#sheet metal fabrication

Text

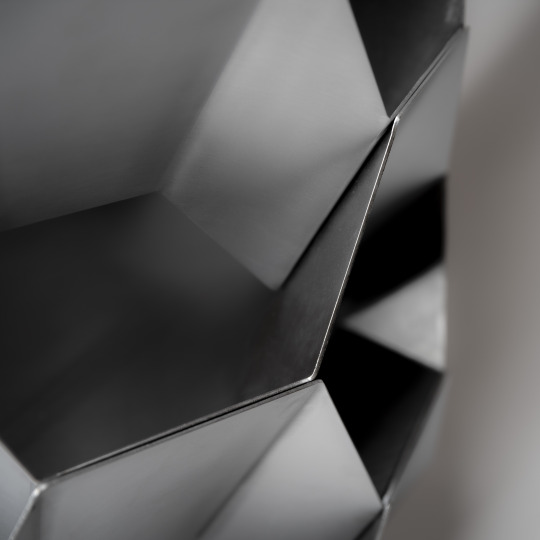

#firebasket#feuerring#firebowl#miunik turo#feuerschale#miunik#product design#sheet metal folding#sheet metal fabrication#parametricmodeling#parametric design#grasshopper#outdoors

194 notes

·

View notes

Text

Mastering Precision Sheet Metal Fabrication: Where Art Meets Science

Precision sheet metal fabrication is the artful synergy of craftsmanship and scientific knowledge. Whether it's in the automotive industry, electronics manufacturing, or medical equipment production, precision sheet metal plays a pivotal role. In this blog post, we delve deep into the world of precision sheet metal and explore how this art and science intertwine.

Defining Precision Sheet Metal

Precision sheet metal fabrication is a highly specialized manufacturing process that encompasses various methods of cutting, bending, stamping, and welding metal sheets. The goal of these processes is to produce parts and components to exact specifications and dimensions without compromising the quality of the metal material. These parts are typically used in applications that demand high levels of precision, requiring meticulous control and inspection at every step.

Applications of Precision Sheet Metal

Precision sheet metal finds wide-ranging applications across various industries, including but not limited to:

Electronics Manufacturing: Precise enclosures, panels, and connectors are essential to ensuring the safety and stability of internal components in electronic products.

Medical Equipment: Medical devices often require highly precise components to ensure accurate measurements and operations.

Aerospace Industry: Aerospace demands lightweight, high-strength components, and precision sheet metal is key to achieving this goal.

Automotive Manufacturing: Various components in automobiles, including bodywork, chassis, and engine parts, rely on precision sheet metal fabrication.

The Craftsmanship of Precision Sheet Metal

The manufacturing process of precision sheet metal is an art that marries precision with expertise. It involves critical steps such as:

Design and Planning: Careful design and planning are necessary before commencing fabrication, ensuring accuracy and consistency.

Material Selection: Choosing the right metal material is crucial for the performance of the final product.

Cutting and Stamping: Employing cutting and stamping machinery to shape the metal sheets into the desired form.

Bending and Shaping: Utilizing bending and shaping operations to curve metal sheets into the required shapes.

Welding and Assembly: Welding individual components together to assemble the final product.

Quality Control

The essence of precision sheet metal lies in quality control. Rigorous quality control procedures and inspection methods ensure that every component meets specifications. This includes the use of high-precision measuring tools, visual inspections, and material testing.

Conclusion

Precision sheet metal fabrication is a domain where craftsmanship and scientific knowledge beautifully converge. Its wide-ranging applications, from electronics to aerospace, make it indispensable in our modern world. Through continual refinement of processes and quality control methods, precision sheet metal fabrication will continue to play a pivotal role in supporting our modern way of life and technological advancements. It's a testament to how art and science work hand in hand to create excellence in manufacturing.

