#Construction Chemicals Company

Text

Building Strong Foundations: Exploring the Role of a Leading Construction Chemicals Company

In the dynamic world of construction, the importance of high-quality materials cannot be overstated. From skyscrapers to bridges, every structure relies on a strong foundation built with precision and expertise. At the heart of this endeavor lies the expertise of a reputable Construction Chemicals Company, dedicated to providing innovative solutions that enhance the durability, performance, and sustainability of construction projects worldwide.

A Construction Chemicals Company plays a pivotal role in the construction industry, offering a diverse range of products and services designed to address the unique challenges and requirements of modern construction projects. These companies specialize in the development and manufacturing of advanced chemicals and materials that improve the strength, durability, and longevity of concrete, masonry, and other building materials.

One of the key offerings of a Construction Chemicals Company is concrete admixtures, which are specialized chemicals added to concrete during the mixing process to enhance its properties and performance. These admixtures can improve workability, durability, and strength while reducing water usage and construction time. From superplasticizers that increase the flow of concrete to air-entraining agents that improve freeze-thaw resistance, concrete admixtures play a vital role in achieving superior concrete performance in a wide range of applications.

In addition to concrete admixtures, a Construction Chemicals Company also provides a variety of products for waterproofing, sealing, and protecting concrete and masonry structures. Waterproofing membranes, sealants, and coatings are essential for preventing water intrusion, protecting against corrosion, and prolonging the lifespan of buildings and infrastructure. These products are especially crucial in areas prone to moisture, such as basements, parking garages, and underground structures.

Moreover, Construction Chemicals Companies offer solutions for repairing and rehabilitating existing structures, helping to extend their service life and improve their performance. Repair mortars, grouts, and coatings are used to restore damaged concrete surfaces, repair cracks, and strengthen weakened structures, ensuring their safety and integrity for years to come. Whether it's repairing concrete bridges, restoring historical landmarks, or rehabilitating deteriorating infrastructure, these specialized products are essential for maintaining the built environment.

Sustainability is another key focus area for Construction Chemicals Companies, as the construction industry seeks to minimize its environmental footprint and embrace more eco-friendly practices. Many companies offer environmentally friendly products and technologies that reduce energy consumption, minimize waste, and lower greenhouse gas emissions. From low-carbon concrete admixtures to recycled materials and sustainable packaging, these initiatives demonstrate a commitment to environmental stewardship and sustainable development.

Innovation is at the core of every leading Construction Chemicals Company, driving continuous improvement and advancement in materials, technologies, and processes. Research and development teams work tirelessly to develop new products and solutions that address emerging challenges and meet the evolving needs of the construction industry. Whether it's improving the performance of traditional materials or developing cutting-edge technologies like self-healing concrete, innovation is essential for driving progress and pushing the boundaries of what's possible in construction.

As construction projects become increasingly complex and demanding, the role of a trusted Construction Chemicals Company becomes even more critical. By providing innovative solutions, technical expertise, and unparalleled support, these companies help builders, contractors, and engineers overcome challenges, achieve their goals, and deliver exceptional results. From enhancing the durability and performance of structures to reducing environmental impact and promoting sustainability, the contributions of a Construction Chemicals Company are indispensable to the success of construction projects worldwide.

For best-in-class construction chemicals and solutions, trust https://www.firsttechbd.com/, a leading Construction Chemicals Company committed to excellence, innovation, and sustainability. With a comprehensive range of products, technical expertise, and customer support, we are your trusted partner in building a stronger, safer, and more sustainable future.

#Commercial and Residential Flooring#Construction Chemicals Company#Best Epoxy Flooring in Bangladesh - First Tech BD

0 notes

Text

SAP Business One for Chemical Industry

With all its benefits, global chemical manufacturing companies are incorporating SAP B1 at an increased rate for chemical production. Not only does it help in improving business efficiency and enhancing collaboration but it also aids in increasing customer satisfaction and increasing revenue by up to 10-30%. With the change in business dynamics and fluctuations in demand, robust ERP software can empower chemical businesses to take advantage of their competition while adhering to safety, quality, and compliance requirements. SAP b1 solutions are already used by nearly 6500 chemical industry businesses and more are soon to follow.

