#Plasticindustry

Text

Discover the superior performance of our Oil Sealed Vacuum Pumps! Engineered for precision and reliability, these pumps are the cornerstone of industrial efficiency.

For more details, visit- https://www.acmeairequipments.com/vacuum-pump-different-types-applications/

#acmeairequipments#vacuumpump#oilsealedvacuumpump#foodindustry#chemicalindustry#plasticindustry#pharmaceuticalindustry#beverageindustry

0 notes

Text

0 notes

Text

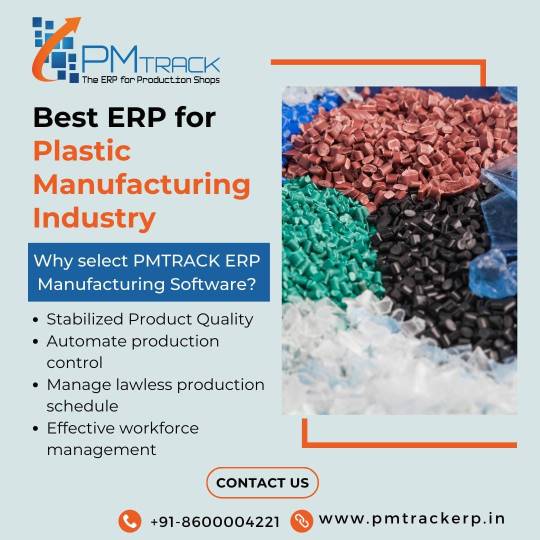

Granules for Plastic Bottles — Exploring the Raw Materials

In the vast landscape of plastic manufacturing, plastic bottles stand as ubiquitous containers that shape our daily lives. These bottles, whether holding water, soda, or cleaning solutions, are an integral part of modern living. Behind their seemingly simple appearance lies a complex world of raw materials, each contributing to the bottle’s composition, strength and sustainability. In this exploration, we delve into the intricate realm of plastic bottles, uncovering the essential raw materials that make them what they are.

Understanding the Basics: PP Raw Material, PET Bottle Raw Material and More

Plastic bottles are predominantly crafted from a variety of raw materials, each lending unique properties to the final product. Polypropylene (PP) raw material, a versatile thermoplastic polymer, is often utilized in the production of bottle caps. Its high melting point, durability and resistance to moisture make it an ideal choice for preserving the contents within. On the other hand, PET (Polyethylene Terephthalate) emerges as a star player in the realm of plastic bottles. PET bottle raw material is renowned for its clarity, lightweight nature and recyclability, making it a sustainable choice for beverage containers.

Plastic Dana and Granules: The Building Blocks

Digging deeper into the manufacturing process, plastic dana and granules emerge as pivotal building blocks. Plastic dana, a semi-finished plastic product, serves as the precursor to various end-products, including bottles. These granules, available in different materials like polypropylene, polyethylene and PVC, undergo meticulous processing to create the final bottle structure. Viztaar Marketplace for Polymers is a revolutionary platform that connects buyers with top-tier suppliers of plastic raw materials, ensuring a seamless procurement process. Explore their insights at https://insights.viztaar.com to stay abreast of the latest trends and market dynamics.

Navigating the Polymer Price Landscape - PP Raw Material Price, Plastic Granules Price and More

The plastic industry, like any other, is influenced by market dynamics that impact material prices. Understanding the price trends of key components like PP raw material, plastic granules and PET bottle raw material is crucial for manufacturers and stakeholders. Viztaar Marketplace provides valuable insights into polypropylene raw material price, plastic raw material price and plastic granules price, enabling informed decision-making. Navigating these price landscapes becomes a strategic move for businesses seeking efficiency and cost-effectiveness.

Embracing Sustainability: HDPE and PVC Granules

Sustainability has become a paramount consideration in the plastic industry. High-Density Polyethylene (HDPE) granules, known for their strength and recyclability, play a role in the evolution towards eco-friendly packaging. PVC granules, although widely used, have faced scrutiny due to environmental concerns, prompting the industry to explore alternative materials. Viztaar Marketplace champions sustainable practices, emphasizing the importance of responsible material choices in the production of plastic bottles.