#aviation#sheet metal fabrication#sheet metal manufacturing#sheet metal stamping#sheet metal design#sheet metal market#robots#robotics

7 notes

·

View notes

Text

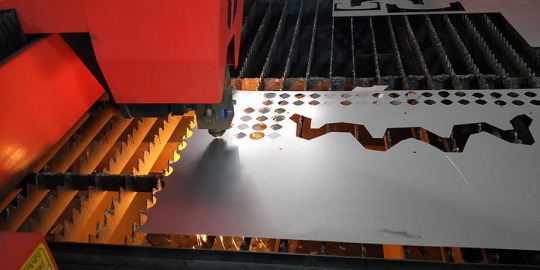

#lasercutting #cncprocessing #cnc #cncservices

#cnc milling service#cnc car parts#online cnc machining services#sheet metal fabrication#sheet metal processing services#custom sheet metal fabrication#cnc turning services#cnc machining services#online cnc precision machining

2 notes

·

View notes

Text

Sheet metal panels with copper coated mild steel weld studs fired in place. For more information on stud welding take a look at our blog post.

https://www.vandf.co.uk/blog/stud-welding-custom-sheet-metal-work-components/

2 notes

·

View notes

Text

Sheet Metal Fabrication

Avalon the top-rated EMS companies in India renowned for their quality services, technical expertise, and customer satisfaction.

#Sheet Metal Fabrication#Powder Coating & Welding#Complete Turnkey Solutions#electronics manufacturing services#electronic manufacturing services#electronic manufacturing services companies#electronics manufacturing services India#electronics manufacturing services chennai#top Ems companies in India#bestEmscompanies in India#EMS

2 notes

·

View notes

Text

On-demand Metal Manufacturing

In order to stay competitive, manufacturers are turning to technology to rearrange all the supply chain: from new products’ design to manufacturing processes and its improvements.

On-demand manufacturing is a highly-demanded service of producing metal parts in precise amounts required — and right away when they’re needed.

What it consists off?

Sheet metal processing (laser cutting, CNC punching and bending, stamping, rolling), mechanical processing (CNC milling and turning, boring, threading, grinding), welding (robot and manual, spot welding), tubes processing (cutting, bending), surface treatment (shot blasting, tumbling, powder coating, wet painting, hot-dip galvanizing), assembly, drawing’s designing, etc.

Unlike traditional manufacturing, it is cost-effective and does not require a minimum batch size to be ordered, and it allows you to have your components in short turnaround time, maintaining cost-per-part low, and realizing products fastly.

In addition, manufacturing on demand significantly reduces the cost of storing, managing, and distributing inventory. Due to high adaptability, it can accommodate both one-off and large-scale (serial) production runs.

On-demand manufacturing serves the needs of a wide range of customers for whom traditional manufacturing isn’t an ideal option. This may include customers who require bridge tooling while they ramp up to high-volume production, who have encountered supply chain disruptions, or who have variable or unpredictable demand for new or existing products.

On-demand manufacturing also makes manufacturing more economical for customers to enter markets with low-volume, niche or customized products. For some customers, traditional manufacturing might not fill their needs. This may apply to customers that face supply chain disruptions, whose demand for custom-made or new components is not constant and unpredictable, or when there are needed bridging tools (while increasing production volume).

#business#news#developers & startups#sheet metal fabrication#sheet metal market#on demand#manufacturing

3 notes

·

View notes

Text

Precision Sheet Metal Fabrication Manufacture in India!

Discover the potential of Precise Sheet Metal Fabrication Manufacturing with our expert guidance and careful attention to detail.