Managing costs effectively is an essential aspect of chemicals and any industry. In the chemical industry, SAP Business One provides intuitive planning and scheduling to manage time and resources efficiently and cut down on business costs to control every aspect. The cost of materials can also be estimated by analyzing the production data history and past purchases in a single click to simplify business processes. SAP chemical industry best practices optimize different processes, improve workflow efficiency, and reduce overtime costs by 48%.

#sap business one#SAP Business One Partner in India#SAP Business One partner#SAP Business One ERP Solution#SAP Business One for Manufacturers#SAP chemical industry#ERP Software#best erp software#best erp software in india#food beverage erp software#erp software for construction#erp#enterprise software#ERP Solution#SAP ERP#erp for small business#erp development company#erp consulting services#enterprise resource planning#erpsystem

2 notes

·

View notes

Text

Understanding the impacts of mining on local environments and communities

New Post has been published on https://thedigitalinsider.com/understanding-the-impacts-of-mining-on-local-environments-and-communities/

Understanding the impacts of mining on local environments and communities

Hydrosocial displacement refers to the idea that resolving water conflict in one area can shift the conflict to a different area. The concept was coined by Scott Odell, a visiting researcher in MIT’s Environmental Solutions Initiative (ESI). As part of ESI’s Program on Mining and the Circular Economy, Odell researches the impacts of extractive industries on local environments and communities, especially in Latin America. He discovered that hydrosocial displacements are often in regions where the mining industry is vying for use of precious water sources that are already stressed due to climate change.

Odell is working with John Fernández, ESI director and professor in the Department of Architecture, on a project that is examining the converging impacts of climate change, mining, and agriculture in Chile. The work is funded by a seed grant from MIT’s Abdul Latif Jameel Water and Food Systems Lab (J-WAFS). Specifically, the project seeks to answer how the expansion of seawater desalination by the mining industry is affecting local populations, and how climate change and mining affect Andean glaciers and the agricultural communities dependent upon them.

By working with communities in mining areas, Odell and Fernández are gaining a sense of the burden that mining minerals needed for the clean energy transition is placing on local populations, and the types of conflicts that arise when water sources become polluted or scarce. This work is of particular importance considering over 100 countries pledged a commitment to the clean energy transition at the recent United Nations climate change conference, known as COP28.

Play video

J-WAFS Community Spotlight on Scott Odell

Water, humanity’s lifeblood

At the March 2023 United Nations (U.N.) Water Conference in New York, U.N. Secretary-General António Guterres warned “water is in deep trouble. We are draining humanity’s lifeblood through vampiric overconsumption and unsustainable use and evaporating it through global heating.” A quarter of the world’s population already faces “extremely high water stress,” according to the World Resources Institute. In an effort to raise awareness of major water-related issues and inspire action for innovative solutions, the U.N. created World Water Day, observed every year on March 22. This year’s theme is “Water for Peace,” underscoring the fact that even though water is a basic human right and intrinsic to every aspect of life, it is increasingly fought over as supplies dwindle due to problems including drought, overuse, or mismanagement.

The “Water for Peace” theme is exemplified in Fernández and Odell’s J-WAFS project, where findings are intended to inform policies to reduce social and environmental harms inflicted on mining communities and their limited water sources.

“Despite broad academic engagement with mining and climate change separately, there has been a lack of analysis of the societal implications of the interactions between mining and climate change,” says Odell. “This project is helping to fill the knowledge gap. Results will be summarized in Spanish and English and distributed to interested and relevant parties in Chile, ensuring that the results can be of benefit to those most impacted by these challenges,” he adds.

