#crusherparts

Text

BDI WEAR PARTS

Why choose BDI Crusher Spare and Wear Parts?

(1) We are manufacturer. You are getting manufacturer price, usually we are save 30~50% of the cost for our customers. And we can customize the required wear parts according to the drawings you provide.

(2) Delivery is easy, cheap and world-wide, the shipment direct ship to your location. There is no warehousing fee, no second transportation fee, etc…

(3) Supporting multiple brands of crushers around the world.

(4) Our foundry has a lot of experience with OEM crusher manufacturers meanwhile our quality control is stricter than OEM

(5) BDI replacement parts are guaranteed to meet the OEM specification in both dimensional tolerance and material specification.

(6) BDI crusher parts outperformed OEM parts with longer wear life, our proprietary alloys offer increased toughness and durability, tested for longest usable wear life, we have many case histories in which wear life increase of 60% are common, and some in which wear life increase up to 200%.

(7) Large inventory of crusher parts for immediate deliveries around the world.

BDI Wear Parts is a dynamically growing company with many years of experiences in production and supply of Crusher wear parts, Crusher spare parts, Ball mill liners, Forged steel balls, Crusher backing compound and Reverse engineering services. We supply wear parts to the USA, Canada, Europe, Australia and Africa.

Our focus on quality crafting, cost-effectiveness and customer satisfaction, together with our desire to continuously provide our customers with the best products has helped us succeed in the quarry and mining industry.

We have two big advantages to offer your company over our competition:

1. Unique technique for its cone crusher liner production.

Please contact our sales and care department for any inquiries!

www.bdiwearparts.com

#autoshredder#mine#wearpart#recycling#mining#cement#scrapmetal#crushing#recycle#shredder#goldmining#aggregate#processing#crushingandscreening#miningequipment#mineral#crusherparts#crusherwearparts#crushers#manganesesteel#castings#manganese#demolition#mobilecrushing#crushercastings#metalrecycling#metalcrusher#metal#wearparts#scrap

0 notes

Text

#SerMining#SerMaden#Stone#crusher#basalt#crusherparts#miningengineering#quarry#construction#aggregate#pebble#gravel#asphalt#dolomite#granite#limestone#conecrusher#compoundcrusher#jawcrusher#impactcrusher#stonecrusher#verticalshaft#verticalshaftcrusher#rockcrushing#crushedstone#coal#bentonite#gypsum#barite#kaolin

1 note

·

View note

Text

Hello, we are a manufacturer of vulnerable parts for crushers. Our main products are jaw plates, composite hammer head, blow bar, armored cone, cone liner, etc. Please contact me to add an option to your buying channel.

#CrusherParts#GenuineAlternative#Crusher#crusherspareparts

#spareparts#machinery#spare#parts#equipment#jawplate#conemantle#bowlliner#Crusherequipment#crushersparepart#crusherpart#simsumspare#heavyequipment

#jawplate,#segmentedjawplate,#jawcrusher,#stonecrusher,#mobilecrusher,#miningcrusher,#miningmachine,#concrete

1 note

·

View note

Text

Getting the most out of your Jaw Crusher | Jaw crusher parts

www.bdiwearparts.com

When should you change a Jaw Liner?

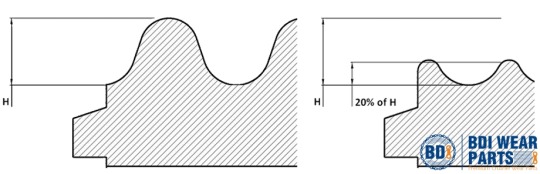

Change or rotate a jaw liner when there is less than 20% life left anywhere along the working face of the jaw liner.

Swing and Fixed jaw liners do not normally wear at the same rate. The wear rate differs from application to application. Typically the ratio is 2 Fixed Jaw liners for every 3 Swing Jaw liners.

Why should you change a Jaw Liner?

Excessively worn jaw liners place additional stresses in the crusher frames and bearings.

Jaw Liners that are worn too thin can crack and damage the crusher body resulting in expensive repairs and prolonged downtime.

