Text

Bolt It Right: Innovative U-Bolts for Every Project

When it comes to fastening and securing components across various industries, from automotive to construction, U-Bolts are an indispensable ally. These versatile tools, shaped like the letter U with screw threads on both ends, are used to support pipework, secure tubing, and hold together machinery. This blog post explores the various kinds of U-Bolts, their applications, and why sourcing from reputable U-bolt exporters India can make a significant difference in your projects.

Introduction to U-Bolts

In the vast landscape of industrial fasteners, U-Bolts stand out as pivotal components utilized extensively across various sectors, including construction, automotive, and marine industries. These U-shaped bolts are distinctive for their ability to securely clamp down pipes, conduits, and other cylindrical bodies to surfaces, ensuring stability and structural integrity. The versatility of U-Bolts lies in their simple yet effective design, which comprises a curved body with threaded arms on both ends that can be fastened with nuts.

Central to the effectiveness of U-Bolts is the precision in their manufacturing. Material selection, dimensional accuracy, and threading are critical factors that determine the durability and suitability of U-Bolts for specific environments. This is where U-bolt exporters India have carved a niche. Known for their commitment to quality and innovation, Indian exporters have mastered the art of producing high-grade U-Bolts that meet rigorous international standards. They offer a range of materials, from carbon steel to stainless steel, each tailored to resist the environmental challenges of the applications they serve.

The capability of Indian manufacturers to provide customized solutions sets them apart. Whether the requirement is for standard piping support in commercial buildings or specialized applications in corrosive marine environments, U-bolt exporters India can deliver products designed to meet exact specifications. Their role extends beyond mere suppliers to collaborative partners who contribute to the engineering and design process, ensuring that the U-Bolts not only fit the technical requirements but also contribute to the overall efficiency and safety of projects.

As global industries continue to expand and evolve, the demand for reliable and adaptable fastening solutions like U-Bolts also grows. In this context, U-bolt exporters India are not just fulfilling a need in the market; they are actively enhancing how industries secure and stabilize their most critical structures. Choosing the right U-Bolt, and more importantly, the right exporter, can make a substantial difference in the success of any project.

Types of U-Bolts and Their Applications

U-Bolts are diverse in their designs and applications, meeting the specific needs of various industries with precision. Each type of U-Bolt serves a unique purpose, and U-bolt exporters India have honed their manufacturing processes to cater to these varied requirements with expertise. The most common types include:

Standard U-Bolts

Standard U-Bolts serve as the cornerstone of secure fastening across a myriad of industries. Their straightforward design, comprising a U-shaped body with threaded arms, makes them versatile and reliable for a wide range of applications. Typically used to secure pipes, conduits, and machinery to surfaces, standard U-Bolts provide stability and support in construction, automotive, and plumbing projects. Available in various materials such as carbon steel and stainless steel, these U-Bolts offer durability and corrosion resistance, ensuring long-lasting performance even in demanding environments. With their ubiquity and effectiveness, standard U-Bolts continue to be a trusted choice for fastening needs in diverse industrial settings.

Long Tangent U-Bolts

Long Tangent U-Bolts are engineered to provide extended reach and increased clearance for specific fastening requirements. With longer legs compared to standard U-Bolts, they offer versatility in applications where additional space is necessary, such as when mounting objects with insulation or requiring a larger grip. These U-Bolts ensure a secure and stable connection between pipes, conduits, or other cylindrical objects and their support structures. Their design facilitates proper alignment and minimizes the risk of slippage or shifting, making them ideal for use in construction, electrical installations, and automotive systems. Available in various materials and sizes, Long Tangent U-Bolts offer tailored solutions to meet the unique needs of different projects, ensuring optimal performance and reliability.

