#Pretreatment Technologies

Text

Biomass Refining Market Overview, Demand, Key Players and Regional Outlook Study 2017 – 2032

Overview:

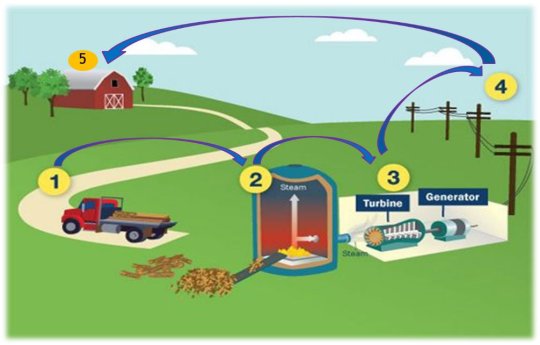

The Biomass Refining Market refers to the market for converting biomass feedstock into value-added products through various refining processes. Biomass refers to organic materials derived from plants and agricultural residues, which can be used as a renewable and sustainable source of energy and chemical feedstock. Biomass refining involves the conversion of biomass into biofuels, biochemicals, bioplastics, and other valuable products. The Global Biorefinery Market is estimated to reach over USD 336.39 billion by 2031, exhibiting a CAGR of 9.06% during the forecast period. Here is an overview, key trends, key points, and demand factors related to the Biomass Refining Market:

Key Trends:

• Shift towards Renewable Energy: The increasing focus on reducing greenhouse gas emissions and dependence on fossil fuels has propelled the demand for renewable energy sources. Biomass refining plays a vital role in the production of biofuels, such as bioethanol and biodiesel, which can replace fossil fuels in transportation and power generation.

• Circular Economy and Waste Valorization: Biomass refining enables the valorization of organic waste streams and by-products from agricultural, forestry, and food processing industries. It contributes to the circular economy by converting waste materials into valuable products, reducing waste generation and promoting sustainable resource utilization.

• Advanced Conversion Technologies: Advancements in biomass refining technologies, such as pyrolysis, gasification, and enzymatic hydrolysis, have improved the efficiency and scalability of biomass conversion processes. These technologies offer opportunities for the production of advanced biofuels and high-value biochemicals from diverse biomass feedstocks.

• Biorefineries and Integrated Value Chains: Biomass refining often takes place in biorefineries, which are facilities that integrate multiple conversion processes to maximize the production of various products from biomass. Integrated value chains, where different industries collaborate to optimize biomass utilization, are emerging to leverage the potential of biomass refining across multiple sectors.

• Policy Support and Incentives: Government policies and incentives promoting renewable energy, sustainable development, and decarbonization efforts are driving the demand for biomass refining. Supportive regulations, financial incentives, and research and development initiatives are encouraging investments in biomass refining technologies and infrastructure.

Key Points and Demand Factors:

• Bioenergy Demand: The demand for bioenergy as a renewable alternative to fossil fuels in transportation and power generation is a significant driver for biomass refining. Biofuels derived from biomass, such as bioethanol and biodiesel, are sought after to meet renewable energy targets and reduce carbon emissions.

• Sustainability and Environmental Concerns: Biomass refining offers a more sustainable and environmentally friendly alternative to traditional fossil fuel-based industries. The utilization of biomass feedstocks helps reduce greenhouse gas emissions, promote waste valorization, and minimize the environmental impact of energy and chemical production.

• Renewable Chemicals and Materials: The demand for renewable chemicals and materials, such as bioplastics, bio-based polymers, and biochemicals, is growing. Biomass refining enables the production of these sustainable alternatives, driven by consumer preferences for eco-friendly products and the need to reduce reliance on petrochemicals.

• Feedstock Availability: The availability and accessibility of biomass feedstocks, including agricultural residues, dedicated energy crops, and forestry residues, influence the demand for biomass refining. Regional biomass availability and supply chain logistics play a crucial role in determining the viability and competitiveness of biomass refining operations.

• Technological Advancements and Cost Competitiveness: Continuous technological advancements in biomass refining processes, such as improved conversion efficiency, scalability, and cost reduction, are key factors driving market demand. The ability to produce biofuels and biochemicals at competitive prices compared to fossil fuel alternatives is essential for market growth and adoption.

We recommend referring our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into this market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/trailer-substation-market/6736/

Market Segmentations:

Global Trailer Substation Market: By Company

• Hitachi

• Siemens

• Matelec

• Efacec

• EATON

• CG

• GE

• EKOS Group

• WEG

• Delta Star

• Meidensha Corporation

• AZZ

• Ampcontrol Pty Ltd.

• Tadeo Czerweny S.A.

• Tgood

• VRT

• Powell Industries

• Jacobsen Elektro

• Elgin Power Solutions

• Aktif Group

Global Trailer Substation Market: By Type

• HV Trailer Substation

• LV/MV Trailer Substation

Global Trailer Substation Market: By Application

• Energy

• Infrastructure

• Industrial

• Others

Global Trailer Substation Market: Regional Analysis

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Trailer Substation market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/trailer-substation-market/6736/

Reasons to Purchase Trailer Substation Market Report:

• To obtain insights into industry trends and dynamics, including market size, growth rates, and important factors and difficulties. This study offers insightful information on these topics.

• To identify important participants and rivals: This research studies can assist companies in identifying key participants and rivals in their sector, along with their market share, business plans, and strengths and weaknesses.

• To comprehend consumer behaviour: these research studies can offer insightful information about customer behaviour, including preferences, spending patterns, and demographics.

• To assess market opportunities: These research studies can aid companies in assessing market chances, such as prospective new goods or services, fresh markets, and new trends.

• To make well-informed business decisions: These research reports give companies data-driven insights that they may use to plan their strategy, develop new products, and devise marketing and advertising plans.

In general, market research studies offer companies and organisations useful data that can aid in making decisions and maintaining competitiveness in their industry. They can offer a strong basis for decision-making, strategy formulation, and company planning.

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Biomass Logistics#Feedstock Preprocessing#Biomass Pretreatment#Biomass Densification#Torrefaction#Pyrolysis#Gasification#Fermentation#Enzymatic Hydrolysis#Pretreatment Technologies#Conversion Pathways#Process Optimization#Sustainability#Green Chemistry#Carbon Neutrality#Market Analysis#Market Trends#Market Growth#Market Forecast#Competitive Landscape#Key Players#Industry Outlook.#These tags cover various aspects of the biomass refining mar

0 notes

Text

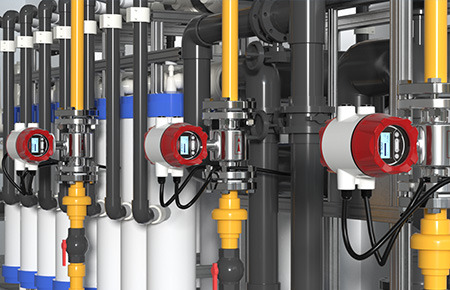

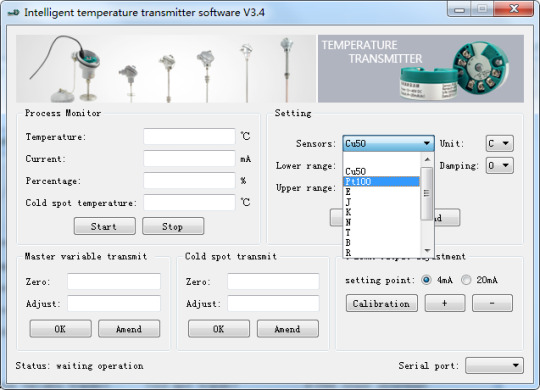

Application of Industrial Analyzer

Popularize computer applications

The application of computers, especially microcomputers, in the field of component analysis instruments is a revolution in the whole field of component analysis instruments and a major trend in the development of component analysis instruments since the late 1970s. At present, computers have been widely used in data processing of various modern component analysis instruments, monitoring the functions of component analysis instruments, controlling their work, and various operating parameters. The combination of computer and component analysis instruments has become an effective tool for automatic control of the production process. Due to the emergence of microcomputers, especially single-chip microcomputers, some "intelligent" component analysis instruments with microcomputers have been produced in succession.