Worn Jaw liners affect production and draw more power.

Figure 1 above: Shows the Liner profile, H is the tooth height of a new liner and 20% of H is an indication of when to rotate the Jaw liner.

BDI Wear Parts is a dynamic, fast-growing company with years of experience in the production, application, and supply of Crusher wear parts, crusher parts, wear parts, spare parts, stone crusher parts, ball mill liners, screen media, idler, bucket teeth, conveyor idlers, grader cutting edges, excavator bucket teeth, chocky blocks, self-cleaning screens, asphalt plant parts, polyurethane screen panels, dozer cutting edges, auto shredder hammers, log washer parts, and forged steel balls. We supply and ship parts across the globe to the USA, Canada, Europe, Australia, Africa, and other countries.

#crusherparts#CrusherWearParts#CrusherSpareParts#JawCrusherParts#ConeCrusherParts#StoneCrusherParts#SandvikCrusherParts#MetsoCrusherParts#SymonsCrusherParts

1 note

·

View note

Photo

Valve shell, Valve, Support frame of the Excavator, Shot blasting machine lining plate, Shot blasting machine blade, Shot blasting machine nut, Grate Bars & Plates, Crusher & Shredder Parts, Wear Resistant Parts, Hydraulic Fittings, Valve & Pump Parts, Bucket Teeth & Adapters, and other casting parts. #valveindustry #excavatorpart #crusherparts #shredderparts #wearparts #fittings #pumpparts (在 Fuyang District) https://www.instagram.com/p/CBSLBoRDxXl/?igshid=1ezbrfdluoamn

0 notes

Photo

Professional sand - stone aggregate production equipment #crusher #crushers #crusherp #crusherpride #crusherz #crusherlife #crusherhat #crusherperformance #crushervickyramadhan #crusherdog #crushernation #crushersgame #crusherparts #crushersbaseball #crusher2 #crusherrun #willingindustryhttp://bit.ly/2v6ZisE (at Shanghai, China)

#crusherpride#willingindustryhttp#crusherhat#crusherrun#crusherz#crusher#crushersbaseball#crusherdog#crusherlife#crusherp#crushers#crushersgame#crusher2#crushernation#crusherperformance#crushervickyramadhan#crusherparts

0 notes

Text

How to Choose the Right Crusher

A crusher is a machine that can break large chunks of concrete, stone, or other building materials into smaller chunks of specified grain size by using mechanical energy to break them down. Crushers are crucial in the mining industry which reduces the size of chunks of minerals and help in their processing. Crushers can take blocks as large as they wish. It may be required to go through many crushing stages in order to obtain the desired end result.

The precision at which crushers breakdown the material they are supplied with is what sets them apart from other types. There are two types of crushers that are primary or secondary crushers (for rough-finished goods) and tertiary or quaternary crushers (for fine finished products).

What are the most important factors to consider when choosing a crusher?

It is important to be aware of the condition of your shredder parts and make use of the manganese profile that is most appropriate to suit your needs whenever you can to ensure you're using the most cost-effective wear components.

The tracking of the wear foundry is used to calculate the price per ton

For your mill liners foundry needs, do not purchase components that are worn. Do not just check their costs. This is the main criterion to evaluate a vendor that will endure for a long period of. You can monitor your wear and calculate how much of each tonne capacity was used. If you track installation dates and daily production using belt scales or loaders you can determine the cost per ton of material processed. If you want to win your business, choose the provider that charges the lowest per tonne.

Manganese Plates

In some instances, higher grade manganese may provide more extended wear, but this must always be monitored to ensure that you're getting from them. Manganese comes in three purity levels of 12 percent, 14 percent, and 18 percent -- the greater the manganese content, the better the wear. It is essential to remember that the better quality and expensive manganese must have been hard at work, also called cold worked. The higher grade manganese won't be worth the cost and benefits if you can't work to the maximum. If you are looking to learn details about mill liners foundry, you must check it out here at CrusherParts website.

