#vacuumpump

Link

TAEVision 3D Mechanical Design

Parts AutoParts Aftermarket

@msmotorservice MSMotorservice KS Kolbenschmidt GmbH Pierburg

BrakeBooster PowerBrakeBooster VacuumPump

▸ TAEVision Engineering on Pinterest

▸ TAEVision Engineering on Google Photos

Data 188 - Aug 05, 2022

#TAEVision#engineering#3d#mechanicaldesign#parts#autoparts#aftermarket#MSMotorservice#KS Kolbenschmidt#PIERBURG#BrakeBooster#brake booster#power brake booster#PowerBrakeBooster#vacuum pump#VacuumPump

2 notes

·

View notes

Text

Discover the superior performance of our Oil Sealed Vacuum Pumps! Engineered for precision and reliability, these pumps are the cornerstone of industrial efficiency.

For more details, visit- https://www.acmeairequipments.com/vacuum-pump-different-types-applications/

#acmeairequipments#vacuumpump#oilsealedvacuumpump#foodindustry#chemicalindustry#plasticindustry#pharmaceuticalindustry#beverageindustry

0 notes

Video

youtube

Oilles rotary vane vacuum pumps

0 notes

Text

Whitepaper: Leak Detection for Electric Vehicle Battery Production

Electric vehicles are a decisive factor in reducing CO2 emissions in

road traffic. They store the energy required for propulsion in batteries

and an electric motor converts it into motion. If the batteries are

charged with electricity from renewable energy sources, they even

have a completely CO2-free energy balance. Today, lithium-ion

batteries are used almost exclusively as accumulators. Vacuum

technology is indispensable for their production.

This white paper shows how test gas leak detection ensures quality

The proper functioning, quality and safety of lithium-ion batteries, which are

used as accumulators in electric vehicles, depends on their integrity and

impermeability to external influences such as moisture ingress. For this

reason, leak detection systems are used in battery production to check the

batteries. Pfeiffer Vacuum supplies the necessary vacuum solutions from a

single source.

You can download the white paper as a PDF here:

www.pfeiffer-vacuum.com

Read the full article

0 notes

Text

SWAM has continued to grow from its humble beginnings to an international supplier of high quality products. Part of its success is due to the inherited nature of continually improve in every aspect of its business and our mission statement also reflects our focus and drive.

Swam is Asia's one of the largest Blowers, Compressors and Pumps manufacturing company, offers world class products complying to international standards and certifications.

We are known for technology, innovation and excellence has acuired excdptional product design and development capabilities to meet stringent quality and performance requriements and to confirm to the customers tough and diversified specifications. SWAM emphasize on innovative design, precision engineering, advanced technology, excellence in performance and quick response to their customers.

With over 04 decades of experience we have adequately matured to execute different projects and is today represented in over 15 countries. We sees itself as being recognised as a world leader, providing high quality robust products.

For more details, reach out to us at:

#manufacturer#supplier#BioGasBlowers#Compressors#TurboBlowers#ScrewBlowers#TruckBlowers#vacuumpump#blowers#industrialblowers#AirInjection#RotaryPistonBlower#BioGasBlowersmanufacturer#SwamPneumatics#swam#swamatics

0 notes

Text

Diaphragm Vacuum Pump

A diaphragm vacuum pump uses a flexible diaphragm to adjust the volume within a pumping chamber, creating a vacuum on one side while maintaining atmospheric pressure on the other. It operates continuously, without oil, and produces minimal noise, achieving an ultimate vacuum pressure of 0.08 MPa. The pump's PTFE-based design makes it suitable for handling toxic substances, and its non-stick surface prevents the buildup of solid materials and contaminants.

With an evacuation rate of 30 L/min, it provides high-cost performance, reliable quality, and a unique structure tailored to the diverse needs of laboratories, hospitals, and industries. This pump is commonly used for various tasks such as vacuum filtration, distillation under reduced pressure, rotary evaporation, vacuum concentration, and solid-phase extraction.