Widely adopt new technologies

The emergence of new technologies such as laser technology, solid gas sensors, large-scale integrated circuits, superconductivity, photoconductivity, etc. has greatly expanded the variety and application range of component analysis instruments and improved the accuracy, sensitivity, stability, and automation of instruments. At present, the development of science and technology has entered a new stage, with new disciplines, new technologies, and new processes emerging in endlessly. Many achievements in natural science and engineering technology have not been fully applied in the field of component analysis instruments. Component analysis instruments must widely use the latest achievements in all disciplines so that they can develop faster and better serve scientific and technological progress and national economic development.

Continuously improve the degree of automation

With the improvement of the level of automation products in China, it is urgent to gradually apply various mature composition analysis instruments and analysis methods in the laboratory to the production practice, and become a means to continuously and automatically complete the necessary measurement, supervision, and adjustment tasks in the production process. Therefore, on the one hand, efforts should be made to solve the research and development of the automatic sampling and sample pretreatment system required by the process component analysis instrument, and on the other hand, the automation degree of the main machine of the component analysis instrument should be improved to make it fully automatic. In fact, it is not only necessary for the automation of the production process, but also necessary for the laboratory analytical instruments to continuously improve the degree of automation of the component analysis instruments. Therefore, improving the degree of automation is one of the main development trends of the current component analysis instruments.

Standardize as much as possible

In the early 1960s, some widely used laboratory composition analysis instruments, such as gas chromatography, began to use the so-called "building block" structure. It is to decompose the instrument into several standard components, which are properly combined according to different purposes to meet the requirements of different functions. In addition, standardized plug-ins shall be used as far as possible in terms of electronic components, which can be an amplifier, a program controller, a computer online interface, etc. To realize the standardization, serialization, and unit combination of the component analysis instrument is not only conducive to reducing the production cost of the instrument and shortening the manufacturing cycle, but also can simplify the operation technology, improve the use flexibility, reduce the maintenance workload, and promote the application of the component analysis instrument. Therefore, it is one of the development directions that should be advocated.

Gradually popularizing computer technology, widely using the latest achievements in various disciplines, constantly improving the degree of automation of the instrument, and striving to achieve standardization and serialization are the main development trends of the current composition analysis instrument.

Supmea Process Automation Instrument Company

Supmea Co., Ltd., founded in 2006, is a national high-tech enterprise engaged in the R&D, manufacturing, sales, and service of process automation instruments. The headquarters of the company is located in Qiangtang District, Hangzhou, which integrates the national economic and technological development zone, a university town, and a cross-border e-commerce zone. The company has more than 400 employees, more than 90% of whom have college degrees or above, and has gathered a large number of professional and technical talents in automation, measurement, and control, communication, electronics, electrical, mechanical, and other fields.

Supmea is a director unit of the China Instrument and Meter Society. Since 2013, Supmea has been awarded the honorary titles of the most growth-oriented enterprise, Zhejiang provincial science, and technology-oriented enterprise, national high-tech enterprise, etc. Due to its outstanding development achievements in recent years.

The company's products mainly include temperature, pressure, flow, level, analysis, and other process automation instruments, which are widely used in various industrial fields and have won the trust and reputation of nearly 500000 customers. At present, the company has set up service centers in Beijing, Shanghai, Guangzhou, Nanjing, Chengdu, Wuhan, Changsha, Jinan, Zhengzhou, Suzhou, Jiaxing, Ningbo, and other places, and has set up offices and contact points in Singapore, the Philippines, and other countries. Its business covers more than 120 countries and regions.

2 notes

·

View notes

Text

How To Treat The Exhaust Air From Poultry And Meat Processing Companies?

Industries like poultry and meat processing companies causes odour nuisance to the neighborhood. There have been several technologies to tackle this situation. The requirement of an exhaust air treatment system is determined on the basis of the size of the facility, the specific processing operations involved, the exhaust air volume, and pollutant load to be treated, and the resulting nuisance potential. Elixir enviro Systems Pvt Ltd (www.elixirenviro.in) is a pioneer in odour control. Elixir Enviro Systems Pvt Ltd designs the required upstream and downstream processes for the effective odour control strategy. The strategies include appropriate ventilation design and pretreatment steps for the optimal operation of the Odour Control Unit(OCU).

What kind of exhaust air treatment system should be used in a slaughterhouse? It could vary for different facilities and is purely decided on case-by-case basis. Here are the commonly used exhaust air treatment systems for slaughterhouses:

Biological Exhaust Air Treatment

Biological elimination of pollutants from air is the most environmental-friendly technique since it ensures minimal use of chemical agents and in many cases, it comes as the lowest lifetime cost alternative compared with other treatment technologies. In biological exhaust air treatment, microorganisms are used to convert odour components to CO2 and H2O.

Bioscrubber

Bioscrubbers are also called Bio-washers. In the Bioscrubber, absorption of air pollutants and the reaction or degradation of the pollutants occurs in two reactors. In the first stage the air is being washed or gets in contact with the air having the pollutant load and the absorbent or the liquid absorbs the pollutant from the air. In the second stage, this absorbent is treated biologically and circulated back to the washing stage. If you look in general, the Bioscrubbers are mainly employed for highly soluble and low volatile compound treatment.

Bio-Trickling Filter

The contaminated air is passed through the packing media made of inert materials. In these filters, a liquid phase is trickled into the media. The pre-humidification can be avoided in the bio-trickling filters as the water phase can provide the moisture for the biomass activity. In Bio-Trickling filters inert materials with chemical stability, low weight and good mechanical properties are preferred. These filters are well aerated systems and the microorganism responsible for the degradation are usually aerobic but deeper into the bed, there is also anaerobic degradation. The flip side of this process is the requirement of micro and macro-nutrient supplementation to assure that the microorganisms are getting enough nutrients for the growth. If this nutrient supplementation is not properly regulated, this can lead to clogging of the unit.

Biofilter

What is biofilter? It is basically a porous layer made up of organic material. It supports the microbial population. The odorous air is forced into the porous layer where the biological degradation takes place. Odor emission is controlled to over 95 percent with biofilters. It should be noted that media moisture content affects the functioning of biofilters. The biofiltration technology is an entrenched odour pollution control technology in various parts of the world.

Chemical Absorption

The solubility behaviour of contents determines the absorption of gas in liquid. In absorption too, the efficiency is determined by adjusting the pH to acidic or alkaline. Hence the absorbers function as chemical scrubbers.

Process Combination

Rather than limiting to one technique, usage of a combination of techniques has proven to be more efficient in slaughterhouse facilities. For example, combination of chemical and biological processes is mostly practiced.

CONCLUSION

Odor emission is an important measure that should be taken by slaughterhouse or meat and poultry processing facilities for the well-being of humans and environment. Elixir Enviro Systems Pvt Ltd is a pioneer in the field of odour control from such industries. Different kinds of cost-effective and highly efficient odor control systems are designed and implemented by the company all over India.

1 note

·

View note

Text

Center Enamel Provides Easily Expanded GLS Tanks as Agricultural Water Tanks

Center Enamel Provides Easily Expanded GLS Tanks as Agricultural Water Tanks

In the agricultural sector, efficient and reliable water storage solutions are crucial for ensuring consistent irrigation and supporting livestock. Center Enamel, a global leader in tank manufacturing, offers Glass-Lined Steel (GLS) tanks that stand out for their exceptional expandability, making them an ideal choice for agricultural water storage needs. These tanks are designed to meet the dynamic demands of agriculture, providing a scalable and durable solution that grows with your needs.

