#in vadodara

Text

youtube

#in vitro fertilization#in vitro diagnostics market#investment#in vadodara#in viaggio#in vino veritas#Youtube

0 notes

Text

HAST Test Sieves Manufacturer in Vadodara - Precision and Quality

Explore top-quality HAST test sieves manufactured in Vadodara. Trust our precision and commitment to excellence for accurate and reliable testing results.

#Sieves manufacturer#Hast Test Sieves manufacturer#Haver EML Test Sieve Shakers#Ro-tap Sieve Shaker#Certified sieves#Calibrated sieves manufacturer#in vadodara#gujarat#mumbai#india

0 notes

Text

Connect with Polywin | Exceptional Wire & Cable Solutions

Reach out to Polywin for all your wire and cable needs. Get in touch with us through email or phone, Contact Polywin today for reliable and efficient service.

#Best Quality#Copper Bare Wire#Bare Wire#Copper Bare Wire supplier#Copper Bare Wire Manufacturer#Aluminium Bare Wire#Aluminium Bare Wire supplier#Aluminium Bare Wire Manufacturer#in vadodara#gujarat#india

0 notes

Text

RK Industries |Contact Us for Dye Solutions Expert Assistance

RK Industries provides top dye solutions for textiles, printing inks focusing on innovation, precision & customer satisfaction to enhance business operations

#Top#Leading Exporter of#Leading Manufacturer of#Oeko Tex Certified#Contact Details#email of#Rk Dyechem Private Limited#Products#Manufacturer#Suppliers#Dealers#in Vadodara#Gujarat#India#Vietnam#Brazil

0 notes

Text

Lakshmi Vilas Palace, Vadodara, Gujarat, India

#art#design#architecture#history#luxury lifestyle#style#luxury house#luxury homes#palace#lakshmi vilas palace#vadodara#india#gujarat#patio#fountain#luxury home

1K notes

·

View notes

Text

Lukshmi Vilas Palace, Vadodara, India.

#beyondheritage#lukshmi villas palace#vadodara#gujarat#india#south asia#architecture#indian architecture

151 notes

·

View notes

Text

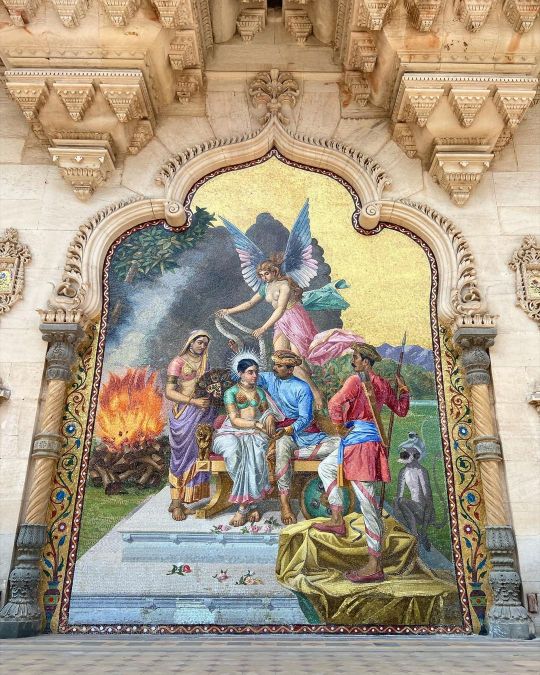

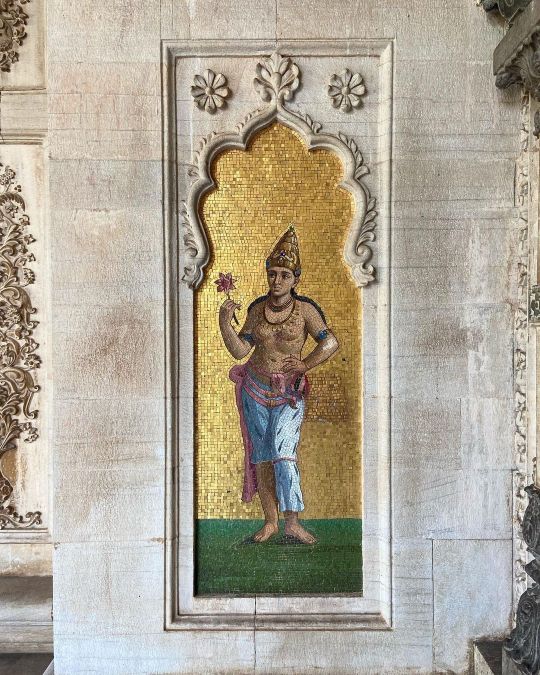

venetian mosaic murals at laxmi vilas palace, vadodara, india; ph. sharang pawar

#so gorg omg#laxmi vilas palace#vadodara#india#indian architecture#venetian murals#italian architecture#sharangpawar#upl#🌟#art

