#India Industrial Fasteners Market

Text

#Global Industrial Fasteners Market Analysis#Global Industrial Fasteners Market Forecast#Global Industrial Fasteners Market Outlook#Global Industrial Fasteners Market Research Report#Global Industrial Fasteners Market Revenue#Global Industrial Fasteners Market Segmentation#India Industrial Fasteners Market#India Industrial Fasteners Market Growth#India Industrial Fasteners Market Trends#Industrial Fasteners Market Competitive landscape#Industrial Fasteners Market in India#Industrial Fasteners Market Overview#Industrial Fasteners Market Size

0 notes

Text

One of the top wholesalers, suppliers, and importers of a variety of high-quality Fasteners and Fixing including nuts and bolts, metal screws, machine tools, fastener expansion tubes, heavy-duty anchors, anchors for general fixing, pipe clamps, industrial screws, and other items is Kaizen Metals india Screw India.

Our cutting-edge infrastructure facility located in Jamnagar guarantees standardized product manufacture.

These items, which come in a variety of shapes and sizes, are renowned for their smooth finishes, resistance to corrosion, dimensional precision, and durable construction.

For timely, safe, and secure product delivery to customers, our logistic support specialists leverage a large distribution network.

The superior quality of the things our business creates is the single aspect that supports it, and we never compromise on that in any way.

All of our goods are rigorously tested for their durability and safety. We take steps to ensure that none of our valued customers have ever complained about any of our items.

Our company has achieved an unachievable height that is only attained by a very small number of businesses thanks to our moral business methods and unwavering dedication.

We have been able to provide our clients very consistent and trustworthy items at rock bottom prices because of our extensive experience, thorough understanding of this company range, and the presence of incredibly committed and assiduous employees in our crew.

With the help of a group of knowledgeable, skilled, committed, and diligent individuals, this team approached every assignment with great care. Our staff includes purchasing agents, quality inspectors, packaging specialists, and many more.

These individuals were hired based on their expertise and understanding of their respective fields. Their upbeat demeanor and expert understanding of the field create a productive atmosphere where employees love the work they do. Additionally, this team is periodically refreshed in accordance with the most recent market trends.

#nuts and bolts#metal screw#machine tools#fastener expansion tube#heavy duty anchors#general fixing anchors#pipe clamps#industrial screws#fixings and fasteners#fixings and fastener#screws#bolts#nuts#coach-screws#screw hooks#rivets#cotters#cotter-pins#washers

1 note

·

View note

Text

Know all about Indian Panche or Dhoti

'Panche,' another name for Dhoti, is a 4.5m long rectangular piece of cloth. This unstitched fabric is wrapped around the legs and knotted at the waist. Karnataka men dress aesthetically in panche. This outfit exemplifies an ethnic fusion of tradition and modernity. Karnataka men wear panches with shirts on a variety of occasions. Dhoti is popular in Tamil Nadu, Kerala, Andhra Pradesh, Maharashtra, Karnataka, Bihar, Madhya Pradesh, Assam, West Bengal, Odissa, Konkan, and Goa in India.

Origin and History

The origin of Panche traces its existence and emergence centuries ago, when temple priests in Karnataka wore this attire, particularly when performing religious and ritualistic pujas and occasions. The traditional colours associated with this traditional attire were pure white or saffron. It was also observed that Mahatma Gandhi wore this outfit on various public occasions, including when he travelled abroad. It was also worn by devotees and priests of the 'Hare Krishna' sect, and later by commoners as this attire became a fashion trend in South India.

Style & Attire

This Karnataka traditional attire is worn by wrapping the dhoti around the hips and tucking the ends to secure it in place. To complete the look, an additional piece of cloth is draped across the body and fastened onto the shoulder with the loose end corners of the cloth. Men sometimes fold the panche in half like the south Indian white lungi to reveal their legs for comfort or while working.

Innovations

With the passing years, the innovative wind of technology has blown over the state of Karnataka. Technological advancements and improvements have undoubtedly turned the textile industries in Karnataka on their heads, propelling the creative ball to new heights. With each passing year, more fabric textures are introduced. To achieve acceptance of the costume from future generations, current priorities are blended with layers of tradition.

More silk has been introduced into the Panche fashion world, which is preferred for most occasions. The Panche is accompanied by the wearers in decorative and stylish kurtas and shirts over cotton vest. Rich colours and delicate embroideries at the borders in gold and silver threads are becoming popular. Cotton versions of these costumes are being considered for daily use in addition to festive and religious occasions. An Angavastram, a cloth made of cotton or silk, is worn with the Panche, which is worn around the neck and covers one shoulder of the body.

Global Presence

Cotton panche is lighter and softer, acting as a soothing factor for the wearer throughout the year, especially during the summers. As a result, people and international markets all over the world readily accept and embrace this outfit.

Wearing Panche

Gold embroidered Thundu (angavastram) is commonly paired with the Panche, as well as Indian mojaris, gold plated watches, rings, and bracelets, glamorising the overall appearance.

Essentially, the bridegrooms of south Indian weddings or the main lead hosting the religious ceremony or pujas must wear this attire as a cultural and traditional symbol. Furthermore, this attire can be worn for special occasions and celebrations. Today, the availability of this attire in a variety of comfortable fabrics makes it easier to wear on a daily basis as well as for semi-formal occasions.

Interesting Facts and Comparisons

South Indian men have a habit of folding the Panche in half, revealing the lower portion of their legs beginning at the knees. However, this style is considered inappropriate, especially in front of the ladies, so the Panche must be worn in a loosened form in front of the elders and ladies, completely covering the legs.