With their easily expandable design, superior durability, and commitment to quality, Center Enamel’s GLS tanks are the optimal solution for agricultural water storage. They offer a flexible, scalable, and reliable option that adapts to the growing needs of the agricultural sector. By choosing Center Enamel, agricultural businesses are assured of a product that not only meets but exceeds their expectations, providing consistent and high-quality water storage solutions.

As a leading storage tank manufacturer in China. Center Enamel can provide GFS Tanks, SS Tanks, Epoxy Coated Steel Tanks, Galvanized Tank, Aluminum Dome Roofs, Wastewater and Biogas Project Equipments for global customers.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Advantages of GLS Tanks as Agricultural Water Tanks

Easily Expandable Design

One of the most significant advantages of Center Enamel’s GLS tanks is their modular design, which allows for easy expansion. As agricultural operations grow, the need for additional water storage can quickly increase. Center Enamel’s GLS tanks can be easily expanded by adding additional rings, accommodating increased water storage without the need for entirely new tank systems. This flexibility ensures that farmers can scale their water storage capacity efficiently and cost-effectively.

Durability and Longevity

Center Enamel’s GLS tanks are manufactured using advanced glass-fused-to-steel technology. This process creates a robust, corrosion-resistant surface that can withstand harsh environmental conditions, making it ideal for agricultural settings. The longevity of these tanks ensures that they remain a reliable water storage solution for many years, reducing the need for frequent replacements and repairs.

Hygienic and Safe

Ensuring the quality of water used in agriculture is vital, whether for irrigation or for livestock consumption. The smooth, glass-coated interior surface of Center Enamel’s GLS tanks is not only easy to clean but also resistant to the growth of bacteria and algae. This feature maintains the purity of stored water, supporting the health of crops and animals alike.

Cost-Effective and Efficient Installation

The prefabricated nature of Center Enamel’s GLS tanks allows for rapid on-site assembly, significantly reducing installation time and labor costs compared to traditional water storage solutions. This efficiency minimizes disruption to agricultural operations and ensures that water storage needs are met promptly.

Proven Success in Agricultural Projects

Center Enamel’s GLS tanks have been successfully implemented in various agricultural projects worldwide. For instance, in an Oman Drinking Water Project, Center Enamel provided 600M³ capacity tanks, ensuring a reliable water supply for agricultural needs. These tanks have demonstrated their effectiveness in maintaining consistent water availability, essential for successful farming operations.

Comprehensive After-Sales Support

Center Enamel is committed to providing exceptional customer service. Their comprehensive after-sales support includes maintenance, inspection services, and technical assistance to ensure the continued efficient operation of their GLS tanks. This support ensures that agricultural businesses can rely on their water storage solutions for the long term.

Center Enamel combines the excellent performance of various tanks to provide customers with solutions composed of diverse equipment combinations. This approach allows us to flexibly meet the needs and requirements of different application fields. Throughout the project construction process, the teams at Center Enamel collaborate closely, actively coordinate, and prioritize each step, conducting rigorous checks at every level to ensure the smooth completion of projects.

From being a leader in the Global GFS tank industry to becoming a diversified environmental equipment smart manufacturer in China, Center Enamel utilizes crucial core technologies to continuously iterate and upgrade equipment in research and development. This drives the sustained high-quality development of the company in the face of new challenges. Leveraging existing brand advantages, technological strengths, and team capabilities, the company will continue to focus on cutting-edge industry technologies. Adhering to a diversified development strategy, Center Enamel aims to elevate environmental business to new heights while jointly creating a beautiful picture of green hills and clear waters.

0 notes

Text

Exploring the Challenges and Limitations of Using Napier Grass Bio CNG

Introduction

Napier grass, known for its robust growth and high yield, is increasingly being recognized as an excellent source for the production of bio Compressed Natural Gas (bio CNG). As companies like Gruner Renewable explore the advantages of this renewable energy source, it's also important to consider the potential challenges and limitations that may arise with its use. This article delves into the practical constraints and technical hurdles associated with utilizingnapier grass bio cng pump

production, providing a balanced perspective on its sustainability and efficiency.

Understanding napier grass bio cng pump

Napier grass, or Pennisetum purpureum, is a perennial tropical grass that is cultivated extensively in various parts of the world for animal fodder and increasingly for bioenergy production. When used as a feedstock for bio CNG, the biomass is converted into biogas through anaerobic digestion, which is then purified to produce bio CNG—a renewable alternative to fossil fuel-derived natural gas.

Potential Challenges and Limitations

1. Feedstock Availability and Seasonality

One of the primary challenges in utilizingnapier grass bio cng pump

source is its availability and the seasonal nature of its growth. Although Napier grass can produce high yields, its productivity can fluctuate due to climatic conditions, water availability, and land quality. Ensuring a consistent and reliable supply of Napier grass throughout the year can be challenging, particularly in regions with pronounced dry seasons.

2. High Initial Setup and Operational Costs

The setup cost for a bio CNG plant using Napier grass includes expenses related to land acquisition, plant construction, and the installation of anaerobic digesters and other necessary technology. Additionally, the operational costs involving harvesting, transportation, and processing of Napier grass can be significant. These financial requirements may pose a barrier to entry for smaller producers or new entrants in the renewable energy market.

3. Conversion Efficiency and Technology

While advances have been made in anaerobic digestion technologies, the conversion efficiency of turning Napier grass into bio CNG can vary. The fibrous nature of Napier grass requires pretreatment to enhance its digestibility by microbes in anaerobic digesters. Developing and optimizing these pretreatment processes to maximize biogas yield can require additional investment in research and development.

4. Competition with Food Production and Land Use

Although Napier grass is praised for not competing directly with food crops, the land used to cultivate Napier grass could potentially be used for agricultural food production. This competition for land must be carefully managed, especially in regions where arable land is scarce and the population density is high.

5. Environmental Impact

While bio CNG production significantly reduces greenhouse gas emissions compared to fossil fuels, the cultivation of Napier grass must be managed responsibly to avoid negative environmental impacts. These can include biodiversity loss due to large-scale monoculture practices, overuse of water resources in irrigation, and the potential use of chemical fertilizers and pesticides that can harm local ecosystems.

Gruner Renewable’s Approach to Overcoming Challenges

At Gruner Renewable, we are committed to addressing these challenges through innovative solutions and sustainable practices:

● Integrated Crop Management: We implement sustainable agricultural practices that minimize water usage and chemical inputs while promoting soil health and biodiversity.

● Advanced Biogas Technology: Our investment in research and development focuses on improving biogas yield and operational efficiencies, reducing costs, and enhancing the sustainability of bio CNG production.

● Diversification and Rotation: Where possible, we advocate for crop rotation and the integration of Napier grass with other biomass sources to reduce risk and dependency on a single feedstock.

Conclusion

While there are challenges associated with using Napier grass for bio CNG production, the potential benefits in terms of renewable energy provision and environmental sustainability are significant. Gruner Renewable remains dedicated to pioneering solutions that address these limitations, driving forward the adoption of bio CNG as a key component of a sustainable energy future.

Call to Action

To learn more about how Gruner Renewable is innovating in the field of bio CNG production and overcoming the challenges associated with Napier grass, visit our website today. Join us in our journey toward sustainable energy solutions that benefit both the planet and future generations.

