#tapering off LT4

Text

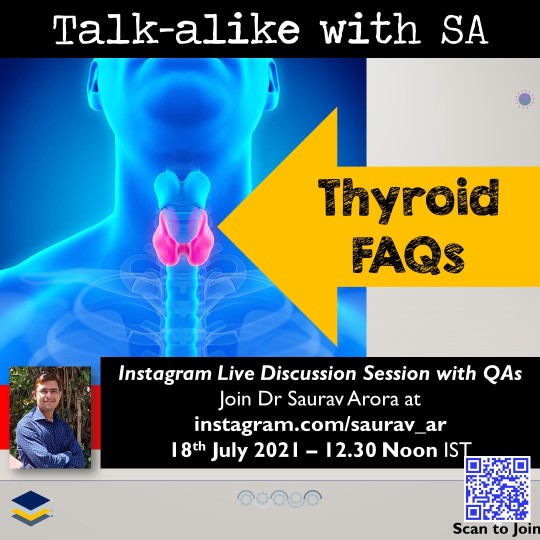

Thyroid - Frequently Asked Questions

Thyroid – Frequently Asked Questions

This podcast is an audio excerpt of the Instagram live series Talk alike by Dr Saurav Arora delivered on 18 July 2021. It aimed at discussing the Thyroid disorders and the frequently asked questions related to it such as:

Common investigations

Relevance of Ft4, TSH and anti TPO antibodies, USG thyroid, RAUI scan, Technetium scan etc.

Frequency of investigations advised

Duration of treatment…

View On WordPress

#anti TPO antibodies#dr saurav arora#dr saurav arora tips#FT4#homeopathic materia medica#Homeopathic Materia Medica Tips#homeopathy education#homeopathy in thyroid disorders#homeopathy podcast#hypothyroidism#isupporthomeopathy#mm tips by dr saurav arora#role of tests in thyroid disease#tapering off LT4#thyroid#thyroid diseases#thyroid function tests#TSH#vividhomeopathy

0 notes

Text

ZR1 Retrospect – From Racer Kit to Corvette Supercar

For most of 2016 and 2017, it seemed that the C7 ZR1 would never arrive. The car was supposed to debut at the 2017 Detroit Auto Show but was a no-show. When Chevrolet announced a new “LT5” engine, speculation went wild over the possibility of another DOHC super engine. Then the April 2017 issue of Car and Driver featured a computer rendering of the ZR1 that was just about right on. Through the rest of 2017 there was a steady drip of images of camouflaged ZR1s and juicy details, including the announcement that the new ZR1 would have an eight-speed automatic transmission and be available in as a convertible. Rumor mills are so much fun. Finally on November 11, 2017, the sinister-looking ZR1 debuted in Dubai and didn’t disappoint! Think Z06, but with more power and aero and a bigger price tag. Maximum-performance Corvettes have never been inexpensive.

The C7 ZR1 is the third iteration of a performance model Corvette wearing the “ZR1” moniker. To see the progress of the ZR1, let’s take a walk through the ZR1’s lineage. The original ZR1 arrived in 1970 as a racer kit option that was the L88 suspension package with the solid-lifter LT-1. The package included the LT-1 engine; a metal fan shroud; a four-speed, wide-ratio transmission; heavy-duty power brakes; transistor ignition; a special aluminum radiator; special shocks and springs and front and rear antisway bars. There were no special badges or body parts. This car was strictly for racing and the RPO ZR1 package was very reasonably priced at $968.95. For just $6,160.95, a customer had the basics for a SCCA B/Production Corvette. The ZR1 option was offered from 1970-’72 with a total of 53 units sold. There was supposed to be a ZR2 racer kit with the LS7 454, but it didn’t make it into production in 1970, but was available in 1971 with the slightly milder LS6 454. Just 12 ZR2 ’71 Corvettes were sold.

The ZR-1 moniker resurfaced around 1988 when rumors about a super Corvette under development surfaced. Most Corvette fans said, “What’s a ZR-1?” The car’s development nickname was King of the Hill, a tag that lives on to this day for C4 ZR1s. This would be the first time Chevrolet offered a separate performance model Corvette. Performance engine options had been around since 1956, but the C4 ZR-1 was a complete package Corvette that was very exotic. The star of the C4 ZR-1 was its all-aluminum, Lotus-designed, fuel-injected DOHC 350ci engine. The engine is still a beauty nearly 30 years later and is iconic for its unique eight-pack abs-style intake manifold. The regular Corvette’s L98 engine had 250 horsepower; the ZR-1’s LT5 had an extra 125 horsepower. Yes, 375 horsepower in 1990 was a very big deal.

