#ore processing

Text

Top 6 Steps of Iron Ore Processing

Iron ore is a type of mineral that is mined from the earth. It is used in a variety of ways, including in the production of steel. However, it can also be a pollutant. When iron ore is exposed to air, it creates rust. This rust can contaminate water and soil and make them unusable. For this reason, it is important to remove iron ore from these areas. After being removed from the mine, iron ore must go through a number of processing steps.

Iron ore processing steps are as follows:

Screening

Stockpiling and Crushing

Feeding the Crusher (Reclaim)

Grinding

Spiral gravity separation

Magnetic division

0 notes

Text

The fact that this is canon non-genderbend long haired Kabru ... Madame Kui please, I'm about to start chewing glass.

#Kabru#Dungeon Meshi#Dungeon Meshi spoilers#sorry for locking spoiler conscious anime onlys out of this post for the sake of a stupid meme but it was crucial to my process#also I can imagine Kabru growing out his hair post canon. as a treat.#I posted this pic in one of my group chats with “guy who uses 'ore wa'”#also shout out to buzzcut Kabru looking like the butchest woman twitter can handle before they get scared

2K notes

·

View notes

Text

marbled skies & shimmering stardust 🌠✨

#My Characters#Atlas#accidentally ended up making this m ore detailed than initially intended#and i almost considering redoing the whole colouring process. b ut#just a lil experiment#but.. my atlas.. they are everything to me 🥹

706 notes

·

View notes

Note

wait no please explain mineral processing!!!

I gasped in delight at the ask, haha. I love mineral processing.

Mineral processing is the theory of economically getting your desired element out of whatever it naturally comes in. So Li out of spodumene, or Cu out of chalcopyrite. It's usually split into hydrometallurgy and pyrometallurgy (liquid chemistry and melting the fuck out of it, respectively), and often taught as hard rock extraction, but you need it for Every Element, really. So you can also focus on extracting phosphates, or nitrates, or uranium! It's chemistry++~

Personally, I know the most about copper extraction and my focus is on hydrometallurgy/geometallurgy, although pyrometallurgy is near to my heart. Copper is coincidentally a really good example of how the two work because it comes as so many natural minerals. (Further explanations under the cut...)

So for copper minerals! You have a whole slew of oxides and sulfides. They occur in different part of your orebodies under different states of oxidation/sulfidation. Take Chrysocolla, Malachite, Chalcocite, and Chalcopyrite. (Cu-silicate)(an oxide), (Cu-carbonate)(an oxide), (Cu-Sulfide), and (Cu-Fe-Sulfide).

Mines usually use hydrometallurgy for oxides by sticking them in a leach heap and pouring sulfuric acid over the whole thing. The acid selectively picks up the Cu ion from silicates and carbonates, leaving the primary tetrahedra alone. The sulfides can work with this chemistry if the mineral's comfort zone is outside of the current conditions (Chalcocite does leach, but usually leaves a Cu ion in the structure as CuS) but minerals like Chalcopyrite are very poor leachers because the outer rim of ions are ripped away, leaving a somewhat-hypothetical "passive layer" of Fe/S that won't react with the acid. So if you have a mine with a lot of Chalcopyrite, you'll be leaving money on the table unless you do something.

So people use pyrometallurgy! Which is what we've been using since the Bronze Age, really. You crush the rock to micrometer grains, use the hydrophobic properties of sulfur to "float" the sulfides in water, then send all of it to the smelter and melt the shit out of it, while adding particular chemicals and minerals to enhance copper recovery while suppressing sulfides you don't want, like sphalerite and galena.

It's REALLY cool. I'm biased of course, but I absolutely love the whole cycle. xD Being in mineral processing also gets you on the backside of geopolitics because you're the only person who understands how to GET things and WHERE to get them and why it's not as simple as pulling Cu out of the ground.

Feel free to ask questions!! I love processing so much, and mining in general, even though I'm only a master's student.