110 notes

·

View notes

Text

The Heart of Boiler Systems: Exploring the Role of IBR Fitting and Flanges

Boiler systems serve as the backbone of numerous industrial processes, powering everything from heating and hot water supply to steam generation in various manufacturing operations. Within these systems, ensuring safety, efficiency, and reliability is paramount, and this is where IBR (Indian Boiler Regulations) fitting and flanges play a pivotal role. As a trusted distributor in Vadodara and a leading dealer in Gujarat, Tubetrading is dedicated to providing top-quality IBR fitting and flanges to industries across the region. In this blog post, we'll delve into the significance of IBR fitting and flanges in boiler systems, explore their crucial functions, and highlight the expertise of Tubetrading in supplying these essential components.

Understanding IBR Fitting and Flanges

IBR fitting and flanges are integral components of boiler systems that ensure seamless operation and compliance with safety standards mandated by the Indian Boiler Regulations. These regulations are designed to safeguard the integrity of boiler components, prevent accidents, and promote efficient energy utilization. IBR fitting and flanges are manufactured according to stringent specifications outlined by the IBR to guarantee durability, reliability, and performance in demanding industrial environments.

The Role of IBR Fitting and Flanges in Boiler Systems

1. Pressure Regulation: IBR fitting and flanges are designed to withstand high-pressure environments commonly found in boiler systems. They play a crucial role in regulating and controlling the flow of fluids, gases, and steam within the system, ensuring optimal pressure levels for efficient operation.

2. Sealing and Joint Integrity: Proper sealing and joint integrity are essential to prevent leaks and maintain the integrity of boiler systems. IBR fitting and flanges are equipped with robust sealing mechanisms, such as gaskets and O-rings, to create a tight seal between interconnected components, minimizing the risk of leaks and ensuring system integrity.

3. Connection and Interoperability: IBR fitting and flanges serve as connection points between various components of boiler systems, including pipes, valves, and vessels. Their standardized dimensions and configurations enable seamless interoperability, facilitating efficient assembly, maintenance, and repair of boiler systems.

4. Compliance and Certification: Compliance with IBR regulations is mandatory for all boiler components used in India. IBR fitting and flanges undergo rigorous testing and certification processes to ensure compliance with safety standards and regulatory requirements, providing peace of mind to industries reliant on boiler systems.

Tubetrading: Your Trusted Supplier of IBR Fitting and Flanges in Gujarat

As a reputable distributor and dealer of IBR fitting and flanges in Vadodara and Gujarat, Tubetrading prides itself on delivering superior-quality products and exceptional service to its customers. Here's why industries trust Tubetrading for their IBR fitting and flanges needs:

1. Extensive Product Range: Tubetrading offers an extensive range of IBR fitting and flanges, including elbows, tees, reducers, bends, and flanges in various sizes, materials, and specifications. Whether you need standard or customized components, we have the expertise and resources to meet your requirements.

2. Quality Assurance: At Tubetrading, quality is our top priority. We partner with reputable manufacturers who adhere to strict quality control measures and comply with IBR regulations. Our products undergo thorough inspection and testing to ensure they meet the highest standards of performance, reliability, and safety.

3. Expert Guidance: With years of experience in the industry, the team at Tubetrading possesses in-depth knowledge of IBR fitting and flanges and their applications in boiler systems. We provide expert guidance and technical support to help our customers select the right components for their specific needs, ensuring optimal performance and efficiency.

4. Timely Delivery: We understand the importance of timely delivery to our customers' operations. With our efficient logistics network and inventory management systems, we strive to fulfill orders promptly and ensure on-time delivery of IBR fitting and flanges to our customers across Gujarat.