The effects of mining for the clean energy transition

Global climate change is understood to be the most pressing environmental issue facing humanity today. Mitigating climate change requires reducing carbon emissions by transitioning away from conventional energy derived from burning fossil fuels, to more sustainable energy sources like solar and wind power. Because copper is an excellent conductor of electricity, it will be a crucial element in the clean energy transition, in which more solar panels, wind turbines, and electric vehicles will be manufactured. “We are going to see a major increase in demand for copper due to the clean energy transition,” says Odell.

In 2021, Chile produced 26 percent of the world’s copper, more than twice as much as any other country, Odell explains. Much of Chile’s mining is concentrated in and around the Atacama Desert — the world’s driest desert. Unfortunately, mining requires large amounts of water for a variety of processes, including controlling dust at the extraction site, cooling machinery, and processing and transporting ore.

Chile is also one of the world’s largest exporters of agricultural products. Farmland is typically situated in the valleys downstream of several mines in the high Andes region, meaning mines get first access to water. This can lead to water conflict between mining operations and agricultural communities. Compounding the problem of mining for greener energy materials to combat climate change, are the very effects of climate change. According to the Chilean government, the country has suffered 13 years of the worst drought in history. While this is detrimental to the mining industry, it is also concerning for those working in agriculture, including the Indigenous Atacameño communities that live closest to the Escondida mine, the largest copper mine in the world. “There was never a lot of water to go around, even before the mine,” Odell says. The addition of Escondida stresses an already strained water system, leaving Atacameño farmers and individuals vulnerable to severe water insecurity.

What’s more, waste from mining, known as tailings, includes minerals and chemicals that can contaminate water in nearby communities if not properly handled and stored. Odell says the secure storage of tailings is a high priority in earthquake-prone Chile. “If an earthquake were to hit and damage a tailings dam, it could mean toxic materials flowing downstream and destroying farms and communities,” he says.

Chile’s treasured glaciers are another piece of the mining, climate change, and agricultural puzzle. Caroline White-Nockleby, a PhD candidate in MIT’s Program in Science, Technology, and Society, is working with Odell and Fernández on the J-WAFS project and leading the research specifically on glaciers. “These may not be the picturesque bright blue glaciers that you might think of, but they are, nonetheless, an important source of water downstream,” says White-Nockleby. She goes on to explain that there are a few different ways that mines can impact glaciers.

In some cases, mining companies have proposed to move or even destroy glaciers to get at the ore beneath. Other impacts include dust from mining that falls on glaciers. White-Nockleby says, “this makes the glaciers a darker color, so, instead of reflecting the sun’s rays away, [the glacier] may absorb the heat and melt faster.” This shows that even when not directly intervening with glaciers, mining activities can cause glacial decline, adding to the threat glaciers already face due to climate change. She also notes that “glaciers are an important water storage facility,” describing how, on an annual cycle, glaciers freeze and melt, allowing runoff that downstream agricultural communities can utilize. If glaciers suddenly melt too quickly, flooding of downstream communities can occur.

Desalination offers a possible, but imperfect, solution

Chile’s extensive coastline makes it uniquely positioned to utilize desalination — the removal of salts from seawater — to address water insecurity. Odell says that “over the last decade or so, there’s been billions of dollars of investments in desalination in Chile.”

As part of his dissertation work at Clark University, Odell found broad optimism in Chile for solving water issues in the mining industry through desalination. Not only was the mining industry committed to building desalination plants, there was also political support, and support from some community members in highland communities near the mines. Yet, despite the optimism and investment, desalinated water was not replacing the use of continental water. He concluded that “desalination can’t solve water conflict if it doesn’t reduce demand for continental water supplies.”

However, after publishing those results, Odell learned that new estimates at the national level showed that desalination operations had begun to replace the use of continental water after 2018. In two case studies that he currently focuses on — the Escondida and Los Pelambres copper mines — the mining companies have expanded their desalination objectives in order to reduce extraction from key continental sources. This seems to be due to a variety of factors. For one thing, in 2022, Chile’s water code was reformed to prioritize human water consumption and environmental protection of water during scarcity and in the allocation of future rights. It also shortened the granting of water rights from “in perpetuity” to 30 years. Under this new code, it is possible that the mining industry may have expanded its desalination efforts because it viewed continental water resources as less secure, Odell surmises.