0 notes

Text

Sheet Metal Fabrication

When it comes to sheet metal fabrication, you need quality you can trust. That's why you should turn to Nagualmetal for all your sheet metal needs. We use the best materials to create high-quality sheet metal products that will stand the test of time. Get outstanding results with Nagualmetal's sheet metal fabrication services today! Read more : https://nagualmetal.en.alibaba.com/productgrouplist-924878740/Sheet_Metal_Fabrication.html?spm=a2700.shop_plgr.88.11.646d7b2cmd1SpG

#cnc machining service#progressive stamping die#sheet metal fabrication#plastic injection mold#prototype fabrication

0 notes

Text

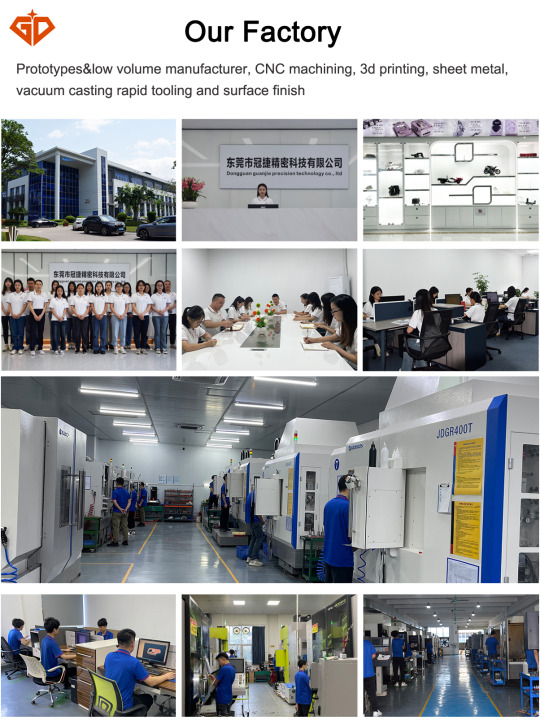

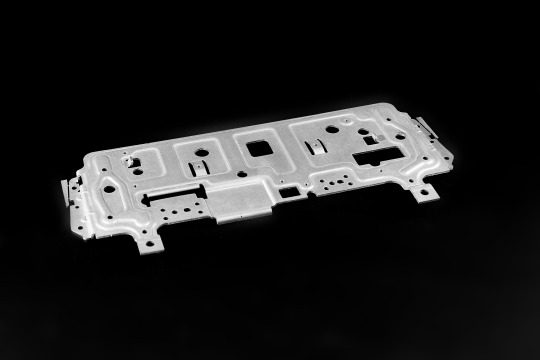

We are a Prototypes&low volume manufacturer, provide CNC machining, 3d printing, sheet metal, vacuum casting rapid tooling and Injection Molding.If you need it for your recent projects, please contact me:[email protected]

#prototyping#cncmachining#5 axis machining#cnc milling services#sheet metal#sheet metal fabrication#sheet metal manufacturing

0 notes

Text

Various Types of Metals Used in Sheet Metal Fabrication

The process of cutting, bending, punching, and welding thin, flat metal sheets into different forms is known as sheet metal fabrication. Sheet metal fabrication is a process used to form and configure various metals, including aluminum, titanium, steel, copper, tin, brass, and steel. Silver, gold, and platinum are good ornamental metals. Many different things with differing thicknesses are made…

View On WordPress

#Online Sheet Metal Fabrication#Sheet Metal Fabrication#Sheet Metal Fabrication Process#Sheet Metal Fabrication services#Sheet Metal Fabrication Techniques

0 notes

Text

5 Common Misconceptions About Sheet Metal Contractors Debunked

In the world of construction and manufacturing, sheet metal contractors play a vital role. However, there are several misconceptions surrounding their work that often lead to misunderstandings. Let’s debunk some of these myths to gain a clearer understanding of what sheet metal contractors really do.

Sheet Metal Work is Limited to Roofing and Gutters Contrary to popular belief, sheet metal contractors aren’t solely responsible for roofing and gutter installations. While they do handle these tasks expertly, their expertise extends far beyond. From HVAC systems to custom fabrications for machinery, sheet metal contractors are adept at various applications, making them indispensable in numerous industries.

Sheet Metal Work is Only for Large-Scale Projects Another misconception is that sheet metal contractors are only needed for massive construction projects. In reality, they cater to projects of all sizes, including residential, commercial, and industrial. Whether it’s crafting bespoke metal fittings for a home renovation or fabricating intricate components for a manufacturing plant, sheet metal contractors are equipped to handle diverse projects with precision and efficiency.