The Marketplace Advantage: Buy Plastic Granules with Viztaar

For manufacturers seeking to buy plastic granules, Viztaar Marketplace offers a comprehensive platform for seamless transactions. By connecting buyers with reputable suppliers, Viztaar ensures a transparent and efficient procurement process. Whether you’re in search of polypropylene granules, PP granules, or polyethylene granules, the marketplace simplifies the sourcing journey. Navigate the platform with price and technical details at and witness firsthand the convenience of acquiring top-quality plastic raw materials.

Shaping the Future of Plastic Bottles

In conclusion, the journey of plastic bottles from raw materials to the final product is a testament to innovation, sustainability and marketplace efficiency. By exploring the intricacies of PP raw material, PET bottle raw material, plastic dana and granules, we gain a deeper appreciation for the science behind the bottles we encounter daily. Viztaar Marketplace emerges as a key player in this narrative, providing valuable insights and facilitating transactions that shape the trajectory of the plastic industry. As we move towards a future that demands responsible manufacturing practices, Viztaar Marketplace stands at the forefront, steering the industry towards a more sustainable and efficient tomorrow.

#PlasticIndustry #RawMaterials #Sustainability #ViztaarMarketplace #PlasticBottles

#PlasticIndustry#RawMaterials#Sustainability#ViztaarMarketplace#PlasticBottles#bulkbuying#industrialsupplies#bulkmaterials#b2binnovation#industrialmaterials#qualityassured#reliablesourcing#sellerbenefits#viztaar#optimizedpurchases

0 notes

Text

Boost Your Plastic Industry Business!!!

The plastic manufacturing process is not a single process. There are different types of plastics, each has a unique manufacturing process.

The six main types are:

Polyethylene Terephthalate.

High Density Polyethylene.

Polyvinyl Chloride.

Low Density Polyethylene.

Polypropylene.

Polystyrene or Styrofoam.

The plastic manufacturing process needs to be continually reviewed, impacting the bills of materials that determine the final product.

ERP can help streamline the plastic manufacturing process in several ways:

Streamline business processes.

Improve operational efficiency.

Automate quality assurance and production control & more.

Acumatica Cloud ERP is a centralized method for managing all aspects of plastic manufacturing processes: https://bit.ly/47xpsT8

#tayanasolutions#billofmaterial#plasticindustry#ai#tech#finance#products#employees#team#quality#hr#workflows#procurement#operations

0 notes

Text

Maximizing Efficiency with Purging Compounds in Injection Molding

Introduction to Purging Compounds in Injection Molding

Discover the crucial role purging compounds play in the plastic industry, specifically in injection molding. These compounds serve as a vital component to clean injection molding machines, eliminating any lingering plastic residue post-production.

Benefits of Purging Compounds in Injection Molding

Residue Removal for Enhanced Quality: Purging compounds effectively eliminate resin residue from injection molding machines, ensuring cleanliness and readiness for subsequent production runs. This prevents defects in final products, minimizing waste and maintaining high-quality production standards.

Equipment Maintenance Assurance: Purging compounds aid in equipment maintenance by preventing resin buildup that could lead to machine damage. This proactive approach reduces the risk of costly repairs and downtime, ultimately extending equipment lifespan and decreasing maintenance costs.

Enhancing Production Efficiency: The use of purging compounds streamlines the cleaning and maintenance processes, reducing downtime and allowing for increased production time and output. This translates to heightened overall production efficiency, contributing to greater profitability for businesses.

Selecting the Right Purging Compound

When choosing a purging compound for injection molding, it's crucial to align the selection with specific requirements. The best purging compound manufacturers, such as Novanative, provide cost-effective, high-quality, and efficient solutions. Novanative's extensive product range, including Ultra Purge and Lusin Clean from Chemtrend, caters to various applications in plastic processing.

