#anodizing

Photo

🧬 #daithpiercing 🧬 🌸 @lamujerbarbudatattoo 🌸 ❌ @xmadrid_ ❌ #daith para @nariko_pili mil gracias por la confianza siempre 🙏🏻🙏🏻 Le ponemos esta bonita joya anodizada en varios colores de la casa @inariorganics Perforado co. Técnica aséptica y aguja americana #katananeedles #madrid #earpiercing #piercingmadrid #toyabodyart #anodizing #titaniopiercing #safepiercing #lamujerbarbudatattoo #xmadrid #alcorcon (en La Mujer Barbuda) https://www.instagram.com/p/Cev0-jFMBEt/?igshid=NGJjMDIxMWI=

#daithpiercing#daith#katananeedles#madrid#earpiercing#piercingmadrid#toyabodyart#anodizing#titaniopiercing#safepiercing#lamujerbarbudatattoo#xmadrid#alcorcon

8 notes

·

View notes

Text

Understanding Anodizing: Type II vs. Type III

Anodizing is a surface treatment process that imparts a range of benefits to metal, most commonly aluminum. This electrochemical process not only enhances the aesthetic appeal of the metal but also provides several functional advantages.

Two prominent types of anodizing, known as Type II and Type III anodizing, offer distinct properties and applications.

Type II Anodizing: The Essentials

Type II anodizing, often referred to as conventional or sulfuric anodizing, is a widely employed method for aluminum finishing. This process involves immersing the aluminum in a sulfuric acid bath and applying an electrical current. The result is the growth of an oxide layer on the metal surface. Key characteristics of Type II anodizing include:

Thickness of Oxide Layer:

The oxide layer formed in Type II anodizing is relatively thin, typically ranging from 0.0001 to 0.001 inches.

Color Options:

Type II anodizing offers a variety of color options, making it suitable for decorative applications. Dyes can be introduced during the process to achieve different colors.

0 notes

Text

The Role of Anodizing in Electronics: Protecting and Beautifying Components

Can you define the word "anodizing" for me? If not, get ready to have your mind blown! The corrosion-resistant properties of anodized metals are just one of the many advantages of this intriguing finishing procedure. Anodizing is a service that should be considered if you are in the Vancouver area and need metal finishing.

Learn more about anodizing and why it's crucial for providing top-notch corrosion resistance in this in-depth article. The numerous anodizing technologies that are used to make metal parts last longer and look better will also be examined in detail. So, settle back with a cup of coffee (or tea) as we explore the fascinating world of anodizing in lovely Vancouver.

Anodizing Parts to Prevent Corrosion and Its Advantages

Corrosion is an annoying problem when working with metal parts. It degrades the parts' structural integrity and functionality in addition to their visual appeal. Anodizing is the hero that comes to the rescue in these situations. Anodizing is a procedure used to protect metal surfaces against corrosion by coating them in a thin layer of oxide first.

Anodizing's ability to increase the corrosion resistance of metals like aluminum and titanium is one of its primary advantages. Anodizing produces an oxide coating that is highly resistant to corrosion and corrosion-causing elements such moisture, humidity, salinity, and chemicals. With the right anodized coatings, metal components can withstand harsh environments and corrosive substances for considerably longer.

Furthermore, unlike paint or plating, which can crack or wear off over time, anodized coatings are an essential part of the material and will not disappear. They won't easily peel or flake off because of this. Furthermore, these coatings are extremely long-lasting, making them ideal for uses where reliability over time is paramount.

Anodization not only greatly reduces the likelihood of corrosion, but it also increases the hardness and scratch resistance of the material. As a result of these improvements, anodised parts are more durable and more pleasing than their untreated counterparts. Metal products in Vancouver (or anywhere) would benefit greatly from anodizing as a finishing procedure because it provides excellent corrosion protection and also makes the parts significantly more durable.

Methods and Procedures for Anodizing

Adding an oxide layer to the surface of a metal is known as anodizing, and it's used as a finishing process. Vancouver is home to a wide range of sectors, and one that relies heavily on this process is metal finishing. So how does anodizing function, exactly?

Immersing the metal part in an electrolyte bath and applying an electric current induces a controlled oxidation reaction, which is the first step in the anodizing process. This results in oxygen ions bonding with the metal, which forms an oxide layer. Variables like voltage and time can be used to change the thickness of this layer.