Western jeans and trousers have always been in a competitive league with dhoti attire. However, the traditional and cultural essence of these dhoti costumes, such as Panche, distinguishes itself from the rest.

#Traditional#clothing#cotton#style#outfits#colors#fabric#costume#dhoti#Indian#occasional#dress#culture#weddings#pattern#celebrations

4 notes

·

View notes

Text

Understanding the Industrial Uses of Pipes and Tubes

Sagar Steel Corporation is one of the most excellent Pipes and Tubes Suppliers in India. India is a hub of industrial innovation and production. Pipes and tubes are the forgotten treasures of industrial engineering and construction; they discreetly facilitate the movement of materials, gasses, and fluids required for numerous activities. These cylindrical components are adaptable and may be used in a variety of industries, including those unrelated to their primary function. Let's look at the many characteristics of pipes and tubes, as well as their important role in modern industrial settings.

It's critical to understand the differences between pipes and tubes before discussing their applications. Despite having the same appearance, they might fulfill diverse functions according to their structural characteristics. Pipes carry fluids or gasses under pressure and are typically standardized in diameter and thickness. On the other hand, tubes are more precisely measured and are frequently used in non-pressurized systems for material transfer or structural reasons. This guide explores the top Pipes and Tubes Manufacturer in India, Unraveling the strands that make them vital.

India's industrial progress is dependent on the efficiency of its components. Discover how Indian Pipes and Tubes Manufacturers contribute significantly to the country's industrial landscape, catering to diverse sectors from construction to petrochemicals.

As a market pioneer, we believe our distinctive goods, such as Round Bars Manufacturer and Fasteners Manufacturer in India, should thoroughly benefit our clients.

For More Detail

Website: sagarsteel.net

Product: Pipes and Tubes Supplier in India

Other Product: Flange Manufacturer In India.

0 notes

Text

"Market Trends and Future Outlook: Navigating Opportunities and Challenges in the Indian Inconel and Monel Industry"

Introduction:

The Indian market for Inconel and Monel products is characterized by dynamic trends, driven by evolving industry demands, technological advancements, and global economic factors. Understanding these trends and anticipating future developments is crucial for stakeholders in the Inconel and Monel industry to capitalize on opportunities and overcome challenges. In this article, we analyze the current market landscape, identify key trends, and forecast the outlook for the Indian Inconel and Monel industry.

Suppliers of Fasteners

Brief Overview:

The Indian Inconel and Monel industry have witnessed steady growth fueled by increasing demand from sectors such as aerospace, automotive, oil and gas, and infrastructure development. Factors such as rapid urbanization, investments in infrastructure projects, and technological innovations are driving the adoption of these high-performance alloys. However, the industry also faces challenges related to raw material availability, pricing volatility, global competition, and regulatory compliance.

Elevator Bolt Manufacturers in Mumbai

Applications:

1. Growing Demand in Aerospace and Defense: The aerospace and defense sector represents a significant market for Inconel and Monel alloys in India, driven by the expansion of the aviation industry, defense modernization initiatives, and the indigenous development of aircraft and spacecraft. Demand for lightweight, corrosion-resistant materials for aircraft components, engines, and structural parts is expected to fuel continued growth in this segment.

2. Expansion in Oil and Gas Exploration: The oil and gas industry presents lucrative opportunities for Inconel and Monel products in India, particularly in offshore exploration, refining, and petrochemical processing. The need for corrosion-resistant materials capable of withstanding harsh environments and high temperatures is driving demand for Inconel and Monel alloys in pipelines, valves, heat exchangers, and drilling equipment.

3. Infrastructure Development Projects: India's ambitious infrastructure development projects, including transportation networks, power generation facilities, and industrial infrastructure, are driving demand for Inconel and Monel products in construction, engineering, and manufacturing applications. These alloys offer superior corrosion resistance, durability, and longevity, making them ideal for bridges, tunnels, power plants, and industrial machinery. Stainless Steel Fasteners Manufacturers in Mumbai

4. Technological Advancements: Advancements in manufacturing technologies, such as additive manufacturing, powder metallurgy, and surface coating techniques, are expanding the capabilities and applications of Inconel and Monel alloys in India. The adoption of these technologies enables the production of complex geometries, customized components, and high-performance coatings tailored to specific industry requirements.

5. Global Market Dynamics: The Indian Inconel and Monel industry are influenced by global market dynamics, including raw material prices, currency fluctuations, trade policies, and competition from international manufacturers. Manufacturers must stay abreast of these factors to remain competitive, optimize supply chain management, and explore export opportunities in global markets.

SS Fasteners Suppliers

Conclusion:

The Indian market for Inconel and Monel products is poised for continued growth, driven by increasing industrialization, infrastructure development, and technological innovation. While the industry faces challenges related to raw material sourcing, pricing volatility, and regulatory compliance, opportunities abound in aerospace, oil and gas, infrastructure, and other sectors. By leveraging technological advancements, fostering innovation, and embracing sustainable practices, stakeholders can navigate the evolving landscape of the Indian Inconel and Monel industry and capitalize on emerging opportunities for growth and expansion.

0 notes

Text

ASADEEP Furnishing Private Limited Established in 1979 by the owner named honorable Mr. Mahesh Gupta, proudly introduce ourselves as one of the fastest growing manufacturers and suppliers of Furnishing Fabrics. For us, we have got great respect for the infrastructure facilities which is our weaving units, of our made fabrics among all the fastening product of our country.

