#Roughing the Flange

Note

Hi there. I was wondering if you could write about mafia austin!elvis. Where the reader (female) is young and naive. Her, older brother who is around 10-15 years older than her maybe was employed by Elvis, and always comes home bruised up. Her brother tries to hide the fact that he has a younger sister from Elvis because he doesn't want her to be tainted by any means. One night the reader finds out what her brother's line of work actually entails, she decides to confront Elvis herself. This then leaves Elvis obsessed with the reader and causes him to take drastic measures to have her all to himself. You can decide how this ends based on what you're comfortable writing.

Thank you.

This is right up my ally! I love this!

Deal

Austin!Elvis x reader

Warning: Emotional manipulation, Obsessed Austin!Elvis, Mild smut, Naive reader ( reader's 18, Elvis is 31, Mark is 33), Mention of death, Near death experience, Blackmail, First kiss. ( if my maths is wrong you can correct)

Summary: life was looking up, your brother and you lived in a big house, no longer striving for food but it was beginning to come with a cost.

It all started when your father passed, you were 15 then and your mother walked out long before he died, it was just you and your brother Mark. It was rough the few years he died, you lose your house, and barely eat and Some of your dad's friends would help before they decided they had done enough and kicked you two back into the street

It wasn't until recently that your lives begin to turn around, Mark had gotten a job that paid well, very well, that's where as good as could be or that's what you thought, you remember you were talking to your new friends, the topic was one you didn't quite understand, it was something about boys and "Fun stuff" whatever that meant when your brother comes stumbling in, hunched over against the doorway before noticing the sets of eyes on him and stood straight like that never happened "Ladies." he greeted on his way to the kitchen. That was one of many you noticed, he came home like that more and more, with bruises appearing on his body more it scared you but it reached the peek when he ended up at the hospital, you ran faster than you ever had, the closer you got to his room, two voices come out heated, one was your brother and the other had a southern drawl, reach the room the door was flanged out and a man in a dark purple suit, with jet black hair and sideburns, a pair of expensive shades over his eyes stepped out followed by a man with blue eyes and Shaggy dirty blonde hair, Mister purple looked at you for a second before walking to the exit, Mister Shaggy blonde behind him, for a moment you watched the men leave then rushed into your brother's room, a gasp torn itself from your lips and tears budded in your orbs "Mark!" you cried and hugged him without thinking gaining a sharp "OW!" you immediately backed away with an "I'm sorry!!" Mark simply laughed "It's okay little bee" he smiled at your pouting-worried face.

"Who was that man?" you titled your head as you watched his expression change more than once, trying to find something to say. "Nobody, sis, nobody." he smiles, and shakes your hair, making a whine leave your pouted lips, you didn't accept that, and you won't accept that, telling him you were going to the restroom and you'd be back. You walked up to one of Marks's nurses and asked who the man was "Oh honey that was Elvis Presley, he's a very serious man, and he runs this town." she answers, "Do you know where he lives ma'am?" she again answered your question, you thanked her and decided to say goodbye to your brother, he would be there for a few days. Tomorrow You were able to get a friend to drop you off at his address and after enough annoying the gatekeeper you were allowed into the beautiful mansion, and an appointment with Mr. Presley "You got some nerve little girl." he sat his shades on his desk and leaned back into his office chair, his eyes were a stormy blue as he looked you up and down "What do ya want hmm?" he asked, looking, sounding unimpressed and mildly bored "I want you to leave my brother alone." you spoke, luckily without stuttering, your eyes looked into his with determination, a singular eyebrow rose and a spark enter his eyes as quickly as It came it vanished "I think about it. Come back tomorrow. " he answered after a thick silence, you went to protest but was shut down with a look of the man before you. You were then escorted out of Elvis's home and to your home, by a guy named Jerry who was the same man who picked you up the next day.

You were led to his bedroom, the room was dark-lit, with a large bed of a gold and black theme, and red curtains framing the plush headboard of the bed, the walls were painted black with golden lines. The room looked like a king's private chamber, you sat on the bed and waited for the man in question, the bathroom door opened and Elvis stepped out in a robe of maroon, he didn't look at you at first, he was too busy tying a knot, giving you time to admire him, his tan skin glowed beautifully, his black hair hanged in front of his ice blues as he looked down "I'll make ya a deal." he looked at you, a smug smirk tugging on the corner of his plump lips "Have sex with me and I'll take care of you and your bother. Whatcha ya say darlin'?" his voice lowered, seductive tone taking over "What's sex?" a puzzled expression come to his face from your question "You don't know?" he answered you with his own question to which you just nodded, that smirk from before returned as he gently pushed you onto the massive bed "Why don't I show ya?" he whispered, soon his lips lockied with yours, his tongue dominating yours, exploring your mouth. His fingers ran down your body to your wetting cunt, sliding your underwear to the side and beginning to rub at the entrance got core, mewls, and moans were swallowed by Elvis as two of his fingers pushed inside, pumping them in and out slowly just enough to prepare you for his hardening cock, clothes then flanged out across the bedroom. The bed creaked as his slow thrusts became harder, faster sending you to a state of bliss, you never once played with yourself let only stick something inside, you gasped as he rolled his hips, triggering your climax and forcing a scream of his name out, Elvis grunted as he pulled out, his cum spraying on your sex.

You stayed the night that day, he personally drove you home telling you that he would tell your brother the good news. It was three days later that your brother was finally home, and a knock came on the door "Coming!" you shouted as you walked to the door, opening Elvis stood with some of his men, "Hi darlin'" he smiled softly at you, and a rush of heat came to your cheeks before muttering a "Come in" and moving out the way "Boss?" Mark stood up using his crutches, his busted lip turned into a frown, and the purple-black bruise illiterate around his face "What are you doing here?" he asked Elvis, gesturing you to come to the side, which like the good sister you listen to him "Well I came to tell you the good news." Elvis's smiled, almost mockingly as he walked towards you both "Good news?" Mark asked, his eyebrows frowning "Your darlin' little sister asked me to leave ya alone" Elvis replied, gently pulling you into his chest, tucking a strand of hair behind your ear, looking at you like you hold the moon and stars before looking at your brother, a strange glint in his ocean eyes "You never have to work again."

BANG

You screamed in terror as your brother's body dropped to the floor, falling into a splatter of brain and blood, tears streamed down your eyes as you thrashed in Elvis's arms as he dragged you out of your home to his car "Shush little lamb, it's okay." he whispered in your ears as he held your trembling form as his driver drove off.

Little lamb? It was fitting, wasn't it? The little lamb who didn't know she was trapped in the jaws of the wolf in sheep's clothing until it was too late, only able to cry for her last of kin in the wolf's den, his pack snickered and howled with laughter in the shadows. little lamb stuck with the alpha as she wondered would the wolf find another lamb or was he gonna devour her whole.

#elvis imagine#yandere!elvis x reader#elvis 2022#austin elvis imagine#elvis smut#elvis presley x reader#austin butler smut#elvis x reader#yandere austin butler x reader#austin butler x reader#candy answer

320 notes

·

View notes

Note

May I have Thomas Hewitt or Bubba Sawyer giving their S/O breast massages after breastfeeding their baby (Slashers and their S/O's baby) You can add other slashers if you like. Even I'm starting to like the Sinclairs

Bodacious boob brimming ask bro!

