#Specialty Chemicals

Text

Aluminum Market: Products, Applications & Beyond

Aluminum is a versatile element with several beneficial properties, such as a high strength-to-weight ratio, corrosion resistance, recyclability, electrical & thermal conductivity, longer lifecycle, and non-toxic nature. As a result, it witnesses high demand from industries like automotive & transportation, electronics, building & construction, foil & packaging, and others. The high applicability of the metal is expected to drive the global aluminum market at a CAGR of 5.24% in the forecast period from 2023 to 2030.

Aluminum – Mining Into Key Products:

Triton Market Research’s report covers bauxite, alumina, primary aluminum, and other products as part of its segment analysis.

Bauxite is anticipated to grow with a CAGR of 5.67% in the product segment over the forecast years.

Bauxite is the primary ore of aluminum. It is a sedimentary rock composed of aluminum-bearing minerals, and is usually mined by surface mining techniques. It is found in several locations across the world, including India, Brazil, Australia, Russia, and China, among others. Australia is the world’s largest bauxite-producing nation, with a production value of over 100 million metric tons in 2022.

Moreover, leading market players Rio Tinto and Alcoa Corporation operate their bauxite mines in the country. These factors are expected to propel Australia’s growth in the Asia-Pacific aluminum market, with an anticipated CAGR of 4.38% over the projected period.

Alumina is expected to grow with a CAGR of 5.42% in the product segment during 2023-2030.

Alumina or aluminum oxide is obtained by chemically processing the bauxite ore using the Bayer process. It possesses excellent dielectric properties, high stiffness & strength, thermal conductivity, wear resistance, and other such favorable characteristics, making it a preferable material for a range of applications.

Hydrolysis of aluminum oxide results in the production of high-purity alumina, a uniform fine powder characterized by a minimum purity level of 99.99%. Its chemical stability, low-temperature sensitivity, and high electrical insulation make HPA an ideal choice for manufacturing LED lights and electric vehicles. The growth of these industries is expected to contribute to the progress of the global HPA market.

EVs Spike Sustainability Trend

As per the estimates from the International Energy Agency, nearly 2 million electric vehicles were sold globally in the first quarter of 2022, with a whopping 75% increase from the preceding year. Aluminum has emerged as the preferred choice for auto manufacturers in this new era of electromobility. Automotive & transportation leads the industry vertical segment in the studied market, garnering $40792.89 million in 2022.

In May 2021, RusAl collaborated with leading rolled aluminum products manufacturer Gränges AB to develop alloys for automotive applications. Automakers are increasingly substituting stainless steel with aluminum in their products owing to the latter’s low weight, higher impact absorption capacity, and better driving range.

Also, electric vehicles have a considerably lower carbon footprint compared to their traditional counterparts. With the growing need for lowering emissions and raising awareness of energy conservation, governments worldwide are encouraging the use of EVs, which is expected to propel the demand for aluminum over the forecast period.

The Netherlands is one of the leading countries in Europe in terms of EV adoption. The Dutch government has set an ambitious goal that only zero-emission passenger cars (such as battery-operated EVs, hydrogen FCEVs, and plug-in hybrid EVs) will be sold in the nation by 2030. Further, according to the Canadian government, the country’s aluminum producers have some of the lowest CO2 footprints in the world.

Alcoa Corporation and Rio Tinto partnered to form ELYSIS, headquartered in Montréal, Canada. In 2021, it successfully produced carbon-free aluminum at its Industrial Research and Development Center in Saguenay. The company is heralding the beginning of a new era for the global aluminum market with its ELYSIS™ technology, which eliminates all direct GHG emissions from the smelting process, and is the first technology ever to emit oxygen as a byproduct.

Wrapping Up

Aluminum is among the most widely used metals in the world today, and is anticipated to underpin the global transition to a low-carbon economy. Moreover, it is 100% recyclable and can retain its properties & quality post the recycling process.

Reprocessing the metal is a more energy-efficient option compared to extracting the element from an ore, causing less environmental damage. As a result, the demand for aluminum in the sustainable energy sector has thus increased. The efforts to combat climate change are thus expected to bolster the aluminum market’s growth over the forecast period.

#Aluminum Market#aluminum#chemicals and materials#specialty chemicals#market research#market research reports#triton market research

4 notes

·

View notes

Text

Specialty Chemicals Market: Unraveling Growth Opportunities in Emerging Economies

According to the study by Next Move Strategy Consulting, the global Specialty Chemicals Market size is predicted to reach USD 762.08 billion with a CAGR of 4.4% by 2030.

Request for a sample, here: https://www.nextmsc.com/specialty-chemicals-market/request-sample

In recent years, the Specialty Chemicals Market has witnessed significant growth, driven by advancements in technology, increasing industrialization, and growing demand for high-performance chemicals across various sectors. One of the key drivers behind this growth is the expansion of the market into emerging economies.

Emerging economies, characterized by rapid industrialization, urbanization, and a burgeoning middle class, present immense growth opportunities for the specialty chemicals sector. These economies, including countries such as China, India, Brazil, and Mexico, are experiencing robust economic growth, coupled with a rise in disposable income levels and changing consumer preferences. As a result, there is a growing demand for specialty chemicals across diverse industries, including automotive, construction, agriculture, healthcare, and consumer goods.

The automotive sector, in particular, holds significant potential for the specialty chemicals market in emerging economies. With increasing vehicle production and a shift towards electric and hybrid vehicles, there is a rising demand for specialty chemicals used in automotive coatings, adhesives, lubricants, and fuel additives. Moreover, stringent environmental regulations and a growing emphasis on sustainability are driving the adoption of eco-friendly specialty chemicals in the automotive industry.

