#Mining slurry pumps

Text

Mining slurry pumps | Dewatering pump on rent in Tamil Nadu | Power Rental- Book Now.....

Mining slurry pumps | Dewatering pump on rent in Tamil Nadu | Rent submersible pump in India | Power Rental- Book Now.....Mine Dewatering PumpsAt Perennial Technologies Pvt.Ltd., we offer all types of dewatering pumps for mine. Our range of dewatering mining pumps includes pumps like:-Submersible Dewatering Pumps, Underground Mine Dewatering Pumps, Surface Pumps, End Suction Pumps, Slurry pumps, Barge Mounted Pumps, etc. with a capacity of 10 HP-1000 HP.Why Choose the Right Dewatering Methods?The presence of undesired and unwanted water in any site can lead to many problems such as increased costs, safety risks, and delays to your project. Hence, it is of utmost importance to perform dewatering.Dewatering minimizes equipment damage, it also helps to firm the soil. Dewatering not only reduces slip hazards but also eliminates the release of toxic materials into the surrounding environment.The Need for Dewatering pump on rent in Tamil Nadu.In the mining process, pumps play a central role. Mine dewatering pumps are used for the slurry transfer, wastewater, water supply and boosting, abrasive sludge dewatering, mineral processing, tailing transfer, reagent dosing, and more.Perennial Technologies Pvt. Ltd. provides an extensive range of pumps including slurry, Underground Mine Dewatering Pumps, End Suction Pumps, and submersible pumps to support your operations.As mine sites are located in some of the most remote regions, you need to select a high-quality product that will provide reliable performance.However, the presence of water in mines leads to flooding and other safety hazards.Thus, this is the point where mine dewatering pumps come into the picture. They provide an essential solution to maintain safe and efficient mining operations.Dewatering mining pumps are designed in such a way that they can remove water from mines and hence can prevent flooding and keep operations running smoothly.Dewatering pumps for mines are used to control water levels in underground and open-pit mines.Dewatering mining pumps help to maintain the stability of mine walls and ceilings by removing water from mines. This will reduce the threats of accidents and injuriesMine dewatering pumps ensure that mining operations are profitable and productive too.Let us understand what Slurry Pumps and Submersible Pumps.Underground Dewatering Mining PumpsWe, at Perennial Technologies Pvt. Ltd., offer the very best and most durable machines available. We assure you to offer quality in both product and support. Perennial Technologies Pvt. Ltd. is renowned for superior quality and reliability in underground mining equipment.Our dewatering mining pumps are specifically designed and engineered to work in the highly corrosive applications associated with high-pressure mine dewatering.Submersible PumpsThese are one of the popular types of mine dewatering pumps. Due to portability, they can move from one location to another. They can be used in underground and open-pit mining applications.Applications of Mine Dewatering PumpsOpen pit dewateringUnderground dewateringTo Enhance mine safety, productivity, profitability, etc.Removal of excess accumulated water due to either seepage or rainfall in the pits of minesEnvironmental water management applicationsSlurry TransportationMetal Extraction and RefiningDrainage or water transfer applicationsQuarrying applicationsIndustrial water transferRent submersible pump in India

0 notes

Photo

Ore Processing - April 2022

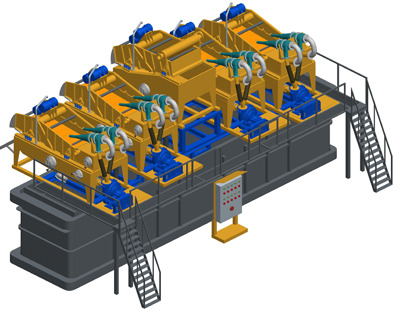

I was surprised that they allowed us into the ore processing building. I was amazed that they allowed us to take pictures. At the mine, the ore is crushed, washed, and then brought into the processing area. Certain chemicals are added that bind to the copper and float to the surface with the bubbles of air that are pumped through the slurry. I guess they allow pictures because the basic process hasn’t changed since the 1700s so no one is going to steal any trade secrets. The closeup in the second image shows a better view of the bubbles overflowing the processing tanks and taking the now copper rich slurry to the next step.

After the slurry is settled out and evaporated, it is melted in a furnace and the almost pure copper is cast into large anodes. Those anodes are shipped to a final processing facility where electrical current is used to transfer pure copper to a final form.

MWM

20 notes

·

View notes

Text

Tobee® Hydraulic Submersible Slurry Sand Pump with Agitator used for Dredging and Ocean Sand Mining.

Email:[email protected]|Web:www.tobeepump.com | Web: www.slurrypumpsupply.com | Web: www.tobee.cc | Web: www.hydroman.cn

1 note

·

View note

Text

Maximizing Efficiency and Performance with High Flow High Head Pumps in the UAE

Introduction:

High Flow High Head pumps are vital components in various industries across the UAE, providing unparalleled efficiency and performance in fluid management. High Flow High Head Pump UAE In this article, we delve into the significance of these pumps, their applications, and why they are crucial for businesses in the region.

Understanding High Flow High Head Pumps:

High Flow High Head pumps are designed to handle large volumes of fluid while generating significant pressure, making them ideal for applications requiring both high flow rates and high discharge heads. These pumps are engineered with advanced technologies to ensure reliability, durability, and optimal performance even in demanding environments.