Thomas Hewitt, Bo Sinclair, Vincent Sinclair, and Lester Sinclair, AFAB! Reader, gender neutral reader, racially ambiguous reader, fluff, some suggestive content, headcanons, mentions of breastfeeding, boob massaging, not really NSFW but I still tagged it since I go into some light detail

Thomas Hewitt

you rarely breastfed your baby directly

instead you opted to pump then store the milk for later

while you didn't mind Luda Mae or Thomas watching you breastfeed your baby, Hoyt and Monty were another thing

So you pumped, stored, bottled, then fed your baby like that

But the silicone flange on your pump cracked then tore rendering the device useless until you can get new ones

So you opted to do things the old fashioned way

You never realized how spoiled you were with that fancy pump until you actually had to have your baby drink directly from the tap

It wasn't an unbearable pain but man did you prefer the pump

Afterwards it felt like your breasts were twice as sore than usual

And lucky you with your big bear of a man to come to your rescue

Thomas held you in his lap with your back to his chest and took handfuls of your breasts

He softly rolled your boobs in his hand trying to be careful not to get too rough with your poor sore body

And while you were getting relief from your previous feeding session, Thomas was starting to use your breasts as stress balls

There is just something about how soft and squishy your chest is that really helps him relax

Honestly, he turns massaging your breasts into a daily thing

It's less of a sexual thing with Thomas and more of loving way to destress with you

Bo Sinclair

He can't keep it in his pants

However, it surprised you that he mind your breastfeeding

It wasn't sexual to him, you're the parent of his child doing your part in taking care of it

"Now don't you go drinkin' 'em dry," Bo teased one day, "gotta save some for your pops."

A teasing comment once every blue moon was all that came from him

If you're really tired, he'll hold your guys' baby for you while the little thing suckles

Now when you asked for him to rub your breasts?

Bo went and took it the wrong way

He immediately went for your nipples and became confused when you hissed and pulled away

"Not like that!" you whined grabbing his calloused hands, palm down, to press to your sore breasts

Bo is still turned on by this but will gladly massage your breasts

You don't have to ask him twice

"My baby's all spent and sore?" he'd coo in a low voice as his hands worked wonders in easing the tension in your tits

Having Bo massage you would most likely turn into sex

He just can't help himself with your beautiful body that gave birth to his kid relaxing under his hands

Maybe if you weren't so irresistible, Bo would be less horny

Vincent Sinclair

Vincent suggested that you pump in private or breastfeed in private since he doesn't know how Bo will react

The last thing he wants is some sleazy comment being slung at you by his brother

But Vincent was delightfully surprised when Bo didn't say anything

Sure he glanced to see if he could see some titty but other than that he didn't care

"Glad I dont have to worry 'bout accidentally drinkin' your breastmilk," Bo joked when he learned how you'd rather breastfeed than pump

Vincent on the other hand

He was pretty pumped, pun intended, to drink from you

Massaging your breasts? He's already on it

Long fingers gently rolling the fat of your chest against his palms

Holding and lifting them a little so you could get some relief from their weight

A teasing swipe over your nipple that has you sending a playful warning glance at him

Sit on his lap while he sketches and he'll use your boob like a stress ball with his free hand

Vincent is so gently with your sore breasts you'd honestly fallen asleep one time while he massaged and played with them

Lester Sinclair

Lester gets slightly flushed when he sees you breastfeed

it's less him getting turned on by the act but more that your titty is out

And boy does he love your boobs

He'd help you pump if that's easier

While he does get a little flustered while you're breastfeeding, he still loves to cuddle up to you and your baby while it feeds

Lester would run his hand along the back of the baby's head just in awe at what you two had created

He's at your beck and call whenever you're breastfeeding

Lester has 100% hand fed you while you breastfed your baby

Now when the baby has its post-meal nap, you don't even have to ask twice

His hands are on your breasts the second you put your baby down

It's 50/50 whether Lester turns the massage sexual

Sometimes he just likes reviling in the trust you have for him and how much he loves you as his hands work on your sore boobs

Lester massages your breasts to he's worship the body that birthed his child

The course skin on his hands dragging over your shirt covered breasts as they work out your soreness

He absolutely melts when you lean into him while he's rubbing your boobs

The relaxed look on your face makes him want to cry and hold you until you realize how much he absolutely adores you

Other times, Lester likes to try to get you riled up during the massage

A quick kiss to your neck, a little jiggle, oops did he rub your nipple?

Honestly, he's tried your breastmilk out of curiosity more than any sort of kink

Lester isn't one to actively seek our your breastmilk but he does love sucking your titties and he isn't disappointed when he gets a little snack in the process

#my writing#slashers#slasher#slasher fandom#vincent sinclair#bo sincalir#lester sinclair#thomas hewitt#slasher smut#vincent sinclair x reader#bo sinclair#lester sinclair x reader#slasher x reader#slasher x reader smut#slasher fluff#slasher x reader fluff

165 notes

·

View notes

Text

It's ugly but it's attached. I wouldn't expect it to survive being put on and pulled off again without the body being nice and hot.

Just squeezing it makes it tear off again in areas that are very thin.

I'll add a bead of super glue around the gash for added support.

I need new glue, though. The nozzle on mine is all plugged up.

I superglued it first, then melted the vinyl that was already there together, adding in some chunks I'd cut out from the inside of the neck hole which can be rough and have excess vinyl sometimes.

Not the most stable, but what I started with was very mishapen and rough, and I had a hard time getting the partially dried glue out of the bottle and onto where it needed to be, so that didn't help.

There are still holes and gaps. Her head had been ripped apart from the flange and glued back together before I bought her.

5 notes

·

View notes

Text

Fighting God

Has anyone wondered what it would be like to witness jujutsu sorcerers from a non-sorcerer perspective.

Like imagine, clocking out of work to see Gojo or another socerer beating the fuck out of a cursed spirit and the civilian being the tired overworked worker they are thinking, 'buddy, rough day again.'

I mean, name a time when someone would fight air if they're not beyond fruastrated or piss out drunk.

-----------------------------------

Here's a scenario for you:

It was another rough day at work today. Not only did Civilian A spill coffee on themselves this morning, but they had to wear the same drenched uniform all the way until their shift ended. It didn't help that it was white of all colors. They stayed and worked overtime as they did everyday, if not for the money, then no one would be willing to stay in the place we call work.

Dawn was approaching, and birds were beginning to go back to their nests. As they singed songs of lullaby luring their young ones to sleep, streets grew emptier until it was just shadows. Adults used to say monsters lurk under beds, in the shadows where light can't reach. Where your eyesight can't see, but what were monsters if they were just fairytales - fables used to scare children into submission.

Street lights guilded the poor civilian, and soon, a whisk of air was heard. Like the sound of flanging sticks in the air at rampant speeds children used to play swords with. It continued, first distant, then increasingly louder as if it was near.

Civilian A looked up from their phone, and unsurprisely, it was the same tall white-haired man they saw week after week wandering late at night. They used to wonder if it was the stress that made his hair turn gray, but upon closer inspection, you can say it was perhaps dyed. Maybe he was a cosplayer dressing as a superhero without a cape, but day after day, they saw him fight air.

If he wasn't drunk, then maybe he lost the lottery. At first, it was understandable excuses such as "I'm taking a run" or "I lost something here." But this late at night? When it was literally almost midnight, something tells them it wasn't just a coincidence.

"Morning!" said the tall man. "Just taking out the trash, you know, like what normal people do." As if he wasn't trying not to sound suspicious, why use the term 'normal,' if he had nothing to hide.

But unknowst to them, Gojo Satoru was fighting a special grade curse - one draining unspecting victims like vampires sucking out their lifespan. He had to appear normal and with normacy meant no infinty. Using fists and kicks took longer than he was expecting. If only he could use his technique: hollow purple.

'Maybe he was a serial killer,' thought Civilian A. 'Disposing of their victims', and that was when they decided to make a run for it. Thankful that they already had their headphones on. They turned up the volume on their phone and pretended they didn't hear him.

After all, no one wanted to know what a suspicious man was doing late in an alley way at night. What if it was a drug deal gone wrong. What if he struggled with his victim he was intending to kidnap. The possibilities are endless when it comes to fists and fights.

2 notes

·

View notes

Text

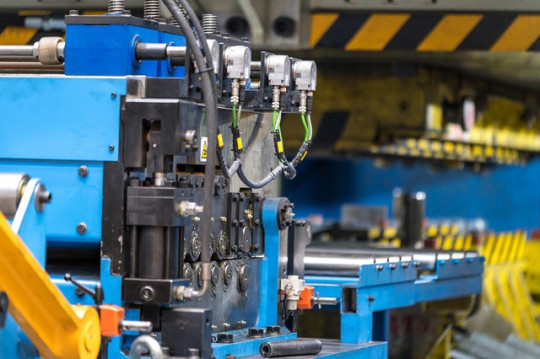

Common Issues and Solutions of Deep Draw Press Machines

Deep draw press machines are integral to the metal forming industry, producing high-quality, complex shapes from sheet metal. However, operators often encounter several issues that can affect the quality, efficiency, and output of the manufacturing process. Understanding these problems and implementing effective solutions is essential for maintaining productivity and quality. Here, we discuss common issues associated with deep draw press machines and provide solutions, concluding with a recommendation for a leading manufacturer of these machines.