Square U-Bolts

Square U-bolts are specially designed to provide stability and strength when fastening square-shaped objects or structures. Their unique square shape ensures a secure grip and prevents rotation, making them ideal for applications where a stable connection is paramount, such as in framing and construction projects. Square U-bolts are commonly used to secure posts, beams, and other square components in place, ensuring structural integrity and preventing movement or displacement. Available in a variety of sizes and materials including stainless steel and galvanized steel, these U-Bolts offer durability and resistance to corrosion, making them suitable for both indoor and outdoor applications. With their reliability and versatility, Square U-Bolts are indispensable components in ensuring the stability and safety of various structural installations.

Custom U-Bolts

Custom U-Bolts offer a versatile and flexible approach to fastening solutions, catering to the specific requirements of diverse applications. Unlike standard U-Bolts, which have predefined sizes and configurations, custom U-Bolts can be precisely engineered to meet unique specifications. This includes customization of dimensions, materials, thread sizes, and even specialized coatings or finishes. Whether it's accommodating non-standard pipe diameters, unusual mounting surfaces, or challenging environmental conditions, custom U-Bolts provide a tailored solution for every situation. U-bolt exporters India specialize in producing custom U-Bolts with precision and expertise, ensuring that each fastening component perfectly aligns with the needs of the project. By opting for custom U-Bolts, businesses can achieve optimal performance, reliability, and efficiency in their fastening applications, ultimately contributing to the success of their projects.

Choosing the Right U-Bolts for Your Project

Selecting the appropriate U-Bolts is crucial for ensuring the structural integrity and longevity of your project. With a myriad of options available, partnering with reputable U-bolt exporters India and Square Head Bolts Suppliers can streamline the decision-making process while guaranteeing quality and reliability.

First and foremost, consider the environmental factors your project will encounter. U-bolt exporters India offer a range of materials, including stainless steel and galvanized steel, each tailored to withstand specific conditions such as corrosion from exposure to moisture or chemicals.

Next, evaluate the load requirements of your application. U-bolt exporters India can provide guidance on selecting the right size and strength of U-Bolts to support the intended weight without compromising safety.

Additionally, factor in any special considerations such as temperature variations, vibration levels, or potential for expansion and contraction. Indian exporters can customize U-Bolts to accommodate these unique needs, ensuring a precise fit and optimal performance.

Lastly, assess your budget and timeline constraints. U-bolt exporters India are known for their competitive pricing and efficient manufacturing processes, making them an ideal choice for projects with cost and time sensitivities.

By collaborating with U-bolt exporters India, you can confidently choose the right U-Bolts for your project, knowing they are backed by industry expertise and stringent quality standards.

U-Bolt Coatings and Finishes

U-bolt exporters India offer a variety of coatings and finishes to enhance the performance and durability of their products. From galvanized coatings for corrosion resistance in outdoor environments to fluoropolymer finishes for extreme conditions, Indian exporters ensure that their U-Bolts are equipped to withstand the challenges of any application. These coatings not only protect against rust and corrosion but also provide a polished appearance, making them suitable for both functional and aesthetic purposes. With a range of options available, U-bolt exporters India ensure that your fastening solutions are tailored to meet your specific requirements.

U-bolt exporters India

When sourcing U-Bolts, particularly for large projects or specialized requirements, it is crucial to partner with experienced and reliable exporters. U-bolt exporters India are renowned for their high-quality manufacturing standards and cost-effectiveness. They offer a wide range of U-Bolts, including custom options, and can provide valuable guidance on the best choices for specific applications.

Installation Tips for U-Bolts

Proper installation of U-Bolts is crucial for ensuring their effectiveness and longevity. U-bolt exporters India recommend several tips for optimal installation. Firstly, ensure that the U-Bolts are tightened evenly to prevent uneven stress distribution. Secondly, use appropriate torque values to avoid over-tightening, which can lead to deformation or damage. Additionally, regularly inspect the U-Bolts for signs of wear or corrosion, and replace them as needed to maintain structural integrity. By following these installation tips, provided by experienced U-bolt exporters India, you can maximize the performance and lifespan of your U-bolt assemblies.