Conclusion

In conclusion, IBR fitting and flanges are the heart of boiler systems, playing a critical role in ensuring safety, efficiency, and compliance with regulatory standards. As a trusted distributor and dealer in Vadodara and Gujarat, Tubetrading is committed to supplying top-quality IBR fitting and flanges to industries across the region. With our extensive product range, quality assurance, expert guidance, and timely delivery, we are your reliable partner for all your IBR fitting and flanges needs. Contact Tubetrading today to learn more about our products and services and discover how we can support your boiler system requirements.

#IBR Fitting and Flanges distributor in Gujarat#IBR fitting and flanges distributor in Vadodara#IBR fitting and flanges dealer in Gujarat#IBR fitting and flanges#Gujarat#Maharashtra#Rajasthan#Madhya Pradesh#Daman#Uttar Pradesh

7 notes

·

View notes

Text

Preserving Assets: The Role of Corrosion Inhibitors in Industrial Maintenance

Corrosion is a persistent threat to industrial assets, causing billions of dollars in damages annually across various sectors. From oil and gas facilities to manufacturing plants, the impact of corrosion can be devastating, leading to equipment failures, production downtime, and costly repairs. However, with the right preventive measures in place, such as corrosion inhibitors, industrial facilities can effectively mitigate the risk of corrosion and prolong the lifespan of their assets. As a leading chemical company in Vadodara, Imperial Oilfield Chemicals Pvt. Ltd. (ICPL) understands the critical role of corrosion inhibitors in industrial maintenance. In this blog post, we'll explore the importance of corrosion inhibitors, their applications, and the expertise of ICPL as a corrosion inhibitor manufacturer and exporter in India.

Understanding Corrosion Inhibitors

Corrosion inhibitors are chemical compounds designed to protect metal surfaces from the damaging effects of corrosion. By forming a protective barrier on the metal surface or altering the corrosion process, inhibitors prevent or slow down the oxidation and deterioration of metals in corrosive environments. Corrosion inhibitors are widely used in various industries, including oil and gas, petrochemicals, power generation, water treatment, and manufacturing, to safeguard critical assets and infrastructure from corrosion-related failures.

The Importance of Corrosion Inhibitors in Industrial Maintenance

1. Asset Protection: Industrial facilities rely heavily on equipment and infrastructure made of metal, such as pipelines, tanks, vessels, and machinery. Corrosion inhibitors play a crucial role in protecting these assets from corrosion, extending their service life and reducing the need for frequent repairs or replacements.

2. Cost Savings: Corrosion-related failures can result in significant financial losses due to equipment downtime, production disruptions, and repair expenses. By incorporating corrosion inhibitors into maintenance programs, industries can minimize the risk of corrosion-related failures and realize substantial cost savings in the long run.

3. Safety and Reliability: Corrosion compromises the structural integrity of industrial assets, posing safety hazards to personnel and the surrounding environment. Corrosion inhibitors help maintain the reliability and safety of critical infrastructure, reducing the likelihood of accidents, spills, and environmental contamination.

4. Environmental Protection: Corrosion-related leaks and spills can have detrimental environmental consequences, polluting soil, water bodies, and ecosystems. By preventing corrosion and minimizing the risk of leaks and spills, corrosion inhibitors contribute to environmental protection and sustainability efforts.

Applications of Corrosion Inhibitors

Corrosion inhibitors find applications across various industrial sectors, where metal components are exposed to corrosive environments. Some common applications of corrosion inhibitors include:

Oil and Gas Production: In the oil and gas industry, corrosion inhibitors are used to protect pipelines, well casings, and production equipment from corrosion caused by corrosive fluids, gases, and environmental conditions.

Water Treatment: Corrosion inhibitors are added to cooling water systems, boilers, and wastewater treatment facilities to prevent metal corrosion caused by dissolved oxygen, scale formation, and aggressive ions.

Manufacturing: In manufacturing processes involving metal components, such as automotive, aerospace, and electronics manufacturing, corrosion inhibitors are used to protect parts, components, and machinery from corrosion during production, storage, and transportation.

Marine and Offshore Structures: Corrosion inhibitors are applied to marine vessels, offshore platforms, and coastal structures to protect against corrosion in seawater environments.

ICPL: Your Trusted Corrosion Inhibitor Manufacturer and Exporter in India

As the best chemical company in Vadodara, ICPL is dedicated to delivering high-quality corrosion inhibitors tailored to the specific needs of industrial clients. Here's why ICPL is the preferred choice for corrosion inhibitors in India:

Expertise and Experience: With decades of experience in the chemical industry, ICPL possesses the expertise and technical know-how to develop and manufacture corrosion inhibitors that meet the highest quality standards and regulatory requirements.