1. Wrinkling of the Sheet Metal

Issue: During the deep drawing process, the sheet metal may develop wrinkles, usually around the flange area. This occurs when the compressive stresses exceed the material's strength to resist buckling.

Solution: To prevent wrinkling, it’s essential to use appropriate blank holders with sufficient force to restrain the metal sheet. Adjusting the blank holder pressure according to the thickness and strength of the material can help maintain the balance between preventing wrinkles and not hindering the metal flow.

2. Tearing of the Sheet Metal

Issue: Tearing typically happens when the tensile stress during the drawing process exceeds the material's ductility limit.

Solution: Ensuring optimal punch and die clearance is crucial. Additionally, selecting a material with higher ductility and employing intermediate annealing stages for materials with limited formability can prevent tearing. Proper lubrication to reduce friction during drawing can also help.

3. Springback

Issue: Springback occurs when the drawn metal part does not retain its intended shape after being released from the die, affecting dimensional accuracy.

Solution: Using a tighter die radius can help control springback. Implementing process controls like over-bending or using stress-relief processes post-drawing can also be effective.

4. Earing

Issue: Earing refers to the formation of peaks and troughs around the open end of drawn cylindrical parts, particularly in anisotropic materials like rolled aluminum.

Solution: Choosing materials with low anisotropy can minimize earing. Adjusting the blank shape and optimizing the draw ratio based on material properties are also practical strategies.

5. Poor Surface Finish

Issue: Scratches and marks on the surface of drawn parts can occur due to inadequate lubrication, rough die surfaces, or foreign particles trapped between the die and the sheet metal.

Solution: Dies must be regularly maintained and free of debris. Improved lubrication systems that evenly distribute the lubricant over the sheet metal can prevent scratches and ensure a smoother surface finish.

6. Die Wear

Issue: Frequent use of deep draw presses leads to die wear, affecting the quality of the drawn parts and leading to more frequent maintenance or replacement.

Solution: Using higher quality, wear-resistant materials for dies can extend their life. Regular inspections and maintenance routines to refurbish dies can also ensure consistent quality and operational efficiency.

How SMT Parkash Can Help

For businesses looking to enhance their deep drawing capabilities, choosing the right equipment is crucial. SMT Parkash, a leading manufacturer of deep draw press machines in India, stands out in the industry. Known for their robust construction, precision engineering, and exceptional after-sales service, SMT Parkash’s machines provide an optimal balance of performance and durability. Their presses are designed to tackle the common issues in deep drawing, equipped with advanced features that reduce downtime and enhance the overall quality of the products.

0 notes

Text

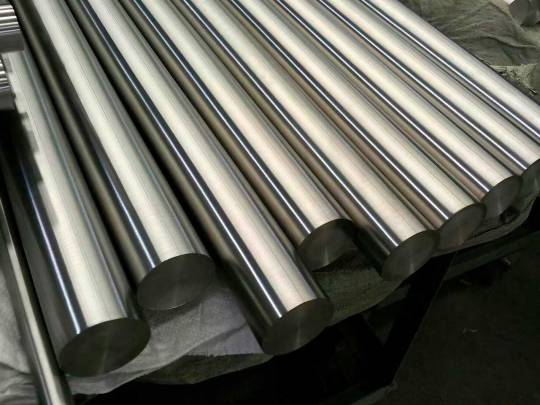

The Use of SS Round Bars in the Oil and Gas Industry

Introduction to SS Round Bars

The possible areas that the round bars would be put to use are unlimited within the dynamic world of the oil and gas industry: ranging from the drilling process to the construction of pipelines, these rough cylindrical bars exude the strength, durability, and reliability necessary for survival under the tough conditions the industry is known for.Hans Metal India is the major Stainless Steel Round Bar Manufacturer in India

SS Round Bars: A Vital Ingredient to Oil and Gas Infrastructure

The round bar, solid bar, or rod is nothing but a cylindrical metal bar of a circular cross-section. Such bars are most commonly made out of high-strength steel alloys—carbon, stainless, or alloyed steel. They have been proven very appropriate for the hostile conditions during oil and gas exploration and production. We are alos the top supplier of Stainless Steel Sheet Manufacturer in India and Round Bar Suppliers in UAE.

Applications of SS Round Bars in Oil and Gas Operations

Drilling Equipment: Used as a drill string, a drill collar, and in the making of a stabilizer, it provides structural support and stabilization as one drills through. They transfer both torque and weight to the drill bit and support the effective penetration of the earth's crust to expose potential oil and gas deposits.You could possible like SS Round Bar Manufacturer in India and Copper Sheet Manufacturers in India

Pipes and Tubing: Round bars are used for the manufacturing of pipes and tubing, in addition to cases made for oil and gas wells. These are the elements that convey unprocessed crude oil, natural gas, and other fluids from the reservoir to the surface in addition to bearing the structure of downhole equipment.

Valves and Fittings: Valves, flanges, and fittings for pipes in oil and gas pipelines and processing facilities can be found with round bars as well. This equipment gives room for the control and direction of fluid flow, pressure control, and connection of the different portions of the pipeline system.Also, check out:Round Bar Manufacturer in Mumbai and Round Bar suppliers in Saudi Arabia

Benefits of Using Round Bars in the Oil and Gas Operations

Strength and Durability: Round bars with high tensile strength and resistance to corrosion will ensure reliability and a long life in critical infrastructure needed to support the working of oil and gas operations.

Versatile: Round bars can be custom-designed in size, diameter, and material composition as per the specific needs of varied applications in the oil and gas industry. Economically

Viable: Though robust, round bars prove to be an economically viable solution for oil and gas companies in the long run, as they require less maintenance.

Conclusion

In conclusion, round bars are supportive in activities of oil and gas as they serve the integrity of structures and strength, and versatility of drilling equipment, piping systems, and processing facilities. These are some of the main aspects that any oil and gas company has to understand and know about the products in order to have efficient, safe, and reliable operations.

#Stainless Steel Round Bar Manufacturer in India#Stainless Steel Sheet Manufacturer in India#Round Bar Suppliers in UAE#SS Round Bar Manufacturer in India#Copper Sheet Manufacturers in India#Round Bar Manufacturer in Mumbai#Round Bar suppliers in Saudi Arabia

0 notes

Text

Teflon Envelope Gaskets D&d Engineered Merchandise Inc

Often used as a seal for steam and scorching valves, taylor ring gaskets are minimize from quite a lot of sheet metals and shaped into corrugated concentric rings. Often found in sulfuric acid plants, Durlon® 9000 Step Ring Gaskets are capable of withstanding the thermal biking and aggressive chemical corrosion, making them the best gasket resolution. Gasket Resources Inc. improved the step ring gasket from its unique “glued” design by using a CNC machine to chop one strong piece to stop the potential of gasket separation. Filled PTFE – PTFE with graphite (carbon), glass and mineral – we source by buyer requirement if another fillers are required. Glass fibre is commonly added in several percentages and completely different fibre lengths, usually glass fibre will increase put on resistance with less deformation beneath load, creating a tougher material with lower thermal enlargement. The Federal Institute for Materials Research and Testing (BAM) tests the sealing material compatibility to be used in flanged connections with liquid and gaseous oxygen.