Partnering with Novanative for Optimal Results

Novanative, a trusted purging compound provider in the plastic industry, offers an intuitive website interface. It allows easy navigation to find the most suitable products for your enterprise. Avail of free samples to test the effectiveness of their purging compounds firsthand. Ensure the chosen purging compound aligns with the materials used, prioritizing non-toxic and non-abrasive options.

Conclusion: Elevating Plastic Industry Performance

Embracing purging compounds in injection molding processes delivers multifaceted advantages, enhancing efficiency and productivity. Collaborating with a reliable provider like Novanative ensures access to top-tier products tailored to specific needs. This strategic partnership not only boosts profitability but also contributes to long-term success in the dynamic plastic industry landscape.

#ultrapurge#chemtrend#extruders#injectionmolding#machinemaintenance#plasticindustry#novanative#industrialchemicals#thermoplasticmoldingmachines#delhi

0 notes

Text

#colormasterbatch#colorcoating#color#polymer#polymerscience#chemical#plasticindustry#plasticmanufacturing#colormasterbatchmarketreport#colormasterbatchmarketresearch#colormasterbatchmarketsize#grandresearchstore

0 notes

Text

Unlocking the Versatility of Calcium Carbonate: A Comprehensive Guide to Its Multifaceted Uses

Calcium carbonate, a ubiquitous mineral found in nature, is more than just an essential component of shells and coral reefs. Its versatility extends into various industries, enriching products and processes.

In this guide, we will unravel the potential and multifaceted uses of calcium carbonate, exploring its presence in plastic, paint, talc powder, electrical cables, powder coating, agricultural practices, and animal feed.

Let's delve into this mineral's vast realm and understand how it influences different sectors.

1. Introduction to Calcium Carbonate

Understanding Calcium Carbonate and Its Forms

Calcium carbonate, represented by the chemical formula CaCO3, is a naturally occurring mineral abundantly found in the Earth's crust. It appears in various forms such as limestone, chalk, and marble. This mineral is not only a fundamental element in geological formations but has a significant presence in industries due to its unique chemical and physical properties.

2. Versatility of Calcium Carbonate

Calcium carbonate's versatility is showcased by its extensive applications across multiple industries. Let's explore its adaptability and contributions.

Calcium Carbonate in Plastic Industries

Calcium carbonate is a game-changer in the plastic industry. Its addition to plastics enhances their strength, durability, and resistance to heat. Moreover, it is a cost-effective way to achieve these properties, making it a preferred choice.

Calcium Carbonate in Paint Industries

In the realm of paints, calcium carbonate for paint industry serves as an extender, contributing to opacity and enhancing the paint's quality. Additionally, it aids in reducing the overall production cost of paints, making it an economically feasible option.

Calcium Carbonate in Talc Powder Industries

When it comes to talc powder production, calcium carbonate is an invaluable component. Its addition enhances the texture, brightness, and smoothness of talc powder, making it ideal for various applications.

Calcium Carbonate in Electrical Cable and Powder Coating Industries

The electrical cable and powder coating industries benefit from calcium carbonate's unique properties. It is used as a coating material, enhancing electrical insulation in cables and providing protective coatings in powder coating processes.

Calcium Carbonate in Agricultural and Animal Feed

In the agricultural sector, calcium carbonate finds its application as a soil conditioner and pH regulator, improving crop yields. Furthermore, it's an essential additive in animal feed, promoting bone health and overall growth.

3. Types and Variations of Calcium Carbonate

Calcium carbonate comes in various types and forms, each with distinct characteristics and applications.

Ground Calcium Carbonate

Ground calcium carbonate is the most common form, finely ground to various mesh sizes. It is utilized in a multitude of industries, including plastics, paints, and agriculture, owing to its ease of incorporation and effectiveness.

Coated Calcium Carbonate Powder

Coated calcium carbonate powder for electrical cable industries is engineered to have a controlled surface coating, enhancing its compatibility with specific applications like electrical cables and powder coatings. This modification tailors its properties to meet industry demands.

Natural Calcium Carbonate

Natural calcium carbonate, sourced from limestone and marble, is preferred for its purity and quality. It serves diverse applications, from pharmaceuticals to food and beyond.

