#Polydimethylsiloxane

Text

Silicone Recycling

While consumer silicone products are often selected to replace single-use plastics, reducing the amount of waste generated overall, they too eventually must be disposed of - so what happens to the waste? Although silicone is a polymer, it has a silicon, oxygen based backbone, not carbon based like most polymers and plastics known. As such, silicone will often find its way into landfills when recycled by consumers, as it cannot be recycled with the other polymers in the stream. Silicone is not biodegradable, and takes a considerable length of time to break down.

Silicone can be recycled at designated recycling centers, though typically through mechanical means, resulting in a 'downcycled' product. Apart from consumer recycling, overall recycling rates of silicone is expected to steadily increase over the coming decade.

Sources/Further Reading: (Image source - Gosili) (2023 article) (2022 book chapter) (Business Research Insights) (Newtop blog) (1997 book chapter)

#Materials Science#Science#Silicone#Polydimethylsiloxane#Polymers#Recycling#Waste#WasteWednesday#2024Daily

26 notes

·

View notes

Text

Polydimethylsiloxane, the first choice for high-quality cosmetic materials!

As a high-performance material, polydimethylsiloxane is leading the trend of future technology. With its excellent properties and diversified application fields, it has become an indispensable key material in all walks of life. Whether you work in electronics, automotive, cosmetics or other fields, polydimethylsiloxane will bring unlimited innovation to your products.

Polydimethylsiloxane has excellent thermal stability and weatherability, making it ideal for use in the electronics industry. It maintains stability at high temperatures while providing excellent insulation and dielectric resistance. Therefore, polydimethylsiloxane is widely used in the fields of electronic components, optical devices and packaging materials, providing products with reliable protection and excellent performance.

So, is polydimethylsiloxane safe for use in cosmetics?

Dimethicone is widely used in cosmetics as a silicone-based moisturizer, lubricant and emollient. In general, polydimethylsiloxane is considered a relatively safe ingredient, but the following points still need to be noted:

Low Toxicity: Dimethicone has no appreciable toxicity in routine use. However, if the recommended dosage is exceeded or used in an inappropriate manner, it may cause skin irritation or allergic reactions. Therefore, when using cosmetic products, it is advisable to follow the product instructions and do a proper skin test.

Packaging quality: polydimethylsiloxane itself is a stable and non-volatile substance, but if the packaging of cosmetics is not up to standard or the storage conditions are improper, polydimethylsiloxane may be oxidized or polluted. Therefore, choosing a cosmetic brand with a good reputation and reliable quality and storing and using it correctly are important factors to ensure safety.

Adaptability: Everyone's skin type and health is different. Dimethicone may cause skin irritation or sensitivity in some people. If you have special skin problems, it is recommended to consult a professional doctor or dermatologist before using new cosmetics.

All in all, polydimethylsiloxane is generally considered a relatively safe ingredient and has passed multiple safety assessments. However, individual differences and product quality still have an impact on its safety. Therefore, when choosing and using cosmetics, it is recommended to pay attention to product quality, adaptability and follow the manufacturer's instructions to ensure your health and safety. If you have any discomfort or doubts, it is recommended to consult a professional doctor.

Conclusion: Contact us now to explore the innovation journey brought by polydimethylsiloxane! Let polydimethylsiloxane become one of the keys to your success, and create a brilliant future together!

0 notes

Text

Polydimethylsiloxane Market Size, Share, Trends, Global Demand, Growth and Opportunity Analysis

"Global Polydimethylsiloxane Pdms Market document focuses on the efforts toward professional marketers, providing much-needed market research methodologies to the overall marketing processes. This market research report endows with all the crucial information regarding the market which helps to give guidance to a new user to grasp the market intensely. By keeping end users at the centre point, a team of researchers, forecasters, analysts and industry experts work exhaustively to formulate Polydimethylsiloxane Pdms market research report. It is the most appropriate, rational and admirable market research report provided with a devotion and comprehension of business needs.