((And NO STUPID QUESTIONS. The mining industry is a goddamn black box DO NOT feel bad if you don't know what stuff means or formulas, or processes. I swear I learn one new word a week. They also have fifty names for everything too because 50 names are always better than 1. 👍)

#Mineral processing is like- the pinnacle of geology in my opinion. I feel so biased saying this! lmfao. I love it though! It's why it#matters if you have Bornite or Chalcopyrite in the ground; or if your ore deposit is in an ophiolite or a porphyry; or if your gold is in a#quartz vein or a fault zone. If your gold is stuck as native in quartz you might not be able to get it out!#To be clear I'm a geologist too. Technically in engineering because that's where this stuff is taught but I identify as Geologist~#mining#mineral processing#geology#I hope I didn't talk too much! I tried to give a good explanation without teaching a class. It's so much info. lol

22 notes

·

View notes

Text

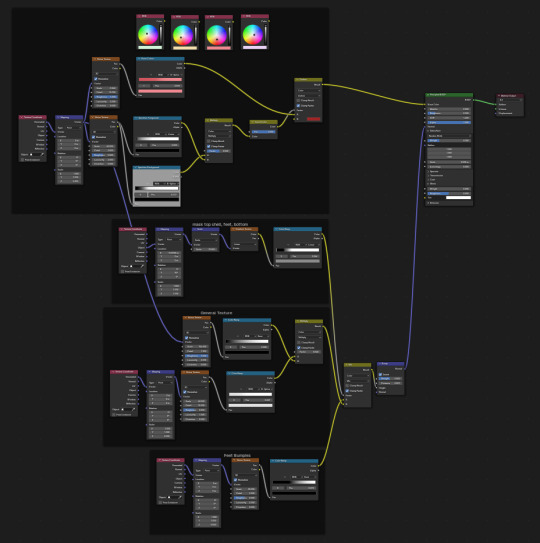

Process - Sunakawa Cake 🎂

A little breakdown of how I made my 3D recreation of the "thank you sunakawa" cake from Ore Monogatari ~

1. Collecting reference

Aside from referencing stills from the anime, I came across the official cake sketch from Madhouse's website! It was really helpful in identifying all the toppings on the cake and other details.

Next was collecting real-life references of all the ingredients I needed to make and taking notes of the shapes, textures and variety.

2. Modelling & Texturing

I go back and forth between modelling and texturing, and jump all over the place so I'll break things down based on the toppings/elements:

A. Macaron

I referenced Canosie Lab's macaron tutorial here, tweaking the process a little bit; using one mesh instead of two and using particles to distribute the boolean meshes. I ended up with LOTS of vertices, so I made a lower poly version of the macaron and used those to avoid bogging down the computer. As for the texture, I used Blender's procedural nodes, utilizing mostly the noise texture node.

Above: The first row are the lower poly versions of the macaron and the second row are the original meshes with around 200,000 vertices each o_o

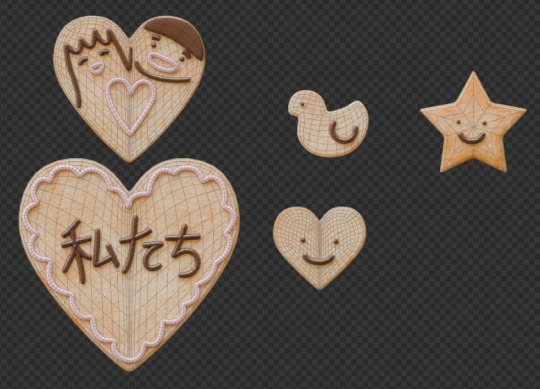

B. Cookies

There's not much to it here; I just modeled the cookies and used procedural textures I've made for a previous project (I'll post that project soon!!!)

The icing is made using bezier curves with some bevel depth. I used the draw tool to draw on the cookies. I did the same for the writings on the cake.

C. Strawberries

I've previously made strawberries for another project so I just used those but baked them to a lower poly mesh first. I used Canosie Labs' strawberry tutorial as reference :) I initially used a scaled down version of the regular-sized strawbs, but decided to make a proper mini strawberry 🍓

Left: with scaled down regular strawberries, Right: proper mini strawberries.