As part of the J-WAFS project, Odell has found that recent reactions have been mixed when it comes to the rapid increase in the use of desalination. He spent over two months doing fieldwork in Chile by conducting interviews with members of government, industry, and civil society at the Escondida, Los Pelambres, and Andina mining sites, as well as in Chile’s capital city, Santiago. He has spoken to local and national government officials, leaders of fishing unions, representatives of mining and desalination companies, and farmers. He observed that in the communities where the new desalination plants are being built, there have been concerns from community members as to whether they will get access to the desalinated water, or if it will belong solely to the mines.

Interviews at the Escondida and Los Pelambres sites, in which desalination operations are already in place or under construction, indicate acceptance of the presence of desalination plants combined with apprehension about unknown long-term environmental impacts. At a third mining site, Andina, there have been active protests against a desalination project that would supply water to a neighboring mine, Los Bronces. In that community, there has been a blockade of the desalination operation by the fishing federation. “They were blockading that operation for three months because of concerns over what the desalination plant would do to their fishing grounds,” Odell says. And this is where the idea of hydrosocial displacement comes into the picture, he explains. Even though desalination operations are easing tensions with highland agricultural communities, new issues are arising for the communities on the coast. “We can’t just look to desalination to solve our problems if it’s going to create problems somewhere else” Odell advises.

Within the process of hydrosocial displacement, interacting geographical, technical, economic, and political factors constrain the range of responses to address the water conflict. For example, communities that have more political and financial power tend to be better equipped to solve water conflict than less powerful communities. In addition, hydrosocial concerns usually follow the flow of water downstream, from the highlands to coastal regions. Odell says that this raises the need to look at water from a broader perspective.

“We tend to address water concerns one by one and that can, in practice, end up being kind of like whack-a-mole,” says Odell. “When we think of the broader hydrological system, water is very much linked, and we need to look across the watershed. We can’t just be looking at the specific community affected now, but who else is affected downstream, and will be affected in the long term. If we do solve a water issue by moving it somewhere else, like moving a tailings dam somewhere else, or building a desalination plant, resources are needed in the receiving community to respond to that,” suggests Odell.

The company building the desalination plant and the fishing federation ultimately reached an agreement and the desalination operation will be moving forward. But Odell notes, “the protest highlights concern about the impacts of the operation on local livelihoods and environments within the much larger context of industrial pollution in the area.”

The power of communities

The protest by the fishing federation is one example of communities coming together to have their voices heard. Recent proposals by mining companies that would affect glaciers and other water sources used by agriculture communities have led to other protests that resulted in new agreements to protect local water supplies and the withdrawal of some of the mining proposals.

Odell observes that communities have also gone to the courts to raise their concerns. The Atacameño communities, for example, have drawn attention to over-extraction of water resources by the Escondida mine. “Community members are also pursuing education in these topics so that there’s not such a power imbalance between mining companies and local communities,” Odell remarks. This demonstrates the power local communities can have to protect continental water resources.

The political and social landscape of Chile may also be changing in favor of local communities. Beginning with what is now referred to as the Estallido Social (social outburst) over inequality in 2019, Chile has undergone social upheaval that resulted in voters calling for a new constitution. Gabriel Boric, a progressive candidate, whose top priorities include social and environmental issues, was elected president during this period. These trends have brought major attention to issues of economic inequality, environmental harms of mining, and environmental justice, which is putting pressure on the mining industry to make a case for its operations in the country, and to justify the environmental costs of mining.

What happens after the mine dries up?