The analysis of market trends and dynamics is based on several factors in the credible Polydimethylsiloxane Pdms report. These factors can be listed as; supply and demand, current trends/opportunities/challenges, market segments and sub-segments, technological breakthroughs, market size, value chain and stakeholder analysis, competitive landscape. The research and analysis performed in this industry report assists clients to forecast investment in an emerging market, expansion of market share or success of a new product. Global Polydimethylsiloxane Pdms market research report provides a comprehensive study on production capacity, consumption, import and export for all major regions across the world.

Access Full 350 Pages PDF Report @

Polydimethylsiloxane (PDMS) market will grow at a rate of 5.80% for the forecast period of 2021 to 2028. Polydimethylsiloxane (PDMS) market report analyses the growth, which is currently being growing due to rise in the demand from various end- industries.

Countries Studied:

North America (Argentina, Brazil, Canada, Chile, Colombia, Mexico, Peru, United States, Rest of Americas)

Europe (Austria, Belgium, Denmark, Finland, France, Germany, Italy, Netherlands, Norway, Poland, Russia, Spain, Sweden, Switzerland, United Kingdom, Rest of Europe)

Middle-East and Africa (Egypt, Israel, Qatar, Saudi Arabia, South Africa, United Arab Emirates, Rest of MEA)

Asia-Pacific (Australia, Bangladesh, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Sri Lanka, Thailand, Taiwan, Rest of Asia-Pacific)

Objectives of the Report

To carefully analyze and forecast the size of the Polydimethylsiloxane Pdms market by value and volume.

To estimate the market shares of major segments of the Polydimethylsiloxane Pdms

To showcase the development of the Polydimethylsiloxane Pdms market in different parts of the world.

To analyze and study micro-markets in terms of their contributions to the Polydimethylsiloxane Pdms market, their prospects, and individual growth trends.

To offer precise and useful details about factors affecting the growth of the Polydimethylsiloxane Pdms

To provide a meticulous assessment of crucial business strategies used by leading companies operating in the Polydimethylsiloxane Pdms market, which include research and development, collaborations, agreements, partnerships, acquisitions, mergers, new developments, and product launches.

Key questions answered

How feasible is Polydimethylsiloxane Pdms Market for long-term investment?

What are influencing factors driving the demand for Polydimethylsiloxane Pdms near future?

What is the impact analysis of various factors in the Global Polydimethylsiloxane Pdms market growth?

What are the recent trends in the regional market and how successful they are?

Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America

The major players covered in the polydimethylsiloxane (PDMS) market report are Dow., Wacker Chemie AG, KCC CORPORATION., Alfa Aesar, Thermo Fisher Scientific; CHT Group, BRB International b.v., Spectrum Chemical Manufacturing Corp., Siltech Corporation, Wynca Group, Iota Silicone Oil (Anhui) Co., Ltd, Clearco Products Co., Inc., Specialty Silicone Products, Inc., Santa Cruz Biotechnology, Inc., GELEST, INC., Tokyo Chemical Industry Co., Ltd, Merck KGaA, Quzhou Ruilijie Chemical Industry Co., Ltd., Elkay Chemicals Pvt. Ltd., KCC Basildon and ARIHANT SOLVENTS AND CHEMICALS among other domestic and global players. Market share data is available for global, North America, Europe, Asia-Pacific (APAC), Middle East and Africa (MEA) and South America separately. DBMR analysts understand competitive strengths and provide competitive analysis for each competitor separately.

Browse Trending Reports:

Automatic And Smart Pet Feeder Market

Europe Leather Furniture Market

Nail Gun Market

Networked Audio Products Market

Canada Leather Furniture Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 888 387 2818

UK: +44 208 089 1725

Hong Kong: +852 8192 7475

Email: [email protected]

"

0 notes

Text

Polydimethylsiloxane (PDMS) Market will Witness Huge Growth till 2028

Polydimethylsiloxane (PDMS) Market research report serves as one of the best medium to help startups in business planning. It brings all the relevant data, which provides insights into consumers’ buying nature, location and thinking pattern. Keeping an eye on which actions are followed by the competitors and their future business plans for the estimation period 2022-2028 is easy by referring this report. Monitoring present and upcoming market trends is possible with this Polydimethylsiloxane (PDMS) Market report. High-quality and effective market research report has the potent to minimize business risks which can create problems in making marketing related decision.