0 notes

Text

Specialty Chemicals Distributors | Industry | 9041070303

Specialty Chemicals Distributors

About Us: Spacialty Chemical Brothers - Your Partner in Specialty Chemicals

At Spacialty Chemical Brothers, we are dedicated to delivering high-quality specialty chemicals tailored to meet your specific needs. With extensive technical expertise spanning a wide range of processing solutions and formulation technologies, we have become a trusted vendor for some of the biggest names in the industry. specialty chemicals distributors

Our Mission

Our mission is to provide the highest value to our clients through our products. We prioritize sustainability, profitability, and environmental responsibility in every task we undertake.

State-of-the-Art Infrastructure

Our manufacturing plant, located in Mumbai, India, boasts cutting-edge facilities overseen by a team of experienced doctorates and chemical engineers. With a manufacturing capacity of up to 30,000 MT per annum, our plant ensures high-standard processing and production.

Our Expert Team

Our team is comprised of passionate leaders, skilled technical staff, experienced logisticians, creative salespeople, and knowledgeable marketing personnel. Together, we bring extensive experience and expertise to the specialty chemicals industry in India.

Commitment to Research and Development

Our reputation for excellence is built on our commitment to research and development. Our well-equipped laboratory features advanced equipment, including distillation and extraction units, vacuum chambers, high-end stirrers, and laboratory-grade dissolvers. This allows for rapid prototyping, thorough analysis, and advanced application technology.

Quality Assurance

We conduct thorough analyses of our products before they are dispatched to ensure they meet client specifications. Our processes are well-documented and adhere to standard operating procedures. Every product's performance, quality, and specifications are rigorously checked before final dispatch.

Compliance and Standards

We adhere to the highest industry standards and maintain the following compliances:

ISO 9001:2008

REACH

GOTS

OEKO-TEX

Products and Services

We offer a diverse range of products and services to meet the needs of various industries, including:

Pretreatment and Dyeing Auxiliaries

Thread Lubricants

Personal Care Aides

LSR – Silicone Inks

Our products are suitable for a wide array of applications in industries such as conventional textiles, technical textiles, rubber, and sewing thread.

Why Choose Spacialty Chemical Brothers?

Choosing Spacialty Chemical Brothers means opting for excellence, reliability, and innovation in specialty chemicals. We are committed to providing superior products and services that drive your success while maintaining our dedication to sustainability and environmental responsibility.

For more information or to discuss your specific needs, please contact us. We look forward to partnering with you to achieve your goals with our high-quality specialty chemical solutions.

#specialty chemicals distributors#specialty chemicals industry#specialty chemicals industry in india#specialty chemicals distributors in india

0 notes

Text

Streamlined Cell Separation with pluriBead® - No Pretreatment Required

Explore pluriBead's efficient cell separation technology using non-magnetic microparticles. No need for pretreatment; achieve target cell isolation with ease and save time in your lab processes.

0 notes

Text

Mimaki shows TraPis textile prints at Fespa

At this year’s Fespa event, Mimaki showed off an interesting pigment transfer concept that it first previewed at last year’s ITMA show, which it calls TraPis, standing for TRAnsfer Pigment System.

The idea is to print an image onto transfer paper and then transfer it in a calendar heat press, which is essentially the same process as for dye sublimation. But the difference is that the image is not sublimated into the fibers of the material and instead sits on the surface, as with most pigment ink textile solutions.

Marc Verbeem, supervisor of product management at Mimaki Europe, says that this gives it a textured finish, and so it’s mostly suitable for home decor such as pillows or towels rather than apparel. It has all the certification required to produce clothing but Verbeem says that the texture is not so comfortable to wear. Also, the ink will only survive 5-10 washing cycles, which is fine for home decor use but not nearly good enough for clothing.

He explains, “The advantage is that you can use any type of fabric without needing any form of pretreatment.” It will work with cotton, wool, nylon and even polyester. That said, the material does have to be able to withstand at least 150°C heating in the calendar. More heat generally improves the washability but too much heat will also limit the colour gamut that it can reproduce.

Mimaki has adapted its TS330-1600 dye sublimation printer with new firmware to be able to run the inkset that the TraPis approach requires. Otherwise, it’s a relatively standard 1.6m wide roll-to-roll printer for transfer papers.

The system uses a water-based pigment ink with an eight-color inkset that consists of CMYK plus red, green, blue and light black. As with most textile pigment inks, it will print to a wide range of different fabrics.

It does require a specific transfer paper with a coating designed to hold the TraPis ink. This transfer paper is made by Coldenhove but it’s only available through the Mimaki dealer channel.

Once printed, the image is transferred from the paper to the textile via a calendar heat press. However, it will not work with the majority of calendars because it requires much higher pressure – at least 8 bar – whereas most calendars designed for dye sublimation can only manage 6 bar. This limits the choice to Klieverik and Monti Antonio, both of which can supply suitable units. As with dye sublimation, the heat within the press releases the ink from the paper but it’s the high pressure that then forces the ink onto the fabric.

The key advantage to this system is that there’s no need to pretreat the fabric, and there’s no need for any washing or steaming, which eliminates the need for water as well as the time this would take. Judging from the samples shown at Fespa, the results seem quite good. Many printers will be familiar with the concept of printing to transfer paper, and this does offer a reasonably cost-effective approach, albeit there’s a limited choice of calendar units and transfer papers.

It’s also worth noting that Mimaki previewed another technology prototype last year with its NeoChromato process for recycling polyester prints that have previously been dye-sublimated, such as exhibition graphics. I’ve already written about this technology here, which will be shown at drupa.

Mimaki will also use its stand at drupa to highlight its work with the Indian Tiny Miracles foundation, which supports women working in local communities. For drupa, the group has produced environmentally friendly, Mimaki-branded cotton bags which are helping to replace plastic bags.

Although Mimaki used Fespa to officially launch the TraPis system, it won’t be available until June of this year. You can find further details from mimaki.com.

0 notes

Text

Textile Pretreatment Chemicals Market to Reach US$ 26.6 Billion by 2031

The Global Textile Pretreatment Chemicals Market is estimated to flourish at a CAGR of 3.9% from 2023 to 2031. According to Transparency Market Research, sales of Textile Pretreatment Chemicals are slated to total US$ 26.6 billion by the end of the aforementioned period of assessment.

A prominent driver behind this market's evolution is the increasing emphasis on sustainable and eco-friendly practices. As consumers become more conscious of the environmental impact of textile production, textile manufacturers are compelled to adopt greener alternatives. This has led to a rise in the demand for pretreatment chemicals that are non-toxic, biodegradable, and low in volatile organic compounds (VOCs). Companies that can provide such eco-friendly solutions are well-positioned to capitalize on this growing trend.

The advent of smart textiles has opened up new avenues for pretreatment chemicals. These textiles incorporate advanced technologies such as sensors, conductive fibers, and self-cleaning properties. As a result, the demand for specialized pretreatment chemicals that enable these functionalities has skyrocketed. Manufacturers who can develop innovative chemical formulations to enhance the performance and functionality of smart textiles stand to gain a competitive edge in the market.

The textile pretreatment chemicals market is witnessing a surge in demand from emerging economies. As disposable income levels rise and consumer preferences evolve, these countries are witnessing significant growth in their textile industries. This presents an immense opportunity for pretreatment chemical manufacturers to tap into these expanding markets and establish a strong presence.

To Remain Ahead of Your Competitors, Request a Sample: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=85641

Market Segmentation

By Service Type

Desizing Agents: Chemicals used to remove size materials from fabrics.

Scouring Agents: Used to remove natural impurities and added substances from fibers.

Bleaching Agents: Applied to whiten fabrics and remove natural coloration.

Mercerizing Agents: Chemicals used to increase fabric strength, luster, and dye affinity.

By Sourcing Type

In-house Manufacturing: Companies producing chemicals within their facilities.

