#WasteWednesday

Text

Slag

A general term for the waste produced during smelting, slag mainly consists of oxides, though the exact composition depends on the metals and minerals being processed. Essentially, during smelting, two things are produced: the target metal/alloy, and its slag. It is typically classified into one of three categories: ferrous (containing iron/generated during iron or steel production); ferroalloy (generated during ferroalloy production); or non-ferrous (essentially, all other smelting processes). Slag is generally disposed of in a solid form in slag dumps, where they can potentially leach toxic or heavy metals into nearby soil and groundwater. The push to recycle slag, or find applications for it, has therefore been increasing in recent years.

Sources/Further Reading: (Images - Wikipedia) (ASMS) (USGS) (2021 book chapter) (2021 article) (2017 article)

34 notes

·

View notes

Text

E-Waste Disposal Practices

Estimates put the amount of electronic waste produced annually at around 50-60 million tons, a number that continues to increase. While this is only a small percentage of the total waste produced around the world, the toxic components that can be found in electronic waste can have a disproportionate effect on the environment. Some electronics, like batteries, are prohibited from being disposed of by consumers in the general waste stream (in some countries, at least), but not all electronics have such restrictions. When disposal is used, e-waste typically winds up in landfills or incinerators, both of which can release harmful chemicals to the environment.

With disposal discarded as an option, there are three general remaining scenarios: reuse, refurbishment, or recycling. For the general consumer, the specifics of the more sustainable methods are often irrelevant; individuals need only find a company that collects e-waste. However, research should be done to determine the end location for the waste, as some collection agencies simply ship the waste off to other countries for disposal. (There is also the question of wiping electronics which can contain personal information, but that is a topic for a different forum.)

Sources/Further Reading: (Image source - Earth.org) (EPA) (EPA - Used batteries) (Safety Culture) (EcoWatch) (WHO)

21 notes

·

View notes

Text

The Composition of E-Waste

Electronic waste, also known as e-waste, is made up of a wide variety of different materials. The category of waste can include everything from toys and consumer electronics to medical equipment to telecommunications equipment, all of which have differing amounts of nearly every type of common materials (plastics/polymers, glass, metals, ceramics, semiconductors, etc.). By weight, iron, plastics, aluminum, and copper make up the majority of many e-waste materials. Looking at value, though, precious and scarce metals make up most of the cost (such as gold, silver, and palladium, or selenium, tantalum, and germanium).

Beyond that, many forms of electronic waste contain toxic or hazardous chemical such as arsenic, lead, mercury, or chromium:

Batteries and cathode ray tubes often contain lead

Mercury can be found in thermostats and sensors, in gas discharge lamps and many printed circuit boards (PCBs)

Liquid crystal displays and printer inks and toners should be treated separately and chlorofluorocarbons, hydrochlorofluorocarbons, and hydrofluorocarbons can be found in electronics such as refrigerators with insulating foams

To give an example for all these facts, let's look at mobile/cell phones:

Phones are said to contain ~40 different elements

Of the most common materials by weight, phones are ~43% plastic, 7% iron, 3% aluminum, and 13% copper

Looking at precious metals, phones are ~3000ppm silver, 320ppm gold, and 120ppm palladium (approximated as over 90% of the value of the phone in terms of raw materials)

Rare earth metals can be found in many places in a phone, include the screen, circuitry, and speakers. Vibrating cell phones are usually thanks to neodymium, dysprosium, and/or praseodymium.

Phone batteries are typically lithium-ion but older phones especially can have nickel-metal-hydride or nickel-cadmium batteries

The plastic casing is typically polycarbonate and/or acrylonitrile butadiene styrene

Chargers are mostly copper and plastic, but can contain flame retardants that can include gold, cadmium, or bromine

Sources/Further Reading: (Image source - 2018 article) (2014 article) (2013 article) (ACS) (CompoundChem) (WEForum)

26 notes

·

View notes

Text

Iron and Steel Recycling

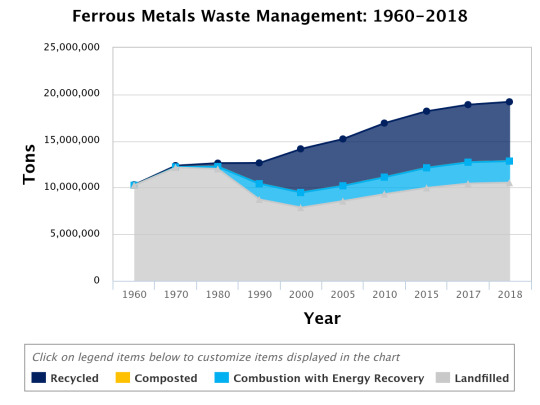

As with most other metals, ferrous metals (irons and steels) are considered to be infinitely recyclable. They are also often considered to be the most recycled materials on Earth. Most iron or steel produced today uses some degree of scrap iron or steel, and estimates from 2019 put the US recycling rate at around 70%, with different industries recycling at different rates. The automotive industry, in particular, has a very high rate of recycling for ferrous metals.