Download Sample Report PDF (Including all Table & Figures), here –

Polydimethylsiloxane (PDMS) Market report guides how, when and where to expand the business by making right investment. Potential competitors are identified here along with allow business players to increase the product portfolio. Customers’ wants and a clear view on future business growth are provided in this Polydimethylsiloxane (PDMS) Market study report. Right investment in the product development has great importance in the increase of product sales. It also allows attaining the comprehensive understanding of how customers perceive products. It also reveals how their requirements are shaped as well as influenced and how they choose the product launch on the basis of them. Novel product launch ideas provided here work as the perfect guide for the key participants to augment the product sales.

Key Players

Key players mentioned in the report are as follows -

DuPont de Nemours, Inc.

Shin-Etsu Chemical Co., Ltd.

Wacker Chemie AG

Avantor, Inc.

Elkem ASA

KCC Corporation

Dongyue Group Limited

Alfa Aesar

CHT Group

Growth drivers and Market Value:

This report, from Stratview Research, studies the Polydimethylsiloxane (PDMS) Market value and growth drivers over the trend period of 2022-27. According to the report -

Polydimethylsiloxane (PDMS) market is likely to witness a healthy CAGR of 5.6% during the forecast period. The factor contributing to the high growth of the polydimethylsiloxane (PDMS) market is mainly the organic growth of various end-industries, especially industrial process and household & personal care, where the usage of polydimethylsiloxane is rapidly increasing due to its exceptional properties such as durability, dielectricity, adhesion, and foam control.

Segment Analysis:

Based on Form Type:

Based on the form type, the PDMS market is segmented as elastomers, fluids, resins, and others. The elastomer segment dominates the market, owing to its wider industrial applications such as personal care products, medical devices, microfluidic devices, and others.

Based on Region:

In terms of regions, Asia-Pacific is expected to be the dominant region in the market in the coming five years. Asia-Pacific region is the largest market for industrial process, building & constructions, and electrical & electronics, etc. thus, creating high demand for PDMS in the region. Rapid industrialization and urbanization in the developing countries such as India and China are likely to boost the demand for PDMS in the region during the forecast period.

Know more about the report, click here

Polydimethylsiloxane (PDMS) Market research report also has the potent to bring overlooked and abandoned consumers back into focus by covering all the important market and customer data. It further assists to raise the business success rates. It spots out consumer requirements and augments the future engagements of the firm with them. Important findings are covered in this Polydimethylsiloxane (PDMS) Market study report to help newly emerging industry players to establish their business in the cut-throat market. Studying customer behavior is significant as it assists them factors that can change customers’ buying decision making. By having complete understanding of how customers decide on particular product or service launch, central participants are able to spot out the products and fill in the gap which are required and the products that are outdated. This Polydimethylsiloxane (PDMS) Market report permits novice players to have best understanding regarding target market and create products, which are going to fascinate novel customers, sell and develop brand loyalty. Engaging customers is one of the leading factors to attain precise and actionable insights, which drive the rapid product development. All the customer related factors including their motivations, inclinations and buying nature are all covered here.

About us –

Stratview Research is a global market research firm that offers reliable market reports, market entry strategies, strategic growth consulting, and more. The market experts compile high-quality market information to help users obtain granular level clarity on current business trends and expected future developments. Stratview Research also offers customisation of the reports. Reach out to the analysts to customize the given report according to your priority/requirement.

Stratview Research has also launched Composights, an online portal that offers free thought leadership reports, whitepapers, market report synopsis, and much more for Composites and allied industries, worth US$ 20,000 every year.

Click here to sign up (No costs involved): https://www.stratviewresearch.com/composights/sign-in

Connect with the team at –

Stratview Research

E-mail: [email protected]

Direct: +1-313-307-4176

0 notes

Text

Polydimethylsiloxane (PDMS) Market Competitive Insights and Precise Outlook 2021-2026

The polydimethylsiloxane (PDMS) market study also lists certain market-impacting variables and domestic regulatory changes that have an impact on the Polydimethylsiloxane (PDMS) Market present and future developments. Some of the key data points used to estimate the market situation for specific nations are consumption volumes, production sites and volumes, import export analysis, price trend analysis, cost of raw materials, and upstream and downstream value chain analysis. When giving prediction analysis of the country data, it also takes into account the presence and accessibility of international brands, the difficulties they encounter owing to strong or weak competition from local and domestic brands, the influence of domestic tariffs, and trade routes.