Dolomite

Dolomite, a calcium magnesium carbonate mineral, is another variant of calcium carbonate. It offers both calcium and magnesium benefits, making it a desirable choice for various applications.

4. Benefits and Applications of Calcium Carbonate

Enhancing Properties in Various Industries

Calcium carbonate significantly enhances product properties, be it improving the durability of plastic products or the texture of talc powder. Its versatility ensures it plays a crucial role in a multitude of applications.

Cost-Effectiveness and Environmental Friendliness

An appealing aspect of calcium carbonate is its cost-effectiveness. Industries benefit from improved product quality without a hefty price tag. Furthermore, it is environmentally friendly, aligning with sustainability initiatives.

5. Choosing the Right Calcium Carbonate Supplier

Introduction to Arawali Supply Chain Solutions

Arawali Supply Chain Solutions is a trusted name in providing top-notch calcium carbonate products. Their commitment to quality and reliability makes them a preferred choice in the industry.

Factors to Consider in Supplier Selection

When choosing a calcium carbonate supplier, factors like quality, consistency, pricing, and reliability are paramount. Arawali Supply Chain Solutions excels in all these aspects, making them a standout choice.

Ensuring Quality and Reliability

Arawali Supply Chain Solutions ensures the highest quality standards in their calcium carbonate products, meeting industry specifications and client expectations. Their reliability in delivering on time adds to their appeal.

In conclusion, calcium carbonate's versatile nature makes it a fundamental component across various industries. From improving plastic properties to enhancing the texture of talc powder, its uses are manifold. As you explore options for calcium carbonate supply, trust Arawali Supply Chain Solutions for consistent quality and reliability. Make an informed choice and unlock the potential of calcium carbonate for your specific industry needs.

#CalciumCarbonate#VersatileMineral#IndustrialApplications#ArawaliSupply#PlasticIndustry#PaintIndustry#TalcPowder#ElectricalCables#PowderCoating#Agriculture#AnimalFeed#Sustainability#QualityMatters#SupplierChoice#IndustryInsights

0 notes

Text

मत्स्यपालन हौद PVS / HDPE

वैशिष्ट्य :

कमीत कमी जागेत मत्स्यपालन करता येते.

कमी पाण्याचा वापर करून मत्स्यपालन योग्य रित्या यशस्वी करता येऊ शकते.

कमी जागेत जास्त हौद लावून योग्य व्यवसथापन करून कमी जागेत जास्त उत्पादन घेऊ शकतो.

1 ते 2 मनुष्यबळ असेल तरी सुद्धा उत्तम रित्या कामाचे व्यवस्थापन होऊ शकते.

माश्यांना जर कोणता रोग आला असेल तर तो लगेच ओळखून त्यावर पटकन योग्य उपाय करणे शक्य होते आणि होणारे आर्थक नुकसान होण्या पासून वाचवू शकतो.

0 notes

Text

#erpsoftware#clouderp#erp#plastic#molding#plasticindustry#manufacturingsoftware#plasticandrubberindustry#erpsystem#pmtrack#erpsolution

0 notes

Text

Allied Way India - Plastic Water Tank Blow Molding Machine

Allied Way India is recognized as one of the top Plastic Water Tank Blow Moulding Machine Producers, Exporters, and Suppliers in India. It is frequently utilized for Plastic Water Tank Blow Molding. We guarantee that everything is produced in accordance with the established criteria, resulting in no damage for the buyer. Contact us, for more details.

#PlasticWaterTankBlowMoldingMachine#plasticindustry#plastics#watertanks#watertank#agriculturaltank#machinery#engineering#manufacturer#AlliedWayIndia#Faridabad#Haryana#India

0 notes

Text

Blow Molding Resins Market Forecast 2024 to 2032

Blow molding is a manufacturing process used to create hollow plastic objects, such as bottles, containers, and other packaging items. Blow molding resins are materials that are used in this process to produce these plastic products. These resins are selected based on their properties, such as melt flow rate, melt temperature, strength, transparency, and chemical resistance, to meet the specific requirements of the end product.