Applications in the UAE:

In the UAE, High Flow High Head pumps find extensive use in industries such as construction, agriculture, water treatment, and mining. They are employed for tasks such as dewatering, irrigation, drainage, and slurry pumping. Their ability to efficiently move large quantities of water or other fluids over long distances makes them indispensable in these sectors.

Benefits of High Flow High Head Pumps:

Increased Efficiency: These pumps are designed to minimize energy consumption while maximizing output, resulting in cost savings for businesses.

Enhanced Performance: With their ability to handle high flow rates and pressure, they ensure continuous and reliable operation, reducing downtime.

Versatility: High Flow High Head pumps can be customized to suit specific applications, offering flexibility and adaptability to diverse industries.

Durability: Constructed with robust materials, these pumps are built to withstand harsh conditions and provide long-term service life.

Why Choose Oasis Pumps?

Oasis Pumps in the UAE is a trusted provider of High Flow High Head pumps, offering a wide range of options tailored to meet various industrial requirements. With a focus on quality, reliability, and customer satisfaction, Oasis Pumps ensures that businesses in the UAE have access to top-notch pumping solutions that deliver exceptional performance and value.

Conclusion:

High Flow High Head pumps play a crucial role in optimizing fluid management processes in the UAE's industrial landscape. Their ability to deliver high efficiency, performance, and durability makes them indispensable for businesses across various sectors. High Flow High Head Pump UAE With Oasis Pumps as a reliable partner, businesses can maximize their productivity and achieve operational excellence with cutting-edge pumping solutions.

0 notes

Text

Maximizing Efficiency: Submersible Slurry Pump and Solar Light Tower

In the realm of industrial operations, efficiency and sustainability are paramount. Two key innovations that are revolutionizing the landscape are the submersible slurry pump and the solar light tower. Let's delve into how these technologies are reshaping industries worldwide.

Submersible Slurry Pump:

Enhancing Fluid Handling Efficiency Submersible slurry pumpᅠhave emerged as indispensable tools in various industries, particularly in mining, construction, and wastewater treatment. These pumps are designed to handle abrasive and viscous fluids, making them ideal for applications where traditional pumps fall short.

Efficient Fluid Handling:

Submersible slurry pumps excel in transporting slurries containing solids, such as sand, gravel, or sludge. Their submersible design allows for direct immersion in the fluid, minimizing energy losses associated with friction and elevation changes.

Versatility and Adaptability:

These pumps come in a range of sizes and configurations to suit diverse operational requirements. Whether it's dewatering mines, cleaning settling ponds, or processing industrial wastewater, submersible slurry pumps offer unparalleled versatility.

Reduced Maintenance:

With fewer moving parts exposed to abrasive materials, submersible slurry pumps require less maintenance compared to conventional pumps. This translates to lower downtime and operational costs, contributing to overall efficiency.

Solar Light Tower:

Illuminating the Path to Sustainable Lighting Solutions Solar light towers represent a significant shift towards sustainable lighting solutions, particularly in remote or off-grid locations where traditional power sources are limited or unavailable. These towers harness the power of the sun to provide illumination for various applications, including construction sites, events, and emergency response scenarios.

Renewable Energy Source:

By utilizing solar panels to capture sunlight and convert it into electricity, solar light towerᅠeliminate the need for fossil fuels, reducing both carbon emissions and dependency on finite resources. This makes them an eco-friendly alternative for lighting needs.

Portability and Flexibility:

Solar light towers are designed for easy transportation and setup, making them ideal for temporary lighting requirements in remote areas. Their compact size and adjustable height features ensure adaptability to different environments and situations.

Cost-Effective Lighting Solution:

While the initial investment in solar light towers may be higher than traditional lighting options, the long-term benefits outweigh the costs. With minimal operating expenses and no fuel consumption, solar-powered lighting offers significant savings over time.

In a world where efficiency and sustainability are increasingly valued, innovations like the submersible slurry pump and solar light tower are reshaping industries for the better. By optimizing fluid handling processes and providing renewable lighting solutions, these technologies contribute to a more efficient and eco-conscious future. Stay updated on the latest developments in industrial innovations at solidscontrolworld.com.

0 notes

Text

What Are the Air Operated Diaphragm Pumps and Their Uses?

The most crucial thing in different industries and projects is to search for the innovative ways for increasing fluid handling efficiency. Different options are available, when it comes to choose something for better and enhanced fluid efficiency. If you are looking for one such innovative method, you will find name of Air operated diaphragm pumps on top – the most advanced pumps that come with a number of added features. These pumps, often abbreviated as AOD pumps, offer a host of benefits that make them indispensable in various industries. Air operated diaphragm pumps operate through a simple yet effective mechanism.

What Are the Benefits of Using Air Operated Diaphragm Pumps

You will get a number of added benefits of using air operated diaphragm pumps. They are the best source of offering you the following benefits:

Capable Enough to Handle a Wide Range of Fluids from Solvents to Viscous Liquids

One of the key advantages of AOD pumps is their versatility to handle a wide range of fluids, from thin solvents to viscous liquids, slurries, and even abrasive materials. This versatility makes them suitable for diverse applications across industries.

They Can Evacuate Air from the Suction Line Automatically

Air operated diaphragm pumps are self-priming, meaning they can automatically evacuate air from the suction line and begin pumping without the need for manual priming. This feature simplifies operation and makes them ideal for applications where continuous pumping is required.

Dry-Running Capabilities

Unlike many other pump types, AOD pumps can run dry without suffering damage. This attribute is particularly beneficial in situations where fluid levels may fluctuate or when dealing with intermittent flow conditions.