Gaskets can be found as standard DIN,ANSI, JIS size flanges and can be manufactured to suit any bespoke size or shape. Bronze Filled PTFE – Using Bronze powder as an additive from between 40% and 60% improves wear resistance. It does unfortunately reduce chemical inertness however then again it does tremendously improve hardness and compressive energy, and in addition provides higher dimensional stability and reduces creep and chilly circulate. Most TFCO products are made in the USA at our manufacturing facility in La Porte, IN, located about 50 miles southeast of Chicago. Various different fillers, such as ceramic, bronze, or polymeric materials, can be utilized further to tailor the properties of PTFE gaskets for specific applications. Available in varied types, such as sheet gaskets, spiral wound gaskets, and moulded gaskets, PTFE gaskets offer versatility and ease of installation, enabling seamless integration into complex sealing functions.

Expanded PTFE is much softer and extra flexible than regular PTFE gaskets and thus conforms simply to irregular and rough surfaces. PTFE sheetsVirgin PTFE sheet, incessantly misidentified as Teflon sheet, is a excessive efficiency thermoplastic with a very low moisture absorption price, an incredibly low coefficient of friction, and good dielectric energy. PTFE sheet is made from a fluoropolymer with low friction and exceptional chemical and weather resistance. PTFE sheets are obtainable in various sizes and thicknesses ranging from 6 to one hundred fifty mm. In sealing, PTFE gaskets are a beacon of excellence and dependability.

ptfe gasket sheets

In current years, advancements in PTFE gasket technology have led to revolutionary options that address common sealing challenges. One notable pattern is the development of modified PTFE gaskets, which incorporate specialized fillers or reinforcements to boost efficiency characteristics. These fillers, such as glass fibres or graphite, enhance the gasket's resilience, dimensional stability, and ability to resist larger pressures and temperatures. Solid PTFE gaskets without fillers offer excellent chemical resistance and low friction properties. Highly versatile and conformable gaskets with wonderful chemical resistance. The material features distinctive resistance to a variety of environments, which makes our product highly versatile.

Our mission is to be considered a thought leader and skilled manufacturer in hydraulic and pneumatic sealing merchandise. We are capable of present our prospects with technical expertise and innovation capabilities to ensure they obtain the highest quality sealing solutions, quick. Comprising preformed rings of chevron shaped layers of steel and filler material, spiral wound gaskets are often utilized in larger pressure functions. PTFE can be able to maintain it is useful properties in temperatures as little as -200°C and as high as 260°C. This ensures our gaskets provide constant efficiency, and a superior life expectancy compared to comparable gaskets. Gasket Resources Inc. supplies timely and accurate manufacturing facility fabricated minimize gaskets, welded gaskets, and sheet merchandise obtainable for quite so much of industries.

GORE GR Sheet Gasketing is a troublesome, dimensionally-stable and chemical-resistant gasket sheet for sealing steel pipe and tools flanges in a broad range of applications and course of situations. It reliably seals flanges with rough surfaces, and is good for flanges that require complicated gasketing shapes or larger gasketing sizes. Multi-directional ePTFE gasket material TEADIT® 24 SH TEADIT® 24 SH is a gasket sheet produced from pure, multidirectionally expanded PTFE. A particular production course of ensures equal tensile strength in all instructions. This makes gaskets cut from TEADIT ® 24 SH probably the greatest, most versatile and most reliable gasket supplies in the marketplace. Cold circulate and creep have been eliminated, gasket parameters have been drastically improved, whereas all the superb bodily properties of PTFE have been fully retained.

1 note

·

View note

Text

Non-asbestos Gasket Material

It is ready to withstand extra aggressive chemical environments than conventional non-asbestos gasket materials. Expanded PTFE has the same properties as PTFE, plus it is much more compressible. This permits for sealing even with troublesome gasket purposes having irregular or rough surfaces.

All Seals has experience within the offering of precisiongaskets, including compressed non-asbestos gaskets for all kinds of industries and functions. L460 is a premium sheet gasket material utilizing graphite and aramid fibers certain together with a high-quality nitrile rubber binder. L460 is designed to carry out at excessive temperatures and pressures, that includes excellent sealing capacity, excessive resistance to creep, and good steam resistance.

From oil refineries to petrochemical crops, many mission-critical operations require refrigeration for temperature-specific processes. Trust John Crane to ensure every compressor seal and coupling maintains optimal efficiency and reliability. With a broad range of complicated gear, the chemical trade faces key operational challenges — and it trusts John Crane to resolve them. Our 200 global rapid-response services make certain that chemical industry customers are never removed from service, repair or help. Our engineered options optimize the reliability and efficiency of our customers’ mission-critical tools. If you’re thinking about accelerating the model new power transition across the global course of industries, you’ll match right in.

The BLUE-GARD® Style 3000 compressed fiber gasketing is made with aramid fibers with an NBR binder. This gasket offers improved torque retention and drastically lowers emissions ranges. Garlock BLUE-GARD® Style 3000 compressed fiber gasketing is made with aramid fibers with an NBR binder. Other respected spiral wound gasket producers are Garlock and Lamons. Since then, a myriad of manufacturers of SWG has emerged, additionally in growing international locations as India and China.

These materials are selected for their capability to resist varied industrial circumstances, including different temperatures, pressures, and chemical exposures. Garlock BLUE GARD® gaskets and seals have a singular blend of aramid fibers, fillers and elastomeric binders that provide improved torque retention and drastically decrease emission ranges. Operational prices are minimize via lowered waste, maintenance, fluid loss and energy consumption.

non asbestos gasket

This compressed fiber gasket material is manufactured with aramid fiber strengthened with a nitrile binder. Blaylock Gasket & Packing is proud to stock an in depth stock of non-asbestos sheet material that can be utilized to create gaskets or bought by the sheet. Our non-asbestos sheet is a compressed sheet produced from a mixture of aramid and other artificial fibers and bonded with a quantity of binders, the most typical being nitrile rubber gasket material (NBR). It utilises a mix of part recycled and virgin fibres to create an economical product.

KMA Gaskets manufactures the absolute best quality copper head gaskets in and around South Africa at the absolute best value for cash. Our devoted staff of gasket makers within the South Africa area will make you a precision cut gasket to your specific needs and requirements. 960 An SBR/Aramid blend - SBR is good in steam and chemical purposes and has excellent abrasion resistance. Standard industrial grade sheet mechanically bonded on each side of a .004″ thick 316 chrome steel metallic tang core. Used the place stresses and pressures are excessive and improved handleability is necessary.

The inside and outer rings of a spiral wound gasket may be the similar material as the winding core or a special one. Incorporates an outer metal ring that serves as a centering device for the gasket on the flange face. It also acts as a compression cease, providing further radial energy and stopping over-compression of the gasket. This design is extensively used with raised face flanges, serving to to align the gasket during set up and operation. The spherical kind is, in fact, the usual shape for the raised face (RF), male-and-female (M&F), and tongue-and-groove flanges (T&G) for petrochemical functions.

Imagine all the lively chemicals and fluid conditions that dominate numerous industrial and commercial applications. A single gasket type will likely satisfy the stringent codes that are enforced by one or two of those sites, however there’s no method they’ll match every course of. That’s the true power of CNAF, the group’s nearly unlimited variety of gasketing options. Glass and aramid fibres dominate, however then there are carbon fibres, Kevlar and a quantity of other different mineral bases. The key, therefore, is to stop this strength from being perceived as a weak point.

#cna sheet gasket#compressed non-asbestos gaskets#compressed non-asbestos gasket sheet material#non asbestos gasket#non-asbestos gasket material

0 notes

Text

Metal Stamping Supplier - Types and Meanings of Metal Stamping

Today, many industries require complex metal structures or finished metal parts to manufacture their components. There is a growing need to meet these requirements across many industries, including automotive, aviation, medical, engineering, food processing, and more. Metal stamping is the process of turning flat metal sheets into different shapes of finished metal products. This process is used to produce these complex metal structures. Increasing demand for these metal parts has led to an increase in the number of metal stamping service providers across the globe.

How do metal stamping companies work?

A Metal Stamping supplier uses sophisticated tools to shape and design raw metal sheets in a way that suits their clients' needs. A series of processes is used to transform the sheets into the final metal structures, including blanking, bending, punching, and more.