Utilize the appropriate profiles

youtube

It is crucial to choose the correct profile for crushing. In the absence of this, wear life could be reduced and production output could be affected. Different profiles are available in accordance with the material to be crushed as well as the output desired. This will allow for increased production throughput while improving the resistance to wear. If you have a problem with a particular part of the wear Find a service provider who can scan it and recommend bespoke modifications. This can help you in putting material into specific places to prevent premature wear. Wear liners for jaw, cone, and gyratory crushers may be utilized to achieve this.

Conclusion

If you don't compare your efficiency throughput to the cost of the parts you use, you might not get the most out of the wear parts you have. This could impact your earnings. You can make informed purchasing choices by keeping track of what you wear.

0 notes

Photo

Aluminium pattern and corbox with matchplate #foundrypattern #foundrypatternmaking #foundrypatterns #foundry #foundries #aluminiumpatterns #aluminumfoundry #woodenpatterns #woodenpattern #pumps #pumpcasing #pumpindustry #pumppatterns #valvepatterns #valveindustry #valvemanufacturer #windandenergy #windmill #windmills #windmillpattern #windmillpatterns #oilandgasindustry #crusherpatterns #crusherparts #miningmachinery #miningindustry #manholecover (at Coimbatore, Tamil Nadu) https://www.instagram.com/p/CQT5z8YrY7L/?utm_medium=tumblr

#foundrypattern#foundrypatternmaking#foundrypatterns#foundry#foundries#aluminiumpatterns#aluminumfoundry#woodenpatterns#woodenpattern#pumps#pumpcasing#pumpindustry#pumppatterns#valvepatterns#valveindustry#valvemanufacturer#windandenergy#windmill#windmills#windmillpattern#windmillpatterns#oilandgasindustry#crusherpatterns#crusherparts#miningmachinery#miningindustry#manholecover

0 notes

Text

BDI WEAR PARTS

BDI Wear Parts is a dynamically growing company with many years of experiences in production and supply of Crusher wear parts, Crusher spare parts, Ball mill liners, Forged steel balls, Crusher backing compound and Reverse engineering services. We supply wear parts to the USA, Canada, Europe, Australia and Africa.

Customize the required wear parts according to the drawings you provide.

If you couldn’t find a suitable crusher replacement part, or the material of your crusher replacement part is not good and affects the service life, you can choose us, and we will customize it according to the drawings you provide.

And our proprietary alloys offer increased toughness and durability, tested for longest usable wear life, we have many case histories in which wear life increase of 60% are common, and some in which wear life increase up to 200%. We are manufacturer. You are getting manufacturer price, usually we are save 30~50% of the cost for our customers.

Through the recruitment of highly experienced staff, BDI is able to source and provide compatible quality crusher spares and wear parts for all leading mobile crushing and screening equipment at highly competitive prices.

Our focus on quality crafting, cost-effectiveness and customer satisfaction, together with our desire to continuously provide our customers with the best products has helped us succeed in the quarry and mining industry.

We have two big advantages to offer your company over our competition:

1. Unique technique for its cone crusher liner production.

2. Clean Manganese Steel

Please contact our sales and care department for any inquiries!

www.bdiwearparts.com

#autoshredder#mine#wearpart#recycling#mining#cement#scrapmetal#crushing#recycle#shredder#goldmining#aggregate#processing#crushingandscreening#miningequipment#mineral#crusherparts#crusherwearparts#crushers#manganesesteel#castings#manganese#demolition#mobilecrushing#crushercastings#metalrecycling#metalcrusher#metal#wearparts#scrap

0 notes

Text

BDI WEAR PARTS

BDI Wear Parts is a dynamically growing company with many years of experiences in production and supply of Crusher wear parts, Crusher spare parts, Ball mill liners, Forged steel balls, Crusher backing compound and Reverse engineering services. We supply wear parts to the USA, Canada, Europe, Australia and Africa.

Customize the required wear parts according to the drawings you provide.

If you couldn’t find a suitable crusher replacement part, or the material of your crusher replacement part is not good and affects the service life, you can choose us, and we will customize it according to the drawings you provide.

And our proprietary alloys offer increased toughness and durability, tested for longest usable wear life, we have many case histories in which wear life increase of 60% are common, and some in which wear life increase up to 200%. We are manufacturer. You are getting manufacturer price, usually we are save 30~50% of the cost for our customers.