Portable and Easy to Install

Air operated diaphragm pumps are typically compact and lightweight, making them easy to transport and install. Their simple design also means they require minimal maintenance, reducing downtime and operational costs.

Adjustable Flow Rates

By controlling the air supply pressure, operators can easily adjust the flow rate of AOD pumps to suit specific application requirements. This flexibility allows for precise fluid handling, optimizing processes and minimizing wastage.

Safe Operation

AOD pumps are inherently safe to operate, especially in hazardous environments. Since they are driven by compressed air rather than electricity, there is no risk of sparking or electrical hazards, making them suitable for use in explosive atmospheres.

Where Are Air Operated Diaphragm Pumps Used?

Air operated diaphragm pumps find application across a wide spectrum of industries that are the following.

Chemical Industry - AOD pumps are commonly used for transferring chemicals, acids, solvents, and corrosive liquids safely and efficiently.

Mining and Construction - Their ability to handle abrasive slurries makes AOD pumps invaluable in mining and construction operations for dewatering, sludge transfer, and wastewater treatment.

Food and Beverage – Such pumps are utilized for handling food-grade liquids, such as juices, syrups, and dairy products, thanks to their hygienic design and ability to handle solids without damage.

Paints and Coatings - In the manufacturing of paints, coatings, and inks, AOD pumps are employed for transferring pigments, resins, and other viscous materials.

Waste Management - From sewage treatment plants to landfills, AOD pumps play a crucial role in managing and transferring various types of waste fluids.

You have to choose the best model of such pump and place an order accordingly.

Summary: Air operated diaphragm pumps offer a combination of versatility, reliability, and safety that make them indispensable in numerous fluid handling applications across industries.

0 notes

Text

🌟Optimizing Industrial Operations with Schurco Slurry Pumps: A Comprehensive Guide🌟

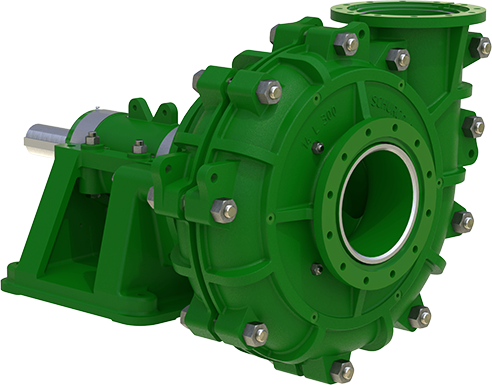

In industries where handling abrasive and high-density slurries is a daily challenge, the importance of reliable and efficient slurry pumps cannot be overstated. At Schurco Slurry, we specialize in manufacturing cutting-edge slurry pumps designed to excel in demanding applications such as mining, mineral processing, dredging, and more. This article delves into the fundamentals of slurry pumps, their diverse applications, the types available, and how Schurco Slurry's solutions can elevate operational efficiency.

🌊🔧Understanding Slurry Pumps🌊🔧

Slurry pumps are specialized centrifugal pumps engineered to handle mixtures of solids and liquids known as slurries. Unlike standard pumps used for clean fluids, slurry pumps are constructed with robust materials and specialized designs to withstand the abrasive wear caused by solid particles within the slurry. They are essential in environments where conventional pumps would quickly deteriorate under such conditions.

🏭🌊🔩Applications of Slurry Pumps 🏭🌊🔩

🏭🌊🔧The versatility of slurry pumps makes them indispensable in various industries:

Mining: Slurry pumps play a crucial role in transporting mine tailings, transferring ore slurries, and facilitating dewatering operations. The abrasive nature of mineral processing requires pumps capable of handling high concentrations of solids during tasks like crushing, grinding, and flotation. ⛏️🌊🔧

Dredging: In dredging operations, slurry pumps are instrumental in removing sediment and sludge from waterways, harbors, and industrial ponds, ensuring efficient water management and navigation. 🚢🌊🔧

Chemical Processing: Slurry pumps are used to handle corrosive slurries in chemical plants, facilitating the safe and efficient transport of chemicals throughout the production process. 🧪🌊🔧

🔄🌊🔧Types of Slurry Pumps🔄🌊🔧

Schurco Slurry offers a range of slurry pump types tailored to specific industry needs:

Centrifugal Slurry Pumps: The most common type, centrifugal slurry pumps use centrifugal force to propel the slurry through the pump. They are available in horizontal, vertical, and submersible configurations to accommodate various installation requirements.

Submersible Slurry Pumps: Ideal for underwater applications and tasks requiring high-head pumping, submersible slurry pumps operate efficiently in submerged conditions, making them suitable for dredging and wastewater treatment.

Horizontal vs. Vertical Slurry Pumps: Horizontal pumps are typically used for high-flow applications, while vertical pumps are ideal for installations where space is limited and can also be submerged for specific applications.