We believes that in the days leading up to that time, Asadeep is a huge name, fame, brand and power, as we started our business in very small scale but now it is an exporter and importer among different countries. Our main motto is to provide beautiful and pure collection to our vendee.

Asadeep is world’s largest maker and collaborating Industry manufacturing all type of fabrics with keen eye using pure material, none of any materials fined which have impurities. We make sure all the related particles while manufacturing it. These fabric are accouterment with mixing by twisting them together making yarn. The yarn are interlaced, crochet or they iron onto the fabric.

We are leading & Famous for Sofa Fabrics, Outdoor Fabrics, Chair Fabrics, Home furnishing Fabrics manufacturer & Supplier in India

Endorsed by industry experience of 40+ Years, we are the leading manufacturers and suppliers of Fabrics. Our products are specialized well known for its softness and smooth finishing. We have several variety of design and textures available in our firm. We have experts to making products with latest trendy designs and textures, who make products by analyzing everything. This procedure make us gain a huge clientele in the market. Our team members are hardworking and efficient, they work round the clock to achieve the set targets. All of our expertise are well educated and stamina to complete the need of our vendee. There is also a quality controlling unit, which keeps a strict manifestation on the quality of the yarn used to manufacture the fabrics.

#asadeep#asadeepfurnishing#asadeepfurnishingdelhi#sofa upholstery fabric manufacturers in india#chair fabric manufacturers in india#Outdoor fabric manufacturers in india#Furnishing fabric manufacturers in india#Curtain fabric manufacturers in india#Cushion Fabrics manufacturers in india#panel projects manufacturers in india#Auditorium Fabric manufacturers in india#Fire Retardant Fabric manufacturers in

1 note

·

View note

Text

Monel K500 Pipes & Tubes Stockists In India

About Monel K500

Monel K500 is a nickel-copper alloy that is essentially a stronger, harder version of Monel 400, due to the addition of aluminum and titanium to the alloy's composition. This makes it more suitable for applications where higher strength and hardness are required, while still maintaining the excellent corrosion resistance of Monel 400.

Properties of Monel K500 include:

High Strength: It offers greater strength and hardness than Monel 400, often achieved through age-hardening.

Corrosion Resistance: Like Monel 400, it is highly resistant to a range of corrosive environments.

Non-Magnetic: The alloy retains its non-magnetic properties even at lower temperatures.

Good Fatigue Strength: Especially useful in the marine and chemical processing industries.

Applications

Monel K500 is typically used in:

Oil and gas extraction industries (especially for pump shafts, impellers, and valves)

Marine applications

Chemical processing equipment

Chains, cables, springs, valve trim, fasteners for marine service

Purchasing Monel K500 Pipes & Tubes

When purchasing Monel K500 pipes and tubes, consider the following:

Specifications: Ensure that the product meets specific standards (like ASTM, ASME, etc.) relevant to your application.

Supplier Reputation: Choose suppliers with good market standing and positive reviews to ensure quality and reliability.

Certification: Ask for material test certificates and other documentation to verify the material composition and properties.

Size and Dimensions: Make sure the dimensions and sizes meet your specific requirements.

Cost: Monel alloys can be more expensive than common stainless steel due to their nickel content. Ensure the cost aligns with your budget and the application's value.

Verification

If you're looking at a specific company named "Navneet Corporation" for purchasing Monel K500 pipes and tubes:

Verify the Business: Check if they have a website, customer reviews, and any business registrations.

Product Range: Confirm they stock or can manufacture Monel K500 in the forms and specifications you need.

Ask for Quotes: Contact them directly to get detailed product specifications, pricing, and lead times.

If you have more specific details about the company or need further assistance, feel free to ask!

0 notes

Text

Supplier of SS Industrial Fittings in Madhya Pradesh

Krystal Steel is a Manufacturer, Stockiest, and Supplier of SS Industrial Fittings in Madhya Pradesh.

Krystal Steel was Founded in 2013, in Ahmedabad, Gujarat, India.

We specialize in an extensive range of stainless steel products, encompassing SS sheets, plates, coils, fasteners, pipes, tubes, bars, wires,

rods, strip coils, angles, channels, flats, industrial valves, flanges, fittings, and dairy valves.

Our diverse range of industrial fitting products is available in various standard materials to cater to diverse needs.

Manufactured with precision using stainless steel, our industrial fittings exhibit dimensional accuracy and high functionality across

diverse application areas.

With a well-equipped manufacturing unit and a team of highly qualified professionals boasting years of experience, we ensure the production

of top-quality SS fittings. Utilizing only the finest quality raw materials, we maintain high standards in our manufacturing processes.

We conduct multiple quality tests to assess the efficiency and quality of our fittings, ensuring they meet stringent industry standards.

Our commitment extends to providing timely, seamless, and convenient delivery of fittings to our valued customers.

Features:

Robust design

Impeccable finish

Corrosion resistance

Long durability

High strength

Bend fittings

Due to the optimum performance and impeccable design, all the fittings are highly demanded industrial fittings in the market.

Below is the list of our industrial fittings.

Tube fittings

Pipes fittings

Washers

Flanges

Elbow fittings

Bend fittings

Reusable fittings

Banjo fittings

Reducers

Coupling

Hex nipple

Pipe nipple

Krystal Steel is a Manufacturer, Stockiest, and Supplier of SS Industrial Fittings in Madhya Pradesh Including locations like Indore, Bhopal,

Jabalpur, Gwalior, Ujjain, Dewas, Satna, Rewa, Ratlam, Sagar, Singrauli, Pithampur, Neemuch, Morena, Chhindwara, Bhind, Damoh, Shivpuri,

Mandsaur, Hoshangabad.