But this wasn’t just an exotic engine stuffed under the hood of a stock Corvette. To handle the extra power, special 315/35ZR17 Goodyear Z-rated tires were mounted to 11-inch-wide rear rims. To cover the larger tires, the body gradually tapers out from the end of the front fenders to cover wider rear tires. The taillights were square-like with rounded corners and the exhaust tips were rectangular. All of the Z51 suspension and brake parts were standard.

The ZR-1’s price was staggering. The base Corvette cost $31,979 and the ZR-1 option was an additional $27,016, for a grand total of $58,995, plus options. From 1990-’95 a total of 6,922 ZR-1s were sold. 1990 was the best year with 3,032 units sold. By 1993 engineers bumped the power up to 405 horsepower, and in 1994 very handsome-looking five-spoke wheels helped make the ZR-1 look unique. The one critique was that it didn’t look much different from a regular Corvette. From 1990-’93, one has to look for the ZR-1 badge, or have a keen eye to notice the wider rear-section. Looks and price aside, the ZR-1 was universally praised for its power and handling.

When the C5 came along, it was such an improvement over the C4, no one was pining for a ZR1. Then when the C5 Z06 arrived in 2001, offering ZR1-level performance, for around $20,000 less than a ’95 ZR-1, the old King of the Hill was definitely out to pasture. The C5 and C6 Z06 was the new Corvette performance champ. Fast-forward to 2007-’08, the Corvette rumor mill was heating up with rumors of a new super Vette called the Blue Devil. When a test mule was caught on a smart phone video with the distinctive whine of a supercharger, the cat was out of the bag.

When the ’09 ZR1 made its debut, heads exploded. Unlike the C4 ZR-1, the C6 ZR1 was an in-your-face, $103,300, 205-mph velvet brute of a Corvette. The C6 ZR1 was built on the Z06 platform so it had all of the C5-R racer-inspired hardware. Like the C4 ZR-1, the big news was under the hood. Z06 customers thought their 505-horsepower LS7 was a brute, but the ZR1’s supercharged LS9 packed 638 horsepowe with 604 lb-ft of torque. The all-aluminum LS9 engine was not only supercharged, it had an intercooler, port fuel-injection, a 10.75-quart dry-sump oil system and a LUK dual-disc clutch. The TR-6060 six-speed transmission was beefed up and the gear ratios are closer than those in the Z06.

Modern Corvettes are all about suspension and brakes. The Speedline forged aluminum-alloy wheels measure 19×10 in the front and 20×12 in the rear, and are shod with Michelin Pilot Sport tires measuring 285/30R19 on the front and 335/25R20 on the rear. The Brembo carbon ceramic rotors are vented and cross-drilled; measure 15.5×1.6-inches in the front and 15×1.4-inches in the rear. Six-piston calipers are in the front; and four-piston units are in the rear; with pads that are twice the size as those used on the Z06; and will last a lifetime for street use. The Z06 suspension used the next-generation Delphi Magnetorheological variable shocks, softer springs, larger antiroll bars and revised rear suspension geometry.

The entire front end and roof section was made of carbon fiber. Clearcoat covered the carbon-fiber chin spoiler, rocker panel, and roof section. The new hood was 1-inch taller than a regular Corvette’s and a Plexiglas window shows off the LS9’s intercooler. The front and rear fender flares were the same as the Z06, but the front fenders had larger, more aggressive vents and the back end was finished off with a short, full-width spoiler. ZR1 badges adorn the front fenders and rear bumper cover; and the interior is trimmed with ZR1 badges and embroidery on the seats. The speedometer goes up to 220, but there was a 205-mph governor on the car. The C6 ZR1 was another super-expensive Corvette. Costing $103,300, the ’09 ZR1 was over double the $47,895 base Vette. The ’13 ZR1 went for $112,575. From 2009-’13 Chevrolet sold 4,684 ZR1s.

The C7 ZR1 carries the traditional ZR1 status of being a true GT supercar. All of the C7’s delightful attributes are present, plus a lot more. For the first time, a ZR1 is available as a coupe or convertible; and with a seven-speed manual or eight-speed automatic transmission. The 6.2-liter (376ci) LT5 engine is similar to the Z06’s LT4, but with a 56 percent larger Eaton supercharger, additional port injection, a stronger crankshaft, a more efficient electronic bypass valve and higher volume intercooler fluid. The dedicated 10-spoke wheels are the very similar in size to those on the Z06; the ZR1’s front wheels are a half-inch wider. The ZR1 uses the Z06’s Z07 Package, but with refined spring rates and dampers. Traction Control and Active Handling is a must, and is standard.