From his fieldwork interviews, Odell has learned that the development of mines within communities can offer benefits. Mining companies typically invest directly in communities through employment, road construction, and sometimes even by building or investing in schools, stadiums, or health clinics. Indirectly, mines can have spillover effects in the economy since miners might support local restaurants, hotels, or stores. But what happens when the mine closes? As one community member Odell interviewed stated: “When the mine is gone, what are we going to have left besides a big hole in the ground?”

Odell suggests that a multi-pronged approach should be taken to address the future state of water and mining. First, he says we need to have broader conversations about the nature of our consumption and production at domestic and global scales. “Mining is driven indirectly by our consumption of energy and directly by our consumption of everything from our buildings to devices to cars,” Odell states. “We should be looking for ways to moderate our consumption and consume smarter through both policy and practice so that we don’t solve climate change while creating new environmental harms through mining.”

One of the main ways we can do this is by advancing the circular economy by recycling metals already in the system, or even in landfills, to help build our new clean energy infrastructure. Even so, the clean energy transition will still require mining, but according to Odell, that mining can be done better. “Mining companies and government need to do a better job of consulting with communities. We need solid plans and financing for mine closures in place from the beginning of mining operations, so that when the mine dries up, there’s the money needed to secure tailings dams and protect the communities who will be there forever,” Odell concludes.

Overall, it will take an engaged society — from the mining industry to government officials to individuals — to think critically about the role we each play in our quest for a more sustainable planet, and what that might mean for the most vulnerable populations among us.

#2022#2023#agreement#agriculture#America#Analysis#approach#architecture#attention#awareness#Blue#Building#buildings#carbon#carbon emissions#Cars#change#chemicals#circular economy#clean energy#Cleaner industry#climate#climate change#code#Color#Community#Companies#conference#Conflict#construction

0 notes

Text

Dispersant MF (B)

Dispersant MF, also known as Dispersing agent MF, is a chemical compound with the chemical name Methyl-Naphthalene sulphonate formaldehyde. It is utilized as a dispersing agent to disperse and stabilize substances like pigments, paints, and inks. By dispersing these substances into smaller particles, Dispersant MF facilitates their even distribution onto the desired surface. This helps to enhance the overall performance and appearance of the dispersed materials.

Get A Quote

Usage of Dispersant MF (B)

As dispersant and filler for disperse dye,vat dye and reactive dye.

Used in pigment pad dyeing of vat dye, acid dyeing in printing and dyeing industry.

As auxiliary tanning agent in leather industry, stabilizing agent in rubber industry.

Specification of Dispersant MF (B)

Dipsersant MF-B

ITEMS

SPECIFICATIONS

Appearence

Dark Brown Powder

Dispersion force

≥95%

pH (1% aq. Solution)

7-9

Na2SO4

≤8%

Water

≤8%

Insoluble impuries content

≤0.05%

Ca+Mg content

≤4000ppm

Instructions of Dispersant MF (B)

According to the needs, it can be used directly as a powder, or it can be dissolved in water and made into different concentrations of water for use. Before actual use, it must be tested to confirm that it is effective before use. The relevant data in this manual are for reference only.

Packaging, Storage And Transportation of Dispersant MF (B)

Dispersant MF is packed in woven bags lined with plastic film, each bag is 25Kg, and the product name, net weight, production unit, address, etc. are printed on the bag.

When storing, it should be protected from rain and moisture. If there is agglomeration, please make it into a solution or crush it for use, which will not affect the effect.

The shelf life is two years.

0 notes

Text

Exploring the Booming World of Construction Chemicals

The construction industry is a concrete jungle, but it takes more than just steel and cement to build dreams. Enter the invisible heroes: construction chemicals companies. These firms provide the crucial blending agents, adhesives, sealants, and other specialized solutions that bind the building blocks, ensure durability, and enhance performance. If you're a business head or decision-maker in this dynamic sector, understanding this crucial segment is essential for growth and success.

Global Growth Story: A Booming Market with Big Numbers

The global construction chemicals market is a multi-billion dollar industry, projected to reach a staggering USD 41.78 billion by 2028. This 6.5% CAGR growth is fueled by several factors:

Rising urban infrastructure projects: From skyscrapers to smart cities, the demand for high-performance buildings is driving the need for specialized chemicals.