Feel free to contact us for more information and inquiries.

Read the full article

0 notes

Text

Hex Bolts and Nuts in Delhi

RKC Company: Your Trusted Source for Hex Bolts and Nuts in Delhi

When it comes to industrial fasteners in Delhi, RKC Company has been a reliable name since its establishment in 1976. With a strong commitment to quality and service, RKC has become a preferred choice for those seeking high-precision Hex Bolts and Nuts.

RKC is more than just a trading company; it's a service-oriented business that understands the importance of meeting deadlines and delivering quality products. Their vast product range, including Hex Bolts and Nuts, is housed in modern warehouse facilities equipped with state-of-the-art computer systems for efficient sales and service.

Safety and durability are paramount when it comes to fasteners, especially for major projects. RKC ensures that their products meet the highest standards of quality, coupled with traceability and a reliable service. This dedication to quality has earned them a stellar reputation in Delhi and beyond.

As a company with 27 years of industry experience, RKC's move to larger premises has facilitated increased sales in India, and their venture into the export market has shown steady growth.

If you're looking for Hex Bolts and Nuts in Delhi, RKC is your go-to source. Their technical expertise, efficient service, and unwavering commitment to quality make them the top choice for all your fastening needs. Choose RKC for fasteners that are built to last.

Hex Bolts and Nuts in Delhi

0 notes

Text

Top Stainless Steel Sheet Supplier in Vadodara

Luvana Metal Corporation is a manufacturer, Exporters, and Top Stainless Steel Sheet Supplier in Vadodara, India.

We provide stainless steel products, including coils, sheets, plates, bars, rods, wires, valves, pipes, fittings, channels, angles,butt weld fittings, flanges, and fasteners.

Luvana Metal Corporation is a well-known provider of superior quality SS sheets, which are highly demanded in the market It is an oxidable

product that is comparatively inexpensive and used in various applications.

Why Luvana Metal Corporation Is Your Best Choice?

250+ Certificates

100% repeat order rate

10 years of experience in the finishing industry

Always innovating

100% pre-factory inspection

Strong supply chain support system

Elevate your projects with our premium stainless steel sheets, meticulously crafted to exceed industry standards for quality and performance.

Whether you're working on architectural designs, kitchen appliances, or industrial machinery, our sheets deliver unmatched durability,

corrosion resistance, and aesthetic appeal.

Designed to meet the diverse requirements of any project, our stainless steel sheets offer a wide range of grades, thicknesses, and finishes.

Choose from a variety of sizes, finishes, and grades in our stainless steel sheet collection.

Our products provide strength, durability, and exceptional corrosion resistance, ensuring confidence in their reliability and longevity.

We utilize state-of-the-art technology and advanced manufacturing techniques to ensure our products deliver superior performance in any application.

We are committed to delivering outstanding customer service and maintaining the highest standards of quality in everything we do.

Luvana Metal Corporation is Top Stainless Steel Sheet Supplier in Vadodara, India, and places like Sankheda, Pavi-jetpur, dabhoi, rangoli, lambda,

nandesari, makarpura, vaghodia, P.C.C, Savli and etc.

Please contact us if you have any questions or would like further details.

0 notes

Text

Bolt It Right: Innovative U-Bolts for Every Project

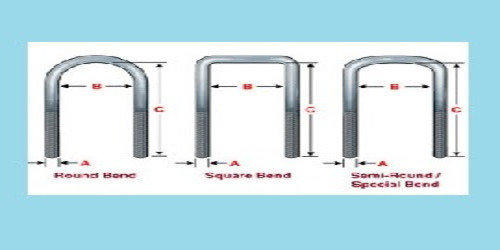

When it comes to fastening and securing components across various industries, from automotive to construction, U-Bolts are an indispensable ally. These versatile tools, shaped like the letter U with screw threads on both ends, are used to support pipework, secure tubing, and hold together machinery. This blog post explores the various kinds of U-Bolts, their applications, and why sourcing from reputable U-bolt exporters India can make a significant difference in your projects.

Introduction to U-Bolts

In the vast landscape of industrial fasteners, U-Bolts stand out as pivotal components utilized extensively across various sectors, including construction, automotive, and marine industries. These U-shaped bolts are distinctive for their ability to securely clamp down pipes, conduits, and other cylindrical bodies to surfaces, ensuring stability and structural integrity. The versatility of U-Bolts lies in their simple yet effective design, which comprises a curved body with threaded arms on both ends that can be fastened with nuts.

Central to the effectiveness of U-Bolts is the precision in their manufacturing. Material selection, dimensional accuracy, and threading are critical factors that determine the durability and suitability of U-Bolts for specific environments. This is where U-bolt exporters India have carved a niche. Known for their commitment to quality and innovation, Indian exporters have mastered the art of producing high-grade U-Bolts that meet rigorous international standards. They offer a range of materials, from carbon steel to stainless steel, each tailored to resist the environmental challenges of the applications they serve.

The capability of Indian manufacturers to provide customized solutions sets them apart. Whether the requirement is for standard piping support in commercial buildings or specialized applications in corrosive marine environments, U-bolt exporters India can deliver products designed to meet exact specifications. Their role extends beyond mere suppliers to collaborative partners who contribute to the engineering and design process, ensuring that the U-Bolts not only fit the technical requirements but also contribute to the overall efficiency and safety of projects.