Read more @ https://creativeedge16.blogspot.com/2022/08/polydimethylsiloxane-pdms-market-latest.html

#Polydimethylsiloxane (PDMS)#Polydimethylsiloxane (PDMS) Market#Polydimethylsiloxane (PDMS) Market Growth#Bulk Chemicals#Coherent Market Insights

0 notes

Text

ingredients: popcorn, partially hydrogenated soybean oil, beta carotene, tertiary butylhydroquinone, polydimethylsiloxane, and buttery flavoring

55 notes

·

View notes

Text

tagged by @milfcutlawquane

rules: tag people who you want to get to know better

relationship status: single, my lifegoal is to keep it that way

favorite color: yellow, deep purple, light blue and dark green

three favorite foods: meatballs with mashed potatoes, roasted reindeer and salmon soup

song stuck in my head: second chances by imagine dragons, with chasing cars cover by sleeping at last in the background lol

last song i listened to: mystery of love by sufjan stevens

last thing i googled: kinetic sand, i wanted to know how it was made (it’s made of fine sand and polydimethylsiloxane)

time: 11.31

dreamtrip: just came from the capital and decided that i’m never travelling again, but i really wanna go to ylläs

anything i really want right now: exchange birthday gifts with my friend and go to mcdonalds

no pressure tags!!: @cdrfox @pecera-de-mariposas

4 notes

·

View notes

Text

The result of the material analysis of Sammy's mystery rubber-like thing is in, and it's mostly made of silicone rubber based on polydimethylsiloxane (aka dimethicone) with a tiny bit of metal soap (they gave calcium stearate as an example, but I think it could be any metal soap).

I tried to google all of these terms, but not a whole lot came up with the combination, so I'm still rather stumped about what object(s) he could have eaten, how often he did or how long ago that was.

The best result was cable sheathing from medical equipment, but that seems rather unlikely? 😅 At least we can rule out something organic, which is a start.

Will do some more research in any case, but if anyone happens to have an idea please let me know!

2 notes

·

View notes

Text

[PDF] Chemistry, Texture, and Flavor of Soy Keith R. Cadwallader and Sam K. C. Chang (Eds.)

Content: PREFACE ; DEDICATION ; INTRODUC...

https://pdfelite.com/product/pdf-chemistry-texture-and-flavor-of-soy-keith-r-cadwallader-and-sam-k-c-chang-eds/?feed_id=3498&_unique_id=662d2bf1288df

0 notes

Text

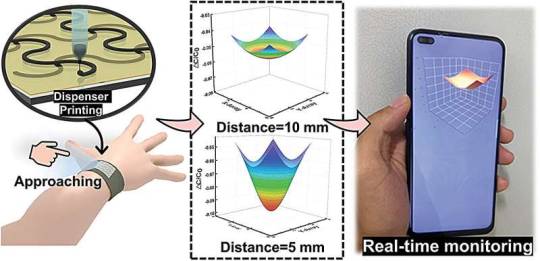

Researchers develop non-contact touch sensors for robotics

A radical new type of touch sensor for robotics and other bio-mimicking (bionic) applications is so sensitive it works even without direct contact between the sensor and the objects being detected. It senses interference in the electric field between an object and the sensor, at up to 100 millimeters from the object.

The researchers at Qingdao University in China, with collaborators elsewhere in China and South Korea, describe their innovation in the journal Science and Technology of Advanced Materials.

Electronic skins have become a crucial element in bionic robots, allowing them to detect and react to external stimuli promptly. This can allow robotic systems to analyze an object's shape, and, if required, also to pick it up and manipulate it.

Read more.