The ZR1’s aggressive front end looks that way because it has five extra cooling radiators. Intercoolers are stacked ahead of the radiators in the outer positions. Like a race car, the front underwing extends back to the front wheelwell openings. At the back end, the basic ZR1 has a low fixed wing. For those that want more, there’s the $2,995 ZTK Package with a taller, adjustable rear wing and winglettes on the outboard edges of the front splitter. Weighing in at 3,600-pounds, the C7 ZR1 had an all-time low power-to-weight ratio of 4.76:1. Now the rest of the story … the price. The basic ZR1 coupe lists for $119,995, the convertible goes for $123,995. A ZR1 convertible can max out to just under $156,000.

The new ZR1 lives up to its predecessor’s reputations and exceeds all performance levels. This will most likely be the “finished” C7 Corvette. At the Dubai debut, Corvette chief engineer Tadge Juechter said that his engineering team did everything they could possibly do to the C7 platform when developing the ZR1. Do you realize what that means? They are already working on the C9. Vette

The post ZR1 Retrospect – From Racer Kit to Corvette Supercar appeared first on Hot Rod Network.

from Hot Rod Network http://www.hotrod.com/articles/zr1-retrospect-racer-kit-corvette-supercar/

via IFTTT

0 notes

Text

Mark Stielow LT4 Engine Swap Into a 1969 Camaro

Mark Stielow’s Camaros have always been on the leading edge of the latest high-tech horsepower movements, and his latest project, Gunner, is no exception. He’s jumped headlong into the emerging LT swap trend, using a Scoggin-Dickey Parts Center-supplied Chevrolet Performance LT4 crate engine.

It’s the engine, of course, that powers the current-generation Corvette Z06 and Camaro ZL1. With a little more than 9 psi of boost generated from an Eaton 1.7L R1740 TVS supercharger spinning at up to 20,000 rpm, the LT4 cranks out an impressive 650 horsepower and 650 lb-ft of torque.

“I’ve always liked the immediate power delivery that comes with supercharging, and the LT4 is a great engine in that regard, with a broad powerband and tremendous low-end punch,” says Stielow. “Considering the technology and performance wrapped up in the crate engine, it would be virtually impossible to build something comparable from the ground up, making it a cost-effective and time-saving choice.”

Despite many architectural similarities with the previous-generation Gen III/IV LS engines, the Gen V LT family has a number of significant changes that make engine swaps just that much more challenging—at least in these early adopter days. For one thing, the engine mounts and even the engine mounting positions on the cylinder block are not shared with LS engines, while the engine accessory drive systems are different, too. In fact, there are no factory applications with conventional hydraulic power steering (the Z06 and ZL1 have electric power steering), meaning a system has to be fabricated.

Finally, and perhaps most importantly, the Gen V LT engines are direct injected, with extremely high fuel pressure. Where the LS engines’ conventional port-injection system operates at up to around 60 psi, the LT engines’ fuel pressure is more than 2,000 psi. In the case of the supercharged LT4, it’s around 2,900 psi.

A camshaft-driven fuel pump mounted to the engine generates the high pressure at the fuel rail and it’s all self-contained within the crate engine package from Chevrolet, but the kicker here is the LT4 needs a very specific engine controller and an additional pulse-width modulated fuel pump controller.

Stielow is stepping around the factory system, somewhat, to set up a steady fuel pressure feed to the engine’s high-pressure pump. He’s doing it with a VaporWorx setup to build extra headroom into the system as part of a plan to up the engine’s output later. We’ll address the engine’s fuel and control systems more thoroughly in a later installment.

When it came to installing the crate engine, Sled Alley in Clinton Township, Michigan—the shop handling the bulk of the Camaro’s fabrication—and Holley collaborated on a set of engine mounts for the car’s Detroit Speed front subframe. We touched on that in a previous installment, but the final, production-spec mounts were used for this stage of the installation. Holley also sent representatives from their Hooker Headers division to fab long-tube and mid-length headers, which will be used as the pattern for production-swap headers. We’ll highlight an entire story on the exhaust system’s fabrication later.