Through the recruitment of highly experienced staff, BDI is able to source and provide compatible quality crusher spares and wear parts for all leading mobile crushing and screening equipment at highly competitive prices.

We have two big advantages to offer your company over our competition:

1. Unique technique for its cone crusher liner production.

2. Clean Manganese Steel

Please contact our sales and care department for any inquiries!

www.bdiwearparts.com

#autoshredder#mine#wearpart#recycling#mining#cement#scrapmetal#crushing#recycle#shredder#goldmining#aggregate#processing#crushingandscreening#miningequipment#mineral#crusherparts#crusherwearparts#crushers#manganesesteel#castings#manganese#demolition#mobilecrushing#crushercastings#metalrecycling#metalcrusher#metal#wearparts#scrap

0 notes

Text

BDI WEAR PARTS

BDI Wear Parts is a dynamically growing company with many years of experiences in production and supply of Crusher wear parts, Crusher spare parts, Ball mill liners, Forged steel balls, Crusher backing compound and Reverse engineering services. We supply wear parts to the USA, Canada, Europe, Australia and Africa.

www.bdiwearparts.com

Customize the required wear parts according to the drawings you provide. If you couldn’t find a suitable crusher replacement part, or the material of your crusher replacement part is not good and affects the service life, you can choose us, and we will customize it according to the drawings you provide. And our proprietary alloys offer increased toughness and durability, tested for longest usable wear life, we have many case histories in which wear life increase of 60% are common, and some in which wear life increase up to 200%. We are manufacturer. You are getting manufacturer price, usually we are save 30~50% of the cost for our customers.

www.bdiwearparts.com

Through the recruitment of highly experienced staff, BDI is able to source and provide compatible quality crusher spares and wear parts for all leading mobile crushing and screening equipment at highly competitive prices.

www.bdiwearparts.com

We have two big advantages to offer your company over our competition:

1. Unique technique for its cone crusher liner production.

2. Clean Manganese Steel

Please contact our sales and care department for any inquiries!

www.bdiwearparts.com

#autoshredder#mine#wearpart#recycling#mining#cement#scrapmetal#crushing#recycle#shredder#goldmining#aggregate#processing#crushingandscreening#miningequipment#mineral#crusherparts#crusherwearparts#crushers#manganesesteel#castings#manganese#demolition#mobilecrushing#crushercastings#metalrecycling#metalcrusher#metal#wearparts#scrap

0 notes

Text

Why choose BDI wear parts

BDI Wear Parts is a dynamically growing company with many years of experiences in production and supply of Crusher wear parts, Crusher spare parts, Ball mill liners, Forged steel balls, Crusher backing compound and Reverse engineering services. We supply wear parts to the USA, Canada, Europe, Australia and Africa.

Customize the required wear parts according to the drawings you provide.

If you couldn’t find a suitable crusher replacement part, or the material of your crusher replacement part is not good and affects the service life, you can choose us, and we will customize it according to the drawings you provide.

And our proprietary alloys offer increased toughness and durability, tested for longest usable wear life, we have many case histories in which wear life increase of 60% are common, and some in which wear life increase up to 200%. We are manufacturer. You are getting manufacturer price, usually we are save 30~50% of the cost for our customers.

Through the recruitment of highly experienced staff, BDI is able to source and provide compatible quality crusher spares and wear parts for all leading mobile crushing and screening equipment at highly competitive prices.

We have two big advantages to offer your company over our competition:

1. Unique technique for its cone crusher liner production.

2. Clean Manganese Steel

Please contact our sales and care department for any inquiries!

www.bdiwearparts.com

#autoshredder#mine#wearpart#recycling#mining#cement#scrapmetal#crushing#recycle#shredder#goldmining#aggregate#processing#crushingandscreening#miningequipment#mineral#crusherparts#crusherwearparts#crushers#manganesesteel#castings#manganese#demolition#mobilecrushing#crushercastings#metalrecycling#metalcrusher#metal#wearparts#scrap

0 notes

Text

BDI WEAR PARTS

BDI Wear Parts is a dynamically growing company with many years of experiences in production and supply of Crusher wear parts, Crusher spare parts, Ball mill liners, Forged steel balls, Crusher backing compound and Reverse engineering services. We supply wear parts to the USA, Canada, Europe, Australia and Africa.