🔑🔄Key Features and Benefits of Schurco Slurry Pumps🔑🔄

Schurco Slurry pumps are engineered with advanced features to optimize performance and reliability:

Wear-Resistant Materials: Our pumps are constructed from high-quality materials such as high-chrome alloys, rubber, and polyurethane to withstand abrasive wear and corrosion, ensuring longer service life. 🛡️🔧

Customized Solutions: We offer tailored pump designs to meet specific application requirements, including material compatibility, flow rate, head pressure, and particle size. 📏🌊🔧

Efficient Operation: Schurco Slurry pumps are designed for energy efficiency, reducing operating costs and environmental impact while maintaining superior performance. 🌱💡🔧

Reliable Support and Service: We provide comprehensive customer support, including technical assistance, maintenance services, and spare parts to ensure optimal pump performance throughout its lifecycle. 🛠️👷♂️🔧

⚖️🌊🔧 Choosing the Right Slurry Pump⚖️🌊🔧

Selecting the appropriate slurry pump requires careful consideration of multiple factors. First, understanding the characteristics of the slurry is essential, including particle size, density, viscosity, and chemical composition. This information helps determine the pump's ability to efficiently transport the slurry without clogging or excessive wear. Next, operational requirements such as desired flow rate, head pressure, suction depth, and the specific installation environment must be evaluated to ensure the pump meets performance expectations. Additionally, material compatibility is critical to prevent corrosion or damage caused by the slurry's corrosive or abrasive nature.

👷♂️Conclusion👷♂️

In conclusion, Schurco Slurry offers a wide range of high-quality slurry pumps designed to optimize industrial processes across various sectors. Whether you require efficient mine dewatering, reliable mineral processing solutions, or effective sediment removal in dredging operations, our pumps are engineered to deliver superior performance and durability. Contact Schurco Slurry today to discover how our innovative pumping solutions can enhance efficiency and productivity in your operations.

0 notes

Text

Maximizing Productivity with Fast Opening Filter Press

In modern industrial settings, a fast opening filter press stands out as an essential device for solid-liquid separation. The process begins by feeding slurry into the machine. As it moves through each chamber, solids collect on cloth filters while clean liquid passes below.

A distinctive advancement in this technology is the incorporation of vibration devices which further optimizes productivity. These presses not only achieve efficient filtration but also ensure rapid cleaning and reuse cycles due to quicker opening mechanisms—a vital aspect for industries aiming at high-throughput processes without compromising quality or efficiency.

Understanding Fast Opening Filter Press

In a fast-opening filter press, slurry enters via the feed pump. The frames hold it all together; hydraulic pistons ensure no leak during processing. Each chamber's cloth filters serve to capture solids while clean liquid escapes below – separation made simple and efficient.

Once every space brims with purified fluid and trapped particles, those same hydraulics compress chambers tightly, ensuring not even a drop slips through unchecked. As pressure ceases, they open for easy unload of residual matter - ready again for industrial tasks large or small. These presses are made from robust metals like stainless steel or cast iron, tailored to the task.

They work solidly and precisely, separating materials in industries like food processing, where purity is crucial, or mining, where water reclamation is key to continued production despite natural scarcity.

Benefits of Quick Operation Mechanisms

Quick-opening filter presses boost productivity by slashing cycle times. They use less energy, too. Built-in automatic belt washing saves labor previously spent on manual cleaning—more time for other tasks now.

Verti-Press designs also enhance efficiency with their vertical chamber stack-up and improve wash results. Automation means fewer mistakes; it’s safer and uses materials better to cut costs—a smart choice for precise filtering needs and exact cake size control from the slurry feed adjustment each cycle. Plus, Filtra-Systems' Verti-Press stands out: added safety against chemical exposure makes it top-tier in filtration technology – ideal for modern 'green' industry demands.

Integrating Vibration Devices for Efficiency

To enhance the fast-opening filter press, engineers integrate vibration devices. These gadgets attach to the machine frame and mass--the "M" in our simple vibratory system diagram. They shake at a set speed when prompted, helping loosen particles sticking to filters or plates after a cycle ends.

They're fine-tuned so their shaking matches exact frequencies that won’t harm equipment by reaching resonance with natural frequencies of the structure—something crucial for avoiding quick wear or catastrophic failures. This precise alignment means maintenance focuses only on real issues first—a principle key in Predictive Maintenance programs working alongside Preventive Maintenance efforts aimed at extending machinery life while ensuring maximal uptime and product quality.

Choosing the Right Filter Press Model

Selecting a filter press demands attention to detail. One must weigh the type of process—continuous or batch? Continuous presses roll out paper non-stop into a large tank through water and chemicals, filtering all at once.

Batch presses soak then push batches through in one shot, great for limited runs like those needed for paper towels. Vertical versus horizontal orientation matters too. Vertical ones filter more surface area with their tubular shape, fitting chemical uses best; whereas horizontal models are better suited if you're aiming for clean white products such as tissues.

Material choice is paramount: plastic, carbon steel, stainless steel—all hinge on your production scale and substance filtered. Stainless stands strong against alkaline scenarios to avoid rust issues. Prices start steeply around $100k but can rocket up depending on size and design choices tailored to industry requirements.

Streamlining Filtration with Rapid Cycles

In the rapid filtration process, constant pressure is key. As slurry fills filter plate spaces, flow lessens and stops when a set low level is hit; then comes core blow with water or air to clear leftover slurry back into tanks for reuse. Optional are cake dry and membrane squeeze steps using compressed air for super-dry cakes by compressing out more liquid.

When drying's done, plates unclamp; they separate so dried material drops free—this ends one cycle before starting anew. Design choices like chamber size affect duration just as much as slurry properties do—from its make-up to particle sizes—and dewatering aids can assist if needed.

Maintenance Tips for Longevity and Performance

Supervisors must integrate preventative checks into the daily routine to ensure optimal filter press performance. Daily tasks include inspecting hydraulic lines and fittings for leaks, as these can quickly escalate if unchecked. If a leak is found, immediately tighten or replace necessary components and monitor any fixes closely.