Sources/Further Reading: (Image source - EPA) (AISI) (USGS) (ISRI) (Recycling.com)

20 notes

·

View notes

Text

Silicone Recycling

While consumer silicone products are often selected to replace single-use plastics, reducing the amount of waste generated overall, they too eventually must be disposed of - so what happens to the waste? Although silicone is a polymer, it has a silicon, oxygen based backbone, not carbon based like most polymers and plastics known. As such, silicone will often find its way into landfills when recycled by consumers, as it cannot be recycled with the other polymers in the stream. Silicone is not biodegradable, and takes a considerable length of time to break down.

Silicone can be recycled at designated recycling centers, though typically through mechanical means, resulting in a 'downcycled' product. Apart from consumer recycling, overall recycling rates of silicone is expected to steadily increase over the coming decade.

Sources/Further Reading: (Image source - Gosili) (2023 article) (2022 book chapter) (Business Research Insights) (Newtop blog) (1997 book chapter)

#Materials Science#Science#Silicone#Polydimethylsiloxane#Polymers#Recycling#Waste#WasteWednesday#2024Daily

26 notes

·

View notes

Text

E-Waste Recycling

Recycling of e-waste is complicated due to the many different components and materials that can be found in a single product. Recycling typically proceeds through the following steps: manual sorting, examination for reusable components, disassembling, shredding, and then separation. Ferromagnetic materials/metals can be separated through the use of large magnets, followed by eddy current separation to extract the paramagnetic materials/metals. The remaining non-magnetic materials are often separated by submerging in water and separating out by density (glass, which doesn't float; plastic which does).

Statistics from 2019 indicate that less than 20% of e-waste was recycled globally. This is not helped by the complications that can arise during disassembling, such as with cell phones whose batteries are no longer designed to be removed and the risks of exposing workers to toxic chemicals. Difficulties also arise in recycling metals through mechanical means, as is typically done. Less than 20% of the elements found in electronics are estimated to be capable of recycling through mechanical means.

Sources/Further Reading: (Image source - EPA) (Earth.org) (EcoWatch) (2016 article) (Wikipedia)

13 notes

·

View notes

Text

Red Mud

The primary source of alumina, and, after further processing, aluminum, is the ore bauxite*. The main technique used to refine bauxite into alumina is known as the Bayer process, developed by Carl Josef Bayer, from Austria-Hungary, in 1888.

While the Bayer process is crucial in the aluminum supply chain today, it also generates what is known as red mud, or bauxite reside, a substance with a high pH, toxic heavy metals, and, often, radioactive elements or compounds. The disposal of this industrial waste product is therefore of high environmental concern. Many safety incidents have been documented regarding the storage and disposal of red mud, the worst of which is often cited as the Ajka alumina plant accident in western Hungary in 2010. The red mud in this incident was stored as liquid waste in reservoirs; when a dam collapsed in one of the reservoirs, the waste flooded nearby areas, including towns, killing several and injuring scores more.

Attempts have been made over the decades to safely dispose of or use the red mud, the former including various neutralization methods and the latter including raw materials recovery (primarily iron, but also titanium and rare earth elements), but large scale processing has yet to be proven economically viable. Several million tons are estimated to be used annually, but this number must be contrasted with the fact that the global stock of red mud, as of 2020, was known to be greater than 5 billion tons.

Sources/Further Reading: (Image source - 2021 review article) (2019 article) (2012 article) (2020 Science.org news article) (1976 US EPA report) (2016 Aluminum Insider article) (Wikipedia)

*Fun fact: bauxite is also the primary source of gallium.

#Materials Science#Science#2024Daily#Waste#WasteWednesday#Aluminum#Processing#Red mud#Bauxite#Safety#Toxicity#Environment#Recycling

21 notes

·

View notes

Text

Cyanide Waste from Gold Production

Because gold is a fairly non-reactive metal, it can be difficult to separate from the other substances in the ores it is found in. One method of gold production involves cyanide leaching. Cyanide is a highly toxic chemical, and safety issues concerning its use, storage, and disposal are thus of concern in the gold industry. It has been estimated that over half of all gold mines use cyanide. While alternatives to cyanide have been suggested, many of these are also toxic.