In the construction industry, rapid urbanization and infrastructure development projects in emerging economies are fueling the demand for specialty chemicals such as adhesives, sealants, and construction chemicals. These chemicals play a crucial role in enhancing the durability, performance, and sustainability of construction materials, thereby meeting the evolving needs of modern infrastructure projects.

Furthermore, the agriculture sector in emerging economies is witnessing a shift towards precision farming practices and sustainable agriculture solutions. Specialty chemicals, including fertilizers, pesticides, and crop protection chemicals, are essential for improving crop yields, enhancing soil fertility, and combating pests and diseases. As farmers increasingly adopt advanced agricultural technologies, the demand for specialty chemicals is expected to surge in the coming years.

In the healthcare sector, rising healthcare expenditure, expanding pharmaceutical industry, and growing awareness about personal hygiene and wellness are driving the demand for specialty chemicals used in pharmaceuticals, medical devices, and personal care products. Emerging economies offer significant growth opportunities for specialty chemicals companies to cater to the evolving needs of the healthcare industry and address healthcare challenges such as infectious diseases and chronic ailments.

Overall, emerging economies present a fertile ground for the Specialty Chemicals Market to thrive and expand its footprint. However, tapping into these growth opportunities requires a strategic approach, including market research, product innovation, investment in R&D, and partnerships with local stakeholders. By capitalizing on the dynamic market trends and evolving consumer preferences in emerging economies, specialty chemicals companies can unlock new avenues for growth and cement their position in the global market landscape.

Expanding on Automotive Sector Growth:

The automotive sector in emerging economies is experiencing exponential growth, driven by factors such as increasing urbanization, rising disposable incomes, and government initiatives to promote the automotive industry. As more consumers in countries like China, India, Brazil, and Mexico aspire to own vehicles, the demand for automobiles is on the rise. This trend is not only confined to traditional gasoline-powered vehicles but also extends to electric and hybrid vehicles, as governments implement stringent emission regulations and incentivize the adoption of cleaner transportation options.

Specialty chemicals play a vital role in the automotive industry, contributing to the performance, safety, and aesthetics of vehicles. Coatings and adhesives, for instance, are essential for protecting automotive surfaces from corrosion, abrasion, and weathering, while also enhancing their appearance. Lubricants and fuel additives are crucial for optimizing engine performance, reducing friction, and improving fuel efficiency, thereby meeting the growing demand for sustainable mobility solutions.

Moreover, the shift towards electric and hybrid vehicles presents new opportunities for specialty chemicals manufacturers to develop innovative materials and technologies. Electric vehicle batteries, for example, rely on specialty chemicals such as lithium-ion electrolytes and cathode materials for optimal performance and energy storage capacity. As governments worldwide implement policies to promote electric vehicle adoption and invest in charging infrastructure, the demand for specialty chemicals in the automotive sector is expected to escalate further.

Elaborating on Construction Industry Expansion:

The construction industry in emerging economies is witnessing a boom, driven by rapid urbanization, population growth, and infrastructure development projects. Countries across Asia, Africa, and Latin America are investing heavily in building residential complexes, commercial buildings, roads, bridges, and other infrastructure to support their growing populations and economies. This surge in construction activities is fueling the demand for specialty chemicals used in various construction applications.

Adhesives and sealants are indispensable in the construction industry, serving as bonding agents for joining different materials and sealing gaps to prevent water leakage and air infiltration. Construction chemicals, including concrete admixtures, waterproofing agents, and protective coatings, enhance the durability, strength, and performance of concrete structures, thereby extending their service life and reducing maintenance costs. As governments prioritize sustainable building practices and energy-efficient construction techniques, the demand for eco-friendly specialty chemicals is on the rise.

Furthermore, the adoption of green building standards, such as LEED (Leadership in Energy and Environmental Design) certification, is driving the use of environmentally friendly construction materials and chemicals. Specialty chemicals manufacturers are responding to this trend by developing innovative products that meet stringent environmental standards while delivering superior performance and durability. By leveraging advanced technologies and sustainable practices, the construction industry in emerging economies can address the growing demand for infrastructure while minimizing its environmental footprint.

Diving into Agriculture Sector Opportunities:

The agriculture sector plays a vital role in the economies of emerging countries, employing a significant portion of the population and contributing to food security and rural development. With increasing pressure to feed a growing population and mitigate the impact of climate change on agricultural productivity, farmers are turning to advanced technologies and modern agricultural practices to improve crop yields and efficiency.

Specialty chemicals are integral to modern agriculture, providing farmers with essential tools and solutions to enhance crop protection, soil fertility, and yield optimization. Fertilizers enriched with micronutrients, bio-stimulants, and growth regulators help replenish soil nutrients, promote plant growth, and improve nutrient uptake efficiency. Pesticides and herbicides play a crucial role in controlling pests, diseases, and weeds that threaten crop health and productivity.

In addition to traditional crop protection chemicals, specialty chemicals manufacturers are developing innovative solutions such as biopesticides, microbial inoculants, and biostimulants that offer environmentally friendly alternatives to conventional agrochemicals. These products harness the power of beneficial microorganisms, natural plant extracts, and biologically active compounds to enhance soil health, stimulate plant growth, and improve crop resilience to biotic and abiotic stresses.