Read Also: U BOLTS MANUFACTURER: HIGH-PERFORMANCE FASTENING SOLUTIONS

U-Bolt Maintenance

Maintaining U-Bolts is essential for ensuring their continued performance and safety. U-bolt exporters India advise regular inspections to check for signs of wear, corrosion, or loosening. Tighten any loose U-Bolts to prevent potential hazards and ensure a secure connection. Additionally, consider applying lubricants to threaded areas to prevent rust and make future adjustments easier. If corrosion is present, U-bolt exporters India recommend cleaning the affected areas and applying protective coatings to prevent further deterioration. By incorporating these maintenance practices, you can extend the lifespan of your U-Bolts and maintain the integrity of your structures.

Why Choose U-bolt Exporters India

Choosing U-bolt exporters India offers a multitude of advantages for businesses worldwide. Indian exporters are renowned for their commitment to quality, offering U-Bolts that adhere to stringent international standards at competitive prices. With a robust manufacturing infrastructure and skilled workforce, U-bolt exporters India can fulfill large volume orders with efficiency and precision, ensuring timely delivery for projects of any scale. Moreover, Indian exporters prioritize customization, allowing customers to tailor U-Bolts to their specific requirements. By partnering with U-bolt exporters India, businesses can access high-quality products, cost-effective solutions, and reliable service, ultimately enhancing project outcomes.

Conclusion

U-Bolts are fundamental in numerous industrial applications, offering versatility, reliability, and strength. Understanding the various types of U-Bolts, their applications, and proper maintenance can significantly enhance project outcomes. For businesses looking to secure high-quality U-Bolts, partnering with reputable U-bolt exporters India can provide an edge in product quality and cost-effectiveness. Whether your project is local or international, ensuring you choose the right U-Bolt and supplier is key to securing your structures safely and efficiently. You can bolt it right for every project with the right bolts and the right partner.

Read Also: U Bolt Dynamics: Crafting Precision Fasteners for Every Need

0 notes

Text

U Bolt Dynamics: Crafting Precision Fasteners for Every Need

In the world of construction, automotive manufacturing, and countless other industries, the unsung heroes are often the smallest components. Among these, U bolts hold a place of critical importance. These U-shaped fasteners are pivotal in their role, offering not just support but also ensuring safety and longevity in various applications. From securing pipelines beneath city streets to holding together the framework of skyscrapers, U bolts are integral to structural integrity and function. In this blog post, we will dive deep into the world of U bolts, exploring their types, manufacturing processes, selection criteria, and how U bolt suppliers play a crucial role in providing high-quality fasteners for every need.

Understanding U Bolts

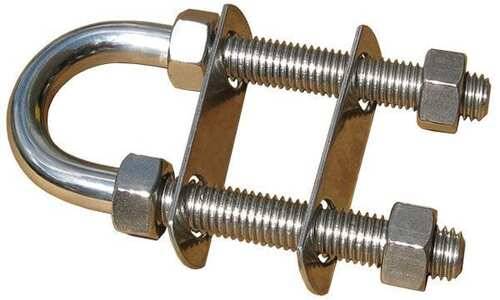

Understanding U bolts goes beyond recognizing their simple U-shaped design. These essential fasteners play a pivotal role in various industries, offering crucial support and stability. To ensure the right fit and performance, it's vital to source U bolts from reputable U bolt suppliers. These suppliers specialize in providing a wide range of U bolts, tailored to specific needs and applications.

By understanding the nuances of U bolts and partnering with reliable U bolt suppliers, businesses can ensure the structural integrity and safety of their projects. From construction to automotive manufacturing, the importance of high-quality U bolts cannot be overstated, making the choice of supplier a critical decision in any procurement process.

Design Features: U bolts are characterized by their U-shaped design, which allows for easy clamping around cylindrical or square objects.

Material Varieties: These fasteners are available in a range of materials, including stainless steel, carbon steel, and galvanized steel, each offering distinct properties suited to different applications.

