#MetsoCrusherParts

Text

Getting the most out of your Jaw Crusher | Jaw crusher parts

www.bdiwearparts.com

When should you change a Jaw Liner?

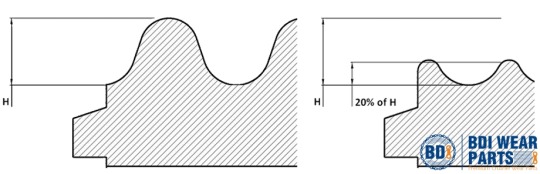

Change or rotate a jaw liner when there is less than 20% life left anywhere along the working face of the jaw liner.

Swing and Fixed jaw liners do not normally wear at the same rate. The wear rate differs from application to application. Typically the ratio is 2 Fixed Jaw liners for every 3 Swing Jaw liners.

Why should you change a Jaw Liner?

Excessively worn jaw liners place additional stresses in the crusher frames and bearings.

Jaw Liners that are worn too thin can crack and damage the crusher body resulting in expensive repairs and prolonged downtime.

Worn Jaw liners affect production and draw more power.

Figure 1 above: Shows the Liner profile, H is the tooth height of a new liner and 20% of H is an indication of when to rotate the Jaw liner.

BDI Wear Parts is a dynamic, fast-growing company with years of experience in the production, application, and supply of Crusher wear parts, crusher parts, wear parts, spare parts, stone crusher parts, ball mill liners, screen media, idler, bucket teeth, conveyor idlers, grader cutting edges, excavator bucket teeth, chocky blocks, self-cleaning screens, asphalt plant parts, polyurethane screen panels, dozer cutting edges, auto shredder hammers, log washer parts, and forged steel balls. We supply and ship parts across the globe to the USA, Canada, Europe, Australia, Africa, and other countries.

#crusherparts#CrusherWearParts#CrusherSpareParts#JawCrusherParts#ConeCrusherParts#StoneCrusherParts#SandvikCrusherParts#MetsoCrusherParts#SymonsCrusherParts

1 note

·

View note