Moreover, the adoption of precision agriculture technologies, including GPS-guided tractors, drones, and sensor-based monitoring systems, is revolutionizing farming practices in emerging economies. By leveraging data-driven insights and real-time analytics, farmers can optimize resource use, minimize input costs, and maximize crop yields while reducing environmental impact. Specialty chemicals companies are aligning their product portfolios with the needs of modern agriculture, offering tailored solutions that integrate seamlessly with digital farming platforms and sustainable agriculture practices.

Inquire before buying, here: https://www.nextmsc.com/specialty-chemicals-market/inquire-before-buying

Exploring Healthcare Sector Dynamics:

The healthcare sector in emerging economies is undergoing rapid transformation, driven by factors such as demographic shifts, rising healthcare expenditure, and increasing prevalence of chronic diseases. As populations age and lifestyles change, there is a growing demand for healthcare services, pharmaceuticals, medical devices, and personal care products.

Specialty chemicals play a critical role in the healthcare industry, providing essential ingredients and formulations for pharmaceuticals, medical devices, and personal care products. Pharmaceutical excipients, for example, are used as bulking agents, binders, disintegrants, and coatings in drug formulations to enhance drug stability, bioavailability, and patient compliance. Specialty polymers and plastics are essential components of medical devices such as implants, catheters, and surgical instruments, offering superior biocompatibility, durability, and performance.

Moreover, specialty chemicals are widely used in the formulation of personal care and cosmetic products, including skincare, haircare, and oral care products. Emollients, surfactants, preservatives, and fragrance ingredients contribute to the sensory attributes, efficacy, and safety of personal care formulations, meeting the diverse needs and preferences of consumers.

As emerging economies invest in expanding their healthcare infrastructure, improving access to essential medicines, and enhancing healthcare services, the demand for specialty chemicals in the healthcare sector is expected to grow significantly. Specialty chemicals manufacturers are innovating and diversifying their product portfolios to address emerging healthcare trends, including personalized medicine, biopharmaceuticals, regenerative medicine, and nutraceuticals. By collaborating with pharmaceutical companies, contract manufacturers, and healthcare providers, specialty chemicals companies can leverage their expertise and capabilities to develop customized solutions that meet the unique requirements of the healthcare industry.

Challenges and Opportunities in Emerging Economies:

While emerging economies offer immense growth opportunities for the specialty chemicals market, they also present unique challenges and complexities that companies must navigate to succeed in these markets. Regulatory compliance, intellectual property protection, supply chain logistics, cultural differences, and market volatility are among the key challenges that companies may encounter when operating in emerging economies.

Regulatory compliance varies across different countries and regions, requiring specialty chemicals companies to stay abreast of local regulations, standards, and certification requirements. Failure to comply with regulatory requirements can lead to delays in market entry, product registration issues, and legal liabilities, undermining business operations and profitability.

Moreover, intellectual property protection is a significant concern for specialty chemicals companies, particularly in emerging economies where enforcement of intellectual property rights may be weak or inconsistent. Counterfeiting, piracy, and unauthorized use of proprietary technologies pose risks to innovation and investment in R&D, deterring companies from introducing new products and technologies to the market.

Supply chain logistics is another challenge that companies face in emerging economies, where infrastructure constraints, transportation bottlenecks, and customs clearance procedures can disrupt the flow of raw materials, intermediates, and finished products. Delays in supply chain operations can impact production schedules, inventory management, and customer satisfaction, affecting business performance and competitiveness.

Cultural differences and market dynamics also pose challenges for specialty chemicals companies entering emerging economies, where business practices, consumer preferences, and distribution channels may differ from mature markets. Building relationships with local partners, understanding cultural nuances, and adapting marketing strategies are essential for success in these diverse and dynamic markets.

Despite these challenges, emerging economies offer vast opportunities for specialty chemicals companies to expand their presence, diversify their customer base, and capitalize on untapped market potential. By adopting a proactive approach, investing in local capabilities, and leveraging strategic partnerships, companies can overcome obstacles and unlock the full potential of emerging economies.

Conclusion:

The Specialty Chemicals Market is poised for robust growth in emerging economies, driven by factors such as rapid industrialization, urbanization, and increasing consumer demand for high-performance chemicals. The automotive, construction, agriculture, and healthcare sectors present significant growth opportunities for specialty chemicals companies to capitalize on emerging trends, technological advancements, and changing consumer preferences.

However, realizing the full potential of emerging economies requires a strategic approach, including market research, product innovation, regulatory compliance, and partnerships with local stakeholders. Specialty chemicals companies must navigate the complex regulatory landscape, address supply chain challenges, and adapt to cultural differences to succeed in these diverse and dynamic markets.

By leveraging their expertise, capabilities, and global presence, specialty chemicals companies can position themselves for sustainable growth and competitiveness in the evolving market landscape. With a focus on innovation, sustainability, and customer-centricity, companies can unlock new avenues for growth, drive market expansion, and create value for stakeholders in emerging economies and beyond.

0 notes

Text

Navigating the Acetone Market Landscape: Trends and Opportunities

The acetone market will grow at a compound annual growth rate of 7.4% in the years to come, to touch a value of USD 9,590.9 million by the year 2030.

Acetone is water-white, volatile, combustible, and mixable in water. Due to its high rate of evaporation and excellent usability as a solvent, it is used to dissolve both synthetic and natural oils, gums, waxes, resins, and other additives. It is…

View On WordPress

#Acetone#chemical industry#Derivatives#Global Market#Growth Drivers#Industrial applications#Manufacturing Processes#market trends#Solvent Market#Specialty Chemicals

0 notes

Text

The Chemistry Behind Clean Water: How Flocculant Chemicals Make a Difference

Introduction

Pure water stands as an irreplaceable treasure, upholding existence throughout the expanse of our planet. The presence of secure and uncontaminated water stands as a foundational requirement for human continuation, a significance that cannot be exaggerated. Yet, the assurance of consuming water devoid of impurities demands an intricate fusion of scientific fundamentals, engineering methods, and inventive advancements. At the core of this pursuit resides the captivating realm of chemistry, where the significance of flocculant chemicals becomes paramount. These chemicals assume a pivotal role in metamorphosing muddled, tainted water into a lucid, revitalizing potion.