An overview of metal stamping

These procedures are commonly followed by metal stamping service providers when they convert raw metal into a finished product. While the basic process may be modified to meet the client's needs, the steps remain the same in most businesses. These steps are:

During the initial pressing process, raw metal or metal stamping blanks are inserted into a mold-like device called a metal stamping press. This first process is called pressing since the sheets of metal in coil form or blank form are pressed into the metal stamping press.

Several tools and die surfaces are found inside a metal stamping press. They are used to cut and design the metal stamping blanks or coils placed within the press. Punching, blanking, bending, coining, embossing and flanging are the most important techniques used to turn blanks into finished products.

The tools inside the press use advanced design techniques such as CAD or CAM to ensure perfection and accuracy in every curve and bend of the final metal part manufactured. Engineering experts in most industries are responsible for these complex processes. A slight error in this process will definitely impact the final quality of the finished metal product, leading to financial loss and loss of reputation for the metal stamping service provider.

Following the creation of the correct designs and tooling, the company uses various finishing techniques, such as machining, to complete production.

Uses of a metal stamping press

To convert metal stamping blanks into desired shapes, metal stamping service providers use a metal stamping press. For these techniques, a metal stamping press is used. In order to give you a better understanding of how metal stamping presses work, here is a brief description of these techniques:

Perforating metal stamping blanks with a die

Getting the outline or rough shape of the product right to avoid burrs is known as blanking

The process of embossing is used to create raised or indented designs on sheets of metal

The sheet metal is stamped with a design on both sides before being embossed or coined for the same purpose as embossing

When metal has to be bent into a U or V shape, press brakes are used to achieve the perfect curve

The process of flanging involves bending the sheet metal near the holes at a perfect 90 degree angle in order to create rims on all sides

Common types of metal stamping presses

One of the most important tools used by metal stamping service providers today is the metal stamping press, which helps to press and fold sheet metal in different shapes.

When the sheet metal is compressed against the die surface, the ram at the top of the press triggers motion. These presses have one ram, which allows them to perform a single operation at a time.

The double-acting presses have two rams, and can perform two operations simultaneously. Here, one ram holds the blanks for punching and stamping, and the other ram holds the blanks for holding.

In the mechanical stamping press, a motor is attached to the mechanical flywheel to produce varying speeds consistently while stamping shallow or simple metal structures. Pressing speed varies from 20 to 1500 strokes per minute, while size can range between 20 and 6000 tons.

Presses that use hydraulic liquid at high pressure are used to stamp sheet metal into the necessary shapes. Depending on their size, they can handle between 20 and 10000 tons, and they have adjustable strokes and speeds.

The mechanical servo press is faster than the hydraulic press, as it uses mechanical motors instead of flywheels to control the stroke, speed, and slide. click here

Metal stamping company Tentral has been in business in China for more than 15 years. Precision metal stamping parts have been our specialty since 2005, serving customers in industries such as automobiles, lighting, construction, medicine, and energy. As the leading manufacturer of metal stamping, we have a professional team and advanced facilities to supply our customers with the most reliable metal stamping parts and sheet metal fabrication parts.

0 notes

Text

Top Stainless Steel Sheet Supplier in Bhopal

Krystal Steel is a Manufacturer, Stockiest, and Top Stainless Steel Sheet Supplier in Bhopal, Madhya Pradesh.

Krystal Steel specializes in stainless steel products such as SS sheets, plates, coils, fasteners, pipes, tubes, bars, wires, rods, strip coils, angles,

channels, flats, industrial valves, flanges, fittings, and dairy valves.

Our stainless steel sheets are manufactured using the finest quality materials and state-of-the-art technology, ensuring unmatched durability,

strength, and corrosion resistance.

Whether you need sheets for architectural, industrial, or decorative purposes, we have the perfect solution to meet your requirements.

From standard sizes to customized dimensions, we offer a wide range of stainless steel sheet options to suit diverse applications.

Whether you need polished, brushed, or textured finishes, we have the perfect solution to complement your design aesthetic.

We understand the importance of cost-effectiveness without compromising on quality. That's why we offer competitive pricing on our stainless

steel sheets, ensuring you get the best value for your investment.

Specification:

Specifications: ASTM A240, ASME SA240

Dimensions: ASTM, ASME, and API

Standard: JIS, AISI, ASTM, GB, DIN, EN, etc.

Surface: 2B, 2D, BA, NO.4, NO.8, 8K, Mirror, Checkered, Embossed, Hair Line, Sand Blast, Brush, Etching

Width: 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc.

Finish: Black, Bright Polished, Rough Turned, No.4 Finish, Matt Finish, BA Finish

Length: 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc.

Krystal Steel is the Manufacturer, Stockiest, and Top Stainless Steel Sheet Supplier in Bhopal, Madhya Pradesh, and locations such as Gwalior, Ujjain,

Pithampur, Bhopal, Khargone, Dhar, Burhanpur, Dewas, Khandwa, and Chhindwara, Govindpura, J.P Nagar Road, Indore, Gwalior, Hoshangabad,

Indore, Itarsi, Jabalpur, Jhabua, Khajuraho, Khandwa, Ratlam, Rewa, Sagar, Sarangpur, Satna, Sehore, Seoni, Shahdol, Shajapur, Sheopur, Shivpuri,

Ujjain, Vidisha.

If you have any questions or require further information, please feel free to contact us.

Read the full article

0 notes

Text

Alloy 20 Sheets And Plates Exporters In India

INTRODUCTION:-

Shasan Piping Solution is a dependable Manufacturers, Exporters, and Suppliers of the a wide range of mechanically utilized items. We are giving the awesome nature of Alloy 20 Sheets and Plates to our regard benefactors for fulfilling their various requests. We are the client's aggressive industry that is giving something similar to our clients at various principles, details, sizes, wall thickness, surface gets done, and shapes.

BENEFITS:-

Alloys is the material that is chromium, nickel, and iron-based austenitic compound. It is made for guaranteeing the higher protection from the corrosive assaults, especially to the sulfuric corrosive. This material is having excellent opposition capacity to the overall consumption, cleft erosion and pitting too. Likewise, it opposes sulfuric corrosive, phosphoric corrosive, and nitric corrosive. Likewise, it is containing niobium for the adjustment against the sharpening.

SPECIFICATION:-

Alloy 20 Sheets and Plates Specification : ASTM B463 / ASME SB463

Dimension Standard : JIS, AISI, ASTM, GB, DIN, EN, etc

Width : 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc

Length : 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

Thickness : 0.3 mm to 120 mm

Form : Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc.

Surface Finishing : Hot rolled plate (HR), Cold rolled sheet (CR),2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, Chequered, embossed, hair line, sand blast, Brush, etching, SATIN (Met with Plastic Coated) etc.

PRODUCT OVERVIEW:-

The produced scopes of Alloy 20 Sheets and Plates are having numerous great properties to offer in view of which it has turned into an ideal fit for various purposes. The properties found in it are high elasticity, great layered precision, predominant surface completions, rough development, high strength, long usefulness, non-destructive body, endure high temperature, and so on.

CONCLUSION:-

Today Alloy 20 Sheets and Plates are widely utilized in numerous modern applications. It resembles heat exchangers, condensers, mash and paper industry, petrochemicals, drugs, specialty synthetics, substance industry, oil and gas handling, seawater applications, cars, building, and developments.

Alloy 20 Sheets and Plates are completely quality tried before dispatched from our industry. The tests are significantly finished for really looking at the item strength. The tests are pitting erosion tests, strength tests, positive material ID tests, and so on. The bundling of the equivalent is finished in wooden beds for more secure transportation.

CONTACT US:-

+91 22-6651 8642

EMAIL ID: [email protected]

WEBSITE: https://www.shasanpiping.com/alloy-20-sheets-and-plates-manufacturers-exporters-suppliers-stockists.html

#"Alloy 20 Sheets and Plates Manufacturers#Alloy 20 Sheets and Plates Suppliers#Alloy 20 Sheets and Plates Stockists

0 notes

Text

Stainless Steel Bar Supplier in Nagpur

Luvana Metal Corporation is a Manufacturer, Exporter, and Stainless Steel Bar Supplier in Nagpur, Maharashtra.