“The mounts are different, which definitely affects a couple of things, but if you’re used to doing LS swaps, the LT swap is in the same ballpark,” said Sled Alley’s Matt Gurjack. “But there are still supporting parts that aren’t in the aftermarket yet. We were fortunate to work with Holley on this project, and builders after this will benefit from the collaboration with new production swap parts, but it’s something to keep in mind when tackling an LT swap right now. It’s going to require some fabrication.”

Backing the LT4 in Gunner is the proven TREMEC Magnum six-speed manual transmission, which was prepared by D&D Performance and adapted to the engine with a Quick Time bellhousing (another Holley brand). The Camaro’s transmission tunnel required some modifications for the desired fitment, which we covered in a previous installment.

Finally, after the engine and trans were installed, Stielow got to work on the wiring harness. There will be more on that in a future installment as well, but for now we’re focused on the installation details of this leading-edge LT swap.

It’s also important to note that, as Matt Gurjack noted, the LT swap trend is still in its infancy and supporting components are coming to the market almost daily. It’s a good bet new mounts and other parts have entered the market in the time it took us to shoot, write, and publish this story.

It’s definitely the next wave in engine swaps and, as always, Mark Stielow is leading the way.

1. Obtained from Scoggin-Dickey Parts Center, the dry-sump Chevrolet Performance LT4 crate engine (PN 19332702) carries a $13,755 list price on S-D’s website. For roughly $500 less, there’s also a wet-sump version (PN 19332621). Considering its lofty 650-hp/650-lb-ft output, it’s difficult to argue with the price because you’d be hard-pressed to assemble a blower-ready long-block and add the supercharger, fuel system, etc., for any less. The accessory drive system shown in this image, however, is not included and neither is the engine controller.

2. A TREMEC Magnum six-speed is a good match with the LT4, with a torque rating of 700 lb-ft. Within the aluminum case, the guts are based on the later-model TR-6060, with thicker, heavier-duty, and stronger gears than the T-56 transmission. It weighs about 135 pounds, which ain’t bad for a gearbox with so much capacity.

3. Prior to installation, the Magnum transmission was taken to D&D Performance for a couple of upgrades, which included pulling off the original plastic shift fork pads and replacing them with more durable bronze pads. If the plastic pads break or wear, the sliders won’t fully engage their respective gears.

4. Stielow wanted to lower the top-gear cruising rpm so the transmission’s original 0.63:1 Sixth-gear cog was swapped with a 0.50 gear, which should lower engine speed by around 400 rpm at 70 mph, giving the supercharged muscle car better fuel economy. By the way, the Magnum is offered in two versions: one with a 2.66 First gear and one with a 2.97 First gear. Stielow is using the 2.66 version. (TREMEC has a cool app to allow you to evaluate your gear ratio choices.)

5. The LT4 uses an eight-bolt pattern for the flywheel, like the LSA production engine and LSX454 crate engine. The crate engine doesn’t include the flywheel and Chevrolet Performance offers one through their catalog, but Stielow went with a Centerforce flywheel to support the added power that will come later.

6. Next, a new DYAD Centerforce dual-friction clutch was installed. Stielow used the same model in three previous Camaro projects that made over 950 lb-ft of torque, and he says it offers exceptional holding power with great driveability, including a great pedal feel and easy modulation.

7. When it came to marrying the Magnum transmission to the LT4, a Quick Time bellhousing served as the intermediary. The bolt pattern is largely the same as the LS engine family. The top bolt position is different but it still enables the Quick Time LS bellhousing to be used. It’s a steel unit that’s SFI 6.1-certified.

8. Sled Alley modified the Centerforce hydraulic release bearing assembly to use this hard line to the clutch master cylinder. The AN fittings enable a “dry break,” allowing the transmission to be removed much easier for service.

9. New Holley engine mounts lock the LT4 in place on the Detroit Speed subframe. They’re new and designed specifically for LT swaps using the Detroit Speed front end, but the word is mounts for original first-gen F-body subframes, as well as A-body and truck applications, are on their way.

10. Nothing makes an engine installation easier than having the front-end sheetmetal and core support out of the way; and here, the Sled Alley guys slowly begin to slip the engine/transmission assembly into the car, taking care to avoid scratching the freshly powdercoated chassis components.

11. The top portions of the engine mounts bolt to the engine. A little antiseize compound on the threads is used as a precaution because the steel bolts are threading into the aluminum block.

12. It takes a little finesse to line up the top of the mounts over the bottom sections, but once they are, through-bolts simply hold the two together to complete the installation.