Importance of Clean Water

Clean water transcends luxury; it's a fundamental entitlement of every human being. The availability of unpolluted and secure drinking water stands as a cornerstone for preserving well-being and averting waterborne ailments. Water tainted with impurities can pave the way for an array of health complications, spanning from gastrointestinal disturbances to grave infections. Thus, the urgency for efficient techniques of water treatment remains of the utmost importance.

Role of Chemistry in Water Treatment

The quest for clean water is where chemistry truly shines. Chemistry provides us with the tools to understand the properties of water, the nature of contaminants, and the mechanisms through which they can be removed. The application of chemical principles in water treatment has revolutionized the way we purify water on a large scale.

Overview of the Flocculation Process

At the heart of water treatment lies the process of flocculation, a phenomenon driven by the interaction between flocculant chemicals and suspended particles in water. Flocculation involves the aggregation of these particles into larger clusters called flocs, which can then be easily separated from the water. This process not only removes visible impurities but also eliminates microscopic contaminants, ensuring the water is safe for consumption.

What are Flocculant Chemicals?

Flocculant chemicals, often referred to simply as flocculants, are substances that facilitate the aggregation of suspended particles in water. They are like molecular maestros orchestrating a complex dance of particles, turning chaos into order. Flocculants play a critical role in water treatment by aiding in the removal of contaminants and turbidity.

Definition and Purpose

Flocculants are polymers with a high molecular weight that possess an affinity for both water and the particles present in them. When added to water, these chemicals interact with suspended particles, causing them to clump together and form flocs. These flocs are heavier and settle down, making it easier to separate them from the clear water.

The Science of Flocculation

Flocculation may sound like a complex scientific process, but at its core, it's all about creating order out of chaos. Imagine a crowded dance floor where individuals are moving chaotically. Now, imagine a skilled dance instructor stepping in and guiding dancers to form couples and groups. Flocculation does something similar to particles in water.

Dispersion and Aggregation

When flocculant chemicals are introduced into water, they disperse evenly due to their affinity for both water and particles. As these molecules spread, they come into contact with suspended particles. This contact leads to the aggregation of particles, much like dancers forming pairs on the dance floor. Particles that were once scattered now begin to clump together.

Bridging and Enmeshment

Here's where the chemistry gets interesting. Organic flocculants act as matchmakers, creating bridges between particles. Think of it as dancers holding hands to form a chain or circle. This bridging creates a loose network of particles, and smaller particles get trapped within this network. It's like dancers in a circle holding hands, preventing anyone from escaping the dance.

Formation of Flocs

As the bridges between particles strengthen and more particles join the network, larger flocs begin to take shape. These flocs are like well-coordinated dance groups, moving together as a unit. Due to their increased size and weight, flocs start to settle down under the influence of gravity. Eventually, they become heavy enough to separate from the clear water, leaving behind a purified liquid.

Application of Flocculants in Water Treatment

Flocculants have found their way into various sectors, contributing significantly to water treatment and purification. Let's dive into some of the key areas where flocculants play a vital role:

Municipal Water Treatment

In the realm of municipal water treatment, flocculants are essential for transforming raw water from rivers, lakes, and reservoirs into potable water. As water sources contain a mix of suspended particles, bacteria, and organic matter, flocculants aid in removing these impurities, ensuring the water meets safety standards.

Industrial Water Treatment

Industries rely on vast amounts of water for various processes. However, the water used in industrial operations often contains contaminants that can impact both product quality and equipment efficiency. Flocculants help industries treat and recycle water, reducing the environmental impact and ensuring smooth operations.

Mining Industry

Mining operations generate significant amounts of wastewater, which can be laden with minerals, sediments, and other pollutants. Flocculants are used to clarify and dewater the wastewater, allowing for safe disposal or reuse. This not only minimizes the environmental impact but also helps recover valuable resources.

Wastewater Treatment

Wastewater treatment plants handle domestic and industrial sewage, aiming to remove pollutants before releasing the treated water back into the environment. Flocculants assist in the sedimentation and filtration processes, aiding in the removal of solids and contaminants from wastewater.

Factors Influencing Flocculation

Certainly, let's delve into the various factors that influence the effectiveness of the flocculation process:

pH Levels

pH plays a crucial role in flocculation. The optimal pH range varies depending on the type of flocculant used. Deviations from this range can lead to reduced flocculation efficiency, affecting the quality of the treated water.

Temperature

Temperature affects the kinetics of flocculation. Higher temperatures can accelerate the process, leading to faster floc formation. However, extreme temperatures can also impact the stability of flocs, potentially affecting the overall treatment process.

Mixing Intensity

The energy applied during mixing affects the collision and adhesion of particles. Proper mixing ensures uniform dispersion of flocculants and enhances the chances of effective particle aggregation.

Particle Size

The size of suspended particles plays a role in flocculation. Smaller particles have a higher surface area, making them more challenging to aggregate. Therefore, the choice of flocculant and process parameters should consider the particle size distribution.