Luvana Metal Corporation provides a wide range of stainless steel products, including coils, sheets, plates, bars, rods, wires, valves,

pipes, fittings, channels, angles, butt weld fittings, flanges, and fasteners.

We provide top-quality Stainless Steel Round Bars to various industries worldwide, available in different sizes and conditions.

Our round bars come in hot rolled, annealed, and pickled conditions. They adhere to DIN, EN, JIS, ASTM, BS, ASME, and AISI standards,

offering a variety of grades.

Manufactured by our advanced manufacturing units, our round bars incorporate cutting-edge technologies.

We deal with branded engineering products to provide you with the optimum quality product range.

We offer a wide range of Stainless Steel, Mild Steel & Glass handrails, constructed with top-quality components and meeting international standards.

Specification:

Size Range: 6.35 mm up to 304.8 mm

Specifications: EN, DIN, ASTM, AISI, ASME, JIS, NACE

Supply Conditions: Ground, Smooth Turned, Rough Peeled, Peeled and Polished, High Tensile, Chamfered

Tolerance: H9, H10, H11, K12, K13, EN 10060

Features:

Corrosion Resistant

High tensile strength

Temperature resistant

Easy formability and fabrication

Low-maintenance (long-lasting)

Environmentally friendly

Very durable

Attractive appearance

Luvana Metal Corporation is a Stainless Steel Bar Supplier in Nagpur, Maharashtra covering locations like Aurangabad, Kolhapur, Mahabaleshwar,

Malegaon, Matheran, Mumbai, Nagpur, Nanded, Nashik, Osmanabad, Pandharpur, Parbhani, Pune, Ratnagiri, Sangli, Satara, Sevagram, Solapur,

Thane, Ulhasnagar, Vasai-Virar, Wardha, Yavatmal.

For further details, please feel free to contact us.

0 notes

Text

RPM Magazine Releases the February 2024 Issue

Check out the February Issue 2024 - the 2nd issue of RPM Magazine's 25th Anniversary Year! Still bringing you the Cars, the Stars, and the Tech Info you have come to expect from the world's best and only family-owned publication that has supported the industry for 25 years and is still going. We thank all of our readers, advertisers, staff, and supporters throughout all the years. Click on the image of the cover to the left to see the sample copy.

FEATURE CAR

LONG HAUL - Roy Greenawalt's wicked blown Chevelle is a lifelong build! “You’ll never finish that car.” The famous phrase said by the naysaying glass-half-empty element of the world, a problem made worse with the internet providing a platform for loud-mouths and snipers to more easily spew their garbage… and Roy Greenawalt is a guy who proudly proved them wrong!

DOUBLE THE FUN - Rob Horton's Turbo/Nitrous Camaro WILL get the drop on you! As a Mechanic by trade, Rob Horton knows cars very well, but we all know that making one go fast and stay together is another whole ball game, and Horton is very good at that, too!

SUBLIME CAT - This wild blown Hellcat is a true 8-second street driven warrior. Obsession is part of our car culture and has been since the wheels of the first motorized vehicle hit the road. Take Don Keller for instance...

THUNDER - Don Erwin's Glidden Tribute T-Bird packs a big block nitrous'd punch! Don Erwin has been in the game for a lot of years and has a stable full Ford cars and trucks, but this Glidden- tribute T-Bird holds a special place.

TECH INSIDER

Welding Exhaust Systems - Pt 5 - Welding your Header. We have our TIG welder ready to go. We have our header tubes tacked together with perfect fitment. We have properly fit the pipes to the flange and have our back purge system setup.

RPM HIDDEN GEM

PLAYING ROUGH - Pat Spangenberg's "Alley Cat" - It's rough, tough, and one potent Poncho! 1964 Catalinas have become highly sought after by collectors and racers alike in recent years.

#rpmmag #rpmmag25yrs #rpmmagazine #hellcat #camaro #glidden #donkeller #patspangenberg #burnsstainless #robhorton #roygreenawalt #donerwin #chevelle #tbird #alleycat

Read the full article

0 notes

Text

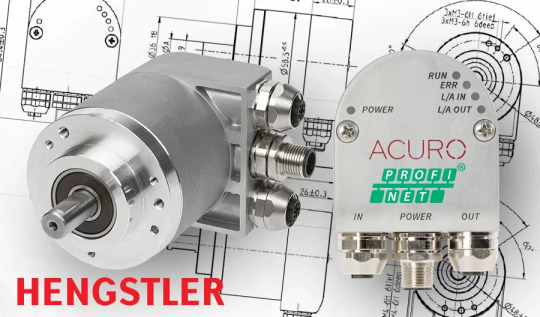

Choosing the Right Profinet Encoder: Characteristics and Best Practices

Profinet Encoder

Multitier encoders with fieldbus, outright encoders collection MEM-Bus, best quality hengstler profinet encoders profile Specifications V4.1 version 3.162 related to Profidrives, demands of the Application Courses 3 and 4, RT Actual Time and IRT Isochronous Real Time Transmission Mode, common telegrams 81, 82, 83, 84, the customer telegram 860, encoders actual time diagnostic function makes sure the gadget state consistent monitoring, MEM-Bus encoders, multitier version with 29-bit resolution, Different mechanical versions are offered. The electric link is provided by 3 M12 adapters, the stout aluminium instance guarantees a high defence level. The building technology allows for high acceleration and rate worth’s and gives the transducer a long life.

Profinet Encoder Characteristics:

Fieldbus user interface: Profinet

Encoder Account V4.1 Variation 3.162

Application courses 3–4

Transmission settings (RT and IRT)

Conventional telegrams 81, 82, 83, and 84

Customer telegram 860

Aluminium situation

Defence level: IP67; shaft side: IP65

Resolution: 29 little bit

PROFINET-ready outright encoders function separately and are non-reactive.

Network frameworks are commonly subject to regular modifications, e.g., in the case of new robotics with constant changes of tools or expansions during procedures. PROFINET-ready outright encoders, Design A58HE (blind hollow birthed) and Version A58SE (shaft), are developed for harsh factory and plant atmospheres.

Conveniently designed right into a wide array of applications, these encoders plug straight right into a connect with marginal requirements and work in different setups, consisting of bus, ring, and star setups that can proceed interaction in the event of a line break.

As absolute encoders, they keep absolute position information even after a power loss, assisting in quick system healing at start-up without the requirement for system re-homing. Prepared for Market 4.0 and the Industrial Internet of Things, data exchange between the Model A58HE, Setting A58SE, and other applications has no influence on the control loophole.

These encoders are non-reactive and can function independently from the PLC or master, moving information through network entrances to various other automation networks and sites, as well as the cloud for analysis.

Encoders with Profane Communications

Encoder Products Company showcased its brand-new Design A58HE and Version A58SE, which are multi-turn, Ethernet-ready outright encoders made for rough manufacturing facilities and plant environments. Along with Ether pet cat Deterministic Interaction, the versions A58HE and A58SE now supply PROFINET communication procedures as well.

These encoders are especially suited to applications where fieldbus connectivity is needed and the encoder has to maintain absolute placement information after power-off occasions. The Model A58HE is a 58 mm encoder in a blind hollow-birthed construction, and the Model A58SE is a 58 mm shaft encoder readily available with either a securing flange or synch flange, in both compact and sturdy arrangements. The portable version is the most compact Ether feline or PROFINET-capable encoder readily available.

“Both the A58HE and A58SE encoders are easily made into a wide variety of applications," claims Sarah Walter, electric designer and EPC Technical Applications Manager. "And with the new heavy-duty design and the new small model—which is one of the most compact devices available on the market—they are unbelievably flexible mechanically. What actually sets our encoders apart, however, is their high accuracy. These absolutes will provide you with accurate activity comments whenever.

Conclusion

Sr. Indus Electro Systems Pvt. Ltd.: The non-reactive and independent operation of these encoders, coupled with their capability to deal with network portals, facilitates efficient information exchange within the network and also extends to cloud-based evaluation. As shown by Encoder Products Company's A58HE and A58SE designs, these encoders satisfy the demands of different applications, offering portable and sturdy configurations to accommodate diverse mechanical demands.