Application Specifics: U bolts find application in diverse industries such as construction, automotive, marine, and telecommunications, where they are used for securing various components like pipes, poles, and equipment mounts.

Load Capacity Considerations: Choosing the right U bolt involves assessing factors such as the anticipated load and the material being clamped, ensuring that the bolt can withstand the required forces without failure.

Surface Finish Options: To enhance durability and corrosion resistance, U bolts can be finished with coatings such as zinc plating, epoxy coating, or hot-dip galvanizing, depending on the environmental conditions they will be exposed to.

Thread Specifications: U bolts feature threads on both ends, allowing for easy installation and adjustment. Thread size and pitch must be selected carefully to ensure compatibility with nuts or other fastening components.

Customization Possibilities: Some applications may require U bolts with specific dimensions, angles, or configurations. Customization services offered by suppliers allow for the creation of tailored solutions to meet unique project requirements.

Supplier Expertise: Working with experienced U bolt suppliers ensures access to high-quality products, technical support, and reliable delivery, essential elements in achieving successful project outcomes.

Types of U Bolts

When it comes to securing various components in different industries, U bolts are indispensable. These fasteners come in a variety of types, each designed to suit specific applications and requirements. Understanding the different types of U bolts is essential for selecting the right one for a particular project. Here, we'll delve into some common types of U bolts and how they are used across various industries.

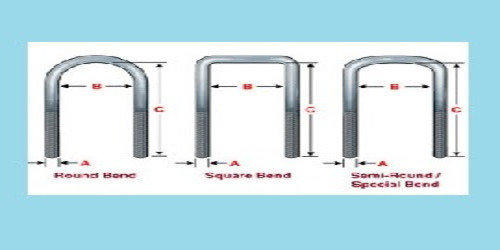

Round Bend U Bolts: As the name suggests, round bend U bolts feature rounded bends on both ends, making them ideal for securing cylindrical objects such as pipes, tubes, or cables. They provide a snug fit around the rounded surface, ensuring stability and preventing slippage. Round bend U bolts are commonly used in plumbing, electrical, and automotive applications.

Square Bend U Bolts: Square bend U bolts are designed for clamping square or rectangular objects securely. Their square-shaped bends provide a tight grip, making them suitable for applications where stability and alignment are crucial. These U bolts are often used in construction, scaffolding, and equipment mounting.

Long Tangent U Bolts: Long tangent U bolts feature extended legs and threads, offering increased clamping force and versatility. They are designed to accommodate thicker materials or multiple components, providing a secure hold even under heavy loads. Long tangent U bolts find application in structural steelwork, bridge construction, and machinery assembly.

Custom U Bolts: In some cases, standard U bolts may not meet the specific requirements of a project. Custom U bolts are tailored to precise specifications, including dimensions, materials, and thread configurations. This customization allows for optimal performance and ensures a perfect fit for unique applications. Custom U bolts are often used in industries such as aerospace, marine, and renewable energy, where standard fasteners may not suffice.

When sourcing U bolts for a project, it's crucial to partner with reliable U bolt suppliers. These suppliers offer a wide range of U bolts in various types, sizes, and materials to meet diverse needs. With their expertise and extensive inventory, U bolt suppliers play a vital role in ensuring that projects are equipped with high-quality fasteners that deliver reliable performance and durability.

Manufacturing Excellence

In the realm of industrial hardware, where precision meets durability, the significance of U bolts cannot be overstated. These unassuming yet essential components serve as the backbone of various applications, from construction to automotive engineering. At the heart of every sturdy structure and reliable machinery lies the reliability of U bolts. In this landscape of manufacturing excellence, the role of U bolt suppliers emerges as pivotal players, ensuring that the foundation of industries remains steadfast.

Manufacturing excellence isn't merely about producing goods; it's a commitment to quality, innovation, and reliability. U bolt suppliers embody this ethos by consistently delivering products that meet and exceed industry standards. Their dedication to precision engineering ensures that each U bolt is crafted with meticulous attention to detail, guaranteeing optimal performance in diverse environments.