13. The transmission crossmember is the result of another collaboration among Stielow, Sled Alley, and Holley. Sled Alley started with Holley’s LS-swap crossmember and found there were just enough small differences with the positioning of the LT engine that modifications were required. They made them and now Holley’s new LT swap crossmember is based on this first one in Stielow’s car. You’re welcome.

14. A Walbro pump is mounted with the transmission on a fabricated bracket to support the transmission cooler. The lines will feed in and out of a heat exchanger built into a C&R radiator.

15. One of the enhancements made to the engine was the replacement of the factory intercooler lid with the one used on the Camaro ZL1. The 2017 Corvette Z06 received a similar lid, but it says “CORVETTE” on top rather than “SUPERCHARGED.” The upshot with the revised designed is a more efficient inlet/outlet design, along with revised “bricks” within the intercooler, all of which is intended to improve cooling by reducing the chance for power-robbing heat soak. Stielow ordered the lid from a Chevrolet dealer, but at the time our story was completed the complementing heat-exchanger bricks were not available. That may change soon and when we learn more we’ll pass along the information.

16. Here’s a shot of the factory, pre-2017 Z06 intercooler lid. It’s easy to see how it tapers down at the front, compared to the new lid—a design feature that didn’t enable optimal cooling efficiency. It’s important to reiterate the advantage of the updated lid is in the application of revised heat-exchanger bricks. The lid is simply required to clear the bricks and will not itself help without them.

17. The LT4 crate engine doesn’t include an accessory drive system and there are two choices from Chevrolet Performance: a CTS-V-based kit for wet-sump applications and a Corvette-based system for dry-sump engines. The dry-sump version (PN 19332614) was used on this project, but it included an A/C compressor that simply didn’t fit. Changes were required. The ABS module and lines had been fitted, too, when this photo was taken.

18. The factory A/C compressor included with the Chevrolet Performance accessory drive was too large and its ports clocked all wrong for the engine’s installation in the Detroit Speed subframe. It will be an issue for stock early F-body frames as well. The solution involved replacing it with a more compact, swap-friendly Sanden unit from Vintage Air. Even still, the subframe required a clearance notch and a mounting bracket was fabricated. Holley stepped up with assistance for the bracket and it may become part of their catalog of LT swap components. This image is from the test-fit/fabrication stage of the installation, prior to the chassis’ powdercoating.

19. Adding hydraulically based power steering was a challenge, and as we outlined in a previous installment, it was solved with a power steering pump and pulley from Turn One. Turn One offers a pump to take the extra load of being in the blower belt track. A power steering pump mount and relocated tensioner were required to fit the DSE chassis; and with some careful layout and component placement adjustments, the stock LT4 blower belt was retained. Because of the packaging requirements, a remote fluid reservoir was required.

20. Additional parts are added to start filling in the blanks of the installation, including the pump for the intercooling system. This is the one called out in the instructions for the crate engine and plugs right into the LT4 wiring harness.

21. Exhaust headers are another important part of the LT swap and Hooker Headers used Stielow’s Camaro to design and fabricate long-tube and mid-length versions that will go into production shortly. We’ll have more on this in an upcoming installment. Stielow’s car will ultimately receive a set of stainless headers with 1 7/8-inch primaries feeding a 4-into-1 collector.

22. The Chevrolet Performance controller for the LT4 is offered in two versions: one for use with the Magnum transmission or a conventional four-speed automatic (PN 19331517) and one for use with GM’s eight-speed automatic (PN 19355174). Along with the controller itself, the kits include the mass air sensor, oxygen sensors, and the all-important fuel pump power module. Here, Mark Stielow lays out some of the harnesses prior to connecting them to the engine. There’s a lot to this portion of the LT swap and we’ll have more on it in a later installment.

Sources

Centerforce – http://www.centerforce.com

D&D Performance – http://www.ddperformance.com

Holley/Hooker/Quicktime – https://www.holley.com/

Scoggin-Dickey Parts Center – http://www.sdparts.com

Tremec – http://www.tremec.com

Turn One Steering – http://www.turnone-steering.com

Vintage Air – http://www.vintageair.com

Walbro – http://www.walbro.com

The post Mark Stielow LT4 Engine Swap Into a 1969 Camaro appeared first on Hot Rod Network.

from Hot Rod Network http://www.hotrod.com/articles/mark-stielow-lt4-engine-swap-into-a-1969-camaro/

via IFTTT

0 notes