#vacuumpump, #diaphragmpump, #labmate

0 notes

Text

#vacuumpumps lobepumps vanepumps sumppumps#pump gearbox blowers chemical#dodgegearbox#sulzarpump gearboxrepair#flendergearbox#gardendenver#blowers#gearboxrepair#gearbox#vacuumpump

0 notes

Text

How to use StonyLab Filter Paper?

Filter paper is a common laboratory tool used in chemistry to separate solid particles from a liquid or to purify a liquid by removing impurities. Here are the basic steps for using filter paper in a chemistry lab:

Materials Needed:

Filter paper, https://stonylab.com/collections/filter-paper

Buchner Funnel, https://stonylab.com/collections/buchner-funnel

Erlenmeyer flask or beaker to collect the filtered liquid,

Vacuum Pump, https://stonylab.com/collections/pump

Remember that the choice of filter paper (porosity, diameter, etc.) and the filtration method (gravity, vacuum, or pressure) may vary depending on the specific requirements of your experiment.

Follow the steps shown in video,

contact us at [email protected] for any questions or product recommendations.

#stonylab#labsupplies#chemistrylab#filterpaper#buchnerfunnel#vacuumpump#erlenmeyerflask#liquidfiltration#chemicalfiltration

0 notes

Text

https://www.fristam.in/products/liquid-ring-self-priming-pumps/

0 notes

Text

Vacuum Pump Manufacturers

In the realm of precision engineering, a group of dedicated manufacturers has been at the forefront of vacuum pump technology. With a deep understanding of the intricacies of vacuum applications, these industry leaders have consistently produced cutting-edge solutions. Leveraging advanced research and development, their vacuum pumps cater to a wide range of industries, including manufacturing, electronics, medical, and more. These manufacturers prioritize quality, reliability, and performance, resulting in vacuum pump systems that meet the most demanding requirements.

In a landscape where each industrial process demands unique specifications, these manufacturers excel in providing tailor-made vacuum pump solutions. By collaborating closely with clients, they engineer pumps that align precisely with the application's intricacies. From oil-sealed rotary vane pumps to dry screw pumps, their diverse product portfolios offer solutions that span from basic applications to high-tech processes. With an unwavering commitment to innovation and a dedication to understanding client needs, these manufacturers continue to push the boundaries of vacuum technology.

A core tenet of these vacuum pump manufacturers is their focus on sustainable engineering. Recognizing the importance of minimizing environmental impact, they invest in designing energy-efficient vacuum systems. By integrating advanced technologies such as variable frequency drives and intelligent controls, they optimize energy consumption without compromising performance. This commitment not only benefits their clients by reducing operational costs but also contributes to a greener future by conserving resources and lowering carbon footprints.

With a global outlook, these manufacturers have established a robust network of distribution and support channels. Their reach extends to various corners of the world, ensuring that clients can access their exceptional vacuum pump solutions wherever they are. Beyond providing top-notch products, they offer comprehensive customer support services, including maintenance, training, and troubleshooting assistance. This commitment to ensuring the seamless operation of their vacuum pumps showcases their dedication to long-lasting partnerships and the success of their clients' endeavors.

0 notes

Text

A vacuum chamber is a sealed container that is evacuated of air. This creates a very low-pressure environment, which is ideal for a variety of applications, such as precision manufacturing, research, and testing. These are used to create parts with very tight tolerances, as well as to study the behavior of materials in a vacuum.

0 notes

Text

vacuum pump system for Rubber Machinery

CE Approved

Cost-effective choice to replace the BUSCH R5/RA Series

Factory Price for wholesale #vacuumpump #vacuumpumpsystem #acvacuumpump #rotaryvanepump #electricvacuumpump #oilvacuumpump #betem #betempump #betemvacuum