Anodizing Comes in a Variety of Flavors

Different anodizing methods achieve different results and have their own set of advantages. The corrosion resistance and aesthetic alternatives provided by sulfuric acid (Type II) anodizing, for example, make it a popular choice for general-purpose applications.

Hardcoat (Type III) anodizing, on the other hand, is appropriate for components that will be exposed to significant stress or friction because of its better wear resistance and hardness qualities. It results in a more substantial oxide layer but requires higher processing voltages.

By learning about these processes, Vancouver companies may select the best anodized finish for their goods or components, maximizing their functionality and durability.

The Anodizing Process: An Overview

Anodizing is a process used to improve the aesthetics of metal components, most commonly aluminum, by coating them with an oxide layer. This treatment improves the material's look and makes it more corrosion-resistant and long-lasting.

To begin anodizing, the metal is submerged in an electrolytic solution while a direct current is applied. Aluminum oxide is formed when oxygen ions combine with aluminum atoms at the surface. This oxide layer can be adjusted in thickness to serve a variety of reasons, from aesthetic enhancement to enhanced corrosion resistance.

After forming, this barrier can be dyed or sealed to give it a new look or improve its protective abilities. These additional procedures guarantee that the anodic finish will turn out exactly as planned.

To truly appreciate the benefits of anodizing, one must have a firm grasp of how the process works. Anodizing is a trustworthy method that may be tailored to a wide range of purposes, including but not limited to increasing corrosion resistance, enhancing visual appeal, and increasing durability.

Anodizing Comes in a Variety of Flavors

Anyone looking for metal finishing in Vancouver should have a firm grasp of the Anodizing Process. But did you know that anodizing comes in a variety of forms? Because each kind offers its own set of benefits and uses, you can pick the one that works best for you.

Sulfuric acid anodizing is a typical process for protecting metals from corrosion. This method forms a thick, porous oxide coating on the metal's surface using sulfuric acid as the electrolyte. It is highly resistant to corrosion and can be dyed to a wide range of colors, making it perfect for use in ornamentation.

Type III anodizing, often known as hard coat anodizing, is another common process. This method forms an oxide layer that is thicker by employing lower temperatures and greater voltages. The resultant coating is ideal for parts that experience friction or abrasion because of its high resistance to wear.

In place of sulfuric acid, chromic acid can be used as an electrolyte in chromic acid anodizing. For precision products where dimensional correctness is of the utmost importance, this type of anodizing is ideal because it produces a thin but dense oxide coating that provides superior corrosion protection.

By learning about the many anodizing techniques in Vancouver, you'll be more equipped to select the one that meets your needs. Whether you're looking to improve corrosion resistance, wear protection, or dimensional precision, a particular type of anodization is available to meet your needs.

Different Metal Finishing Techniques, Including Anodizing

There are a number of options for giving metals a polished appearance, each with their own advantages and disadvantages. But anodizing stands out because of how long it lasts and how well it resists corrosion.

When it comes to preventing corrosion, anodizing is typically superior to other metal finishing procedures like plating or painting. The increased durability of anodized parts makes them a good choice for use in demanding conditions or in sectors where corrosion is a problem.

In addition, the homogeneous coating provided by anodizing penetrates deeply into the surface of the metal to produce a bond that can withstand wear and tear over time. This is especially useful for parts that see heavy use or are frequently exposed to harsh environments.

There is a wide range of color possibilities available when anodizing. Traditional coatings, such as paint or powder, can chip or fade over time, whereas anodized coatings retain their color and quality for far longer.

Anodizing is also environmentally safe, unlike other metal finishing methods that frequently use hazardous chemicals or heavy metals. This method employs safe materials and generates little in the way of waste.

Anodizing provides improved corrosion resistance and durability along with environmental friendliness compared to other metal finishing procedures, which may provide some amount of protection and aesthetic appeal. If you're trying to improve your product's aesthetics or give it a longer lifespan in harsh environments, anodizing is the metal finishing solution for you.

Look no further than Anotek Anodizing Inc if you're in the Vancouver area and need high-quality metal finishing services like Vancouver Electropolishing and dependable anodic coatings. With a focus on complete client satisfaction, we are experts at delivering professional-grade final products. Don't take chances with the quality of your metal finishing; use a professional who knows the value of anodizing.

0 notes

Text

The Importance of Anodizing Aluminum and Powder Coating

Aluminum is a popular material for various products and applications, from cookware to electronics. However, aluminum is also a reactive metal, which can corrode and degrade over time when exposed to certain elements. To protect aluminum products and prolong their lifespan, a process called anodizing is often used.