I made them super shiny with lots of subsurface scattering to make them look juicy and gummy-like -- not the most realistic but I think they look cuter like this :>

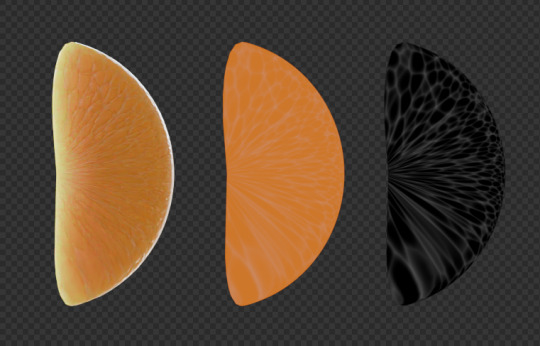

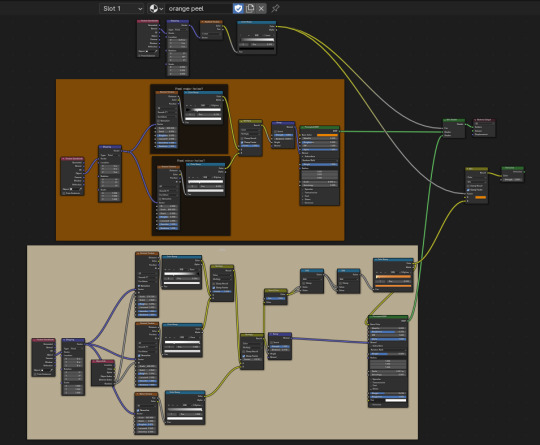

D. Orange slices

The orange slices were the most challenging to make! Did a lot of trial and error to get that pulpy texture oranges have but I managed using a combination of voronoi nodes :") If you look at the pictures below, you can see how the orange looked in the beginning vs. at the end after I refined it some more.

They look fine from a distance but a little janky up close; maybe I'll do a breakdown one day once I figure out a proper node setup.

Above: before & after

Left to right: rendered, colour only, B/W

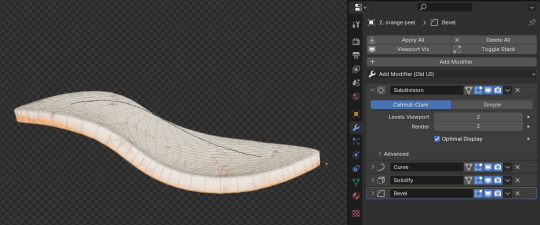

E. Orange peel

A simple plane with a solidify and curve modifier. What's most important here is the texture! I used two different shaders (one for the pith another for the peel) combined using a mask.

F. Jelly beans & choco marbles

A tweaked subdivided square for the jelly beans and subdivided icosphere for the choco marbles. The two use pretty much the same shaders but the jelly beans have more subsurface scattering.

H. Cake

After placing all the toppings, I sculpted the cake (using the multires modifier) a little bit to model the cream that's displaced.

#ore monogatari#sunakawa makoto#process#3d modeling#artists on tumblr#blender#blender 3d#3d model#cake#b3d#3d art#3d render#3d#digital art

20 notes

·

View notes

Text

You know, I went into the anime adaptation of the Swordsmith Village Arc knowing it just wasn't going to have the same punch as previous arcs due to the pacing (primarily being a vehicle for flashbacks as opposed to slowly building tension), lack of impactful villains (Hantengu's back story simply does not have the impact or emotional draw of Rui or the Shabana siblings, and Gyokko is... he's just Gyokko), and incomplete-feeling character arcs (this is all set-up for pay-off on Mitsuri, Muichiro, and Genya, whereas Uzui & Rengoku had more satisfying arcs contained within single story arcs).

I knew this, and despite not totally sticking the landing with filler, I think Ufotable did a fine job with the material they had to work with.

I do have one criticism, though.

IT NEEDED MORE SWORDS.

Swords!!! Are!!!!! Beautiful!!!!! And!!!!!! The craftsmen!!!!!!! Are!!!! Amazing!!!!!!!!!! And!! Nichirinto!!! Are!!! So!!!! Special!!!!!!

GIVE US MORE SWORD LORE, GOTOUGE!!!!!! GIVE ME ALL YOUR TAISHO SECRETS!!!!!!!!!!!!!