As global industries continue to expand and evolve, the demand for reliable and adaptable fastening solutions like U-Bolts also grows. In this context, U-bolt exporters India are not just fulfilling a need in the market; they are actively enhancing how industries secure and stabilize their most critical structures. Choosing the right U-Bolt, and more importantly, the right exporter, can make a substantial difference in the success of any project.

Types of U-Bolts and Their Applications

U-Bolts are diverse in their designs and applications, meeting the specific needs of various industries with precision. Each type of U-Bolt serves a unique purpose, and U-bolt exporters India have honed their manufacturing processes to cater to these varied requirements with expertise. The most common types include:

Standard U-Bolts

Standard U-Bolts serve as the cornerstone of secure fastening across a myriad of industries. Their straightforward design, comprising a U-shaped body with threaded arms, makes them versatile and reliable for a wide range of applications. Typically used to secure pipes, conduits, and machinery to surfaces, standard U-Bolts provide stability and support in construction, automotive, and plumbing projects. Available in various materials such as carbon steel and stainless steel, these U-Bolts offer durability and corrosion resistance, ensuring long-lasting performance even in demanding environments. With their ubiquity and effectiveness, standard U-Bolts continue to be a trusted choice for fastening needs in diverse industrial settings.

Long Tangent U-Bolts

Long Tangent U-Bolts are engineered to provide extended reach and increased clearance for specific fastening requirements. With longer legs compared to standard U-Bolts, they offer versatility in applications where additional space is necessary, such as when mounting objects with insulation or requiring a larger grip. These U-Bolts ensure a secure and stable connection between pipes, conduits, or other cylindrical objects and their support structures. Their design facilitates proper alignment and minimizes the risk of slippage or shifting, making them ideal for use in construction, electrical installations, and automotive systems. Available in various materials and sizes, Long Tangent U-Bolts offer tailored solutions to meet the unique needs of different projects, ensuring optimal performance and reliability.

Square U-Bolts

Square U-bolts are specially designed to provide stability and strength when fastening square-shaped objects or structures. Their unique square shape ensures a secure grip and prevents rotation, making them ideal for applications where a stable connection is paramount, such as in framing and construction projects. Square U-bolts are commonly used to secure posts, beams, and other square components in place, ensuring structural integrity and preventing movement or displacement. Available in a variety of sizes and materials including stainless steel and galvanized steel, these U-Bolts offer durability and resistance to corrosion, making them suitable for both indoor and outdoor applications. With their reliability and versatility, Square U-Bolts are indispensable components in ensuring the stability and safety of various structural installations.

Custom U-Bolts

Custom U-Bolts offer a versatile and flexible approach to fastening solutions, catering to the specific requirements of diverse applications. Unlike standard U-Bolts, which have predefined sizes and configurations, custom U-Bolts can be precisely engineered to meet unique specifications. This includes customization of dimensions, materials, thread sizes, and even specialized coatings or finishes. Whether it's accommodating non-standard pipe diameters, unusual mounting surfaces, or challenging environmental conditions, custom U-Bolts provide a tailored solution for every situation. U-bolt exporters India specialize in producing custom U-Bolts with precision and expertise, ensuring that each fastening component perfectly aligns with the needs of the project. By opting for custom U-Bolts, businesses can achieve optimal performance, reliability, and efficiency in their fastening applications, ultimately contributing to the success of their projects.

Choosing the Right U-Bolts for Your Project

Selecting the appropriate U-Bolts is crucial for ensuring the structural integrity and longevity of your project. With a myriad of options available, partnering with reputable U-bolt exporters India and Square Head Bolts Suppliers can streamline the decision-making process while guaranteeing quality and reliability.

First and foremost, consider the environmental factors your project will encounter. U-bolt exporters India offer a range of materials, including stainless steel and galvanized steel, each tailored to withstand specific conditions such as corrosion from exposure to moisture or chemicals.

Next, evaluate the load requirements of your application. U-bolt exporters India can provide guidance on selecting the right size and strength of U-Bolts to support the intended weight without compromising safety.

Additionally, factor in any special considerations such as temperature variations, vibration levels, or potential for expansion and contraction. Indian exporters can customize U-Bolts to accommodate these unique needs, ensuring a precise fit and optimal performance.

Lastly, assess your budget and timeline constraints. U-bolt exporters India are known for their competitive pricing and efficient manufacturing processes, making them an ideal choice for projects with cost and time sensitivities.

By collaborating with U-bolt exporters India, you can confidently choose the right U-Bolts for your project, knowing they are backed by industry expertise and stringent quality standards.

U-Bolt Coatings and Finishes

U-bolt exporters India offer a variety of coatings and finishes to enhance the performance and durability of their products. From galvanized coatings for corrosion resistance in outdoor environments to fluoropolymer finishes for extreme conditions, Indian exporters ensure that their U-Bolts are equipped to withstand the challenges of any application. These coatings not only protect against rust and corrosion but also provide a polished appearance, making them suitable for both functional and aesthetic purposes. With a range of options available, U-bolt exporters India ensure that your fastening solutions are tailored to meet your specific requirements.

U-bolt exporters India

When sourcing U-Bolts, particularly for large projects or specialized requirements, it is crucial to partner with experienced and reliable exporters. U-bolt exporters India are renowned for their high-quality manufacturing standards and cost-effectiveness. They offer a wide range of U-Bolts, including custom options, and can provide valuable guidance on the best choices for specific applications.