Anodizing is an electrochemical process that creates a thin, protective layer on the surface of the metal. This layer helps to prevent corrosion and wear and can also be used to give aluminum a decorative finish. There are two main types of anodizing: decorative anodizing and industrial anodizing.

Decorative anodizing is often used on aluminum products that will be visible to consumers, such as cookware or electronics. This type of anodizing can produce a wide range of colors, from bright hues to more subdued shades. Industrial anodizing is typically used on products that consumers will not see, such as components for machinery or vehicles.

How Anodizing Works

The metal must first be cleaned and placed in an electrolyte solution to anodize aluminum. A direct current is then passed through the solution, causing the formation of oxide particles on the surface of the aluminum. These particles bond together to form a protective layer resistant to corrosion and wear.

The thickness of this layer can be controlled by changing the voltage of the direct current and the length of time that the current is applied. Once the desired thickness has been achieved, the anodized aluminum is rinsed with water and allowed to dry.

The Benefits of Anodizing

There are many benefits to anodizing aluminum, which is why this process is so prevalent in many industries. Some of the most notable benefits include:

-Improved corrosion resistance: The protective layer created by anodizing helps to prevent corrosion caused by exposure to moisture or other elements.

-Improved wear resistance: The protective layer created by anodizing also helps to prevent wear and tear caused by regular use.

-Increased durability: Anodized aluminum products are more durable than those without this process.

-Aesthetically pleasing: Decorative anodization can add beauty and visual appeal to any product made from aluminum.

To summarize, Anodizing is a process that creates a thin, protective layer on the surface of aluminum products. This layer helps to prevent corrosion and wear and can also be used to give aluminum a decorative finish. There are two main types of anodizing: decorative anodizing and industrial anodizing. Anodized aluminum products are more durable than those that have not undergone this process, making them ideal for a wide range of applications.

Can Anodized Aluminum Be Powder Coated?

Anodized aluminum is a type of aluminum that has been treated to make it more durable and resistant to corrosion. Powder coating is a process in which a powder is applied to the metal to create a smooth, consistent finish. Many people wonder if anodized aluminum can be powder coated, and the answer is yes! Here's a closer look at how this works.

The Process of Powder Coating Anodized Aluminum

Powder coating anodized aluminum is a two-step process. First, the anodized aluminum surface must be cleaned so that the powder can adhere properly. This usually involves using a mild solvent or detergent to remove any dirt, oil, or other contaminants. Once the surface is clean, it's time to apply the powder coat.

Powder coating is typically done using an electrostatic spray gun, which applies a negative charge to the powder particles as they are sprayed onto the metal surface. This helps the particles adhere evenly to the surface. The coated piece is then heated in an oven until the powder melts and forms a smooth, consistent finish.

Benefits of Powder Coating Anodized Aluminum

There are several benefits to powder coating anodized aluminum. First, it creates a more durable finish that can withstand wear and tear better than paint alone. Second, powder coating provides better protection against corrosion than paint or anodizing alone. And third, powder coating can give anodized aluminum a wide range of colours and finishes that are impossible with other methods.

Conclusion:

Powder-coating anodized aluminum is a great way to create a durable, long-lasting finish available in many different colours and finishes. If you're looking for an alternative to traditional painting or anodizing methods, powder coating may be the right option.

Who are we?

We are an aluminum enthusiast, a surplus aluminum supplier in Canada and the USA.

We offer quality Black Aluminum Foil, Aluminum Coil and assorted colour aluminum wire and Aluminum sheets for sale in our warehouse, ready to ship today.

Call us today, Toll-Free: 866–860–0652, if you need further information.

P.s we have many blogs discussing aluminum metals, ranging from their information to common misconceptions. A few examples are:

Are aluminum canoes good?

Does aluminum help with soundproofing?

The benefits of Aluminum in the Construction Industry and building materials.

Can You Paint Aluminum Window Frames?

Additionally, if you ask your device to find “Aluminum Foil “ near me in Toronto,

Or

Find “Aluminum Wire “ near me in Toronto; you will find us on Google Maps. Hooray!