Advancements in Flocculant Technology

As technology advances, so does the field of flocculation. Innovations continue to enhance the efficiency and sustainability of water treatment processes:

Nanotechnology and Flocculation

Nanotechnology has paved the way for the development of nanomaterial-based flocculants. These tiny particles offer high surface area and unique properties, improving flocculation efficiency and reducing the required dosage of chemicals.

Eco-friendly Flocculants

The environmental impact of traditional flocculants has led to the exploration of eco-friendly alternatives. Biopolymers and natural materials are being studied for their flocculation potential, minimizing the ecological footprint of water treatment.

Automation and Precision

Automation and digital technologies are transforming water treatment plants. Advanced sensors and algorithms monitor flocculation processes in real-time, adjusting parameters for optimal performance. This level of precision ensures consistent water quality and reduces operational costs.

Environmental and Health Considerations

While flocculants contribute to cleaner water, their use raises important environmental and health considerations:

Disposal of Flocculated Particles

Once the flocs are separated from the water, they need to be properly disposed of or treated. The disposal method can impact soil and water quality, necessitating careful handling and management.

Impact on Aquatic Ecosystems

The release of treated water back into aquatic ecosystems can have unintended consequences. Flocs that make their way into natural water bodies can affect sedimentation patterns, potentially disrupting aquatic life and habitats.

Human Health Concerns

The presence of residual flocculant chemicals in treated water raises questions about their potential impact on human health. Research is ongoing to ensure that the benefits of water treatment outweigh any potential risks.

Conclusion

The chemistry behind clean water is a captivating tale of science working hand in hand with nature to ensure our most precious resource remains pure and safe for consumption. Flocculant chemicals, those unassuming molecular magicians, play a central role in this endeavor. By harnessing their unique properties, we can witness the transformation of cloudy, contaminated water into a crystal-clear liquid fit for quenching our thirst and sustaining life.

The dance of particles, the orchestration of forces, and the delicate balance between science and engineering create a symphony of purification. From municipal water treatment plants to industrial processes and wastewater management, flocculants shine as the unsung heroes of the clean water revolution. Their ability to aggregate particles and form flocs may seem simple, but the intricacies of this process demonstrate the wonders of chemistry at play.

#flocculant#flocculant chemicals#mining chemicals#flocculant chemical suppliers#mining chemical suppliers#flocculant chemicals manufacturing#chemical manufacturing industries#chemical manufacturing#specialty chemicals#flocculation#nonionic flocculant

0 notes

Text

India is deliberately shifting its focus towards specialty chemicals, which promises higher margins and multiple end-use applications. It has a strong presence in areas such as performance chemicals, pharmaceuticals, dyes, pigments, agrochemicals, where specialty chemicals play an extremely pivotal role.

1 note

·

View note

Text

Danimer Scientific Inc (DNMR) Q1 2023 Earnings Call Transcript

$DNMR Q1 2023 Earnings Call Transcript #earnings #markets #investing

Danimer Scientific Inc (NYSE:DNMR) Q1 2023 Earnings Call dated May. 10, 2023.

Corporate Participants:

James Palczynski — Investor Relations Representative

Stephen E. Croskrey — Chief Executive Officer; Chairman, Board of Directors

Mike Hajost — Chief Financial Officer

Analysts:

Kevin Estok — Jefferies — Analyst

Thomas Boyes — TD Cowen — Analyst

Jon Tanwanteng — CJS Securities — Analyst

Charles…

View On WordPress

0 notes

Text

Sales Slump Solution: Boost Your Business with These 5 Simple Strategies

Sales slumps can be a nightmare for any business, large or small. It's frustrating when you've put so much time and effort into your products or services, and yet sales just aren't coming through. However, before you start panicking, it's important to know that there are solutions out there that can help you boost your business and get back on track. Here are 5 simple strategies that can help you do just that.

Revisit your target audience

One of the main reasons why sales might be slumping is that you're not targeting the right audience. It's essential to take a step back and look at who your target audience is. What are their needs? What are their pain points? By reevaluating your target audience, you can ensure that you're offering a product or service that meets their needs and that your marketing efforts are tailored to the right people.

Revamp your marketing strategy

If your target audience is spot on, then it's possible that your marketing strategy needs some tweaking. Look at your messaging and branding. Are they aligned with your target audience? Is your message clear and concise? You might also want to try different marketing channels to see which ones are more effective for your business. For instance, if you're not seeing much success on social media, you might want to try email marketing or paid advertising.

Improve customer experience

Customers are the lifeblood of any business, and if they're not happy, they won't come back. Improving your customer experience can be a game-changer when it comes to boosting sales. Consider offering personalized experiences, fast shipping, and excellent customer service. Respond to customer inquiries promptly and always make sure to follow up after a purchase to ensure their satisfaction.

Increase product offerings

If you're only offering one product or service, it might be time to consider expanding your offerings. Customers like to have options, and by adding more products or services, you're giving them more reasons to come back. This could also help you reach new audiences who might not have been interested in your current offerings.

Focus on retention

While gaining new customers is essential for any business, it's equally important to focus on retaining current customers. These are the customers who are already familiar with your brand and have had positive experiences with your products or services. Consider offering loyalty programs or exclusive deals to keep them coming back.

In conclusion, a sales slump can be a challenging time for any business owner, but with the right strategies in place, it can also be an opportunity for growth and improvement. By implementing the five simple strategies discussed in this article, including focusing on customer needs, building relationships, improving marketing efforts, exploring new markets, and optimizing operations, businesses can overcome a sales slump and thrive in the long term. For more expert insights and guidance on growing your business, be sure to check out Biz Dispatch. With their wealth of knowledge and resources, you'll have everything you need to succeed in today's competitive business landscape.