Maintaining clean hydraulic oil is essential; also keep bolts at their correct torque level with marks indicating proper tightness. It's critical to keep safety systems well-functioning—repair faulty devices right away to avoid downtime during operations. Tracking press data like cycle time and cake consistency in logs helps identify trends or issues early on.

Monthly maintenance should involve professional servicing alongside cleaning and replacing filter cloths when needed, which prolongs equipment life significantly. Damp cakes indicate it might be time for cloth replacement or process adjustments — something our technicians can analyze via slurry testing onsite.

Case Studies: Productivity Gains in Action

In factories, time is money. One study showed a fast opening filter press it shaves hours off processing. With this tool, cycles run close to 15% quicker than old models.

This means more batches per day; for one business they saw output go up by nearly 25%. That's huge in terms of numbers! Profits soared due to improved staff efficiency.

Smooth operations with minimal stops and starts boosted productivity like never before, truly changing the game on the shop floor.

The hzfilter Fast Opening Filter Press revolutionizes separation processes with its vibration device. This advanced system speeds up cycle times, maximizing productivity in industries needing solid-liquid division. Its design reduces downtime and enhances efficiency, making it a smart choice for businesses aiming to boost output while maintaining quality.

For those seeking reliable operations with less maintenance, this filter press stands out as an essential upgrade—streamlining workflows with remarkable proficiency.

#fast opening filter press#fast-opening filter press#chamber's cloth filters#hzfilter Fast Opening Filter Press

0 notes

Text

The Increasing Use of Multi Screw Pumps in Modern Industry

Multi screw pumps, also known as twin screw pumps, are increasingly being utilized in various industrial applications requiring the pumping of high viscosity fluids. With their ability to smoothly handle fluids like oils, polymers, and solids-laden liquids, twin screw pumps are an important pumping technology for many manufacturing, processing, and waste management operations.

What are Twin Screw Pumps?

Twin screw pumps consist of two intermeshing rotors contained within a casing that mimics the rotor profile. As the screws rotate, the fluid flows through the cavities formed between the rotor screws and the casing. This creates a self-priming, non-pulsing continuous flow ideal for viscous liquids.

Twin screw pumps provide various advantages over other pump types:

Can handle high viscosity fluids without dilution

Generate high pressures and flow rates

Run dry without damage

Reversible operation for fluid backflow

Offer pulse-less operation

Highly efficient resulting in lower energy costs

Key Industrial Applications

The unique capabilities of twin screw pumps make them well-suited for numerous industrial uses, including:

Oil and Gas - Twin screw pumps are commonly used to transfer crude oil, liquefied petroleum gas, drilling fluids and other hydrocarbons containing solids. They can maintain high efficiencies even with gases entrained in the pumped fluid.

Chemicals - Multi screw pumps reliably meter and transfer high viscosity chemicals like polymers, resins, glues and paints. They can move shear-sensitive or non-Newtonian chemicals with low pulsing.

Wastewater - In wastewater treatment, twin screw pumps effectively handle raw sewage, activated sludge and scum laden with stringy materials and debris. They resist clogging and run dry without damage.

Food and Beverage - Multi screw pumps gently transfer fruit concentrates, chocolate, jams, syrups, and other viscous food items without separating them. They also pump dough, batters, and meat slurries.

Pulp and Paper - Twin screw pumps manage the thick pulpy mixtures involved in papermaking. Applications include moving black liquor, coatings, screening rejects and deinking residuals.

Mining - In mining processes, twin screw pumps handle piping of mineral slurries, chemical additives like lime and flocculants, tailings and other high solids sludges.

Power Generation - Multi screw pumps support coal gasification, handling coal water slurries and coal ash removal. They also transfer waste by-products like fly ash and bottom ash.

Marine - On boats and ships, twin screw pumps efficiently pump bilge water, oil sludge, fuels, ballast water and other viscous fluids. They resist corrosion from seawater exposure.

Trends Driving Adoption

Several trends are contributing to the increased use of twin screw pumps in modern industrial settings:

Processing More Viscous Fluids: Manufacturing operations are processing more heavy, thick, and particulate-laden fluids that require smoothly handling multi screw pumps.

Increased Automation and Monitoring: New twin screw pumps have sensors and connectivity allowing for remote monitoring, control and data-driven operation and maintenance.

Expanded Material Options: Multi screw pumps with casings and rotors made from hardened metals, alloys, and non-metallic materials allow pumping of more abrasive and corrosive substances.

Focus on Energy Efficiency: New precision manufacturing and rotor coating technologies have improved the energy efficiency of twin screw pumps, bringing significant operating cost savings.

Growth in Wastewater Treatment: Stringent environmental regulations and population growth have expanded the need for heavy-duty twin screw pumps in municipal and industrial wastewater management.

Demand for Customization: Companies increasingly seek custom-engineered twin screw pumps tailored to their specific process parameters and pumped fluids.

With their versatility, efficiency and heavy-duty construction, multi screw pumps are on track to see expanded adoption across manufacturing, chemical processing, oil and gas, wastewater and other industries handling challenging high viscosity pumping applications. New design enhancements and smarter monitoring capabilities position twin screw pumps as a promising technology to meet future industrial pumping demands. Companies choosing twin screw pumps gain access to a robust pumping platform able to tackle even the toughest viscous fluid transfer duties.