1 note

·

View note

Text

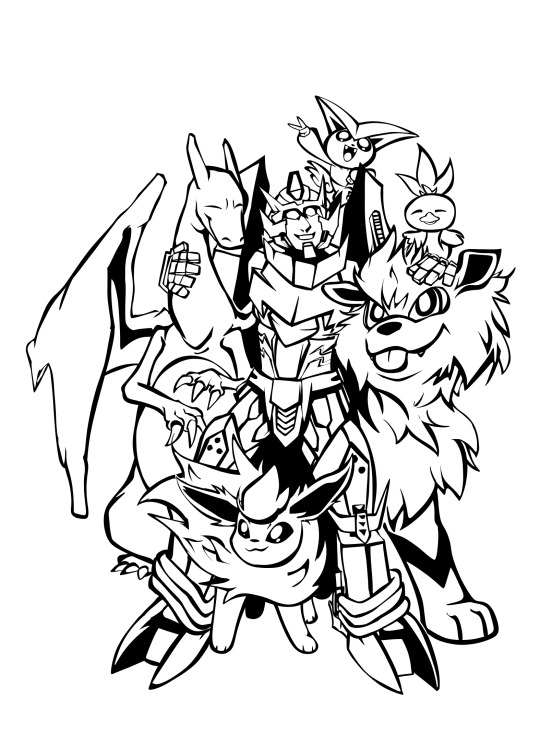

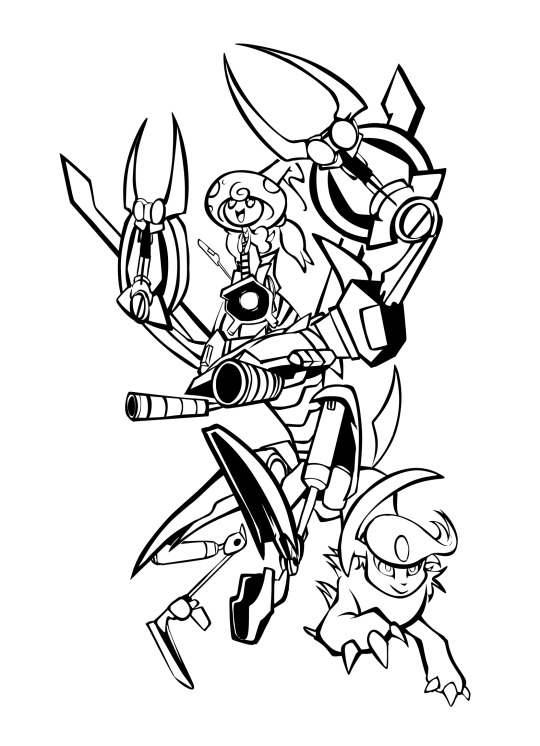

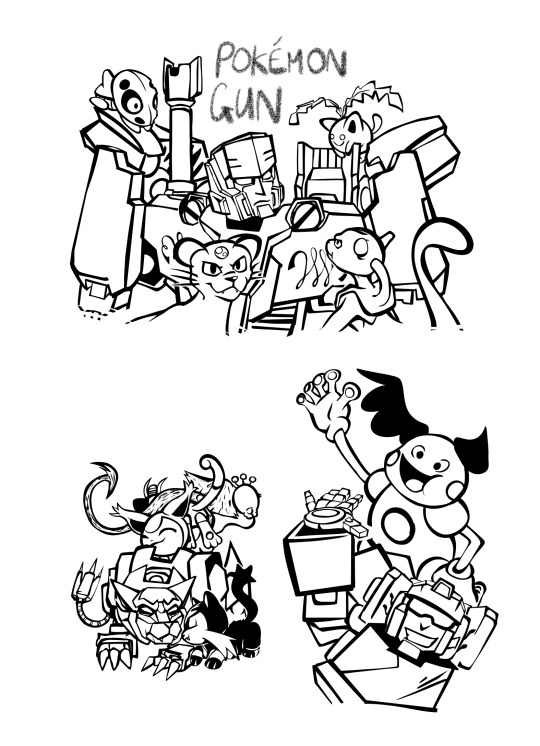

I realized I never posted ALL the colouring book illustrations, and since I no longer have any stock, I figured I'd share.

A collection of little Pokémon teams for Lost Lighters, drawn in 2021! There's a bunch of details I forgot about, but I still consider Ultra Magnus + 10% Forme Zygarde to be the biggest brained choice lol

#mtmte#fanart#whirl#rodimus prime#thunderclash#ultra magnus#getaway#tailgate#cyclonus#skids#idw rung#anode and lug#chromedome#rewind#brainstorm#perceptor#drift#ratchet#megatron#ravage#riptide#nautica#velocity#nightbeat#trailcutter#swerve#pokemon crossover#idw continuity#lost light#my art

509 notes

·

View notes

Link

Alufinish is your proficient partner when it comes to products and processes for the chemical surface treatment of aluminium, steel and zinc. Alufinish, one of our trusted partners, supplies us with an extensive range of chemical surface treatments for metals. Learn more via our website.