One of the hallmarks of manufacturing excellence in the realm of U bolt suppliers is their ability to tailor solutions to meet specific customer needs. Whether it's a bespoke design for a unique application or a large-scale production order, these suppliers exhibit versatility and flexibility in their operations. By leveraging advanced manufacturing techniques and cutting-edge technologies, they empower industries to achieve new heights of efficiency and productivity.

Moreover, manufacturing excellence goes hand in hand with sustainability in today's global landscape. U bolt suppliers recognize their responsibility towards environmental stewardship and adopt eco-friendly practices throughout their operations. From sourcing materials responsibly to optimizing energy consumption, these suppliers strive to minimize their carbon footprint while maximizing value for their customers.

Furthermore, manufacturing excellence isn't confined to the production floor; it extends to every aspect of the supply chain. U bolt suppliers prioritize transparency, reliability, and integrity in their dealings, fostering long-term partnerships built on trust and mutual benefit.

Selection Criteria

When navigating the market for U bolt suppliers, selecting the right partner is crucial for the success of any project or endeavor. Several key criteria should inform this decision-making process to ensure optimal outcomes.

Firstly, expertise and experience play pivotal roles. Assessing a supplier's track record within the industry, including the breadth of their portfolio and the depth of their technical knowledge, provides valuable insights into their capabilities.

Secondly, quality assurance measures are non-negotiable. Look for suppliers who adhere to stringent quality control standards and certifications, ensuring that their U bolts meet or exceed regulatory requirements and industry benchmarks.

Thirdly, responsiveness and communication are vital aspects of a fruitful partnership. Opt for suppliers who prioritize clear and prompt communication channels, fostering transparency and alignment throughout the procurement process.

Additionally, consider factors such as reliability, scalability, and cost-effectiveness when evaluating potential suppliers. A dependable partner with the capacity to scale operations according to your needs, while offering competitive pricing, can significantly enhance project feasibility and success.

Ultimately, the selection of U bolt suppliers should be a well-informed decision, guided by comprehensive assessment against these critical criteria. By prioritizing expertise, quality, communication, reliability, and cost-effectiveness, stakeholders can forge enduring partnerships that drive efficiency, innovation, and success.

Choosing the right U bolt for a specific application requires careful consideration of several factors:

Material: Depending on the environment, a U bolt may need to be made of weather-resistant materials like stainless steel.

Size and Load Capacity: The size and thread design must be suitable for the load it is expected to bear.

Shape: The shape of the U bolt must match the object it is clamping.

Finish: The right finish can greatly extend the lifespan of a U bolt by protecting it against corrosion.

U Bolt Suppliers: Ensuring Quality and Variety

Finding the right U bolt for your project involves more than just understanding the types and manufacturing processes. It requires access to a reliable supplier who can provide high-quality fasteners tailored to your specific needs. U bolt suppliers play a critical role in the ecosystem, ensuring that customers have access to a wide variety of fasteners that meet strict quality standards.

Reputable U bolt suppliers are characterized by their extensive inventory, which includes bolts of different sizes, shapes, and materials. They often offer custom manufacturing services for projects that require unique specifications. Additionally, top suppliers ensure that their products are tested for strength and durability, providing customers with the confidence that their fasteners will perform as expected.

Comprehensive Material Selection: U bolt suppliers meticulously source materials, including high-grade steel and other alloys, to ensure durability and performance across diverse applications.

Advanced Manufacturing Techniques: Leveraging state-of-the-art technologies such as computer-aided design (CAD) and precision machining, suppliers produce U bolts with unparalleled accuracy and consistency.

Rigorous Quality Control Processes: From initial inspection of raw materials to final product testing, suppliers implement stringent quality control measures to maintain the highest standards of quality and reliability.