Outsourced Manufacturing: Reliance on third-party manufacturers for chemical supplies.

By Application

Cotton Textiles: Predominantly used due to its extensive application in clothing.

Wool Textiles: Specialized chemicals required for wool pretreatment.

Synthetic Textiles: Including polyester, nylon, and other man-made fibers.

Others: Blended fabrics and niche textile materials.

By Industry Vertical

Apparel: High demand from fashion and clothing industries.

Home Textiles: Including bedding, curtains, and upholstery.

Technical Textiles: Industrial applications requiring specific properties.

Others: Specialty textiles for medical, automotive, and protective gear.

By Region

North America: Significant market with advanced textile industries.

Europe: Strong focus on sustainable and high-quality textiles.

Asia-Pacific: Largest market with rapid industrialization and production capacity.

Latin America: Growing market with increasing textile manufacturing activities.

Middle East & Africa: Emerging market with potential for substantial growth.

Regional Analysis

North America

The North American market is driven by technological advancements and a focus on high-quality textile production. The region’s stringent environmental regulations also promote the use of eco-friendly pretreatment chemicals.

Europe

Europe emphasizes sustainable practices in textile manufacturing, driving demand for green chemicals. The region’s well-established textile sector continues to innovate, fostering market growth.

Asia-Pacific

Asia-Pacific dominates the market due to its vast textile manufacturing base, particularly in China, India, and Southeast Asia. The region benefits from cost-effective production and a growing middle-class population, boosting textile consumption.

Latin America

Latin America is experiencing growth in its textile industry, supported by increasing investments and the establishment of new manufacturing facilities. Brazil and Mexico are key markets in the region.

Middle East & Africa

This region presents untapped potential, with growing industrialization and investments in textile manufacturing. The demand for pretreatment chemicals is expected to rise as local production scales up.

Market Drivers and Challenges

Market Drivers

Rising Demand for High-Quality Textiles: Consumer preference for better quality fabrics propels the need for effective pretreatment chemicals.

Technological Advancements: Innovations in textile manufacturing processes enhance the efficiency and effectiveness of pretreatment chemicals.

Environmental Regulations: Stricter regulations regarding chemical usage and wastewater management drive the adoption of eco-friendly pretreatment chemicals.

Market Challenges

High Costs of Eco-Friendly Chemicals: The adoption of sustainable chemicals is often hindered by their higher costs compared to conventional alternatives.

Fluctuating Raw Material Prices: Variability in the prices of raw materials can impact production costs and market dynamics.

Complex Supply Chain: Managing a diverse and global supply chain for chemical inputs poses logistical and operational challenges.

Market Trends

Sustainability Focus: Increasing emphasis on sustainable and eco-friendly chemicals in response to environmental concerns and regulatory pressures.

Technological Integration: Adoption of advanced technologies, such as automation and digitalization, to optimize pretreatment processes.

Customization and Specialization: Development of specialized chemicals tailored for specific textile types and applications.

Future Outlook

The textile pretreatment chemicals market is set for steady growth, driven by technological advancements, rising consumer demand for high-quality textiles, and increased focus on sustainability. The market will witness the introduction of innovative and eco-friendly chemicals, meeting both regulatory standards and consumer expectations.

Buy this Premium Research Report | Immediate Delivery Available - https://www.transparencymarketresearch.com/checkout.php?rep_id=85641<ype=S

Key Market Study Points

Impact of Technological Innovations: Assessing how advancements in textile manufacturing technologies influence the demand for pretreatment chemicals.

Sustainability Initiatives: Understanding the shift towards eco-friendly chemicals and its impact on market dynamics.

Regional Growth Patterns: Analyzing the growth potential in emerging markets and established regions.

Competitive Strategies: Evaluating the strategies adopted by key players to maintain market position and drive growth.

Competitive Landscape

The market is characterized by intense competition with several key players, including multinational corporations and regional manufacturers. Leading companies focus on product innovation, strategic partnerships, and sustainability initiatives to gain a competitive edge. Key players in the market include:

BASF SE

Huntsman Corporation

The Dow Chemical Company

Wacker Chemie AG

Archroma

Recent Developments

Introduction of Bio-based Chemicals: Companies are launching bio-based and sustainable pretreatment chemicals to cater to the growing demand for eco-friendly solutions.

Strategic Acquisitions and Partnerships: Major players are engaging in mergers, acquisitions, and partnerships to expand their product portfolios and geographic reach.

Technological Upgrades: Investment in R&D for developing advanced pretreatment solutions that offer higher efficiency and lower environmental impact.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

North America Industrial Filtration Market Will Hit Big Revenues In Future | Biggest Opportunity Of 2024

Latest added North America Industrial Filtration Market research study by Market Research Forecast offers detailed outlook and elaborates market review till 2030. The market Study is segmented by key regions that are accelerating the marketization. At present, the market players are strategizing and overcoming challenges of current scenario; some of the key players in the study are 3M Company (U.S.),Pall Corporation (U.S.),Alfa Laval Inc. (Sweden),Ahlstrom-Munksjö (Finland),Filtration Group (U.S.),Lydall Inc. (U.S.),American Air Filter Company Inc. (U.S.),Dorstener Wire Tech (U.S.),Graver Technologies (U.S.),Hollingsworth & Vose Company (U.S.)} etc.

Free Sample Report + All Related Graphs & Charts @: https://marketresearchforecast.com/report/north-america-industrial-filtration-market-1300/sample-report

The North America Industrial Filtration Marketsize was valued at USD 16.18 USD Billion in 2023 and is projected to reach USD 20.73 USD Billion by 2032, exhibiting a CAGR of 3.6 % during the forecast period.

The latest edition of this report you will be entitled to receive additional chapter / commentary on latest scenario, economic slowdown and COVID-19 impact on overall industry. Further it will also provide qualitative information about when industry could come back on track and what possible measures industry players are taking to deal with current situation. Each of the segment analysis table for forecast period also high % impact on growth.

This research is categorized differently considering the various aspects of this market. It also evaluates the upcoming situation by considering project pipelines of company, long term agreements to derive growth estimates. The forecast is analyzed based on the volume and revenue of this market. The tools used for analyzing the Global North America Industrial Filtration Market research report include SWOT analysis.

In September 2023, Ahlstrom started the production of calendared, new, and embossed synthetic filter media in South Korea. The materials generate limited flow restriction because of higher available surface area and offer extended filter lifetime. These materials are used in both liquid and air filtration applications such as air intake, air pollution control, oil, water, and fuel filtration.,In December 2022, Alfa Laval Inc. formed an agreement with a subsidiary of CVR Energy, Inc., to provide pre-treatment systems, which include agitators, separators, heat exchangers, and pumps. These pretreatment systems will reduce contaminants from feedstocks before converting into biofuel.,In August 2022, Pall Corporation announced the investment of USD 100 million in the state-of-the-art manufacturing facility in Singapore. This investment will provide a surge to the semiconductor industry in the Asia Pacific region amid global chip shortage. Filtration plays a vital role in semiconductor manufacturing as it reduces contaminants. The new facility will strengthen the company’s position and double its production capacity.,In January 2022, Pall Corporation introduced the lube oil filter element portfolio and the new SupralonTM hydraulic, an upgrade for Pall’s Ultipor, Red1000, and Coralon series filters. Supralon filter elements include a new pack construction and stress-resistant technology (SRT) filter media with anti-static characteristics, which help preserve and extend the life of equipment in hydraulic and lubricating fluid applications. ,In October 2021, Ahlstrom- developed new capabilities to test gas adsorption performance at its Pont-Evêque R&D center in France. The development is made as a part of the company strategy to invest and grow in the electric vehicle and industrial filtration markets.}