#human resources#Hiring#employment#clariant#job openings#careeropportunities#passion#getpaid#specialty chemicals#careerdevelopment#humanresources

0 notes

Text

Different Types of Construction Chemicals and Their Applications

Construction chemicals play a critical role in repair and restoration projects for buildings and infrastructure. These chemicals are designed to enhance the strength, durability, and longevity of structures that have been damaged or degraded over time.

Commonly used construction chemicals for repair and restoration projects include:

Concrete Repair Mortars: Used to repair damaged or deteriorated concrete structures such as bridges, tunnels, and parking structures. These mortars are specially designed to restore the structural integrity of the damaged concrete and prevent further deterioration.

Waterproofing Chemicals: Used to prevent water infiltration and damage to the building's structure. These chemicals can be applied to the exterior of the building or incorporated into the concrete mix.

Grouts: Used to fill voids and cracks in concrete structures, and to anchor bolts or rebar. Grouts are formulated to provide high-strength, low-shrinkage, and excellent bonding properties.

Protective Coatings: Used to protect surfaces from environmental damage, chemical attack, or abrasion. These coatings can be applied to concrete, steel, and masonry surfaces to provide long-lasting protection.

Adhesives: Used to bond new materials to existing structures. Adhesives are formulated to provide excellent bonding strength and durability.

In conclusion, construction chemicals play a vital role in the repair and restoration of buildings and infrastructure. They provide a cost-effective and efficient solution to enhance the durability and longevity of structures, helping to prevent future damage and reduce the need for future repairs.

0 notes

Text

Paper Sizing Agents - Roles and Significance

Surface sizing agents are materials that are applied to the surface of paper to improve its strength and printability. These agents work by creating a barrier on the surface of the paper that helps to protect it from moisture and other environmental factors. This barrier also helps to improve the surface strength of the paper, making it more resistant to tearing and other forms of damage.

Additionally, surface sizing agents can improve the printability of paper by creating a smoother and more uniform surface that is better suited for printing.

There are several different types of surface sizing agents that are commonly used in papermaking. Some of the most common include:

Starches: Starches are natural polysaccharides that are derived from plants. They are commonly used as surface sizing agents because they are readily available and relatively inexpensive. Starches are also biodegradable, making them an environmentally friendly choice.

Synthetic polymers: Synthetic polymers such as polyvinyl alcohol (PVA) and polyacrylamide (PAM) are also commonly used as surface sizing agents. These materials are known for their superior strength and durability, making them a popular choice for high-performance paper applications.

Rosin: Rosin is a natural resin that is derived from pine trees. It is commonly used as a surface sizing agent in papermaking due to its ability to improve the strength and printability of paper.

Casein: Casein is a protein that is derived from milk. It is used as a surface sizing agent in papermaking due to its ability to improve the strength and printability of paper.

Alkyl ketene dimer (AKD): AKD is a synthetic wax that is used as a surface sizing agent in papermaking. It improves the strength and printability of paper.

The choice of surface sizing agent will depend on the specific application and the desired properties of the end product. Some paper manufacturers may use a combination of different surface sizing agents to achieve the desired properties.

In conclusion, Surface sizing agents are materials that are applied to the surface of paper to improve its strength and printability by creating a barrier on the surface of the paper that helps to protect it from moisture and other environmental factors. Starches, Synthetic polymers, Rosin, Casein and Alkyl ketene dimer (AKD) are some of the common surface sizing agents used in papermaking. The choice of surface sizing agent will depend on the specific application and the desired properties of the end product.

At Advance Chemicals we offer Sizing agents covering Fortified Rosin, AKD, and both cationic and Anionic Version of Surface Size Agent.

0 notes

Text

Global Synthetic Diamonds Market to Grow at a CAGR of 8.26% by 2028

Triton Market Research presents the Global Synthetic Diamonds Market report sectioned by Coloration (Colored, Colorless), Manufacturing Method (High Pressure-High Temperature [HPHT], Chemical Vapor Deposition [CVD]), Industry Vertical (Construction, Mining, Oil & Gas, Electronics, Healthcare, Jewelry, Other Industry Verticals), Sales Channel (Online Sales Channels, Offline Sales Channels), and Regional Outlook (Europe, North America, Middle East and Africa, Latin America, Asia-Pacific).

The report further discusses the Market Summary, Industry Outlook, Impact of COVID-19, Key Insights, Porter’s Five Forces Analysis, Market Attractiveness Index, Vendor Scorecard, Industry Components, Key Market Strategies, Drivers, Challenges, Opportunities, Competitive Landscape, Research Methodology & Scope, Global Market Size, Forecasts & Analysis (2022-2028).

Triton’s report suggests that the global market for synthetic diamonds is estimated to witness growth at a CAGR of 8.26% over the forecast period 2022-2028.

Request Free Sample Report:

https://www.tritonmarketresearch.com/reports/synthetic-diamonds-market#request-free-sample

Synthetic diamonds or lab-created diamonds are grown in highly controlled laboratory settings using cutting-edge technological procedures that resemble the conditions under which diamonds naturally develop.

Natural diamonds are formed over billions of years in the earth’s crust and require an indefinite amount of time. Synthetic diamonds go through a similar process in a controlled laboratory setting to produce an identical product to natural diamonds. These diamonds are mass-produced, and the cost of production has decreased by 90% due to technological advancement. Synthetic diamonds are manufactured in 6-10 weeks using one of the two methods: high pressure-high temperature or chemical vapor deposition. Thus, the high demand and less production time are anticipated to drive the synthetic diamonds market.