Customization Capabilities: Recognizing the unique requirements of different industries and applications, U bolt suppliers offer customization options, including varying sizes, coatings, and thread types, to meet specific customer needs.

Diverse Product Range: In addition to traditional U bolts, suppliers often offer a diverse range of related products, such as square U bolts, round U bolts, and specialty configurations, providing customers with comprehensive solutions for their fastening needs.

Read Also: A Journey Through the World of Fastening Systems

The Importance of Quality Control

In the realm of U bolt suppliers, quality control isn't just a checkbox; it's a cornerstone of reliability, safety, and customer satisfaction. These seemingly small components play a significant role in supporting crucial infrastructure across various industries, from construction to transportation. As such, ensuring their quality is paramount.

Quality control measures within U bolt manufacturing encompass a spectrum of processes, from material selection to final inspection. Suppliers must meticulously vet raw materials, utilizing only the highest-grade steel or other suitable materials to withstand the rigors of their intended applications.

Precision engineering is another crucial aspect of quality control. U bolts must adhere to precise dimensional specifications to ensure proper fit and functionality. Advanced manufacturing techniques, such as computer-aided design (CAD) and computer numerical control (CNC) machining, enable suppliers to achieve unparalleled accuracy and consistency.

Furthermore, rigorous testing protocols are employed to validate the performance and durability of U bolts. This may include stress testing, corrosion resistance assessments, and fatigue analysis to simulate real-world conditions and ensure long-term reliability.

The importance of quality control extends beyond individual components to the overall reputation and trustworthiness of U bolt suppliers. By prioritizing quality at every stage of the manufacturing process, suppliers demonstrate their commitment to excellence and customer satisfaction, ultimately fostering enduring partnerships and driving industry advancement.

Conclusion

U bolts may be small, but their impact on the safety and integrity of structures and machinery is immense. Understanding the types of U bolts, their manufacturing process, and how to select the right one for your needs is crucial. Equally important is choosing a supplier that can provide high-quality, durable fasteners tailored to your project's requirements.

As industries continue to evolve and new challenges arise, the demand for precision-engineered fasteners like U bolts will only grow. By partnering with reputable U bolt suppliers, businesses can ensure that they are equipped with the best fasteners for the job, contributing to the overall success and longevity of their projects.

In a world where the strength and stability of our constructions, vehicles, and machinery are paramount, U bolts stand out as a critical component. Ensuring that these essential fasteners are of the highest quality and perfectly suited to their intended application is not just a matter of efficiency but of safety and reliability. As we have seen, the dynamics of U bolts encompass a wide range of considerations, from their design and manufacture to the crucial role played by suppliers in delivering precision fasteners for every need. By paying close attention to these aspects, we can continue to build, create, and innovate with confidence, knowing that our smallest components are more than capable of holding together our grandest designs.

Read Also: A Closer Look at Industry-Leading Carriage Bolt Makers

#bolt supplier#manufacturer#business#u bolt manufacturers#U-bolt Suppliers#U-bolt exporters India#U Bolts Manufacturer#U Bolts Manufacturers India

0 notes

Text

Hex bolt manufacturers elevate construction by producing precision-engineered fasteners, ensuring structural integrity, reliability, and unparalleled safety in every build.

0 notes

Text

Square Head Bolts excel with their unique design, providing enhanced grip, stability, and durability - elevating them as a cornerstone in construction innovation.

0 notes

Text

Infusing U-bolt creativity enhances designs by introducing unique angles, shapes, and perspectives, injecting a distinct and captivating aesthetic appeal.

0 notes

Text

U bolts' adaptability in modern engineering ensures robust connections, structural stability, and efficient solutions, meeting diverse design and application requirements seamlessly.

0 notes

Text

U bolts' versatility lies in their adjustable design, robust material, and secure fastening capabilities, meeting diverse industry needs with reliability and adaptability.

0 notes

Text

Nut bolts are essential for industry machinery, ensuring stability and structural integrity by securely holding components together for optimal functionality.

1 note

·

View note