Sources/Further Reading: (Image source - Earthworks) (EU) (NIH)

14 notes

·

View notes

Text

Polyvinyl Chloride Recycling

Also written poly(vinyl chloride) or abbreviated as PVC, polyvinyl chloride is a popular polymeric material and one of the oldest synthetic polymers. The chlorine in its composition typically comes from rock salt, making it greener than those polymers which are derived almost entirely from petrochemicals. However, the vast amounts of PVC that are produced make it important to pay attention to the waste streams of this material - and the hazards that may come along with it.

Older PVC products, now ready for recycling, often contain additives that have since been banned, including lead and phthalates. In addition, the chlorine in the PVC itself can be hazardous during some recycling methods such as thermal recycling, which separates chlorine from the resulting hydrocarbons. These challenges mean that PVC must be separated from other plastics before recycling, and sometimes must even be sorted within the category of PVC as additives can significantly change the properties of the base polymer.

Sources/Further Reading: (Image source - 2022 article) (Baker Institute) (2021 article) (Health Care Without Harm Europe) (EcoMENA)

16 notes

·

View notes

Text

Nylon Recycling

A family of synthetic polymers, nylon is made from fossil fuels and primarily used in textiles and other fiber products, such as fishing nets, toothbrushes, carpets, and dental floss. Nylon is not biodegradable and can release toxic gases if incinerated. Nylon recycling is already in place at an industrial level, and some companies these days are using recycled nylon to make their products, though still often mixed with virgin nylon. However, while the impact is significantly lessened than with virgin nylon, the process to recycle nylon still involves notable energy usage and hazardous chemicals. As such, as with other polymers, additional recycling methods are a topic of interest.

Sources/Further Reading: (Image source - Nord Holding) (EERE) (Caring Consumer) (The Guardian) (Impactful Ninja) (Patagonia) (Recycle Nation)

11 notes

·

View notes

Text

Waste Gases from Iron and Steel Production

Not all byproducts produced in manufacturing are solid wastes that need to be disposed of - many processes, including the production of iron and steel, have gaseous byproducts. In the case of the iron and steel industry, they produce massive amounts of carbon dioxide, estimated in 2022 as 8% of global emissions. Historically, carbon monoxide, carbon dioxide, and nitrogen are produced when processing iron, however, carbon monoxide (being toxic) is generally reacted further to convert it to carbon dioxide. The carbon dioxide and nitrogen are then typically allowed to be released into the atmosphere. As with many other waste products in this day and age, research is ongoing to find uses for the excess CO2, as well as reduce the amount produced and find new ways to produce irons and steels.

Sources/Further Reading: (Image source - 2022 article) (2021 article) (Chemistry World) (Max Planck Research) (Clarke Energy)

11 notes

·

View notes

Text

Gold Recycling

Gold applications include jewelry, electronics, and dentistry, with the majority of recycled gold coming from these three groupings. Gold can be recycled continuously without any loss of value, though different chemical treatments are required based on the purity desired and the other elements that may be mixed in with the waste. As such, currently trends are heading toward recycled gold being a larger part of commercial applications - and the recycling of electric waste in particular is expected to increase.

Sources/Further Reading: (Oxford Gold Group) (gold.org) (US Money Reserve) (gold.info) (Anthropocene) (2020 article)

Image source.

8 notes

·

View notes

Text

Tailings

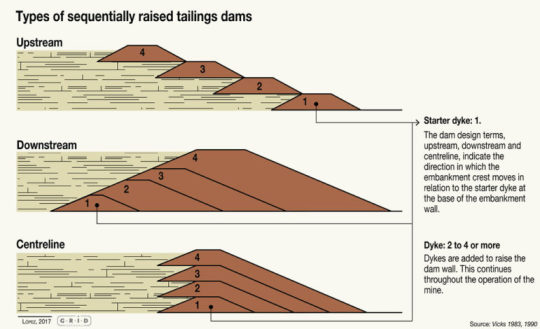

Rather than discuss a specific waste product, as I did in previous weeks, this week's post is on a general waste product known as tailings*. Tailings are the waste material left behind after the target mineral(s) is extracted from an ore and can be in a variety of forms, including solid waste or liquid (often in water), though they are most common in the form of a slurry. Tailings often contain heavy metals and can contain toxic and radioactive materials.