0 notes

Text

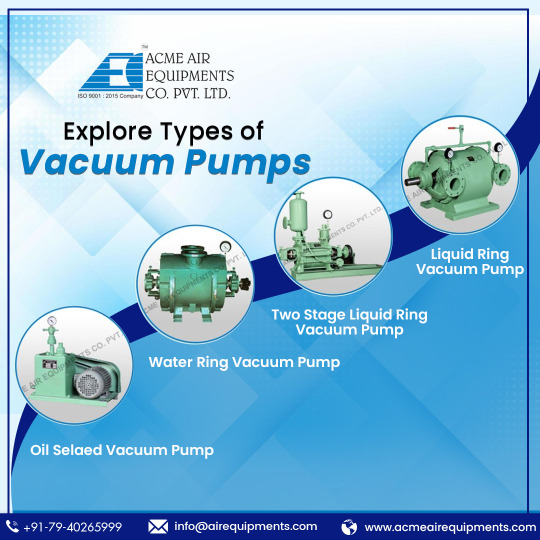

From the Liquid Ring Vacuum Pump to the Two-Stage counterpart, the Water Ring Vacuum Pump to the reliable Oil Sealed Vacuum Pump – each type brings a unique edge to meet your industrial needs. Unleash efficiency with precision-engineered technology.

For more details, visit- https://www.acmeairequipments.com/vacuum-pump-different-types-applications/

0 notes

Video

youtube

SOUZ VACUUM -Roots-liquid ring vacuum system

SOUZ VACUUM offers vacuum system solutions. This means we don’t just ship you a vacuum pump,We work together on each step to create a fully sustainable, custom-fit system. No matter your location, no matter your application, whether it is standardized or customized. SOUZ VACUUM will help you find the solution that is perfect for you and your needs. Liquid ring vacuum pumps are frequently used, in particular in the chemical industry. Besides water, other sealing liquid also can be used as operating medium. In combination with Roots vacuum pumps, vacuum pumping units with high pumping speeds and good ultimate vacuum are thus created. Ultimate pressure: 0.5Pa Liquid ring vacuum pump from SOUZ VACUUM: 1. 2BV monoblock vacuum pump 2. 2BE series big vacuum pump 3. 2SK two stage vacuum pump 4. SK single stage vacuum pump

Welcome to visit our web, www.souzvac.com

Also look forward to hearing you through [email protected]

0 notes

Text

New rotary vane vacuum pump offers energy savings by up to 25%

The new R5 RA 0520 A

The proven R5 RA from Busch now comes in an improved version with a completely redesigned interior. The new vacuum pump is – acc. to an information of the manufacturer – “25 % more energy efficient than its predecessor, thanks to the optimized compression ratio, pump stage dimensions, and oil discharge path.”

It is also available with the company’s variable speed drive, that enables the pumping speed to be adapted to the exact requirements of any process. “As a result, additional energy savings of up to 50 % and a 20 % increase in pumping speed can be achieved. The accessory extends the supply voltage range supported by the vacuum pump, making it suitable for use in almost all countries around the world. This compact and cost-effective solution is also available as a retrofit.”

“Compared to the previous generation, the R5 RA 0520 A has a 20 % smaller footprint, is 25 % lower in height, and the absence of external piping improves leak tightness. The compact and hygienic design features surfaces that repel water and dirt. The total number of spare parts has been reduced by 40 %, making maintenance fast and efficient, with all service-related parts located on one side. Heat emissions have also been decreased through an improved cooling system that combines optimal pump operating temperature with compact construction.”

The new vacuum pump is made for continuous operation in the rough vacuum range with vacuum levels down to 0.1 hPa (mbar). The pumps are suitable for various applications in vacuum packaging, food and plastics processing, and many other industries.

www.buschvacuum.com

Read the full article

0 notes

Text

Swam, a group known for technology, innovation and excellence continues to grow year on year. We believe that quality of our products should speak for us. Practicing innovation and adopting technological upgrades, we are in constant pursuit of excellence.

Our extensive knowledge, experience and expertise give us an edge over competition. We emphasis on innovative design, precision engineering, advanced technology, excellence in performance and quick responsiveness to customers.

For more details, reach out to us at:

#manufacturer#supplier#BioGasBlowers#blowers#industrialblowers#Compressors#TurboBlowers#ScrewBlowers#TruckBlowers#vacuumpump#AirInjection#RotaryPistonBlower#BioGasBlowersmanufacturer#SwamPneumatics#swam#swamatics

1 note

·

View note