0 notes

Text

Innovation under the Surface: Submersible Screw Pump Technology in China

In the realm of fluid mechanics, submersible screw pumps stand as a testament to innovative engineering, offering efficient and reliable solutions for various applications. Among the pilot contributors to this technology is China, where a burgeoning industry has emerged around the development and production of submersible screw pumps. In this article, we delve into the depths of China's submersible screw pump technology, exploring its evolution, applications, and impact.

Submersible screw pumps are a type of positive displacement pump designed to handle viscous fluids, slurries, and abrasive materials with ease. Unlike centrifugal pumps, which rely on kinetic energy to move fluids, submersible screw pumps utilize the action of rotating screws to push fluids along the pump's axis, providing consistent and reliable performance even in challenging environments.

China has emerged as a key player in the submersible screw pump industry, leveraging its expertise in engineering, manufacturing, and innovation to develop cutting-edge pump technology. China Submersible Screw Pump manufacturers have made significant strides in improving pump efficiency, reliability, and versatility, driving advancements that benefit various industries worldwide.

The success of China's submersible screw pump technology can be attributed to several factors. First and foremost of is a strong focus on research and development (R&D), with manufacturers investing in the exploration of new materials, designs, and manufacturing processes to enhance pump performance and efficiency. By embracing innovation, China Submersible Screw Pump manufacturers continually push the boundaries of what is possible, resulting in pumps that are more reliable, durable, and adaptable to different operating conditions.

Another key aspect of China's submersible screw pump technology is its commitment to quality and precision engineering. Manufacturers adhere to stringent quality control measures throughout the manufacturing process, from material selection to final assembly and testing. By ensuring that each component meets exacting standards, China Submersible Screw Pump manufacturers deliver pumps that are built to last and perform consistently over time.

China's submersible screw pump technology finds applications across a wide range of industries, including agriculture, wastewater management, mining, oil and gas, and construction. In agriculture, submersible screw pumps are used for irrigation, drainage, and water transfer, helping farmers optimize water usage and maximize crop yields. In wastewater management, these pumps play a vital role in sewage treatment plants, lifting and conveying wastewater with high efficiency and reliability. In mining and oil and gas operations, submersible screw pumps are employed for dewatering, slurry transfer, and fluid injection, facilitating safe and efficient extraction processes. Additionally, in construction projects, these pumps are utilized for dewatering excavations, tunnels, and foundations, enabling construction activities to proceed smoothly and efficiently.

The impact of China's submersible screw pump technology extends beyond its domestic market, with pumps exported to countries around the world. China Submersible Screw Pump manufacturers have established a reputation for delivering high-quality, cost-effective solutions that meet the needs of diverse industries and applications. With a focus on continuous improvement and customer satisfaction, China's submersible screw pump industry is poised for further growth and innovation in the years to come.

In conclusion, China's submersible screw pump technology represents a shining example of innovation below the surface, offering efficient, reliable, and versatile solutions for various fluid handling applications. With a strong emphasis on research and development, quality engineering, and customer satisfaction, China Submersible Screw Pump manufacturers continue to drive advancements that benefit industries worldwide. As demand for efficient fluid handling solutions grows, China's submersible screw pump industry is well-positioned to meet the challenges of the future and contribute to global progress and prosperity.

0 notes

Text

Valve supplier in Nigeria

African Valve is the top Valve Supplier in Nigeria. African Valve stands as the premier supplier and manufacturer of valves across Africa with a commitment to excellence, we ensure top-notch products and services. We proudly serve clients across Africa, including Nigeria, Kenya, Algeria, Ghana, Tanzania, Sudan, and Ethiopia, ensuring reliable access to top-tier valve solutions continent-wide. As a reputed valve supplier we provide different types of valves available in different sizes and classes made with high standard material quality to meet the needs of various industries.

Choose a premium valve and ensure safety, reliability and durability with African Valve, your trusted industrial Valve Supplier in Nigeria. Here are some major types of valve we manufacture and supply:

Control Valve: It is a type of valve used in various industrial processes to regulate the flow of fluids such as liquids, gases, steam, or slurries

Cryogenic Valve: This type of valve is specifically designed to handle extremely low temperatures encountered in cryogenic applications.

Pressure Reducing Valve: These valves are also known as a pressure regulator, is a type of valve used to control and maintain a lower pressure in a pipeline or system than the pressure of the fluid entering it.

Safety Valve: It is a crucial safety device used in industrial systems to prevent dangerous pressure build-ups.

Check Valve: These valves are also known as a non-return valve or one-way valve, a mechanical device used in piping systems to allow fluid to flow in one direction while preventing reverse flow

Gate Valve: It is a type of valve used to control the flow of fluid within pipes. They consist of a sliding gate or wedge-shaped disc that moves perpendicular to the flow of the fluid.

Butterfly Valve: A butterfly valve is a type of quarter-turn valve that controls the flow of fluid through a pipeline by means of a disc mounted on a rotating shaft.

Globe Valve: It is a type of linear motion valve used for regulating the flow of fluids in pipelines.

Ball Valve: A ball valve is a type of valve used to control the flow of fluids within a piping system. It consists of a spherical closure (the "ball") with a hole or port through the center

Knife Gate Valve: A knife gate valve is a specialized type of gate valve designed for applications involving the flow control of fluids with high concentrations of solids, such as slurries and viscous media.

Foot Valve: A foot valve is a type of check valve commonly used in pumping systems to prevent backflow and maintain prime in suction lines

Electric Actuated Valve: Thay are automated valves that use electric power to control the opening and closing of the valve.