State-of-the-Art Facilities: ICPL operates state-of-the-art manufacturing facilities equipped with advanced technologies and production processes to ensure the consistent quality and performance of its corrosion inhibitors.

Customized Solutions: ICPL offers customized corrosion inhibitor formulations tailored to the unique requirements and operating conditions of industrial applications. Our team of experts works closely with clients to develop solutions that address specific corrosion challenges and performance objectives.

Global Reach: As a corrosion inhibitor exporter in India, ICPL serves clients worldwide, exporting its products to diverse markets across Asia, Africa, the Middle East, and beyond. With a strong global presence and distribution network, ICPL delivers reliable corrosion protection solutions to industries around the globe.

Conclusion

In conclusion, corrosion inhibitors play a crucial role in industrial maintenance by protecting metal assets from the damaging effects of corrosion. As a leading corrosion inhibitor manufacturer and exporter in India, ICPL is committed to providing high-quality corrosion inhibitors that safeguard critical infrastructure, ensure operational reliability, and promote cost-effective maintenance practices. With ICPL's expertise, customized solutions, and global reach, industries can effectively mitigate the risk of corrosion and preserve the integrity of their assets for years to come. Contact ICPL today to learn more about our corrosion inhibitor products and solutions.

#Corrosion inhibitor Vadodara#Best chemical company in Vadodara#Corrosion Inhibitor exporter in India#Corrosion inhibitors manufacturer in India#Oxygen scavenger Chemical in Vadodara#Oxygen scavenger Chemical supplier in Gujarat#Oxygen scavenger Chemical Manufacture India#Oxygen scavenger Chemical exporter in Gujarat#Oil and gas industry#Oil and gas companies#Oil and gas pipelines#leading Oilfield Chemicals manufacturer and exporter in India

7 notes

·

View notes

Text

College aa ke khaasi badh gayi 💀🙂

Group mein message Kiya ki bhai koi aa rhe ho to mere liye Vicks ki goli le aana, kisi ne bhi dekha nhi ab tak message. Ek ko call karne ka try Kiya toh saali call nhi utha rhi

#desiblr#suffer ye suhana nahi#desi tumblr#k²#legit hate life rn#itni THAND BC#vadodara hai ye Manali nahi

7 notes

·

View notes

Text

How Artificial Intelligence is Transforming the Future of IT Services

In an age dominated by technological advancements, the integration of Artificial Intelligence (AI) has emerged as a revolutionary force, reshaping the landscape of IT services globally. As businesses strive to stay ahead in the digital race, it becomes imperative to understand the transformative power of AI in the realm of Information Technology. In this blog post, we explore how Artificial Intelligence is not just a trend but a fundamental shift that is redefining the future of IT services.

Embracing AI for Enhanced Efficiency

1. Intelligent Automation:

AI-driven automation has become the cornerstone of IT services, streamlining processes, and significantly reducing operational costs. Nivida Software, as a leading IT company in India, recognizes the pivotal role of AI in optimizing workflows and increasing overall efficiency.

2. Predictive Analysis:

Nivida Software leverages AI algorithms to analyze vast datasets, enabling proactive identification of potential issues and predicting trends. By staying ahead of challenges, our IT services ensure a seamless experience for clients across Gujarat and Vadodara.

Delivering Precision with AI-Powered Solutions

3. Customized IT Solutions:

As an innovative IT company in Gujarat, Nivida Software understands the diverse needs of businesses. AI allows us to create tailored solutions that align with the unique requirements of our clients, ensuring maximum impact and value.

4. Enhanced Security Measures:

The integration of AI in IT services goes beyond efficiency; it's about fortifying digital landscapes. Nivida Software employs AI-driven security measures to safeguard sensitive data and protect against evolving cyber threats, setting new standards for IT security in Vadodara. Pioneering AI at Nivida Software

5. Cutting-Edge Development:

Nivida Software is at the forefront of AI development, constantly pushing boundaries to create innovative solutions. As an IT company in India, our commitment to staying ahead in the technological curve positions us as a reliable partner for businesses seeking cutting-edge IT services.

6. Nurturing Talent:

The future of IT services lies in the hands of skilled professionals. Nivida Software invests in talent development, ensuring that our team remains well-versed in the latest AI advancements, delivering top-notch services across India, Gujarat, and Vadodara.