Installation Tips for U-Bolts

Proper installation of U-Bolts is crucial for ensuring their effectiveness and longevity. U-bolt exporters India recommend several tips for optimal installation. Firstly, ensure that the U-Bolts are tightened evenly to prevent uneven stress distribution. Secondly, use appropriate torque values to avoid over-tightening, which can lead to deformation or damage. Additionally, regularly inspect the U-Bolts for signs of wear or corrosion, and replace them as needed to maintain structural integrity. By following these installation tips, provided by experienced U-bolt exporters India, you can maximize the performance and lifespan of your U-bolt assemblies.

Read Also: U BOLTS MANUFACTURER: HIGH-PERFORMANCE FASTENING SOLUTIONS

U-Bolt Maintenance

Maintaining U-Bolts is essential for ensuring their continued performance and safety. U-bolt exporters India advise regular inspections to check for signs of wear, corrosion, or loosening. Tighten any loose U-Bolts to prevent potential hazards and ensure a secure connection. Additionally, consider applying lubricants to threaded areas to prevent rust and make future adjustments easier. If corrosion is present, U-bolt exporters India recommend cleaning the affected areas and applying protective coatings to prevent further deterioration. By incorporating these maintenance practices, you can extend the lifespan of your U-Bolts and maintain the integrity of your structures.

Why Choose U-bolt Exporters India

Choosing U-bolt exporters India offers a multitude of advantages for businesses worldwide. Indian exporters are renowned for their commitment to quality, offering U-Bolts that adhere to stringent international standards at competitive prices. With a robust manufacturing infrastructure and skilled workforce, U-bolt exporters India can fulfill large volume orders with efficiency and precision, ensuring timely delivery for projects of any scale. Moreover, Indian exporters prioritize customization, allowing customers to tailor U-Bolts to their specific requirements. By partnering with U-bolt exporters India, businesses can access high-quality products, cost-effective solutions, and reliable service, ultimately enhancing project outcomes.

Conclusion

U-Bolts are fundamental in numerous industrial applications, offering versatility, reliability, and strength. Understanding the various types of U-Bolts, their applications, and proper maintenance can significantly enhance project outcomes. For businesses looking to secure high-quality U-Bolts, partnering with reputable U-bolt exporters India can provide an edge in product quality and cost-effectiveness. Whether your project is local or international, ensuring you choose the right U-Bolt and supplier is key to securing your structures safely and efficiently. You can bolt it right for every project with the right bolts and the right partner.

Read Also: U Bolt Dynamics: Crafting Precision Fasteners for Every Need

0 notes

Text

Understanding the Monel Price chart: Influencing Factors and Market Dynamics

Prices of Monel in Asia experienced a decline due to weak demand from downstream industries, slow recovery in China post-COVID protocols, and increased production costs. In Europe, Monel prices showed a fluctuating trend influenced by raw material costs and limited inquiries from the aerospace and chemical sectors. A slight price increase was supported by reduced energy production costs and higher raw material consumption, but weak demand countered these factors. Meanwhile, in North America, Monel prices rose due to consistent demand, supply chain improvements, and increased input costs, offsetting initial struggles caused by sluggish demand and poor sales. Monel Price chart, including India Monel price, USA Monel price, pricing database, and analysis can prove valuable for procurement managers, directors, and decision-makers to build up their strongly backed-up strategic insights to attain progress and profitability in the business.

Definition

A class of nickel-copper alloys called Monel are renowned for their outstanding corrosion resistance, high strength, and durability. Monel alloys typically consist of 67–80% nickel and 30–33% copper, with trace amounts of iron, manganese, and other metals. These characteristics make Monel excellent for a range of industrial uses, including electrical connectors, chemical processes, oil and gas platforms, naval equipment, and oil and gas platforms. Monel alloys are widely sought after for important applications where corrosion resistance is crucial because they maintain their structural integrity in hostile conditions like seawater, acids, and alkalis.

Request for Free Sample: https://www.procurementresource.com/resource-center/monel-price-trends/pricerequest

Key Details About the Monel Price Trend

Procurement Resource does an in-depth analysis of the price trend to bring forth the monthly, quarterly, half-yearly, and yearly information on the monel in its latest pricing dashboard. The detailed assessment deeply explores the facts about the product, price change over the weeks, months, and years, key players, industrial uses, and drivers propelling the market and price trends.

Each price record is linked to an easy-to-use graphing device dated back to 2014, which offers a series of functionalities; customization of price currencies and units and downloading of price information as Excel files that can be used offline.

Industrial Uses Impacting the Monel Price Trend

Due to its outstanding corrosion resistance and great strength, Monel is used in a variety of applications across industries. It is frequently utilized in the marine industry for shipbuilding, propellers, and seawater valves. Monel is useful for machinery handling corrosive compounds in chemical processes. Additionally, it is used for offshore platforms and processing machinery in the oil and gas sector. Monel is used in the aerospace industry for electrical connectors and for sections of aircraft engines due to its electrical conductivity. It is used in medical and food processing industries for biocompatible equipment and handling corrosive elements in food, as well as fasteners for settings that require corrosion resistance.

Industry Consolidation and Market Concentration:

Supplier Dynamics: Market consolidation among Monel producers and suppliers may lead to pricing power and influence market dynamics. Dominant players with extensive production capacities and distribution networks can leverage economies of scale and pricing strategies to maintain market leadership.

Strategic Alliances and Partnerships: Collaborative arrangements, strategic alliances, and supply chain partnerships enable Monel producers to optimize production efficiencies, reduce costs, and enhance market competitiveness.

Contractual Arrangements and Price Negotiations:

Long-Term Contracts: Long-term supply contracts and procurement agreements between Monel buyers and sellers provide price stability and ensure reliable supply. Negotiated pricing terms, including volume discounts, price indexing mechanisms, and escalation clauses, mitigate price risks and enhance cost predictability.

