#Tube Fittings#Instrumentation Fittings#DoubleFerruleFittings#compression Tube Fittings#pipesandtubes

1 note

·

View note

Text

ABC's of Stainless Steel Tube Fittings

Stainless Steel Tube Fittings are made use of extensively in fluid systems, as well as especially in the Hygienic markets. Typically they are made with 304 and 316L Stainless-steel building and construction, which lessens the possibility of anxiety deterioration fracturing. Trustworthy companies who make Stainless-steel Tube installations will evaluate their products extensively to inspect the stress of the hydraulic capability, as well as make certain that the Fittings do not leak under stress. Stainless Steel is useful for its mechanical homes. The tensile stamina of Stainless Steel is incredibly strong, creating Fittings which are risk-free, reputable and also long lasting. Stainless Steel Fittings are highly immune to corrosion, as well as the leakage price is reasonably low, supplied the they are well-manufactured to sector requirements.

Titanium Tube

Stainless Steel Tube Fittings must be made to address the four most expensive as well as essential issues of liquid systems: inappropriate installment, vibration, leak, thermal shock, giving you with a dependable, gaugeable item with exceptional sturdiness, as well as simplified upkeep. Setup must be come with by an overview to supply guarantee that an installation has been adequately tightened on setup. It ought to preferably be feasible to mount the Installations with hand tools, and they should additionally be very easy to separate and also retighten for maintenance purposes. The ferrule, which is a cone-shaped piece of steel in the case of Stainless Steel Tube Fittings (however can be constructed from plastic), which presses television as it is forced into a tapered seat, must be manufactured so that it can be used on a range of thick- or thin-walled tubing, as well as tough and also soft tubing. It is necessary that the ferrule is able to stand up to the results of resonance, pressure and also thermal cycling. Good quality Tubes is examined for pressure, performance at high and low temperatures, and just how well it withstands resonance which will certainly affect durability tremendously. Sanitary Installations specifically need to provide themselves well to disconnection and also retightening for upkeep functions.

Titanium Sheet

All Fittings need to have a durable tube hold, which is a crucial element in reliable efficiency. There are countless types of Fittings, and also the system demands should be considered in deciding which to utilize. Compression Fittings, which was the first sort of Tube fitting, is composed of three components - a nut, a body, as well as a gasket ring, or ferrule. This type has significant disadvantages - the most essential being that it can just withstand minimal stress, and remake is incredibly challenging due to the building and construction of the securing ring. Screwed installations are largely made use of to join routine 40 pipe. Sanitary fittings are generally readily available in both 304 and 316 Stainless Steel, with male components as well as liners appropriate for butt-welding to tube. These consist of RJT installations, IDF installations and also Clamp installations. Most procedure lines have to be frequently taken apart for cleansing, as well as series of hygienic fitting should appropriate for this purpose and maintenance friendly.

Stainless-steel Fittings have elastomeric O-rings located near each open end to make a seal onto tubes. The tubes is initial pushed onto the suitable: - the O ring is designed to be a loosened press fit on the tubing. A long-term seal is after that used an unique clamp which presses 3 estimates onto the fitting, thus permanently deforming completion of the suitable. After pushing the rubber O-ring is clamped firmly in between television and the suitable making a long-term leak-free joint.

0 notes