However, the high installation and maintenance setup and the dwindling resale value of synthetic diamonds are impeding the growth of the synthetic diamonds market.

Globally, the Asia-Pacific is anticipated to become the fastest-growing region in the synthetic diamonds market. The region’s growth results from numerous reactor plants for synthetic diamond manufacturing and the availability of a skilled labor force. Additionally, increasing disposable incomes, as well as favorable government policies and initiatives in sectors such as telecommunications, healthcare, etc., will propel the growth of the region’s market. This is due to the use of these diamonds in instruments such as head spreaders, lasers, medical instruments, mining drills, etc.

Leading companies in the synthetic diamonds market include Brilliant Earth LLC, New Diamond Technology LLC, Henan Huanghe Whirlwind Co Ltd, Engis Corporation, Heyaru Engineering NV, Labgems, WD Lab Grown Diamonds, Soham Industrial Diamonds, Zhengzhou Sino-Crystal Diamond Co Ltd, Iljin Diamond Co Ltd, Henan Liliang Diamond Co Ltd, Element Six, Sumitomo Electric Industries Ltd, Asahi Diamond Industrial Co Ltd, and Applied Diamond Inc.

The diamond seed, a sliver of single crystal diamond, is the most important raw material required for synthetic diamond production. However, few companies worldwide, primarily in Asia, provide diamond seeds for production, resulting in increased bargaining power. Furthermore, price fluctuations in raw materials such as liquid solvents and methane have a negative impact on the market. As a result, suppliers have moderate to high bargaining power.

Contact Us:

Phone: +44 7441 911839

#synthetic diamonds market share#synthetic diamonds market#cvd diamond market#chemicals and materials#specialty chemicals#market research reports#market research report#triton market research

0 notes

Text

Synthetic Diamonds Market: Global Prospects & Challenges

The staggering ramifications of the COVID-19 pandemic affected the global distribution system of major countries producing synthetic diamonds. However, post-pandemic, the diamond industry was stimulated through digital platforms. With reduced operations, companies relied heavily on digital activities while focusing on their B2C online business. Sale of synthetic diamonds was expected to increase as manufacturers gave more importance to environment friendliness and sustainability in the production of lab-grown diamonds. Thus, due to the rising branding and marketing, along with increasing industrial uses, the global synthetic diamonds market is anticipated to advance with a CAGR of 8.26% during the forecasting period 2022-2028.

Additionally, major countries such as India and China have become a hub for the production and processing of lab-grown diamonds as a result of technological breakthroughs, cost-efficient production of gem-quality stones and growing consumer awareness. The rising production is because synthetic diamonds make an ideal window material for many industrial, R&D, defense and laser applications.

Rising Industrial Demand - Key Driver

Modern technology resembles the conditions under which diamonds naturally develop by using either of the two manufacturing methods high pressure-high temperature (HPHT) or chemical vapor deposition (CVD). Our study estimates that the high pressure-high temperature will dominate the manufacturing method segment, capturing a share of 59.59% during the forecast period 2022-2028. These processes produce synthetic diamonds with the same chemical properties as earth-mined diamonds, allowing them to be used in a variety of industry applications:

Construction

Mining

Healthcare

Defense

Future Prospects

Even though lab-grown diamonds are an inexpensive alternative to earth-mined ones, the high cost of production can result in a setback for the synthetic diamonds market. For instance, a perfect CVD diamond can take 400 hours of hatching time and specialized reactors to culture the diamonds. These reactors consume approximately 10000 units of power monthly, thereby increasing operational costs. However, the ongoing research around quantum computing, simulation, communication and sensing, with potential impacts in healthcare and the automotive industry, is expected to increase synthetic diamonds’ applications and reduce the overall production cost.

For instance, in 2021, a German-Australian start-up Quantum Brilliance announced the installation of a diamond-based quantum accelerator leveraging synthetic diamond technology. The start-up stated promising applications, leading to major benefits for drug design, chemical synthesis, energy storage and nanotechnology.

#synthetic diamonds market#synthetic diamonds#cvd diamonds market#specialty chemicals#chemicals and materials#market research reports#triton market research

0 notes

Text

#Specialty Chemicals#Commodity Chemicals#intermediate manufacturers#sulfamide manufacturer#famotidine manufacturer

0 notes

Text

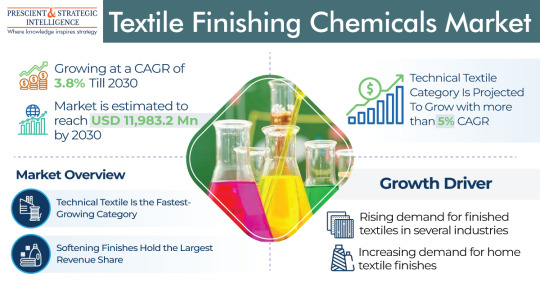

Unveiling Opportunities in the Textile Finishing Chemicals Market

The global textile finishing chemicals market is projected to be worth USD 11,983.2 million by 2030, growing at a CAGR of 3.8%, according to P&S Intelligence. These chemicals are consumed in significant volumes in furniture, textile, and other sectors. In this regard, the growing demand for unique finishes for residential upholstery and advanced textiles is propelling the market. The main aim of…

View On WordPress

#Eco-friendly Solutions#Fabric Enhancement#Global Industry#Innovation#Manufacturing Processes#market trends#Performance Textiles#Specialty Chemicals#Sustainable Finishes#Textile Finishing Chemicals

0 notes

Text

Specialty Chemicals Market Trends, Key Players, DROT, Analysis & Forecast Till 2030

The wide application spectrum of specialty chemicals is estimated to augment the overall market share. Reports created by MRFR detail the developments in the industry that can be expected in the market through the forecast period. The market share of specialty chemicals market size is USD 900 billion and hence, projects a global CAGR of 4% by the end of the forecast period in 2030

The intensifying demand from the global automobile industry is also estimated to have an advantageous effect on the progress of the specialty chemical market in the near future. Furthermore, the shift from the use of commodity chemicals to specialty chemicals is also expected to motivate the markets’ progress in the upcoming period.