Customize the required wear parts according to the drawings you provide.

If you couldn’t find a suitable crusher replacement part, or the material of your crusher replacement part is not good and affects the service life, you can choose us, and we will customize it according to the drawings you provide.

And our proprietary alloys offer increased toughness and durability, tested for longest usable wear life, we have many case histories in which wear life increase of 60% are common, and some in which wear life increase up to 200%. We are manufacturer. You are getting manufacturer price, usually we are save 30~50% of the cost for our customers.

Through the recruitment of highly experienced staff, BDI is able to source and provide compatible quality crusher spares and wear parts for all leading mobile crushing and screening equipment at highly competitive prices.

We have two big advantages to offer your company over our competition:

1. Unique technique for its cone crusher liner production.

2. Clean Manganese Steel

Please contact our sales and care department for any inquiries!

www.bdiwearparts.com

#autoshredder#mine#wearpart#recycling#mining#cement#scrapmetal#crushing#recycle#shredder#goldmining#aggregate#processing#crushingandscreening#miningequipment#mineral#crusherparts#crusherwearparts#crushers#manganesesteel#castings#manganese#demolition#mobilecrushing#crushercastings#metalrecycling#metalcrusher#metal#wearparts#scrap

0 notes

Text

BDI WEAR PARTS

BDI Wear Parts is a dynamically growing company with many years of experiences in production and supply of Crusher wear parts, Crusher spare parts, Ball mill liners, Forged steel balls, Crusher backing compound, Reverse engineering services, Mini excavator ,Mini skid steer loader and Electric pallet jack. We supply wear parts to the USA, Canada, Europe, Australia and Africa.

Compared with Metso, Sandvik, Symons and Telex OEM wear and parts, we can offer high manganese steel, iron casting, steel casting, bronze machined parts and standard hardware with competitive price, super quality, shortest lead time. Now we have a large number of goods in stock , such as Jaw plate, mantle, concave, liners ,bushings. shaft, Gear& Pinion.,etc

BDI wear and spares co., ltd. assembled with cutting-edge technology and talents. Over 30 years of experience in the industry, we have amassed the knowledge and expertise in aggregating technology and mining machinery to promise you high performance products.

1. Cone crusher wear parts of Metso HP, GP crusher series, Sandvik H2800, H3800, H4800, H6800, H8800 series, Cedar Rapids, KPI-JCI, Nordberg,Symons: 2-7FT, Standard & Shorthead Parts

2. Jaw crusher wear parts , Pionner, Svedala, Cedar Rapids, Heiwitt Robbins, Metso

3. Impact crusher casting blow bar, lining plate , Hartel, Cedar Rapids, Pioneer

4. Gyratory crusher AC linings ,Bushings.

5. Other OEM crusher spare & wear parts like Cedar Rapids, JCI, Telesmith, Trio, Heiwitt Robbins, Svedala, etc.

6. Mini excavator ,Mini skid steer loader and Electric pallet jack

We have two big advantages to offer your company over our competition:

1. Unique technique for its cone crusher liner production.

2. Clean Manganese Steel

Benefits of Using A Mini Excavator

Thanks to their versatility and the advanced hydraulics that lend them outsize power, mini excavators are often used in place other construction equipment. They weigh less than full-size excavators and exert less ground pressure. Their compact size allows them to maneuver in places that full-size excavators, backhoes and even skid steer loaders have trouble accessing, making them ideal for small, narrow or congested job sites.

Benefits of using a mini excavator include the following:

1.Small and compact, yet powerful

2.Compact swing for tight work spaces.