1 note

·

View note

Video

youtube

Fenan Aluminum-Firstly install the largest Vertical Anodizing Electropho...

Fenan(FOEN) Aluminum-First one to introduce and install the largest Vertical Anodizing Electrophoresis Production Line in Asia.

In order to create high-quality products, Fenan(FOEN) aluminum has introduced the latest, high-efficiency and high-quality production lines in the world, including the First Vertical Anodizing Electrophoresis Production Line with a monthly output of 5000 tons in Asia.

Compared with the anodized coating production line of the industry's leading profile enterprises, Fenan(Foen) ‘s automatic electrophoresis production line perfectly combines the industry's advanced process technology, equipment and materials.

The intelligent input of all process, control and recording parameters realizes the whole process, all-weather and automatic control, reduces the influence of human factors on the process, ensures the process of product surface treatment, and meets various market demands;

In addition, the design of the production line runs through the advanced concept of resource utilization and environmental protection, so that the power consumption, natural gas consumption and wastewater treatment capacity of each ton of material produced are reduced by half.

While the energy conservation and environmental protection effect are significant, the working environment of employees is improved, and a big step is taken towards an environment-friendly enterprise.

our website:

https://www.foenalu.com/

#youtube#Fenanaluminum#FOENaluminum#verticalanodizingelectrophoresisproductionline#productionline#electrophoresis#anodizing#aluminumextrusion#aluminumprofile#aluminiumextrusion#aluminumtslots#vslots#tslots#2080

0 notes

Photo

Ti/Tanto Tuesday 🍩 • Anodizing by @bear_metals_tx • • • #crispydonutcommunity #cdcedc #edcessentials #titanium #titaniumtuesday #tantotuesday #knuck #bottleopener #lanyardbead #chavesknives #pokerchips #olight #prybar #edcpen #anodizing #edcgear #pocketdump #knifelife #donutedc #donut #everydaycarry #edcknife #edcknives #edccommunity #edccarry #edccooperative #everydaycarryknife #everydaycarrygear #everydaycarrycommunity #everydaycarrydump https://www.instagram.com/p/CfXagYxuQzS/?igshid=NGJjMDIxMWI=

#crispydonutcommunity#cdcedc#edcessentials#titanium#titaniumtuesday#tantotuesday#knuck#bottleopener#lanyardbead#chavesknives#pokerchips#olight#prybar#edcpen#anodizing#edcgear#pocketdump#knifelife#donutedc#donut#everydaycarry#edcknife#edcknives#edccommunity#edccarry#edccooperative#everydaycarryknife#everydaycarrygear#everydaycarrycommunity#everydaycarrydump

0 notes

Photo

Golden Titanium Springs after anodizing

0 notes

Text

i love rabbitholes i just found out there are trans lesbian transformers

#lug and anode you have my heart#and arcee i think is too who is cute and pink and i had a burger king toy of as a kid#i always knew her as 'the purple transformer motorcycle toy' but now i know her name#kae.txt