Segmental Analysis

The segmental assessment of the specialty chemical market is carried out based on source, type, and region. The type segment of the specialty chemical market consists of fragrances ingredients, water treatment chemicals, construction, chemicals, agrochemicals dyes & pigments, personal care active ingredients, flavors ingredients, surfactants, textile chemicals, bio-based chemicals, and polymer additives. The regions included in the specialty chemical market are Latin America, Europe, Africa, Asia Pacific, North America, and the Middle East. The source segment of the specialty chemical market consists of naphtha, crude oil, propane, butane, ethane, wood, and others.

Detailed Regional Analysis

The regional examination of the specialty chemical market includes Latin America, Europe, Africa, Asia Pacific, North America, and the Middle East. The Asia Pacific region’s specialty chemicals market at present rules the global market, and the trend is anticipated to continue in the forecast period. The influences supporting the market's momentum are the swelling prerequisite for specialty chemicals in large-scale businesses such as automotive and construction. The North American specialty chemical market, indicates the second chief market for specialty chemicals and is anticipated to rise at a stable CAGR due to the contribution of the United States specialty chemicals market. In the meantime, the regional market in Europe will also go on to establish itself as an essential market for specialty chemicals in the next couple of years. The incidence of a firm automotive sector has formed development prospects for market companies operating in the region.

Competitive Analysis

The scale of innovation being observed in the market is another reason that is adding to the advancement of the global market in the future. The detrimental impact on the environment by the business practices is estimated to be a key component in the future growth strategies of the market. The funding scenario in the market is estimated to be optimistic and conducive to the development of the stakeholders in the market. The advancement of the market is spurred by the initiatives of the leaders in the global market, who are dedicating resources to the development of the overall market. The government policies in several regions are very conducive to the development of the market in the upcoming period. The advancement of production technology and processes is estimated to augment the global market. The establishment of clear long-term objectives by market titans is estimated to set the tone for the continuing expansion of the market. The identification of areas for sustainable enhancement in the supply chain is estimated to further fortify the market.

The distinguished contributors in the specialty chemicals market are Solvay S.A. (Belgium), Ashland Inc. (U.S.), BHS Specialty Chemicals (U.S.), Givaudan (Switzerland), Evonik Industries AG (Germany), Lanxess AG (Germany), Croda International Inc. (Switzerland), Exxon Mobil Corporation (U.S.), Lenzing AG (Austria), AkzoNobel N.V (Netherlands), DowDuPont, Inc. (U.S.), Henkel AG & Co. KGaA (Germany), H.B Fuller (U.S.), BASF SE (Germany), and Clariant AG (Switzerland).

Industry Updates:

Feb 2021 Clariant Chemicals is expected to buy about 51 percent stake in India Glycols' specialty chemical business. India Glycols is presently represented in three verticals, i.e., nutraceuticals, specialty chemicals, and natural active pharma. Clariant Chemicals is eyeing a 51 percent stake in the specialty chemicals vertical. In terms of value, this transaction is expected to be worth about Rs 1,000 crore and through this investment sale, India Glycols would be raising around Rs 500 crore.

Mar 2021 IMCD, a provider of specialty chemicals and ingredients, has revealed it has reached an arrangement to sell its Nutri Granulations production subsidiary and associated company to Huber Engineered Materials (HEM), a group of J.M. Huber. The deal is anticipated to end at the end of March and the financial terms have not been unveiled. Combining an additional producing site will back supply security and business stability for their customers.

Read the Full Report: https://www.marketresearchfuture.com/reports/specialty-chemicals-market-2026

Contact:

Market Research Future®

99 Hudson Street,5Th Floor

New York, New York 10013

United States of America

Phone:

+1 628 258 0071(US)

+44 2035 002 764(UK)

Email: [email protected]

Website: https://www.marketresearchfuture.com

#Specialty Chemicals#Specialty Chemicals Market#Global Specialty Chemicals Market#Specialty Chemicals Market Trends#Specialty Chemicals Market Share

0 notes

Text

Natraj Chemicals Dyes Intermediates manufacturer and Exporter From India Para-Aminoazobenzene 4 Sulfonic Acid (paabsa)

#direct dyes#export from india#chemical & dyes news#acid dyes#chemical suppliers#specialty chemicals#dyes and pigments companies#manufacturer#fine chemicals

0 notes

Text

Air Products & Chemicals Inc (APD) Q2 2023 Earnings Call Transcript

Air Products & Chemicals Inc (NYSE: APD) Q2 2023 Earnings Call dated May. 09, 2023

Corporate participants:

Sidd Manjeshwar — VP, Corporate Treasurer, IR

Melissa Schaeffer — SVP, CFO

Samir J. Serhan — COO

Seifi Ghasemi — Chairman, President, CEO

Analysts:

David Huang — Deutsche Bank — Analyst

Steve Byrne — Bank of America — Analyst

John McNulty — BMO Capital Markets — Analyst

Christopher Parkinson…

View On WordPress

0 notes