3.Useful in less than ideal terrain

Please contact our sales and care department for any inquiries!

www.bdiwearparts.com

#autoshredder#mine#wearpart#recycling#mining#cement#scrapmetal#crushing#recycle#shredder#goldmining#aggregate#processing#crushingandscreening#miningequipment#mineral#crusherparts#crusherwearparts#crushers#manganesesteel#castings#manganese#demolition#mobilecrushing#crushercastings#metalrecycling#metalcrusher#metal#wearparts#scrap

0 notes

Text

BDI Wear Parts is a dynamically growing company with many years of experiences in production and supply of Crusher wear parts, Crusher spare parts, Ball mill liners, Forged steel balls, Crusher backing compound and Reverse engineering services. We supply wear parts to the USA, Canada, Europe, Australia and Africa.

Drawing on the experience, expertise and financial stability of our highly successful organization, BDI aims to help customers reduce costs, increase parts availability, minimize downtime and provide an even greater after-sales services.

Through the recruitment of highly experienced staff, BDI is able to source and provide compatible quality crusher spares and wear parts for all leading mobile crushing and screening equipment at highly competitive prices.

Our focus on quality crafting, cost-effectiveness and customer satisfaction, together with our desire to continuously provide our customers with the best products has helped us succeed in the quarry and mining industry.

We have two big advantages to offer your company over our competition:

1. Unique technique for its cone crusher liner production.

2. Clean Manganese Steel

Benefits of Using A Mini Excavator

Thanks to their versatility and the advanced hydraulics that lend them outsize power, mini excavators are often used in place other construction equipment. They weigh less than full-size excavators and exert less ground pressure. Their compact size allows them to maneuver in places that full-size excavators, backhoes and even skid steer loaders have trouble accessing, making them ideal for small, narrow or congested job sites.

Benefits of using a mini excavator include the following:

1.Small and compact, yet powerful

2.Compact swing for tight work spaces.

3.Useful in less than ideal terrain

Please contact our sales and care department for any inquiries!

www.bdiwearparts.com

#autoshredder#mine#wearpart#recycling#mining#cement#scrapmetal#crushing#recycle#shredder#goldmining#aggregate#processing#crushingandscreening#miningequipment#mineral#crusherparts#crusherwearparts#crushers#manganesesteel#castings#manganese#demolition#mobilecrushing#crushercastings#metalrecycling#metalcrusher#metal#wearparts#scrap

0 notes

Text

BDI Wear Parts is a dynamically growing company with many years of experiences in production and supply of Crusher wear parts, Crusher spare parts, Ball mill liners, Forged steel balls, Crusher backing compound and Reverse engineering services. We supply wear parts to the USA, Canada, Europe, Australia and Africa.

Drawing on the experience, expertise and financial stability of our highly successful organization, BDI aims to help customers reduce costs, increase parts availability, minimize downtime and provide an even greater after-sales services.

Through the recruitment of highly experienced staff, BDI is able to source and provide compatible quality crusher spares and wear parts for all leading mobile crushing and screening equipment at highly competitive prices.

Our focus on quality crafting, cost-effectiveness and customer satisfaction, together with our desire to continuously provide our customers with the best products has helped us succeed in the quarry and mining industry.

We have two big advantages to offer your company over our competition:

1. Unique technique for its cone crusher liner production.

2. Clean Manganese Steel

Benefits of Using A Mini Excavator

Thanks to their versatility and the advanced hydraulics that lend them outsize power, mini excavators are often used in place other construction equipment. They weigh less than full-size excavators and exert less ground pressure. Their compact size allows them to maneuver in places that full-size excavators, backhoes and even skid steer loaders have trouble accessing, making them ideal for small, narrow or congested job sites.

Benefits of using a mini excavator include the following:

1.Small and compact, yet powerful

2.Compact swing for tight work spaces.

3.Useful in less than ideal terrain

Please contact our sales and care department for any inquiries!

www.bdiwearparts.com

#autoshredder#mine#wearpart#recycling#mining#cement#scrapmetal#crushing#recycle#shredder#goldmining#aggregate#processing#crushingandscreening#miningequipment#mineral#crusherparts#crusherwearparts#crushers#manganesesteel#castings#manganese#demolition#mobilecrushing#crushercastings#metalrecycling#metalcrusher#metal#wearparts#scrap

0 notes