Sheet Metal Work is Basic and Uncreative Some might think that working with sheet metal involves nothing more than cutting and bending metal sheets. However, this couldn’t be further from the truth. Sheet metal contractors are skilled artisans who bring creativity and innovation to their craft. They can transform raw materials into intricate designs and custom fabrications, turning clients' visions into reality. Whether it’s creating unique architectural features or crafting aesthetically pleasing signage, sheet metal contractors excel in blending functionality with artistry.

Sheet Metal Work is Expensive While quality craftsmanship comes at a price, the notion that sheet metal work is exorbitantly expensive is unfounded. In fact, investing in sheet metal solutions often proves to be cost-effective in the long run. The durability and longevity of sheet metal products reduce the need for frequent repairs and replacements, ultimately saving both time and money. Additionally, sheet metal contractors offer bespoke solutions tailored to clients' specific requirements, ensuring optimal value for their investment.

Sheet Metal Work is Hazardous and Unsafe While working with metal does pose certain risks, modern safety protocols and equipment mitigate these hazards significantly. Sheet metal contractors undergo extensive training to adhere to safety standards and guidelines, ensuring a secure working environment for themselves and others. By employing best practices and utilising appropriate protective gear, sheet metal contractors minimise the likelihood of accidents and injuries on the job.

By debunking these misconceptions, it becomes evident that sheet metal contractors are indispensable professionals with a diverse skill set and a commitment to excellence. Whether it’s crafting bespoke fabrications or executing intricate installations, their expertise and dedication contribute to the success of various projects across industries. So, the next time you require sheet metal work, remember to dispel these myths and appreciate the invaluable contributions of these skilled artisans.

0 notes

Text

#miunik#feuerschale#feuerring#firebasket#firebowl#miunik turo#product design#sheet metal fabrication#sheet metal folding#parametric design#parametricmodeling#grasshopper

12 notes

·

View notes

Text

Sheet metal is where creativity meets craftsmanship. It's the magic of transforming ordinary metal sheets into extraordinary creations. From sleek automotive designs to cutting-edge electronics, sheet metal plays a pivotal role in shaping our world. With cutting, bending, punching, and welding at our fingertips, we craft your visions into reality. Whether you're prototyping, mass-producing, or seeking bespoke solutions, sheet metal delivers the versatility and precision your project deserves. Elevate your innovation with sheet metal, where imagination takes form.

8 notes

·

View notes

Text

Aluminium sheet metal brackets. CNC punched and CNC folded. Barrel deburred to remove sharp edges, ready for shipping to our customer.

http://www.vandf.co.uk/gallery/bracket-angle-gallery/

#sheetmetal#sheet metal bending#sheet metal fabrication#cnc punching#cnc brake press#cnc bend#aluminium

2 notes

·

View notes

Text

Progressive Stamping Die

Take metal manufacturing to the next level with Progressive Stamping Die! Our high-quality dies are made to last and are perfect for any custom metal project. Unlock the potential of metal manufacturing with Progressive Stamping Die today! Visit : https://nagualmetal.en.alibaba.com/productgrouplist-919732885/Progressive_Stamping_Die.html?spm=a2700.shop_plgr.88.10

#cnc machining service#progressive stamping die#sheet metal fabrication#plastic injection mold#prototype fabrication

0 notes

Text

Invitation to the 2024 China (Guangzhou) Int’l Metal & Metallurgy Exhibition-2024广州巨浪国际金属暨冶金工业展览会#metal #metallurgy #spring #tube #pipe #casting #diecasting #platemetal #bar #wire #stainlesssteel #foundry #heattreament #industrialfurniture #furnace #sheetmetal #forging #laser #steel

#metal#public exhibition#spring#tube#manufacturer#casting#die casting#stainless steel#sheet metal manufacturing#galvanized#sheet metal fabrication#heat treatment#laser

1 note

·

View note