Influencing Trend:

Adoption of Sustainable Filtration Media Coupled with Growing Digitalization of Filtration Products to Offer Lucrative Growth Opportunities

Market Growth Drivers:

Advances in Healthcare Industry Creating Demand for Sophisticated Industrial Filtration Systems to Propel the Market Growth

The Global North America Industrial Filtration segments and Market Data Break Down are illuminated below:

Type: Air & Gas Filtration and Liquid Filtration,Filter Media: Activated Carbon/Charcoal, Fiberglass, Nonwovens, Metals, Filterpaper, and Combination Filters & Others,Application: Food & Beverage, Power Generation, Semiconductors & Electronics, Chemicals & Petrochemicals, Healthcare, Metals & Mining, Paper & Paints, and Others}

Have Any Questions Regarding Global North America Industrial Filtration Market Report, Ask Our Experts@ https://marketresearchforecast.com/report/north-america-industrial-filtration-market-1300/enquiry-before-buy The regional analysis of Global North America Industrial Filtration Market is considered for the key regions such as Asia Pacific, North America, Europe, Latin America and Rest of the World. North America is the leading region across the world. Whereas, owing to rising no. of research activities in countries such as China, India, and Japan, Asia Pacific region is also expected to exhibit higher growth rate the forecast period 2021-2027.

Highlights of the report:

A complete backdrop analysis, which includes an assessment of the parent market

Important changes in market dynamics

Market segmentation up to the second or third level

Historical, current, and projected size of the market from the standpoint of both value and volume

Reporting and evaluation of recent industry developments

Market shares and strategies of key players

Emerging niche segments and regional markets

An objective assessment of the trajectory of the market

Recommendations to companies for strengthening their foothold in the market

Strategic Points Covered in Table of Content of Global North America Industrial Filtration Market:

Chapter 1: Introduction, market driving force product Objective of Study and Research Scope the North America Industrial Filtration market

Chapter 2: Exclusive Summary – the basic information of the North America Industrial Filtration Market.

Chapter 3: Displayingthe Market Dynamics- Drivers, Trends and Challenges & Opportunities of the North America Industrial Filtration

Chapter 4: Presenting the North America Industrial Filtration Market Factor Analysis, Porters Five Forces, Supply/Value Chain, PESTEL analysis, Market Entropy, Patent/Trademark Analysis.

Chapter 5: Displaying the by Type, End User and Region/Country 2015-2020

Chapter 6: Evaluating the leading manufacturers of the North America Industrial Filtration market which consists of its Competitive Landscape, Peer Group Analysis, BCG Matrix & Company Profile

Chapter 7: To evaluate the market by segments, by countries and by Manufacturers/Company with revenue share and sales by key countries in these various regions (2023-2030)

Chapter 8 & 9: Displaying the Appendix, Methodology and Data Source

Finally, North America Industrial Filtration Market is a valuable source of guidance for individuals and companies.

Get More Information: https://marketresearchforecast.com/report/north-america-industrial-filtration-market-1300/checkout?type=corporate

Key questions answered

Who are the Leading key players and what are their Key Business plans in the Global North America Industrial Filtration market?

What are the key concerns of the five forces analysis of the Global North America Industrial Filtration market?

What are different prospects and threats faced by the dealers in the Global North America Industrial Filtration market?

What are the strengths and weaknesses of the key vendors?

Definitively, this report will give you an unmistakable perspective on every single reality of the market without a need to allude to some other research report or an information source. Our report will give all of you the realities about the past, present, and eventual fate of the concerned Market.

Thanks for reading this article, we can also provide customized report as per company’s specific needs. You can also get separate chapter wise or region wise report versions including North America, Europe or Asia.

Contact US :

Craig Francis (PR & Marketing Manager)

Market Research Forecast

Unit No. 429, Parsonage Road Edison, NJ

New Jersey USA – 08837

Phone: +1 201 565 3262, +44 161 818 8166

[email protected]

0 notes

Text

Three important indicators of the perfect operation of the rotor dehumidifier system

The latest update of COVID-19: According to the website of the Yunnan Provincial Health Commission, three new local confirmed cases (2 Chinese and 1 Burmese) were reported in Yunnan province from 00:00 to 24:00 on July 4. Five new confirmed cases were imported from abroad (3 cases imported from Myanmar and 2 cases imported from Indonesia), and one new asymptomatic infected person imported from Indonesia (imported from Indonesia), all Chinese nationals. Two confirmed cases were cured and discharged from hospital (imported from abroad). In the case of imported cases every day, all provinces should take effective epidemic prevention and control measures to prevent the large-scale counterattack of the COVID-19 virus. Roner dehumidifier, as the temperature and humidity control equipment in the production of vaccine production and detection reagent, so runner dehumidifier manufacturers should continue to further develop and experiment on product stability and energy saving technology of runner dehumidifier.

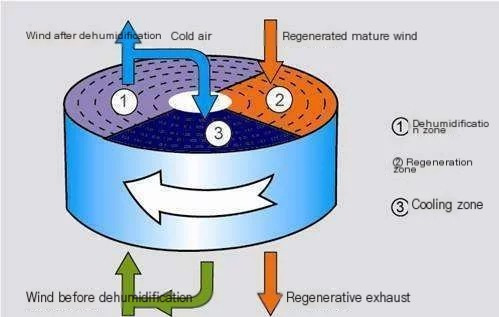

In order to meet the steam system required for runner regeneration cycle heating, 140℃ steam of 0.6MPa is supplied, and the 12℃ / 18℃ medium temperature cold water system and 6℃ / 13℃ low temperature cold water system are supplied to the dehumidifier cooling dehumidification and cooling use after runner regeneration. Air filtered into the air conditioning unit, first through the pretreatment module, part of the moisture in the air after the fresh air table cooling treatment, after cooling dehumidification, achieve certain temperature and humidity requirements, then through the former wheel dehumidification to achieve dew point design requirements, after the table cooling dehumidification treatment to meet the design temperature requirements, by the processing fan to the later dehumidification wheel. The treated air becomes dry air after the dehumidification wheel. The dry air at the outlet adjusts the temperature to 15℃ ~25℃ after the surface cooling, and passes through the medium effect filtration, and is sent to the drying room. The dry air flow at the ultra-low dew point circulates the whole room through the workshop airflow organization system. The debugging of the whole dehumidification purification system, one is to meet the normal work of the dehumidifier, the other is the workshop wind system debugging. There are three systems to meet the workshop environmental temperature and humidity requirements: steam regeneration heating system; front surface cooling and chilled water system; workshop ventilation system. The normal operation of these three systems can ensure that the workshop environment is within the normal range, which is also the three important indicators of the perfect operation of the rotor dehumidifier system.

Roter dehumidifier belongs to an important branch of the field of air conditioning, is a typical representative of heating dehumidification. With the development of science and technology, the advantages of dehumidification and cooling technology began to be recognized and gradually developed. In recent years, our daily demand for rotor dehumidifier is increasing, so China's rotor dehumidifier industry is growing stronger and stronger! The brand on the market is also very various, if you ask Xiaobian wheel dehumidifier which brand is better? I am very confident to introduce this brand. The company integrates research and development, production, sales and service, specializing in the production of special temperature and humidity control equipment. Its strive to build the slogan of "stable and efficient, smart", the core products wheel dehumidifier and high precision constant temperature and humidity air conditioning well received by the market, the company r & d specifically for customer special requirements to provide the best process design, the most suitable equipment selection scheme and control mode, with the most economic and reasonable air treatment scheme to meet the needs of different customers, get the cooperation customers.