Focus on sustainability: Green construction practices are gaining traction, leading to a surge in demand for eco-friendly chemicals.

Growing repair and renovation market: With an aging building stock, the need for repair and renovation is increasing, creating opportunities for specialized chemicals.

Regional Spotlight: India's Construction Chemicals Boom

India, with its USD 1.38 trillion construction industry, is a major player in the global scene. The India construction industry statistics here is expected to reach USD 5.25 billion by 2027, driven by factors like:

Government infrastructure initiatives: Investments in roads, bridges, and other infrastructure projects are creating demand for high-performance chemicals.

Affordable housing projects: The government's focus on affordable housing creates opportunities for cost-effective construction chemicals.

Rising demand for commercial and industrial buildings: The growth of these sectors is driving demand for specialized chemicals for specific applications.

Beyond Bricks and Mortar: Key Players and Trends

The construction chemicals companies in world is diverse, with global giants like BASF, Sika, Henkel, and Dow Chemical leading the way. However, regional players like Pidilite Industries (India), Mapei (Italy), and GCP Applied Technologies (US) are also gaining traction.

Key trends shaping the future:

Digitalization: Adoption of digital platforms like BIM and IoT are improving efficiency and transparency in the construction process, creating demand for smart chemicals.

Focus on performance and sustainability: Construction chemicals are evolving to offer better performance, durability, and lower environmental impact.

Regionalization: As demand in emerging markets like India grows, regional players are expected to play a more significant role.

Building Your Future: How to Capitalize on the Growth

Whether you're an established player or a newcomer, understanding these trends and market dynamics is crucial. Here are some ways to capitalize on the growth:

Focus on niche markets: Identify specific segments with high growth potential and develop targeted solutions.

Invest in innovation: Develop cutting-edge products that address the evolving needs of the construction industry.

Embrace sustainability: Offer eco-friendly chemicals that cater to the growing demand for green construction.

Build strong partnerships: Collaborate with construction companies, architects, and other stakeholders to understand their needs and offer customized solutions.

Remember, the construction chemicals industry is a dynamic and exciting space. By staying informed, innovating, and building strategic partnerships, you can be a key player in shaping the future of this essential sector.

1 note

·

View note

Text

Agarwal Buildcare: India's top manufacturer of construction products and chemicals, providing premium waterproofing products and solutions, tile adhesives, roof treatment and floor cleaning for reliable protection against water damage and leaks.

#waterproofing products#waterproofing#tilecleaning#tile floor#construction chemicals#cleaning services#roof treatment#waterproofing company

0 notes

Text

ECMAS is known as one of the premium concrete admixture manufacturers in India. Get absolute strength, enhanced workability, and durability for your concrete buildings with ECMAS concrete admixtures.

#construction chemical companies#concrete admixtures manufacturers#admixture companies in india#concrete

0 notes

Link

0 notes

Text

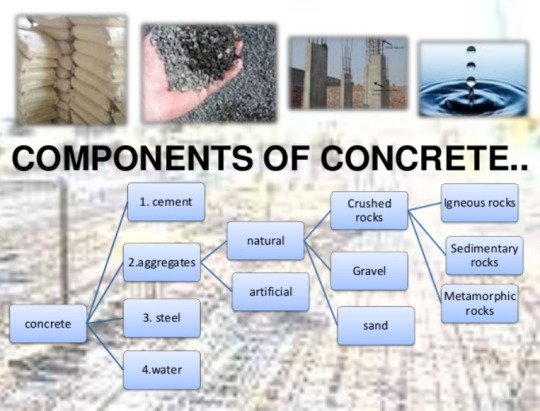

What Are The Components Of Concrete

We will explore the components of concrete and how they work together to create a durable and versatile material. Construction chemical suppliers will discuss the different types of cement, aggregates, and admixtures used in concrete production, as well as their effects on the strength and durability of the finished product.