#Materials Science#Science#Robotics#Sensors#Biomimicry#Dielectric#Carbon nitride#Polydimethylsiloxane#Polymers#Carbon#Nitrides#Composites

15 notes

·

View notes

Text

Instructions for use of Silanol-terminated polydimethylsiloxane

Silanol-terminated polydimethylsiloxane is a commonly used organosilicon compound with many applications. Here are the instructions for its use:

Solubility: Silanol-terminated polydimethylsiloxanes are usually colorless to pale yellow liquids with good solubility. It can be dissolved in many organic solvents, such as toluene, ether and acetone, etc. An appropriate solvent can be selected according to specific needs.

End-capping reactions: Silanol-terminated polydimethylsiloxanes can be end-capped by reacting with silanols such as methylsilanol. This capping reaction can be accomplished by adding a small molecule silanol capping agent, usually in excess.

Surface treatment agent: Silanol-terminated

polydimethylsiloxane can be used as a surface treatment agent to improve surface properties and interfacial wetting. It can provide ultra-low surface tension and enable it to form a uniform coating on the surface of many materials (such as glass, ceramics, metals, etc.).

Release Agents: Silanol-terminated polydimethylsiloxanes can be used as mold release agents to prevent sticking and sticking. It can be applied to the mold surface of rubber, plastic, composite materials, etc., so that there is good separation between the mold and the product.

Functional additives: Silanol-terminated polydimethylsiloxanes can also be used as functional additives to improve the performance of coatings, adhesives, sealants, etc. It can increase the weatherability, chemical resistance and stain resistance of coatings.

It is important to note the following when using silanol-terminated polydimethylsiloxanes:

Safe Handling: Always wear appropriate personal protective equipment such as chemical resistant gloves, safety glasses, and face shield when handling and handling silanol-terminated polydimethylsiloxane. Avoid contact with skin and eyes.

Ventilated environment: When handling silanol-terminated polydimethylsiloxane, make sure to do so in a well-ventilated environment to ensure adequate air movement. Avoid inhalation of VOC gases produced.

Avoid mixing reactions: Silanol-terminated polydimethylsiloxane should be stored separately from acids, alkalis, oxidants and other substances during storage and use to avoid unnecessary chemical reactions and dangers.

Temperature control: During the heating process, the temperature should be carefully controlled to avoid excessively high temperatures that could cause violent reactions or release of vapors.

Fire Extinguishing Measures: In case of fire, use appropriate extinguishing equipment such as carbon dioxide, foam or dry chemical. Avoid using water for fire extinguishing as silanol-terminated polydimethylsiloxanes may not be compatible with water.

Storage Note: When storing silanol-terminated polydimethylsiloxane, it should be sealed and stored in a cool, dry and well-ventilated place. Keep away from fire and high temperature environment.

Detailed understanding: Before use, please read the product manual, safety data sheet and related technical documents in detail to understand its nature, use, safety precautions and emergency treatment methods.

Please note that the information provided above is for reference only. Please perform specific operations according to the actual situation and the product manufacturer's recommendations, and follow relevant safety regulations, laws and regulations.

0 notes

Text

Soft Support Can Make Unexpectedly Stable Glass - Technology Org

New Post has been published on https://thedigitalinsider.com/soft-support-can-make-unexpectedly-stable-glass-technology-org/

Soft Support Can Make Unexpectedly Stable Glass - Technology Org

A team of researchers from Penn and the Brookhaven National Laboratory find a new way to manufacture stable glass.

Glasses are ubiquitous materials found in building materials, beverage containers, soft electronics, and mobile phone screens. A process known as aging creates naturally dense and rigid glass. It involves a slow transformation that can take place over millennia to hundreds of millions of years and is marked by the gradual densification and rigidification of a liquid-cooled below its melting point.

Illustration by Nathi Magubane/University of Pennsylvania

However, in 2007 researchers found that stable glasses can also be produced by condensing the material from the vapor phase, using a process called physical vapor deposition. Vapor deposition allows molecules that have just arrived at the surface to pack better, producing better-aged glasses.

Now, a team of researchers led by Zahra Fakhraai of the University of Pennsylvania’s School of Arts & Sciences, in collaboration with scientists at the Brookhaven National Laboratory, have discovered a method to further expedite this aging process, redefining the fundamental principles that have guided the formation of stable glass. Their findings were published in the journal Nature Materials.