0 notes

Text

color roofing sheets manufacturers

Color roofing sheets are a popular choice in both residential and commercial construction due to their aesthetic appeal, durability, and cost-effectiveness. These sheets are made from various materials such as steel, aluminum, or polycarbonate and are coated with a layer of paint or a special finish to enhance their appearance and resistance to the elements. The manufacturing process, choice of materials, and application areas vary based on the product specifications and intended use.

Overview of Color Roofing Sheet Manufacturing

1. Material Selection: The base material for color roofing sheets is usually steel, aluminum, or polycarbonate. Steel is the most common due to its strength and affordability. The selected metal is typically in coil form before processing.

2. Cleaning and Pretreatment: The metal coils are cleaned and treated to ensure that the surface is free of contaminants and suitable for effective coating adhesion. This involves degreasing, rinsing, and applying a chemical pretreatment that enhances corrosion resistance and paint adhesion.

3. Primer Coating: A primer is applied to the treated metal to further enhance the adhesion of the topcoat and to provide additional corrosion protection. The primer is usually applied on both sides of the sheet.

4. Color Coating: After the primer has set, a topcoat of paint is applied in the desired color. This layer gives the roofing sheets their aesthetic appearance and additional protection against the elements. Advanced coating technologies allow for a variety of colors and finishes, including matte and glossy options.

5. Baking and Curing: The coated sheets are then passed through a curing oven where the paint is baked onto the surface, ensuring durability and color stability.

6. Cutting and Profiling: Once the sheets are coated and cured, they are cut to size and can be profiled into various shapes depending on the roofing requirements. Common profiles include corrugated, trapezoidal, and tile patterns.

7. Quality Control: Throughout the manufacturing process, quality control tests are conducted to ensure that the roofing sheets meet all industry standards for color consistency, coating thickness, and overall quality.

Applications of Color Roofing Sheets

Residential Buildings: Used for roofing in houses, garages, and sheds, offering both protection and style.

Commercial Structures: Commonly used in warehouses, factories, and retail outlets due to their durability and quick installation.

Agricultural Facilities: Used in barns and greenhouses where they provide the necessary protection from weather while contributing to the aesthetic of agricultural setups.

Architectural Projects: Color roofing sheets are used for their aesthetic value in various architectural designs, including modern residential complexes and commercial buildings.

Advantages of Color Roofing Sheets

Aesthetic Appeal: Offers a wide range of colors and finishes that can match any architectural style.

Durability: Coated surfaces resist corrosion, UV radiation, and wear, making them last longer than many traditional roofing materials.

Lightweight: Easier to transport and install compared to traditional roofing materials, which reduces labor and support structure costs.

Energy Efficiency: Some color coatings are designed to reflect more sunlight, which can reduce heating and cooling costs.

Leading Color Roofing Sheet Manufacturer: Hi-Tech Steel Sheets

Hi-Tech Steel Sheets stands out as a leading manufacturer of color roofing sheets, specializing in high-quality products that combine functionality with style. Employing state-of-the-art coating technologies and stringent quality controls, Hi-Tech Steel Sheets ensures that each product meets the highest standards of performance and aesthetics.

More Read: Roofing Sheet | color roofing sheets

0 notes

Text

Bissell Revolution Pet Carpet Cleaner: Ultimate Cleaning Solution

The Bissell Revolution Pet Carpet Cleaner offers powerful and effective cleaning for pet stains. Its advanced technology provides deep cleaning.

A home with pets can often result in tough carpet stains. The Bissell Revolution Pet Carpet Cleaner is designed to tackle these challenging messes. With its specialized features and innovative design, this carpet cleaner effectively removes pet hair, urine, and odors, leaving your carpets fresh and clean.

The powerful suction and rotating brush system ensure thorough cleaning, while the built-in pretreat wand targets stubborn spots. Say goodbye to pet messes with the Bissell Revolution Pet Carpet Cleaner, your go-to solution for maintaining a clean and pet-friendly home.

Features Of The Bissell Revolution Pet Carpet Cleane

Benefits Of The Bissell Revolution Pet Carpet Cleaner

The Bissell Revolution Pet Carpet Cleaner is a game-changer when it comes to maintaining a clean and fresh home environment, especially for pet owners. Let's dive into the key benefits this powerful carpet cleaner has to offer:

Deep Cleaning

- The Bissell Revolution Pet Carpet Cleaner utilizes advanced technology to penetrate deep into carpet fibers.

- Effectively lifting embedded dirt, odors, and pet dander for a thorough clean.

- Leaving your carpets looking and feeling revitalized with every use.

Effective Pet Hair Removal

- Designed specifically for pet owners, this carpet cleaner effortlessly tackles pet hair removal.

- Innovative brush roll technology loosens and lifts stubborn pet hair from carpets with ease.

- Leaving your floors fur-free and fresh, perfect for homes with furry companions.

Eliminates Tough Stains

- Say goodbye to stubborn pet stains and spills with the Bissell Revolution Pet Carpet Cleaner.

- Powerful cleaning formula effectively targets and removes tough stains, leaving carpets spotless.

- Restoring the look of your carpets and keeping them looking as good as new.

Reduces Drying Time

- The Bissell Revolution Pet Carpet Cleaner not only cleans but also speeds up the drying process.

- Innovative technology helps reduce drying time, allowing you to enjoy your freshly cleaned carpets sooner.

- Ensuring minimal disruption to your daily routine and keeping your home clean and cozy in no time.

https://www.youtube.com/watch?v=eEKi93cG7io

How To Use The Bissell Revolution Pet Carpet Cleaner

If you're a pet owner, you know how challenging it can be to keep your carpets clean and free from stubborn pet stains and odors. That's where the Bissell Revolution Pet Carpet Cleaner comes in handy. This powerful machine is designed specifically to tackle pet messes and leave your carpets looking and smelling fresh. In this guide, we'll walk you through the simple steps of using the Bissell Revolution Pet Carpet Cleaner, so you can effortlessly maintain a clean and pet-friendly home.

Preparing The Machine

Before you begin cleaning your carpets with the Bissell Revolution Pet Carpet Cleaner, it's essential to ensure that the machine is properly prepared. Follow these steps:

- Start by removing any furniture or obstacles from the area you plan to clean.

- Inspect the machine's water tank to make sure it's clean and free from debris. If needed, rinse it out and dry it thoroughly.

- Check the dirty water tank to ensure it's empty and properly attached to the machine.

- Before plugging in the machine, locate a nearby power outlet that is easily accessible.

- Now, you're ready to move on to the next step: adding the cleaning solution.

Adding Cleaning Solution

To effectively clean your carpets with the Bissell Revolution Pet Carpet Cleaner, you'll need to add the appropriate cleaning solution. Here's how:

- Start by filling the clean water tank with hot tap water. Check the machine's manual for the specific water level required.

- Once the water tank is filled, add the Bissell Pet Formula cleaning solution. Be sure to follow the recommended dilution ratio provided on the bottle.

- Tightly close the water tank after adding the cleaning solution to prevent any leaks during operation.

Operating The Machine

With the Bissell Revolution Pet Carpet Cleaner prepared and the cleaning solution added, it's time to put the machine into action. Follow these steps:

- Plug in the machine and turn it on using the power switch.

- Adjust the machine's settings to your desired cleaning mode. The Bissell Revolution Pet Carpet Cleaner offers different modes for various types of carpets and levels of dirt.

- Squeeze the trigger located on the handle to release the cleaning solution onto the carpet.

- Slowly push the machine forward to clean the carpet, releasing more cleaning solution as needed. Then, pull it back towards you to suction up the dirty water.

- Continue this process, working in small sections until you've thoroughly cleaned the desired area. You can consult the machine's manual for specific instructions on maneuvering and best practices.