2K notes

·

View notes

Text

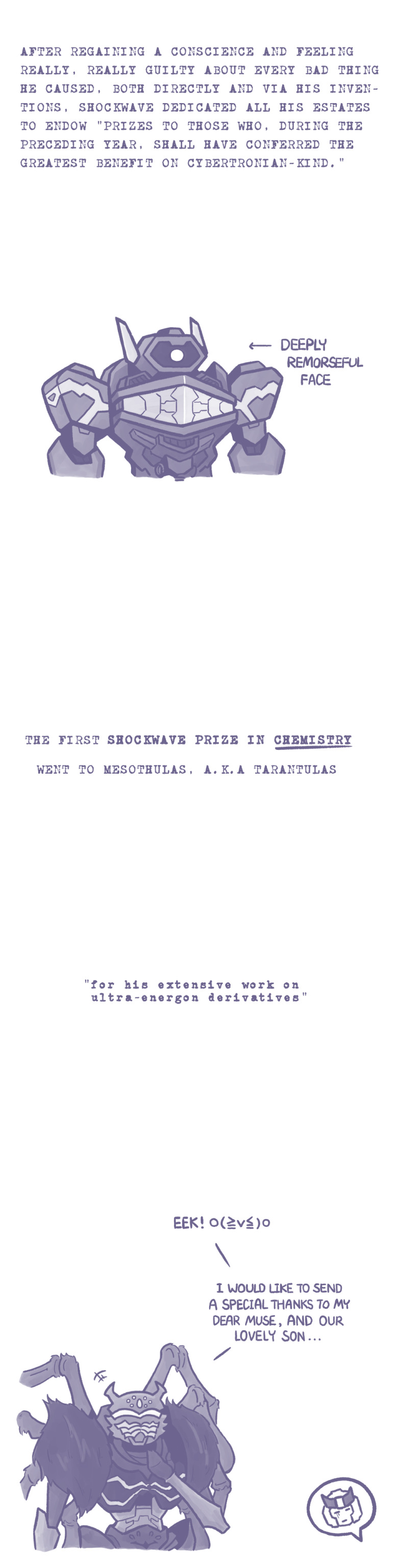

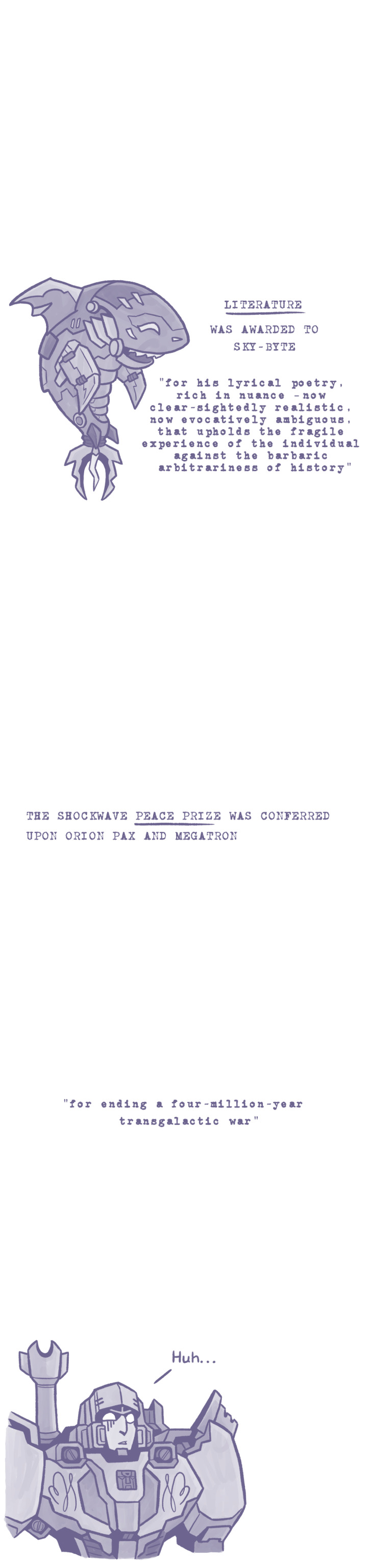

*hey, it's for aspiration, not actual outcome

#tf nobel laureates#shockwave could've gotten all 6#give the cat some credit#he handed over a working democracy and a viable economy#which he virtually built from scratch in 3 years#took george washington 4 years#it's going to take a while for ppl to recognize TC's cultural impact#ANODE HAS CURED DEATH#it started with the peace one#idw shockwave#idw tarantulas#tf anode#idw brainstorm#perceptor#sky-byte#megatron#starscream#idw transformers#maccadam

3K notes

·

View notes

Text

Mermay Day 9- Alligator pipefish Anode

#transformers#maccadam#Anode#idw anode#tf anode#tf fanart#merformers#mermay#mermay 2024#hystdraws#idw transformers#idw

192 notes

·

View notes

Text

put some fur on that beast part 8: epic wife moment

#anode#lug#lugnode#transformers#maccadam#furry#transfurmers#havent done a new furry tramsforber design in 4everrrrrrrrrr#but now im BACK on the GRIND#<- LIAR ALERT im drawing rodimus again rn. funny fluffy fox boy

208 notes

·

View notes

Text

Someone on Twitter pointed this out

So i made this in like 10 minutes

#maccadam#transformers#IDW Anode#Mtmte anode#anode#Tf stratosphere#transformers rise of the beasts#transformers rotb#rotb

2K notes

·

View notes

Text

Figuring out how to draw Anode!

228 notes

·

View notes

Text

Some couple design concepts urah

185 notes

·

View notes