Advantages:

Control and Regulate the flow of fluids

Prevent from leakage of fluids

Quick shut off and quick response in the operation

Pressure regulation

Ensure safety in operations

Easy to operate and install

Versatility comes in different sizes for various industrial applications

Prevention of backflow of fluid

Corrosion Resistance

Industry:

Oil and Gas Industry

Power Generation

Water and Wastewater Treatment

Chemical and Pharmaceutical Industries

Pulp and paper industry

Marine and offshore industry

Petrochemical industries

Textile and Process Industries

Thermal and Nuclear Power industries

Mining and Minerals

HVAC and Plumbing

Food and Beverage

Marine Industry

Irrigation System

Textile industry

Description:

Available materials: Ductile iron, Monel, WCB, WCC, WC6, LCB, LCC, SS304, SS316, CF8, CF8M, CF3, CF3M, Aluminum Bronze, Bronze, Brass, F55, F53, F51, Inconel, Titanium.

Class: 150 to 2500.

Nominal Pressure: PN6 to PN450.

Size: ½” to 80”.

Ends: Flanged, Wafer, Lug, Buttweld, Socket weld, Threaded.

Operations: Lever operated, Gear operated, Electric actuated, Pneumatic actuated.

For more detail visit our website: https://www.africanvalve.com/

0 notes

Text

Submersible slurry pumps are designed to move slurry, sand, and other materials in the dredging, quarrying, and mining industries. Our non-clogging slurry pumps are built to handle the most challenging solids with the highest efficiency.

At JB Pumps India Pvt. Ltd., we manufacture high-quality submersible slurry pumps using advanced technology. Our pumps hold high pumping capacity and the ability to transfer abrasive media, like sand, with high solid content.

Visit Website:

What is Submersible Slurry Pump?

0 notes

Text

Suction Hoses For Different Applications

A suction hose is a vital component in fluid handling systems, enabling the efficient transfer of materials by creating suction or vacuum pressure within the hose. The versatility of suction hoses Ipswich lies in their ability to be tailored to the unique requirements of different applications, whether in small-scale gardening or large-scale industrial operations.

What Is a Suction Hose?

A suction hose is a flexible tube or pipe designed to facilitate the transfer of fluids, gases, or solids by creating a vacuum or negative pressure within the hose. These hoses are commonly used in various industries and applications to suction or draw materials from one location to another. Suction hoses are typically constructed from durable materials such as PVC, rubber, or polyethylene and are reinforced with internal layers to withstand the rigors of suction and transfer operations.

The key feature of a suction hose is its ability to create suction, which allows it to pull materials through the hose without the need for external pumping mechanisms. This makes the suction hose a versatile tool for irrigation, dewatering, fluid transfer, and more.

For example, these hoses play a crucial role in irrigation systems, facilitating the efficient transfer of water from a water source to agricultural fields, gardens, or landscaping areas. Whether drawing water from a well, reservoir, or rain barrel, these hoses ensure precise water delivery to plants, promoting healthy growth and maximizing water efficiency.

In construction, mining, and other industries, dewatering is often necessary to remove excess water from worksites, trenches, or excavation areas. These hoses are employed to pump out water, slurry, or groundwater, allowing for safe and efficient dewatering operations to proceed.

The suction hose is also utilized for transferring various fluids, including liquids, chemicals, and slurries, in industrial processes and manufacturing operations. Whether moving fuels, oils, solvents, or abrasive materials, suction hoses provide a reliable means of fluid transfer, ensuring seamless operations and minimizing downtime.

Cater to Various Applications

A suction hose also comes in various sizes, lengths, and configurations to suit different applications, from small-scale gardening to large-scale industrial operations.

Size

Suction hoses come in different diameters to accommodate varying flow rates and types of materials being transferred. For example, in small-scale gardening applications, smaller diameter hoses may be sufficient for watering plants or transferring liquids from a rain barrel. On the other hand, large-scale industrial operations may require larger diameter hoses to handle higher volumes of fluids or larger solid particles.

Length

The length of a suction hose can vary to meet the specific layout and distance requirements of the application. In gardening, shorter lengths may be suitable for watering plants in a backyard garden, while longer hoses may be needed to reach different areas of a larger garden or landscape. In industrial settings, the hoses may need to span longer distances to connect various equipment or transfer points.

Configurations A suction hose can be customized with different configurations and features to optimize performance for specific tasks. For example, some suction hoses may be equipped with strainers or filters to prevent debris from entering the hose and causing blockages. Others may have reinforced walls or anti-kink features to enhance durability and flexibility. Additionally, these hoses may come with various end fittings or connectors to facilitate easy connection to pumps, nozzles, or other equipment.

0 notes

Text

Slurry Pump UAE | Oasispumps.ae

Dive into the world of superior slurry pumps crafted to perfection for the UAE market. Explore our range of high-performance slurry pumps designed to tackle the toughest mining and industrial challenges. Visit our page now!