Price Hedging and Risk Management: Hedging strategies, such as futures contracts, options, and derivatives, allow market participants to manage price risks and protect against adverse price movements in Monel and underlying raw materials.

Value-Added Services and Differentiation:

Customization and Tailored Solutions: Offering value-added services, such as material customization, technical support, and engineering solutions, allows Monel suppliers to differentiate their offerings and justify premium pricing based on added value and customer-specific requirements.

Quality Assurance and Compliance: Adherence to industry standards, product specifications, and quality assurance protocols enhances customer confidence and supports premium pricing for Monel products with superior quality, reliability, and performance.

Key Players

Arcelor Mittal

Baosteel

JFE Steel Corporation

Special metals corporation

Mangellan metals

Renine Metalloys

Contact Us

Company Name: Procurement Resource

Contact Person: Leo Frank

Email: [email protected]

Toll-Free Number: USA & Canada - Phone no: +1 307 363 1045 | UK - Phone no: +44 7537 132103 | Asia-Pacific (APAC) - Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA

0 notes

Text

The Rise of Fintech: Investment Opportunities in India’s Financial Sector

Invest in India: Unlocking the Fintech Goldmine

The funding area of India is going through a rollercoaster ride, fueled by the great acceleration of the fintech industry. Money doesn't like movements that don't promise any benefits to the shareholders, and the Indian market attracts investors with a promising return. Here, we offer a glimpse into the investment goldmine that is the fintech industry in India, examining the crucial underlying trends, dynamics, actors, and futuristic tech.

The Fintech Boom in India

Market Size and Growth: According to the fintech adoption rate globally, India scored the highest, with a figure of 87% that skyrocketed beyond the global average of 64%. The Indian fintech industry’s market size hit 50 billion USD in 2021, and the area is forecast to tally up to about 150 billion USD by 2025. Let's fasten the nets; the trip is right ahead!

Segments to Watch:

Payments: The Indian payments system is expected to attain 100 trillion transactions and 50 billion revenue by 2030, which is quite positive. Digital wallets, UPIs, and tap-and-go payments are, undoubtedly, the revolution.

Digital Lending: When we consider that in 2022, the market size for digital lending was $270 billion, while in 2023 it is projected to reach 350 billion dollars, there is no doubt of the rise in popularity of this dimension in the future. Small businesses and individuals are not poor outcasts in a vast pool of people or negligible compared to high-tech production tools, but instead play a very important role in driving the economy forward.

InsurTech: India ranks second on the list of insurance technologies in the Asia-Pacific. It is even thought that by the year 2030 there will be a 15-fold increase, and its value will be up to $88.4 billion. Insurtech firms are obsessed with insurance technology.

WealthTech: As easy ways to get rich catch on, more people are choosing wealth management platforms. In terms of Indian Market Wealth Technologies, one could witness growth reaching $237 billion by 2030.

Investment Opportunities:

Government Support: Some actions, like demonetization and GST, that further led to the growth of fintech have created conducive environments. Besides the major cities such as Rio, Bucharest, and Tokyo, lower-level cities like Lodougna and Lien Thai are also adopting this trend.

Conclusion: Seize the Day!

India’s fintech ecosystem is a playground of innovation, ripe for investment. Whether you’re a seasoned investor or a curious newcomer, consider allocating a slice of your portfolio to this dynamic sector. Invest in India, where opportunity meets innovation. Ready to explore India’s fintech frontier? Look no further than Fox&Angel. Our expert advisors blend tradition with technology, guiding you toward smart investment choices. Contact us today to embark on your financial journey!

0 notes

Text

Fumaric Acid Market Size, Share, Trends, Growth and Competitive Analysis

Global Fumaric Acid Market study by Data Bridge Market Research provides details about the market dynamics affecting this market, Market scope, Market segmentation and overlays shadow upon the leading market players highlighting the favourable competitive landscape and trends prevailing over the years.

Fumaric Acid Market report provides top to bottom assessment of the market with respect to income and developing business sector. The report encompasses several market dynamics while also evaluating the growth rate and the market value based on market dynamics and growth inducing factors. The industry analysis report is mainly explored under four major areas which are market definition, market segmentation, competitive analysis and research methodology. Fumaric Acid Market business report also covers strategic profiling of the major players in the market, comprehensive analysis of their fundamental competencies, and thereby keeping competitive landscape of the market in front of the client.

Access Full 350 Pages PDF Report @

Fumaric acid market size was valued at USD 634.35 million in 2023 and is projected to reach USD 937.22 million by 2031, with a CAGR of 5.00% during the forecast period of 2024 to 2031. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand.

Highlights of TOC:

Chapter 1: Market overview

Chapter 2: Global Fumaric Acid Market

Chapter 3: Regional analysis of the Global Fumaric Acid Market industry

Chapter 4: Fumaric Acid Market segmentation based on types and applications

Chapter 5: Revenue analysis based on types and applications

Chapter 6: Market share

Chapter 7: Competitive Landscape

Chapter 8: Drivers, Restraints, Challenges, and Opportunities

Chapter 9: Gross Margin and Price Analysis

Key takeaways from the Fumaric Acid Market report:

Detailed considerate of Fumaric Acid Market-particular drivers, Trends, constraints, Restraints, Opportunities and major micro markets.

Comprehensive valuation of all prospects and threat in the

In depth study of industry strategies for growth of the Fumaric Acid Market-leading players.

Fumaric Acid Market latest innovations and major procedures.