The Blow Molding Resins Market was valued at USD 3,459.2 Million in 2022 and is expected to register CAGR of 3.95 % by 2032.

Key factors such as increasing demand for blow molding resins across various sectors such as packaging, automotive and transportation, and consumer goods, rapid advancements in resin technology, and growing awareness about importance of sustainable products are expected to drive global market growth during the forecast period.

Get a Free Sample Copy

#BlowMoldingResinsForecast#PlasticPackaging#ResinMarketTrends#PackagingMaterials#PlasticIndustry#PackagingSolutions#ResinForecast#PlasticInnovation#SustainablePackaging#PlasticPackagingMarket#ResinTechnology

0 notes

Text

Oil Sealed Vacuum Pumps find applications across diverse industrial sectors, including vacuum engineering, packaging, paper & printing, rubber, plastics, and more.

For more details, visit- https://www.acmeairequipments.com/product/oil-sealed-vacuum-pump/

#acmeairequipments#oilsealedvacuumpumps#vacuumpump#packagingindustry#paperindustry#PrintingIndustry#rubberindustry#plasticindustry

0 notes

Text

#plastics#plastic#plasticsurgery#engineering#plasticpollution#plasticinjectionmolding#moldmaking#plasticfree#injectionmolding#moldmaker#dprinting#molddesign#tooling#cncmachining#partdesign#automation#plasticindustry#plasticsucks#plasticfreeliving#plasticocean#machineshop#productdevelopment#machinist#plasticpollutes#recycle#toolanddie#medical#instamachinist#environment#cadcam

0 notes

Text

Granules for Plastic Bottles — Exploring the Raw Materials

In the vast landscape of plastic manufacturing, plastic bottles stand as ubiquitous containers that shape our daily lives. These bottles, whether holding water, soda, or cleaning solutions, are an integral part of modern living. Behind their seemingly simple appearance lies a complex world of raw materials, each contributing to the bottle’s composition, strength and sustainability. In this exploration, we delve into the intricate realm of plastic bottles, uncovering the essential raw materials that make them what they are.

Understanding the Basics: PP Raw Material, PET Bottle Raw Material and More

Plastic bottles are predominantly crafted from a variety of raw materials, each lending unique properties to the final product. Polypropylene (PP) raw material, a versatile thermoplastic polymer, is often utilized in the production of bottle caps. Its high melting point, durability and resistance to moisture make it an ideal choice for preserving the contents within. On the other hand, PET (Polyethylene Terephthalate) emerges as a star player in the realm of plastic bottles. PET bottle raw material is renowned for its clarity, lightweight nature and recyclability, making it a sustainable choice for beverage containers.

Plastic Dana and Granules: The Building Blocks

Digging deeper into the manufacturing process, plastic dana and granules emerge as pivotal building blocks. Plastic dana, a semi-finished plastic product, serves as the precursor to various end-products, including bottles. These granules, available in different materials like polypropylene, polyethylene and PVC, undergo meticulous processing to create the final bottle structure. Viztaar Marketplace for Polymers is a revolutionary platform that connects buyers with top-tier suppliers of plastic raw materials, ensuring a seamless procurement process. Explore their insights at https://insights.viztaar.com to stay abreast of the latest trends and market dynamics.

Navigating the Polymer Price Landscape - PP Raw Material Price, Plastic Granules Price and More

The plastic industry, like any other, is influenced by market dynamics that impact material prices. Understanding the price trends of key components like PP raw material, plastic granules and PET bottle raw material is crucial for manufacturers and stakeholders. Viztaar Marketplace provides valuable insights into polypropylene raw material price, plastic raw material price and plastic granules price, enabling informed decision-making. Navigating these price landscapes becomes a strategic move for businesses seeking efficiency and cost-effectiveness.