Conclusion

Artificial Intelligence is not merely a technological evolution; it's a paradigm shift that is reshaping the future of IT services. Nivida Software, as a forward-thinking IT company, embraces AI to deliver unparalleled solutions to clients in India, Gujarat, and Vadodara. The journey towards a digitally transformed future begins with Nivida Software – where innovation meets excellence in IT services.

7 notes

·

View notes

Text

ERP in Manufacturing: What You Need to Know for Business Growth

In today's dynamic business landscape, manufacturing companies face numerous challenges, from volatile market demands to complex supply chain management. To thrive in this competitive environment, organizations are increasingly turning to Enterprise Resource Planning (ERP) systems. In this blog post, we will explore the significance of ERP systems for manufacturing companies, their role in software development companies, and the key factors that contribute to business growth.

Understanding ERP Systems for Manufacturing Companies

The Core of ERP: Integration and Automation

ERP systems are comprehensive software solutions designed to integrate and streamline various business processes within an organization. For manufacturing companies, ERP serves as a centralized platform that connects different departments such as production, inventory, procurement, finance, and human resources. The integration of these processes results in improved communication, data accuracy, and operational efficiency.

Key Features of ERP in Manufacturing

1. Production Planning and Scheduling:

ERP systems enable manufacturing companies to optimize production processes by providing real-time insights into resource availability, production capacity, and demand forecasting. This ensures that production schedules are aligned with market demands, reducing the risk of overproduction or stockouts.

2. Inventory Management:

Efficient inventory management is crucial for manufacturing companies. ERP software helps organizations maintain optimal inventory levels, minimize carrying costs, and prevent stockouts. It also facilitates better demand planning and order fulfillment.

3. Quality Control:

ERP systems play a vital role in maintaining product quality by tracking and managing every stage of the manufacturing process. This includes monitoring raw materials, production processes, and finished goods to ensure they meet industry standards and customer expectations.

4. Supply Chain Visibility:

With ERP, manufacturing companies gain better visibility into their supply chain. This visibility helps in identifying potential bottlenecks, reducing lead times, and enhancing collaboration with suppliers. A transparent supply chain is essential for meeting customer demands and maintaining a competitive edge.

5. Financial Management:

ERP systems provide robust financial modules that help manufacturing companies manage budgets, track costs, and generate accurate financial reports. This financial transparency enables informed decision-making and ensures compliance with regulatory requirements.

ERP for Software Development Companies: A Unique Perspective

While traditionally associated with manufacturing, ERP systems have found their way into software development companies as well. The principles of integration, automation, and streamlined processes are just as applicable in the software industry.

Project Management and Collaboration

In software development, ERP systems assist in project management by centralizing tasks, timelines, and resource allocation. This ensures that development teams work cohesively, deadlines are met, and resources are utilized efficiently. Collaboration is enhanced through shared data and communication channels, leading to improved project outcomes.

Resource Allocation and Time Tracking

ERP software allows software development companies to optimize resource allocation and track time spent on different projects. This data-driven approach enhances project planning, improves resource efficiency, and provides insights for future capacity planning.

Scalability and Flexibility

Software companies often face rapidly changing project scopes and client requirements. ERP systems provide the scalability and flexibility needed to adapt to these changes seamlessly. Whether it's adding new features, accommodating changes in project timelines, or expanding the scope, ERP systems empower software development companies to stay agile.

Key Considerations for Implementing ERP in Manufacturing

1. Customization and Flexibility:

Manufacturing companies should look for ERP solutions that offer customization options to align with specific industry needs. Flexibility is crucial, considering the diverse manufacturing processes and business models.

2. User Training and Change Management:

Successful ERP implementation requires thorough training of users and effective change management strategies. Employees need to understand the benefits of ERP and be comfortable with the new system to ensure smooth adoption.

3. Data Security and Compliance:

Given the sensitive nature of manufacturing data, security is a top priority. ERP systems must comply with industry regulations and provide robust security features to safeguard intellectual property, customer information, and business-critical data.

4. Integration with Existing Systems:

Seamless integration with existing software and systems is essential for a smooth transition to ERP. Compatibility with other tools and technologies ensures that there is no disruption in day-to-day operations during the implementation phase.

5. Scalability for Future Growth:

An ERP system should be scalable to accommodate the growing needs of a manufacturing company. It should support expansion into new markets, additional product lines, and increased production volumes without compromising performance.