On the whole, the Profinet Encoder series stands out for its adaptability, reliability, and high performance, making it a beneficial component in the developing landscape of industrial automation.

#profinet encoders#Profinet Encoders Distributors#cable assemblies#maxon distributors india#harting han connectors#hengstler encoders

0 notes

Text

How to Change Blade on Craftsman Circular Saw: Master the Art of Precision

To change the blade on a Craftsman Circular Saw, follow these steps: disconnect the power, remove the arbor bolt and outer flange, replace the blade, and reassemble the saw. Craftsman Circular Saws are versatile tools that require occasional blade changes for optimal performance.

Whether you need to switch out a dull blade or upgrade to a different type, learning how to change the blade on your Craftsman Circular Saw is essential. This simple and straightforward process can be completed in just a few steps, ensuring that you can quickly get back to your woodworking projects.

In this guide, we will walk you through the necessary steps to change the blade on your Craftsman Circular Saw efficiently and safely. By following these instructions, you will be able to maintain the cutting accuracy and overall functionality of your saw.

Mastering Blade Replacement On Craftsman Saws

Learn the art of blade replacement on Craftsman saws with ease by following these step-by-step instructions. Discover how to change the blade on your Craftsman circular saw like a pro.

When it comes to smoothly cutting through various materials, a sharp and properly installed blade is paramount for any circular saw. For Craftsman saw users, mastering the art of blade replacement is essential for achieving precise cuts and ensuring safety. In this guide, we will explore the importance of precision in blade changing, the risks associated with using dull or improper blades, and provide step-by-step instructions on how to change the blade on your Craftsman circular saw.

Importance Of Precision In Blade Changing

When it comes to changing the blade on your Craftsman circular saw, precision is of utmost importance. A well-installed blade not only ensures the longevity of your saw but also plays a vital role in the quality of your cuts. Here are the reasons why precision in blade changing matters:

- Optimal Performance: A properly installed blade allows for smooth rotation and efficient power transmission, maximizing your saw's cutting performance.

- Precise Cuts: With a precise blade installation, you can achieve clean and accurate cuts, whether you're tackling wood, plastic, or other materials.

- Safety: By meticulously following the correct steps for blade replacement, you reduce the risk of accidents and injuries that can occur due to a loose or improper blade installation.

Risks Associated With Using Dull Or Improper Blades

Using a dull or improper blade on your Craftsman circular saw may seem tempting to save time or money, but it can lead to various risks and drawbacks. Here are the risks you should be aware of:

- Poor Quality Cuts: Dull blades can result in rough and jagged cuts, compromising the overall precision and finish of your woodworking or DIY projects.

- Increased Effort: A dull blade requires more force to make cuts, leading to fatigue and potential strain on your saw's motor.

- Reduced Efficiency: Dull blades can slow down your cutting speed, wasting valuable time and affecting productivity.

- Higher Risk of Kickback: Improperly installed or dull blades can increase the chances of kickback, a dangerous phenomenon where the saw jumps back towards the user, potentially causing serious injury.

To ensure optimal performance, precision, and safety, it's crucial to change the blade on your Craftsman circular saw correctly. Let's dive into the step-by-step process of blade replacement for Craftsman saws.

Preparing For Blade Change

Changing the blade on your Craftsman circular saw is a simple and important task that every DIY enthusiast should know. Whether you are a seasoned woodworker or just starting out, knowing how to change the blade properly will ensure smooth and efficient cuts. In this section, we will guide you through the steps of preparing for a blade change, including gathering the necessary tools, ensuring saw safety, and identifying the right blade for your project.

Gathering The Necessary Tools

Before you start changing the blade on your Craftsman circular saw, be sure to have the following tools readily available:

Tools

Details

Allen wrench or hex key

A small Allen wrench or hex key is typically included with your Craftsman circular saw and is used to loosen the blade bolt.

Protective gloves

Wearing protective gloves will keep your hands safe during the blade change process.

Safety goggles

Safety goggles protect your eyes from any debris that may be produced during the blade change.

Dust mask

A dust mask will help you breathe more comfortably by filtering out any sawdust or particles in the air.

Ensuring Saw Safety Before Starting

Prioritizing safety is crucial when changing the blade on your Craftsman circular saw. Here are some key steps to ensure safety:

- Disconnect the saw from the power source: Before beginning the blade change process, unplug the saw from the power outlet or remove the battery for cordless models.

- Place the saw on a stable surface: Make sure the saw is placed on a sturdy and flat surface to prevent any accidental movement during the blade change.

- Secure the saw blade guard: Ensure that the blade guard is properly in place and functioning correctly to protect your hands and prevent accidental contact with the blade.

- Keep the work area clean and organized to minimize the risk of tripping or falling.

Identifying The Right Blade For Your Project

Choosing the right blade for your project is essential to achieve the desired results. Here are some considerations when selecting a blade:

- Type of material: Different blades are designed for specific materials, such as wood, metal, or plastic. Ensure that you choose a blade appropriate for the material you will be cutting.

- Blade size: Circular saw blades come in various sizes, often measured in inches. Choose a blade size that is compatible with your Craftsman circular saw.

- Number of teeth: The number of teeth on a blade affects the cutting speed and finish. Blades with more teeth provide smoother and cleaner cuts, while blades with fewer teeth are better suited for faster cuts.

- Consider any specialized features or coatings that may enhance the performance of the blade for your specific project.

The Art Of Precision: Changing Blades

Changing the blade on your Craftsman circular saw may seem like a daunting task, but with a little know-how and a steady hand, you'll be able to perform this task with ease. In this guide, we'll take you through a step-by-step process to remove the old blade, provide alignment tips for installing the new blade, and walk you through post-installation checks to ensure everything is in proper working order.

Step-by-step Guide To Removing The Old Blade

- Before you begin, make sure your saw is unplugged to prevent any accidental starts.

- Locate the blade guard, which is a protective cover that shields the blade from contact.

- Use a wrench to loosen the bolt in the center of the blade. Turn it counterclockwise to remove the bolt and the outer washer.

- Carefully lift the blade guard and remove the old blade.

- Inspect the arbor, the shaft that the blade attaches to, for any debris or damage. Clean or replace if necessary.

Alignment Tips For Installing The New Blade

Proper alignment of the new blade is crucial for safety and optimal cutting performance. Follow these tips:

- Ensure the blade teeth are facing in the correct direction, usually indicated by an arrow on the blade.

- Securely place the new blade onto the arbor, making sure it sits flush against the inner washer.

- Tighten the bolt with your wrench, turning it clockwise until it is snug. Be careful not to overtighten, as this can cause damage.

- Test the blade by giving it a gentle spin with your hand. It should rotate smoothly and without wobbling.

Post-installation Checks, Ensuring Proper Functionality

Once you have installed the new blade, it's essential to perform a few checks before using your circular saw:

- Reattach the blade guard and ensure it moves freely and covers the blade completely when not in use.

- Double-check that the bolt securing the blade is tight and secure.

- Inspect the blade for any signs of damage or wear. Replace if necessary.

- Plug in your circular saw and test the blade on a scrap piece of wood to ensure smooth, clean cuts.

Changing the blade on your Craftsman circular saw is a task that requires precision and attention to detail. By following these step-by-step instructions for blade removal, alignment tips, and post-installation checks, you'll be able to change the blade and continue your woodworking projects with confidence.

Maintaining Your Craftsman Circular Saw

In order to keep your Craftsman circular saw performing at its best, regular maintenance and care are essential. By taking the time to properly maintain your saw, including handling the blade correctly, you can extend the lifespan of your tool and ensure optimal cutting performance. This section will provide you with some helpful tips on how to maintain your Craftsman circular saw and troubleshoot common issues that may arise after replacing the blade.

Regular Maintenance Tips For Longevity

To ensure the longevity of your Craftsman circular saw, it's important to incorporate regular maintenance into your routine. These simple yet effective tips will keep your tool in top shape:

- Regularly inspect your saw for any signs of wear or damage. Pay special attention to the blade guard, the handle, and the power cord.