#SWORDS SWORDS SWORDS#can you tell I've been doing sword research again? I have.#i am just... so enamored with how a mountain of sand and clay and trees and water and so many hours of physical labor are necessary#for even producing the iron ore in the first place#so much fire#SO MUCH FIRE#and THEN the swordsmith works a totally different magic on it#so much patience#SO MUCH FIRE AGAIN#and charcoal is ever-present along the way#It's just#beautiful#I want so badly to know more about the sword sharpening process#to better appreciate Haganezuka's personal battle#there are knife sharpening classes I could sign up for but I don't know that I'll learn stuff applicable to swords#even if Japanese knives do stem from the same traditions

43 notes

·

View notes

Text

fussing about the old muleskinner novel again, because the cursor & eques brainworms are reactivating, and that was such a relatively easy novel to write, and this one is hard

#del gets personal#cant belive this book abotu am ore comlicated character in a more complicated plot in a more complicated Situation#is harder and more complicated to write. who could have believed it.#anwyay i miht take a break from writing for a wek or two and reread what ive got now#and do some backgroudn work for it. give people names. make some family trees. that sort of thing.#anyway im sure that 40k into c&e i was fussing over how hard it was too. thats jsut what im like. its part of hte process

6 notes

·

View notes

Text

only fellow haters understand

5 notes

·

View notes

Text

my ear may never get better :/

#i still cant hear from it#they told me ny ear would get better after the infection#but the infectiln is gone#i think i lost like .ore than 60% hearing in my left ear#:// and i already have processing disorder and GOD It also got worst#its the bad days ya'll ✋#idk if I can tag this as Hoh but gotta be risy#risky i meant#hard of hearing#actually hoh#mine#ill#vent#mmm

1 note

·

View note

Text

IME 2023 presented the ideal platform to showcase CFlo's Mineral Beneficiation Solutions

11 November, 2023

CFlo recently participated in the 10th International Mining, Equipment & Minerals Exhibition (IME) held at Eco Park in Rajarhat, Kolkata from 6th to 9th November 2023. IME is an ideal platform to display and launch machinery, products, new initiatives, and technologies, as well as to establish strong business alliances and develop and renew regional and international business contacts. This event was a remarkable milestone for CFlo, providing a platform to highlight their patented modular mineral beneficiation technology that can add significant value to mining operations.

The company's advanced mineral beneficiation technology has been designed with the aim of optimizing efficiency, reducing project timelines, and minimizing environmental impact. These solutions cater to a wide range of applications and are particularly valuable for extracting value from low-grade ores. CFlo's participation in IME underscored the company's dedication to pushing the boundaries of what is possible in the mining industry. Their innovative solutions not only increase resource efficiency but also contribute to sustainable mining practices, aligning with global efforts to reduce the environmental footprint of mining operations.

The advanced mineral beneficiation technology reduces contaminants from ore/mineral surface which in turn reduces coal consumption, increases the campaign life of the kiln, reduces raw material costs, and delivers significant efficiencies to overall plant operations. Moreover, it can adapt to the varying nature of the feed material and improve output quality by considerably increasing the Fe value.

Prasun Kr. Dutta, Sales Head, Mineral Processing, CFlo, said, “IME 2023 was a great opportunity to interact and exchange knowledge with some of the biggest mining as well as iron and steel manufacturers. Our patented wet screening technology attracted many visitors who showed interest in exploring our solutions. The production of steel and the country's steel exports are projected to increase significantly and we are excited to offer our technology solutions to augment this leap."

We are grateful to the organizers for offering us a wonderful platform to interact with key business prospects and partners and the opportunity to showcase our latest mineral processing solutions. We hope our participation has added value to the collective vision of building a smarter, sustainable future for our country. IME 2023 was a pivotal event for industry players, and CFlo's presence was a highlight, showcasing the future of mineral beneficiation.

For more information please visit us : https://cfloworld.com/cflo-showcases-mineral-beneficiation-solutions-ime-2023.html .