Favorable dip inside Vigorous high-tech and market latest trends remarkable the Market.

Conclusive study about the growth conspiracy of Fumaric Acid Market for forthcoming years.

Some of the major players operating in the market are:

FUSO CHEMICAL CO., LTD. (Japan)

Polynt (Italy)

Bartek Ingredients Inc. (Canada)

Tate & Lyle (U.K.)

TCI Chemicals (India) Pvt. Ltd. (India)

Huntsman International LLC (U.S.)

Merck KGaA (Germany)

The Chemical Company (U.S.)

BASF SE (Germany)

Akzo Nobel N.V. (Netherlands)

DuPont (U.S.)

Thermo Fischer Scientific, Inc. (U.S.)

Thirumalai Chemicals (India)

Khusheim Holding (Saudi Arabia)

Sip Chemical Industries (India)

Browse Trending Reports:

Hydroxyproline Market

Polymethacrylimide Pmi Foam Market

Trona Market

Bio Based Polypropylene Pp Market

Metallic Microspheres Market

Green Cement Market

Mechanically Fastened Cross Laminated Timber Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 888 387 2818

UK: +44 208 089 1725

Hong Kong: +852 8192 7475

Email: [email protected]

#Fumaric Acid Market Size#Share#Trends#Growth and Competitive Analysis#market size#market report#marketresearch#market share#market trends#market research#market analysis#markettrends

0 notes

Text

Making the Right Choice: Factors to Consider When Selecting an Inconel and Monel Manufacturer in India

Suppliers of Fasteners

Introduction:

Selecting the right Inconel and Monel manufacturer in India is a crucial decision that can impact the quality, reliability, and success of your projects. With numerous manufacturers competing in the market, it's essential to evaluate key factors to ensure you partner with a reputable and reliable supplier. This article outlines essential considerations to help you make an informed decision when selecting an Inconel and Monel manufacturer.

Brief:

Choosing an Inconel and Monel manufacturer requires careful evaluation of factors such as reputation, expertise, manufacturing capabilities, quality assurance practices, and customer service. By assessing these aspects systematically, you can identify a manufacturer that meets your specific requirements and delivers superior-quality products consistently.

Elevator Bolt Manufacturers in Mumbai

Applications:

1. Reputation: Research the reputation and credibility of potential manufacturers by seeking referrals, reading reviews, and evaluating their track record. A manufacturer with a strong reputation and satisfied customers is more likely to meet your expectations and deliver quality products.

2. Expertise: Assess the manufacturer's expertise in working with Inconel and Monel alloys by reviewing their credentials, certifications, and industry experience. Look for evidence of specialized knowledge, technical capabilities, and successful projects relevant to your needs.

3. Manufacturing Capabilities: Evaluate the manufacturer's production facilities, equipment, and capacity to ensure they can fulfill your requirements efficiently and effectively. Consider factors such as production volume, lead times, and flexibility to accommodate custom orders. Stainless Steel Fasteners Manufacturers in Mumbai

4. Quality Assurance Practices: Inquire about the manufacturer's quality assurance practices, testing procedures, and adherence to industry standards. A manufacturer that prioritizes quality control and continuous improvement is better positioned to deliver products that meet your specifications and standards.

5. Customer Service: Consider the manufacturer's level of customer service, responsiveness, and communication channels. A manufacturer that values customer satisfaction and maintains open dialogue fosters a collaborative and mutually beneficial partnership.

SS Fasteners Suppliers

Conclusion:

Selecting the right Inconel and Monel manufacturer in India requires careful consideration of factors such as reputation, expertise, manufacturing capabilities, quality assurance practices, and customer service. By conducting thorough research, soliciting recommendations, and engaging in transparent communication with potential manufacturers, you can make an informed decision that aligns with your objectives and ensures the success of your projects. Remember, investing in a reputable and reliable manufacturer is essential for achieving optimal results and maintaining a competitive edge in your industry.

0 notes

Text

Hastelloy B2 Fasteners Exporters In India

Hastelloy B2 is a nickel-molybdenum alloy known for its exceptional resistance to hydrochloric acid at all concentrations and temperatures. This makes it a preferred material for fasteners used in industries where corrosion resistance is critical, such as chemical processing, pharmaceuticals, and petrochemicals. In India, exporters specializing in Hastelloy B2 fasteners are prominent players in the global market, offering high-quality products that meet stringent international standards.

Indian manufacturers of Hastelloy B2 fasteners adhere to recognized standards such as ASTM B335 to ensure the reliability and performance of their products. These fasteners include bolts, screws, nuts, and washers, designed to withstand corrosive environments and high mechanical stresses. Indian exporters leverage advanced manufacturing techniques and quality control processes to produce fasteners that meet the demanding requirements of various industries.

The expertise and capabilities of Indian exporters in producing Hastelloy B2 fasteners are supported by a robust infrastructure and skilled workforce. With access to modern manufacturing facilities and a culture of continuous improvement, Indian manufacturers can cater to the diverse needs of customers worldwide. Additionally, India's strategic location and well-established logistics network enable efficient transportation of Hastelloy B2 fasteners to global markets, ensuring timely delivery and customer satisfaction.

Furthermore, the Indian government's support for the manufacturing sector through initiatives such as Make in India and export promotion schemes further strengthens the position of Indian exporters in the global market. These initiatives provide incentives for exporters and promote the growth of manufacturing industries, including the production of specialty alloys like Hastelloy B2. As a result, Indian exporters of Hastelloy B2 fasteners continue to play a significant role in meeting the needs of industries requiring high-performance fastening solutions around the world.

0 notes