“What we discovered, rather paradoxically, is that, by using a soft, more flexible substrate during our vapor deposition process, we can make more rigid and denser glasses than previously made,” Fakhraai says. “These findings offer a new way to precisely engineer glass films and pave the way for making durable materials much faster.”

The discovery came about serendipitously when Peng Luo, a postdoctoral researcher in the Fakhraai Group, was encouraged to experiment with soft substrates for glass deposition, primarily as a curiosity, “to see if softer substrates would cause damage to the material,” he says. “But what we saw was glass that exhibited properties as if it aged for many millions of years, far exceeding what can be seen on methods using traditional rigid substrates.”

Luo explains that prior studies used deposition rate and substrate temperature to control the assembly of the surface molecules after they land on the substrate. At appropriate temperatures, the slower the rate of deposition, the more time the landed molecules will have to adjust themselves towards a more stable structure before they become buried and “frozen” by the incoming molecules.

“It’s basically a “self-assembly” of the surface molecules in a way determined by their own mobility at a certain temperature, and we don’t have all that much control over how slow we can deposit,” he says. “Our finding that a soft substrate can make the deposited glass film denser indicates that substrate elasticity can affect the assembly process of the surface molecules, and, therefore, this can be used as a new dimension to control the structure and properties of glass films in a much larger range which was not accessible before.”

By deploying soft substrates such as polydimethylsiloxane, the team showed that it is possible to significantly accelerate stable glass formation, crafting a material with a 2-2.5% higher density than conventional liquid-quenched glasses and as much as 1% larger than any other reported stable glass.

Luo adds that another noteworthy finding is that the molecule they deposited is only a nanometer in length; however, during deposition the surface equilibrium processes can be affected by the soft substrate over a considerable distance, measured to be about 200 nanometers. This distance is notable because it far exceeds what would be expected based on current glass theories, presenting a challenge to existing understanding.

“This effect can be likened to playing a game of telephone in an auditorium packed with 200 people but somehow, quite mysteriously, the message is communicated perfectly without disruption” Fakhraai says. “The soft substrate’s influence over such a large distance suggests a form of long-range communication or interaction on the surface, which is not fully understood and something we’re interested in exploring in future research.”

Source: University of Pennsylvania

You can offer your link to a page which is relevant to the topic of this post.

#advanced materials#aging#amp#Arts#Brookhaven National Laboratory#Building#challenge#Chemistry & materials science news#Classical physics news#Collaboration#communication#Containers#curiosity#disruption#Electronics#Engineer#form#Fundamental#Fundamental physics news#Future#game#glass#how#illustration#interaction#it#LED#Link#liquid#material

0 notes

Text

Black TiO2-infused polydimethylsiloxane composites for efficient solar-assisted water evaporation and thermoelectric ... - ScienceDirect.com

http://dlvr.it/T3rvnF

0 notes

Text

Hydraulic fluids, anti-foaming agents, and lubricants all use Polydimethylsiloxane (PDMS)

A class of polymeric organosilicon compounds known as silicones includes polydimethylsiloxane (PDMS), usually referred to as dimethylpolysiloxane or dimethicone. Due to its adaptability and numerous applications, PDMS is the most popular silicon-based organic polymer. It is renowned in particular for having peculiar rheological (or flow) characteristics.

Polydimethylsiloxane (PDMS) Market is optically clear, inert, non-toxic, and non-flammable in general. It belongs to a variety of silicone oils (polymerized siloxane). It is used in a variety of products, including elastomers, medical equipment, contact lenses, shampoos (because it makes hair lustrous and slippery), food (as an antifoaming ingredient), caulk, lubricants, and heat-resistant tiles.

Read more @ https://influentialblogging.blogspot.com/2022/07/polydimethylsiloxane-pdms-is-used-in.html

#Polydimethylsiloxane (PDMS)#Polydimethylsiloxane (PDMS) Market#Polydimethylsiloxane (PDMS) Market Demand#Bulk Chemicals#Coherent Market Insights

0 notes

Text

0 notes