Slurry Pump UAE

0 notes

Text

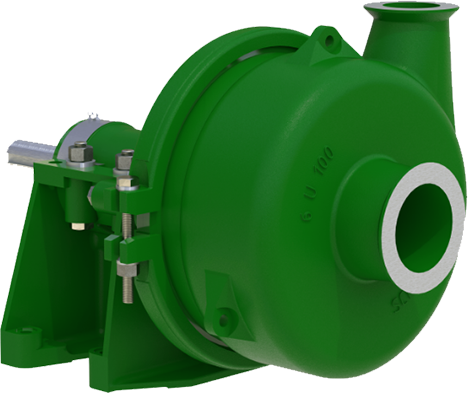

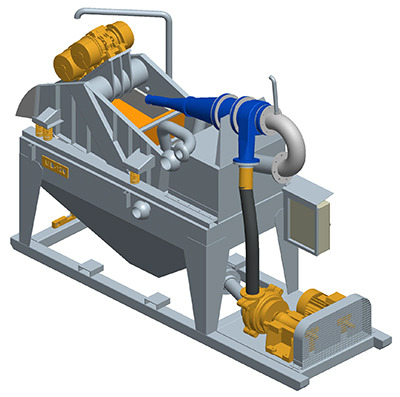

Enhancing Efficiency: Centrifugal Pump and Solids Control Equipment

In industries where fluid handling and solids control are paramount, the synergy between centrifugal pumps and solids control equipment manufacturer plays a pivotal role. Let's delve into their profound applications and the symbiotic relationship they share in various sectors.

Understanding Centrifugal Pumps:

Centrifugal pump are indispensable in numerous industries, including oil and gas, mining, wastewater treatment, and agriculture. Their principle of operation involves converting rotational energy into kinetic energy to move fluid through a piping system. These pumps are renowned for their efficiency, reliability, and versatility.

Applications:

Oil and Gas Industry: In upstream operations, centrifugal pumps facilitate fluid transfer in drilling mud systems, enhancing drilling efficiency and maintaining wellbore stability. They also play a crucial role in transporting crude oil and refined products in downstream processes.

Mining Sector: Centrifugal pumps are instrumental in dewatering mines, handling abrasive slurries, and transporting various liquids, including acids and leachates, in mineral processing plants. Their robust construction and ability to handle solids make them indispensable in this demanding environment.

Water Treatment Plants: Municipal and industrial water treatment facilities rely on centrifugal pumps for the circulation of water, chemical dosing, and sludge handling. These pumps ensure efficient operation and compliance with stringent quality standards.

Understanding Solids Control Equipment:

Solids control equipment encompasses a range of devices designed to separate solids from drilling fluids, wastewater, and other liquids. This equipment plays a crucial role in maintaining drilling mud properties, preventing equipment damage, and minimizing environmental impact.

Applications:

Drilling Operations: In oil and gas exploration, solids control equipment such as shale shakers, hydrocyclones, and centrifuges remove drill cuttings and other debris from drilling mud. This ensures optimal mud properties, improves drilling efficiency, and extends the life of drilling equipment.

Construction Projects: Solids control equipment is employed in construction dewatering applications to remove sediment and contaminants from groundwater, ensuring compliance with environmental regulations and preventing site contamination.

Industrial Processes: Various industries, including food and beverage, pharmaceuticals, and pulp and paper, utilize solids control equipment to separate solids from liquids in production processes, ensuring product quality and process efficiency.

The Synergy: Centrifugal pumps and solids control equipment complement each other seamlessly in numerous applications. Centrifugal pumps provide the necessary hydraulic energy to transport fluids containing solids, while solids control equipment ensures the removal of these solids, thereby optimizing system performance and reliability.

The profound application of centrifugal pumps and solids control equipment underscores their significance across diverse industries. For comprehensive solutions in fluid handling and solids management, visit SolidsControlWorld.com, where innovative technologies meet industry needs.

0 notes

Text

Desanders: Unveiling the Key Players in Efficient Solids Removal

In the realm of industrial processes, where precision and efficiency are paramount, desanders emerge as indispensable tools for the removal of unwanted solids from liquid systems. These innovative devices play a crucial role in maintaining the integrity of various processes across industries like oil and gas, mining, and wastewater treatment.

Desanders, at their core, are hydrocyclonic separators designed to remove sand, silt, and other solid particles from liquids, ensuring downstream equipment operates smoothly and with minimal wear. Their significance lies in preventing abrasive particles from causing damage to pumps, pipelines, and other sensitive components in industrial systems.

One of the primary advantages of desanders is their ability to handle a wide range of particle sizes. Whether dealing with fine sand or coarse debris, these devices efficiently separate solids from liquids through a cyclonic motion, allowing clean liquid to continue its journey through the system while directing separated solids to a designated discharge point.

Oil and gas industries, in particular, heavily rely on desanders to enhance the efficiency of their production processes. In drilling operations, desanders efficiently remove drilled cuttings and sand from drilling mud, preventing damage to drilling equipment and ensuring a smooth drilling process. Similarly, in the production phase, desanders are employed to protect downstream equipment from the abrasive effects of sand and solids.

Mining operations also benefit significantly from desanders. These devices are employed to separate solids from slurry, preventing wear and tear on pumps and maintaining the quality of the extracted minerals. In wastewater treatment plants, desanders play a vital role in ensuring the treated water meets regulatory standards by removing grit and other solids.

Desanders contribute not only to operational efficiency but also to cost savings. By preventing damage to equipment and minimizing downtime for maintenance, these devices help companies avoid costly repairs and replacements. Their versatility and effectiveness make them a crucial component in various industrial settings, where the removal of solids is a prerequisite for smooth and reliable processes.

In conclusion, desanders stand as silent heroes in the world of industrial processes, quietly ensuring the smooth flow of operations by efficiently removing solids from liquids. Their versatility, cost-effectiveness, and ability to handle a wide range of particle sizes make them indispensable tools for industries striving for precision and efficiency in their day-to-day operations.

0 notes