- Keep your saw clean by removing any debris or sawdust after each use. A clean saw not only ensures better performance but also reduces the risk of accidents.

- Check the blade alignment regularly. If you notice any wobbling or vibration during operation, it may indicate a misaligned blade that needs adjustment.

- Keep the motor vents free from dust and debris. Blocked vents can cause the motor to overheat, leading to reduced performance and potential damage to the tool.

- Tighten all the fasteners and screws on the saw, including the blade bolt. Loose screws can cause vibrations and affect the accuracy of your cuts.

- Inspect the power cord for any signs of damage, such as fraying or exposed wires. If you notice any issues, it's crucial to replace the cord immediately to prevent electrical hazards.

- Apply a few drops of lubricating oil to the moving parts of the saw, such as the blade hinge or depth adjustment mechanism, to ensure smooth operation.

Best Practices For Blade Care And Storage

Proper blade care and storage are key to maintaining the cutting efficiency and longevity of your Craftsman circular saw. Follow these best practices:

- When changing a blade, always ensure that the saw is disconnected from the power source. Unplug the cord from the outlet or remove the battery if using a cordless model.

- Inspect the blade for any signs of damage or dullness before installing it. Damaged or dull blades should be replaced immediately to prevent poor performance or accidents.

- Use a blade removal tool or a wrench to safely loosen and remove the blade. Be cautious not to damage the blade teeth during this process.

- Clean the blade thoroughly after each use. Remove any residue or pitch buildup using a brush or a mild cleaning solution. Dry the blade completely before storing it.

- Store the blade in a dry and secure place. Consider using blade protectors or covers to prevent accidental contact and to protect the teeth from damage.

- Keep the blade away from extreme temperatures or moisture, as these can cause corrosion and affect the blade's cutting performance.

Troubleshooting Common Issues After Blade Replacement

If you encounter any issues after replacing the blade on your Craftsman circular saw, here are some common problems and their potential solutions:

Issue

Potential Solution

The blade is not cutting smoothly or is leaving rough edges.

Ensure that the blade is properly installed and tightened. Check for any signs of damage or dullness, and replace the blade if necessary.

The saw is producing excessive heat or unusual smell.

Check that the blade is not binding or rubbing against the material being cut. Ensure proper blade spacing and alignment. If the issue persists, consult a professional for further inspection.

The saw is making loud or unusual noises during operation.

Inspect the blade for any signs of damage or misalignment. Tighten all the fasteners and screws. If the problem persists, seek professional assistance.

The saw is not starting or turning on.

Check the power source and ensure that the saw is properly plugged in or the battery is fully charged. Inspect the power cord for any damage. If the issue continues, consult a professional or contact the manufacturer.

By following these tips and troubleshooting common issues, you can effectively maintain your Craftsman circular saw and keep it in excellent working condition for years to come.

Enhancing The Cutting Experience

Changing the blade on your Craftsman circular saw not only ensures the longevity of your tool but also opens up a world of possibilities to enhance your cutting experience. With the right techniques and attention to detail, you can achieve optimal performance, tackle specialized projects, and prioritize accuracy and safety. In this section, we'll dive into the various ways you can take your cutting game to new heights.

Fine-tuning For Optimal Performance

When it comes to getting the most out of your Craftsman circular saw, fine-tuning your blade choice is key. Selecting the right type of blade for the material you're cutting can make a world of difference in terms of efficiency and results. Whether you're working with wood, metal, or plastic, consider the blade's tooth count, size, and material composition to ensure it meets the demands of your project.

To ensure optimal performance, it's essential to keep your blade sharp and in excellent condition. Over time, blades can become dull or damaged, compromising the quality of your cuts. Regularly inspect your blade for any signs of wear and tear, and if necessary, utilize sharpening tools or replace the blade altogether. Remember, a sharp blade not only improves cutting performance but also reduces the risk of accidents by requiring less force to achieve clean cuts.

Advanced Techniques For Specialized Projects

For specialized projects, where precision and efficiency are paramount, adopting advanced techniques can take your cutting game to a whole new level. Here are some proven strategies to consider:

- Using a guide or fence: When working on long cuts or straight lines, utilizing a guide or fence can provide stability and ensure accurate results.

- Creating beveled cuts: By adjusting the angle of your circular saw, you can create beveled cuts, adding a touch of elegance to your woodworking or construction projects.

- Miter cutting: A technique commonly used in framing and trim work, miter cutting involves making precise angled cuts, allowing for seamless joins and corners.

- Compound cutting: This technique involves tilt and bevel adjustments, enabling the creation of complex cuts for intricate projects such as furniture making or cabinetry.

By familiarizing yourself with these advanced techniques and practicing them, you'll be able to tackle specialized projects with confidence and precision.

Emphasizing Accuracy And Safety Post Blade Change

Once you've successfully changed the blade on your Craftsman circular saw, it's crucial to prioritize accuracy and safety throughout your cutting process. Here are a few steps to follow:

- Secure your workpiece: Before making any cuts, ensure that the material you're working on is securely clamped or supported to prevent it from moving during the cutting process.

- Measure twice, cut once: Double-check your measurements before making any cuts to avoid errors and wasted materials.

- Wear appropriate safety gear: Always wear safety goggles, gloves, and ear protection when operating a circular saw to protect yourself from potential hazards.

- Adopt proper cutting techniques: Maintain a firm grip on the saw, position yourself properly, and use smooth, controlled movements throughout the cutting process.

- Keep your workspace clean: Remove any obstacles or debris from your work area to minimize the risk of accidents and ensure smooth, uninterrupted cutting.

By following these guidelines and taking the necessary safety precautions, you can enhance your cutting experience while prioritizing accuracy and protecting yourself from potential harm.

Frequently Asked Questions On How To Change Blade On Craftsman Circular Saw

How Do You Change The Blade On A Craftsman Circular Saw?

To change the blade on a Craftsman circular saw, follow these steps:

1. Unplug the saw and remove any screws or bolts holding the blade in place.

2. Use a wrench to loosen the arbor nut and remove the old blade.

3. Place the new blade onto the arbor, making sure it is properly aligned.

4. Tighten the arbor nut with a wrench.

5. Double-check that the blade is secure before plugging in and using the saw.

Can I Change The Blade On My Craftsman Circular Saw Myself?

Yes, you can change the blade on your Craftsman circular saw yourself. Just follow the steps mentioned earlier in this article to safely and effectively replace the blade.

Read the full article

0 notes

Text

Installation and Weight Calculation of Stainless Steel Flanges

Stainless steel flange should be sufficient strength, fastening when not deformed, flange sealing surface should be flat clean, installation to carefully clean up oil and rust. GASKET should have good oil resistance and anti-aging performance, as well as better elasticity and mechanical strength, the installation should be based on the shape of the joint selection of different sections and sizes of the gasket, and placed correctly. Stainless steel flange fastening force should be uniform, plastic cushion compression should be controlled at about 1/3. The stainless steel flange should be carried out according to the standard principle and the way, to ensure the use of quality and value, according to normal standard use and installation.

Usually we use stainless steel flange, it is the common lathe to produce the flange, there will be some positive and negative error. People are called theoretical weight, at present, the domestic general use of theoretical weight as the flange standard. In addition, can also use the Chemical department flange standard, stainless steel flange weight calculation and formula calculation as follows:

General Flange Weight Calculation:

(OD * Outside diameter-Inner diameter * diameter-bolt aperture * bolt aperture * bolt hole number) * Thickness * 0.623 * 0.0001 = Stainless steel flange theoretical weight.

2, Plate flange weight Calculation formula is as follows:

(OD * od-Inner diameter * Bore diameter * aperture * hole number) * Thickness * 0.616 * 0.00001

Description: 7.93 is the metal density of stainless steel, different grades of stainless steel have different densities, this value is more commonly used average density value, rough calculation can be used in this quantity, to calculate more accurate to query the relevant data.

3, The welding flange weight calculation formula is as follows: On the part of the welding we are called the size of the head, the big head attached to the flange, the small part is connected to be welded up.

0 notes