================================================

Company Name : CFlo World

Address : Ecospace Business Park Block 4A/Floor 6, Action Area II New Town, Rajarhat Kolkata 700 160, India

Official Email Address: [email protected]

Phone: +91 33 3029 3800

Fax: +91 33 3029 3802

Url : https://cfloworld.com/

0 notes

Text

Processing Waste Dumps of Iron Ore at Goa, India

Processing Iron Ore Waste Dumps at Goa, India

In recent years, the issue of processing waste dumps of iron ore has become increasingly important in the state of Goa, India. As one of the leading iron ore producers in the country, Goa has faced significant challenges in managing the waste generated during the extraction and processing of this valuable natural resource.

Iron ore mining and processing have long been vital to the economy of…

View On WordPress

1 note

·

View note

Text

I was supposed to talk about Lustrum hours processing once upon a time, wasn't I?

#*brainpower seeping into the negatives*#tldr hours are actually an element so dense its metaphysically inverted itself.#you separate the rough ore by magnetic proerties and then send that mineral into large vats of water#and the vats give off O2 gas as the hours bond with H and form crystals and thats how you get refined hours#sskies#hire me failbetter#just googled and apparently K burns purple so im on the right track Hours are just some stupid high-density d shell element#Okay now im putting too much thought into it but Al and K burn purple so what if we pretended Hours was something like fucked up carbon#no no oxygen. so you have something like (K#(K-Hour) CH CO3 so its volatile and itll burn and its a magic stupid mineral with a magic stupid endmember with purple burning k#so the mineral you DONT want is K and they burn that and then send hours to be processed#ITS SO LATE. WHY AM I THINKING ABOUT THIS

4 notes

·

View notes

Text

Jai Balaji Jyoti Steels implements CDE Asia's advanced Mineral Beneficiation Plant for elevating iron ore processing

CDE Asia partners with Jai Balaji Jyoti Steels, a leading private-sector steel manufacturer in Eastern India, to revolutionize iron ore beneficiation in the region.

Jai Balaji Jyoti Steels Limited, a unit of Jai Balaji Group, a trusted name in the steel industry recently installed CDE Asia’s Oremax Multi featuring the Prograde Double-deck rinsing screen with three discharge outlets at Raurkela, Odisha. The plant commissioned in 2021 has a feed capacity of 100 TPH and is designed to increase the grade of iron ore by removing unwanted impurities from raw materials, such as silica, thereby improving the quality of the final product. The inclusion of the Xtrill® lined modular Hydrocyclone for Turbo Dual Wash, along with the Attrition Wash Box (AWB), can significantly enhance the washing quality of the product. The plant operates fully automatically and produces three grades of high-quality products (Fe grade 60+) that are suitable for direct use in the steel industry.

The plant is equipped with a PLC-based automatic system that ensures seamless operations, high productivity, and uninterrupted performance. Its eco-friendly design includes Zero Liquid Discharge technology, which enables the recycling of up to 95% of water.

Prior to implementing CDE Asia’s Iron Ore beneficiation plant, the client had acquired raw materials (58 to 60-grade iron ore) at a high expense from a variety of mines in the Barbil region to replenish raw material stock. The absence of an in-house iron ore beneficiation plant posed a significant challenge in procuring raw materials from the market, leading to inconsistency in the quality of materials and frequent price fluctuations based on their availability. To address this issue, the client decided to invest in their own ore washing plant and awarded the contract for the entire iron ore washing plant to CDE Asia after conducting a comprehensive testing process.

The cutting-edge washing technology by CDE Asia is effectively eliminating all ultra-fines and generating a clean output, which is leading to a longer campaign life in the furnace for the customer. Furthermore, this is decreasing coal consumption during steel production, which positively impacts the economic feasibility of steel-making.

The 100 TPH Oremax Multi in Odisha produces high-quality calibrated lump ore by removing impurities from low-grade ores. The collaboration between Jai Balaji Jyoti Steels and CDE Asia enabled the former to achieve their sustainable mining goals while simultaneously increasing their productivity and profitability.