Cleaning After Use

After successfully cleaning your carpets with the Bissell Revolution Pet Carpet Cleaner, it's important to properly clean the machine itself. Follow these steps for easy maintenance:

- Turn off and unplug the machine.

- Remove the dirty water tank and empty its contents into a sink or toilet.

- Rinse out the dirty water tank and allow it to air dry thoroughly.

- Wipe down the entire machine with a clean cloth or towel to remove any residue.

- Place the machine in a well-ventilated area to dry completely before storing it.

With these simple steps, you can make use of the Bissell Revolution Pet Carpet Cleaner's powerful cleaning capabilities to effectively remove pet stains and odors from your carpets. Make carpet cleaning a breeze and enjoy a clean and fresh living space for both you and your furry companions!

Customer Reviews

Customer reviews of the Bissell Revolution Pet Carpet Cleaner offer insight into the experiences of actual users, helping potential buyers make informed decisions. Let's delve into positive feedback and critique from Bissell Revolution Pet Carpet Cleaner users to understand their experiences.

Positive Feedback

Users of the Bissell Revolution Pet Carpet Cleaner frequently laud its ability to tackle tough pet stains and odors effectively. Many customers appreciate the easy-to-use design and lightweight portability, making it a convenient solution for pet owners dealing with accidents.

Furthermore, several reviewers highlight the machine’s powerful suction and efficient cleaning, leaving carpets noticeably fresher and revived.

Critiques And Concerns

While the majority of users are satisfied with the Bissell Revolution Pet Carpet Cleaner, some express concerns about the durability of certain components. Common critiques include issues with the hose and sprayer functionality, with a few users reporting leaks or malfunctions over time.

Additionally, a small number of users mention that the cleaning solution may leave behind a slight residue if not thoroughly rinsed, leading to potential re-soiling.

Comparison With Other Carpet Cleaners

When comparing the Bissell Revolution Pet Carpet Cleaner with other carpet cleaning machines in the market, it stands out for its unique features and effectiveness. Let's take a closer look at how Bissell stacks up against top competitors.

Bissell Vs. Hoover

Bissell and Hoover are both popular choices for carpet cleaning, but there are key differences between the two. The Bissell Revolution Pet Carpet Cleaner is designed specifically to tackle pet stains and odors, with features such as the CleanShot Pretreater and the Pet Stain Tool. On the other hand, Hoover offers powerful suction and a wider cleaning path, making it suitable for larger carpeted areas. While Bissell excels in pet-specific cleaning, Hoover may be preferred for overall deep cleaning capabilities.

Bissell Vs. Rug Doctor

Comparing the Bissell Revolution Pet Carpet Cleaner with Rug Doctor, they each have their strengths. Bissell's lightweight and maneuverable design, combined with its specialized pet stain and odor removal features, make it an ideal choice for pet owners. In contrast, Rug Doctor is known for its commercial-grade cleaning power, making it suitable for deep cleaning high-traffic areas. While Bissell prioritizes pet-related cleaning, Rug Doctor focuses on heavy-duty overall carpet cleaning needs.

Maintenance Tips For The Bissell Revolution Pet Carpet Cleaner

Proper maintenance is essential to ensure your Bissell Revolution Pet Carpet Cleaner continues to perform at its best. By following these simple maintenance tips, you can keep your carpet cleaner in excellent working condition for years to come.

Regular Cleaning Of Brushes And Nozzles

To maintain optimal cleaning performance, it's crucial to regularly clean the brushes and nozzles of your Bissell Revolution Pet Carpet Cleaner. After each use, be sure to remove any pet hair, debris, or tangled fibers that may have accumulated. This will prevent clogs and ensure that the brushes and nozzles can rotate and extract dirt efficiently.

Proper Storage

When you're done using your Bissell Revolution Pet Carpet Cleaner, storing it properly is key to preserving its longevity. Ensure that you empty the dirty water tank and rinse it thoroughly. Clean the brushes and nozzles as mentioned earlier. It's recommended to store the carpet cleaner in a clean and dry area, away from direct sunlight and extreme temperatures.

Replacing Parts

Over time, certain parts of your Bissell Revolution Pet Carpet Cleaner may wear out and need to be replaced. By regularly checking the condition of the brushes, belts, filters, and other components, you can identify any signs of wear and tear. Replace these parts promptly to maintain the machine's performance and prevent any future issues.

Remember, keeping your Bissell Revolution Pet Carpet Cleaner properly maintained is essential for effective cleaning and longevity. By following these maintenance tips, you can continue to enjoy pristine carpets and a cleaner home.

Frequently Asked Questions For Bissell Revolution Pet Carpet Cleaner

What Are The Key Features Of The Bissell Revolution Pet Carpet Cleaner?

The Bissell Revolution Pet Carpet Cleaner is designed with powerful suction and a brush roll to effectively remove pet stains and odors. It also includes a CleanShot Pretreater to tackle tough spots and stains.

How Does The Bissell Revolution Pet Carpet Cleaner Compare To Other Models?

The Bissell Revolution Pet Carpet Cleaner stands out for its specialized features for pet owners, such as the Pet Hair Strainer and the EZ Clean Brush Roll Cover. These components make it particularly effective for handling pet-related messes.

What Maintenance Is Required For The Bissell Revolution Pet Carpet Cleaner?

Regular maintenance for the Bissell Revolution Pet Carpet Cleaner involves emptying and rinsing the dirty water tank, cleaning the brush rolls, and regularly changing the filters. This ensures optimal performance and longevity of the machine.

Can The Bissell Revolution Pet Carpet Cleaner Be Used On All Types Of Carpets?

Yes, the Bissell Revolution Pet Carpet Cleaner is designed to be safe and effective for use on various carpet types, including low and high-pile carpets, area rugs, and even upholstery. Its adjustable cleaning modes cater to different surfaces.

Conclusion

To sum up, the Bissell Revolution Pet Carpet Cleaner is a game-changer for pet owners. With its powerful cleaning capabilities, it effortlessly removes pet stains and odors, leaving your carpets fresh and spotless. Its user-friendly design and advanced features make it a must-have cleaning tool for every pet owner.

Invest in this carpet cleaner and say goodbye to the hassle of stubborn pet messes.

Read the full article

0 notes

Text

Forecasting NPK Fertilizers Market: Size, Share, Trends, Growth And Forecast

Modern farming practices and technology adoption and increasing global population and food demand are expected to drive the Global NPK Fertilizers Market growth in the forecast period, 2025-2029

According to TechSci Research report, “NPK Fertilizers Market – Global Industry Size, Share, Trends, Competition Forecast & Opportunities, 2029”, the Global NPK Fertilizers Market stood at USD 5.98 billion in 2023 and is anticipated to grow with a CAGR of 4.13% in the forecast period, 2025-2029. The awareness among individuals regarding NPK Fertilizers has led to favorable market conditions for the global NPK Fertilizers market. Several factors contribute to the growth of various NPK Fertilizers products.

The adoption of modern farming practices, such as precision agriculture, no-till farming, and the use of high-yielding crop varieties, has led to an increased requirement for NPK fertilizers. These practices aim to optimize crop production, and NPK fertilizers are a key component in achieving higher yields and better crop quality. Furthermore, the mechanization and commercialization of agriculture have led to increased NPK fertilizer use to ensure the efficient and sustainable production of crops.

Agricultural lands can become depleted of essential nutrients, especially nitrogen, phosphorus, and potassium. To maintain or restore soil fertility, NPK fertilizers are used to replenish these nutrients, ensuring that the soil remains productive. In addition, nutrient balancing is critical to prevent over-fertilization and environmental pollution. Farmers and agronomists use NPK fertilizers to address nutrient deficiencies and maintain the optimal nutrient balance in soil, promoting sustainable agriculture, which will further fuel market growth.