Conclusion: Driving Business Growth with ERP

In conclusion, ERP systems have become indispensable tools for manufacturing companies seeking sustainable growth in a competitive market. By integrating and automating core business processes, ERP not only enhances operational efficiency but also provides valuable insights for strategic decision-making.

For software development companies, the adaptability of ERP systems offers a unique advantage in managing the dynamic and ever-evolving nature of the industry. The principles that make ERP effective in manufacturing—integration, automation, and streamlined processes—are equally applicable and beneficial in the software development landscape.

As businesses continue to evolve, embracing ERP is not just a technological choice; it's a strategic one. Those who invest in robust ERP solutions position themselves for improved competitiveness, increased profitability, and sustainable growth in the long run.

#ERP systems for manufacturing companies#ERP for manufacturing companies#ERP for software development company#ERP software for manufacturing companies#India#Gujarat#Vadodara#ERP India#Business Solutions#manufacurer#ERP software

7 notes

·

View notes

Text

HAST Test Sieves Manufacturer in Vadodara - Precision and Quality

Explore top-quality HAST test sieves manufactured in Vadodara. Trust our precision and commitment to excellence for accurate and reliable testing results.

#Sieves manufacturer#Hast Test Sieves manufacturer#Haver EML Test Sieve Shakers#Ro-tap Sieve Shaker#Certified sieves#Calibrated sieves manufacturer#in vadodara#gujarat#mumbai#india

0 notes

Text

Polywin | Global Innovation and Excellence | Manufacturing

At Polywin, we value the development of our team members as much as we value the development of our products. Join us ,Be part of a culture and exceptional service

#Paper Covered Copper and Aluminum Single and Multi-Strand Wire#Paper Covered Copper Single and Multi-Strand Wire#Paper Covered Aluminum Single and Multi-Strand Wire#Paper Covered Copper Multi-Strand Wire#Manufacturer#Paper Covered Aluminum Multi-Strand Wire#in vadodara#gujarat#india

0 notes

Text

Are you Finding the Micro Disperse of Vat Dyes manufacturer in Vadodara?

RK industry is one of the top Colloisols Dyes manufacturers in Vadodara. We serve the best Micro Disperse of Vat Dyes and Colloisols Dyes manufacturer in Vadodara. We have some products for you like VAT YELLOW GCN, VAT YELLOW 3RT, VAT ORANGE GR, VAT NAVY BLUE BR, etc. For more information, contact us today!

#Micro Disperse of Vat Dyes manufacturer in Vadodara#top Colloisols Dyes manufacturer in Vadodara#best Micro Disperse of Vat Dyes and Colloisols Dyes manufacturer in Vadodara#Colloisols Dyes#Products#Manufacturer#Suppliers#Dealers#in Vadodara#Gujarat#India#Vietnam#Brazil.

0 notes

Text

Are you looking for Tool and Die Steel Supplier in Vadodara, Gujarat?

Whether it’s tool steel, die steel, or any other steel requirement, Virat Special Steels stands out as a trusted supplier in Vadodara!

Today, Vadodara stands as a testament to industrial growth and innovation, particularly in the manufacturing and supply of tool and die steel components. The city's industrial clusters are a hive of activity, where small and medium-sized enterprises (SMEs) thrive on specialization in tool and die production. These clusters are not just local powerhouses but also vital cogs in the national supply chain, providing essential components to industries across India.

One of the best Tool & Die Steels Supplier in Vadodara city is: VIRAT SPECIAL STEELS PVT. LIMITED , INDIA . This is a company that deals in all kinds of tool steel, die steel, plastic mold steel, high speed steel, and alloy steel. They provide value added services, such as material machining, cut pieces, and tailor-made material.

They also offer metallurgical advice and quality assurance. They have a state-of-the-art plant in Gurugram and Ludhiana. They also have a strong distribution network across India.

For more information, you can explore here:

Any further queries feel free to contact us :

🌐https://www.viratsteels.com/ 📬 [email protected] ☎+91 98140-21775

#viratsteels#india#gurgaon#ludhiana#toolsteelsupplier#viratspecialsteels#iso9001#steel#Vadodara#Gujarat#DB6ToolSteel#H13Steel#H11Steel#IndustrialMaterials#ToolAndDie#ManufacturingSolutions#MetalIndustry

2 notes

·

View notes