Tailing slurries were (and still are) historically stored in dams, though there is an increasing push to extract further valuable resources from them, thereby reducing tailings waste. Many existing dams are no longer active, though it is estimated that thousands of the dams exist. Significant failures of tailings dams have caused been catastrophic, and are reported to be increasing in severity and frequency.

Sources/Further Reading: (Image 1 - Earthworks) (Image 2 - Mining.com) (SME) (Tailings.info) (Wikipedia)

*Red mud, previously posted about on this blog, is a specific type of tailing given name.

14 notes

·

View notes

Text

Aluminum Recycling

Last week I posted about one waste product involved with the production of aluminum (Red mud) - this week the discussion is on aluminum waste itself. Aluminum is one of the most recycled materials in the world, and has been called 'infinitely recyclable' by some. This refers to the fact that while many recycled goods such as glass or plastics are used to produce "down-cycled" products, aluminum can be recycled into the same product. Estimates say that 70-80% of all the aluminum that has ever been produced is still in use today.

Economically, recycling aluminum is extremely viable; only about 5% of the amount of energy used to produce new aluminum is used in the recycling process. However, while the rates of aluminum recycling among the industries that use it remain strong, consumable recycling, notably aluminum cans, has been decreasing as of late in some countries, including the US. (Other countries, such as Brazil and Germany, have extremely high aluminum can recycling rates, upwards of 98% in recent years.)

Sources/Further Reading: (Image source - 2022 article) (aluminum.org) (BCG) (ACS) (Greentumble) (Rubicon) (Wikipedia)

11 notes

·

View notes

Text

Chromium Recycling

Last week I posted about one waste product involved with the production of chromium (COPR) - this week the discussion is on chromium waste itself. As the vast majority of chromium production goes toward metal alloys, it is metal recycling that has the biggest impact on chromium recycling. The percentage of chromium that gets recycled depends on the alloy and the industry in question. However, based on studies from the late 1980s on the US chromium industry, only around 20% of chromium was recycled.

One industry that still has issues with chromium waste is leather tanning, where hexavalent chromium can be generated if waste is disposed of improperly. The images above come from improper waste disposal in sub Saharan Africa, though of course it is only one such example. In countries without strict regulations against chromium disposal, the tanning industry is considered a major polluter of the environment. Countries such as Australia, China, Spain, and Brazil, among others, have had issues, and thousands of hectares of land in India and Bangledesh has been rendered barren by chromium disposal.

Sources/Further Reading: (Image source - 2020 article) (911 Metallurgist) (NIH) (2011 article) (2020 article) (2013 article)

7 notes

·

View notes

Text

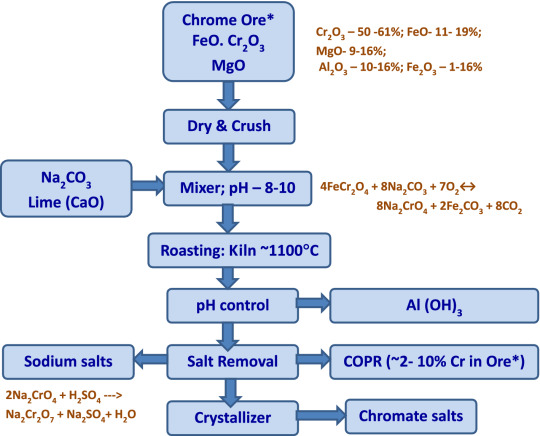

Chromite Ore Processing Residue (COPR)

During the production of chromium, one of the waste products is known as COPR, for chromite ore processing residue. The amount of COPR can vary from process to process, but comes out in the form of a solid mud that still contains some chromium. One form that chromium takes in COPR, at up to 30% of the residue, is known as hexavalent chromium, or Cr(VI).

While it is still used in applications today, hexavalent chromium, in COPR or otherwise, is a toxic substance, and difficult to extract from the residue to be either used or reduced. Historically, storage and disposal of untreated COPR often failed to meet environmental regulations (or predated them), risking leakage into groundwater and soil.

Sources/Further Reading: (Image source - 2021 COPR article) (2015 COPR article) (2014 COPR article) (1991 COPR article) (Maryland COPR disposal sites) (OSHA Cr(VI)) (CDC Cr(VI)) (Wikipedia Cr(VI)) (DCCEEW Cr(VI)) (IMTS 2022 Cr(VI) news article)

6 notes

·

View notes