Mr. Joseph K Thomas, Project In-charge, Jai Balaji Jyoti Steels, says “the decision to choose the CDE Asia system was based on several factors. Firstly, it operates smoothly with minimal dust and noise pollution, ensuring a safe working environment. Secondly, its compact design requires minimal supervision, reducing risks and maximizing resource efficiency. Thirdly, it produces a superior quality product used in DRI. Lastly, after seeing the successful operation of the plant, we are confident with our decision and would definitely recommend this system to others. We are thoroughly impressed with CDE Asia for the successful commissioning of this project and would like to continue working with them in the future as well”.

CDE Asia and Jai Balaji Jyoti Steels champion sustainable steel production through their ground-breaking iron ore beneficiation technology.

For more information please visit us : https://cdeasia.com/news/2023/june/jai-balaji-jyoti-steels-implements-cde-asias-advanced-mineral-beneficiation-plant-for-elevating-iron-ore-processing .

=================== =================== ===================

Company Name: CDE Asia Limited

Address: Ecospace Business Park Block 4A/Floor 6, Action Area II New Town Rajarhat Kolkata 700 160 India

Phone: +91 33 3029 3800

Fax: +91 33 3029 3802

Url: https://cdeasia.com/

Email: [email protected]

0 notes

Text

Get premium quality Iron Ore Processing Plants from the most famous company Kinc Mineral Technologies. These Plants are designed using the highest-quality materials, and techniques and are known for their robust construction and easy maintenance. We are the most famous Iron Ore Processing Plant manufacturers and suppliers in India. For more details, visit our website.

#Iron Ore Processing Plants manufacturers#Iron Ore Processing Plants suppliers#Iron Ore Processing Plants exporters#Iron Ore Processing Plants

0 notes

Text

How to Beat the Potential Lithium Shortage?

By now, lithium is probably recognized as a useful material and is considered to be critical for dealing with climate change. A recent paper in Nature (vol 616, 245) discussed some of the issues. In 2018, demand for lithium was about 55,000 t/a, by 2025 it is expected to reach 150,000 – 190,000 t/a, and by 2100 it could reach 700,000 t/a. The IEA predicts that by 2030, only about half of what is…

View On WordPress

#alternative lithium extraction methods#lithium demand#lithium ore processing#pollution from lithium processing

0 notes

Text

The Sand Grains Foundation plants 200 Saplings at Green Verge 5, New Town, Kolkata

23 January 2023

Sand Grains Foundation recently conducted a tree plantation drive at Newtown, Kolkata as part of their Carbon Offset Program

At Sand Grains Foundation,we recently conducted a tree plantation drive ’41 Shades of Green’ to inaugurate the new Green Verge 5 (Action Area 1B) at New Town, Kolkata.

The event was held in association with Bengal Chapter of Harley Owners Group and 41 Clubs of India, an organization working to serve the needy and underprivileged. 200 saplings were planted to further our cause to offset carbon emissions and live sustainably in harmony with nature.

Established in 2021, the Sand Grains Foundation is a not-for-profit organization that has always fostered sensitivity towards our resources – natural and human. Our environmental program entails achieving Net Zero by 2030. The project revolves around offsetting carbon emissions by planting and nurturing trees thereby aiding the development and use of renewable energy resources. We aim to plant 25,000 trees by 2025-2026 and have taken various other measures for reducing carbon emissions and minimizing our footprint on the planet. On the social development front, unleashing human potential through education and providing medical and developmental aid to backward populations has featured among our priorities.

Mr. Sanjay Singh, Director, Sand Grains Foundation, said, “It gives us immense pride and pleasure to inaugurate the new Green Verge and put another foot forward to increase the green cover of Kolkata. Sand Grains Foundation is committed to arresting carbon emissions which involve protecting and restoring nature on a never-before scale.��

The event saw an overwhelmingly positive response from all the participants as well as the residents from the nearby precincts.

For more information please visit us : https://cdeasia.com/news/2023/january/the-sand-grains-foundation-plants-200-saplings-at-green-verge-5-new-town-kolkata

==========================================================

Company Name: CDE Asia

Address: Ecospace Business Park Block 4A/Floor 6, Action Area II New Town Rajarhat Kolkata 700 160 India

Phone: +91 33 3029 3800

Fax: +91 33 3029 3802

Url: https://cdeasia.com/

Email : [email protected]

0 notes