Embracing Sustainability: HDPE and PVC Granules

Sustainability has become a paramount consideration in the plastic industry. High-Density Polyethylene (HDPE) granules, known for their strength and recyclability, play a role in the evolution towards eco-friendly packaging. PVC granules, although widely used, have faced scrutiny due to environmental concerns, prompting the industry to explore alternative materials. Viztaar Marketplace champions sustainable practices, emphasizing the importance of responsible material choices in the production of plastic bottles.

The Marketplace Advantage: Buy Plastic Granules with Viztaar

For manufacturers seeking to buy plastic granules, Viztaar Marketplace offers a comprehensive platform for seamless transactions. By connecting buyers with reputable suppliers, Viztaar ensures a transparent and efficient procurement process. Whether you’re in search of polypropylene granules, PP granules, or polyethylene granules, the marketplace simplifies the sourcing journey. Navigate the platform with price and technical details at and witness firsthand the convenience of acquiring top-quality plastic raw materials.

Shaping the Future of Plastic Bottles

In conclusion, the journey of plastic bottles from raw materials to the final product is a testament to innovation, sustainability and marketplace efficiency. By exploring the intricacies of PP raw material, PET bottle raw material, plastic dana and granules, we gain a deeper appreciation for the science behind the bottles we encounter daily. Viztaar Marketplace emerges as a key player in this narrative, providing valuable insights and facilitating transactions that shape the trajectory of the plastic industry. As we move towards a future that demands responsible manufacturing practices, Viztaar Marketplace stands at the forefront, steering the industry towards a more sustainable and efficient tomorrow.

#PlasticIndustry #RawMaterials #Sustainability #ViztaarMarketplace #PlasticBottles

0 notes

Text

Manufactured from polyethylene, INDONET separation nets are used for protecting and handling all types of finished or semi-finished mechanical components.

+918046068599

Address:

C1 - B -223, GIDC Industrial Estate, Waghodia, Vadodara, Gujarat 391760

#Indonet#IndonetGroup#industryupdate#sustainableenvironment#nettingsolutions#safenetservices#plasticindustrynews#plasticindustry#nettingindustry#manufacturer

0 notes

Text

Maximizing Equipment Lifespan and Lowering Maintenance Expenses: Exploring the Long-Term Advantages of Purging Compounds in Minimizing Wear, Boosting Reliability, and Extending Machinery Lifetime

Purging compounds play a pivotal role in sustaining production efficiency and minimizing downtime in blow molding manufacturing. Partnering with Ultra Purge, the premier Purging Compounds supplier, can significantly revolutionize and impact your manufacturing processes. Ultra Purge's cutting-edge compounds are meticulously crafted to enhance efficiency and facilitate swift color changes.

By reducing equipment disassembly, cleaning, and reassembly, Ultra Purge effectively saves time and resources. The streamlined operations with Ultra Purge contribute to increased production output and cost-effectiveness. Employing high-quality compounds also decreases scrap material generated during color changes. Thorough cleaning and maintenance with Ultra Purge compounds result in prolonged machinery lifespan and decreased repair costs.

Ultra Purge not only delivers top-notch products but also provides expert support and tailored training for optimal utilization. Guidance on best practices and cleaning methods ensures seamless and efficient operations. Troubleshooting assistance from Ultra Purge minimizes disruptions, ensuring continuous and smooth operations. The consistent quality delivered by Ultra Purge's compounds leads to improved product quality and uniformity, reducing defects and customer complaints.

Ultra Purge stands out with its commitment to environmentally friendly and biodegradable Purging Compounds. By incorporating sustainable practices, Ultra Purge actively contributes to reducing the environmental impact of manufacturing operations. Embracing sustainable solutions not only reduces the carbon footprint but also enhances brand reputation. Collaborating with Ultra Purge results in significant cost savings and improved profitability.

Long-term success and growth are attainable through optimized processes and minimized downtime. Ultra Purge empowers manufacturers to unlock the full potential of their production lines. Choosing Ultra Purge ensures access to high-quality Purging Compounds and comprehensive support for achieving operational excellence.

#ultrapurge#chemtrend#industrialchemicals#injectionmolding#plasticindustry#delhi#novanative#extruders#machinemaintenance#thermoplasticmoldingmachines

0 notes