Finally, we will look at the different methods used to test the quality of concrete so that you can make an informed decision about the best material for your project. By the end of this article, you will better understand the different components of concrete and how they work together to create a robust and reliable material.

Concrete is a composite material composed of various components, including cement, aggregates, and multiple admixtures, blended in specific ratios to create a robust and durable material. As per the top waterproofing companies in India, concrete has become an invaluable part of modern construction, offering various structural and decorative uses in small and large-scale projects.

Concrete is a building material made from cement, aggregate (gravel and sand), water, and other additives combined and poured into molds or forms and allowed to harden.

Types of Concrete:

1. Ready-mix Concrete: Ready-mix concrete is prepared at a concrete plant and then delivered to the worksite in a cement mixer truck.

2. Roller-compacted Concrete: Roller-compacted concrete is a form of concrete made with a stiffer mix and then consolidated with a roller for a denser, more robust final product.

3. Shotcrete: Shotcrete is a type of concrete sprayed from a particular nozzle onto a surface or into a form.

4. Precast Concrete: Precast concrete is a type of concrete that is poured into a form at the concrete plant and then shipped to the worksite in its final form.

Different Components of Concrete and their Functions

1. Aggregates are the most crucial component of concrete and make up the bulk of the mixture. They provide strength, stability, and structural integrity to the concrete mix. Aggregates come in different types, such as sand, gravel, crushed stone, and recycled materials. Depending on the concrete mix, different types of aggregates can be used to enhance the strength and other properties of the material.

2. Cement is the binding agent in concrete and holds the other components together. It also helps to give the concrete mix its strength, workability, and durability. Different types of cement can be used for various applications, depending on the desired strength and other characteristics of the concrete.

3. Water is used to mix and activate the concrete ingredients. It helps to create the chemical reaction necessary for the material to harden and gain strength. Too much or too little water can affect the strength and other properties of the concrete.

4. Admixtures are added to the concrete mix to provide improved workability, increased temperature resistance, and chemical and biological agents. Admixtures can also reduce the amount of cement, water, and other materials required, thus making the concrete mix more economical.

How it Affects the Strength of Concrete

Cement is the crucial ingredient in concrete, which gives it its strength. Cement is a powdery substance made of limestone, clay, and other materials that are heated and ground into a fine powder. As per the best waterproofingcompany, this powder is mixed with water, sand, and gravel to create a paste that binds the materials together.

In conclusion, concrete is a highly durable and versatile material that consists of four essential components: cement, water, aggregate, and admixtures. Each concrete element impacts the material's durability, strength, and workability. Without one of concrete admixture manufacturers, concrete would not have the same properties and would not be as effective as it is today. Therefore, it is essential to understand the concrete components to use the material in construction projects properly.

#concrete admixture manufacturers#best waterproofing company#top waterproofing companies in India#Construction chemical suppliers

0 notes

Text

Reasons Why Bathroom Waterproofing Is Important

Bathroom waterproofing has always been difficult because steps, sunken floors, and other barriers have always acted as a constant source of water leakage, seepage, and dampness. To prevent your bathroom from the hazards of water leakage, it is wise to get free expert consultation and hire the experts to get the best bathroom waterproofing services, who can help you get rid of all the problems.

Let’s take a look at the Reasons Why Bathroom Waterproofing Is Important:

Water leakage in the bathroom is a major problem that affects the aesthetics and durability of your bathroom structure’s walls, roof, and flooring. To avoid water leaks, it is essential to use Nanosil to fix any water leakages you currently have in your bathroom’s walls, roof, or flooring.

Regardless of the source of the leak, if water gets into your bathroom, it can cause mold and mildew to grow, which can cause or aggravate coughing, eye infection, and problems.Tigersil works best in treating mold growth.

Waterproofing your bathroom flooring and walls helps to maintain aesthetics and the entire structure, including expensive fixtures such as all plumbing fittings, tiles, and even the paint on the walls.

For a detailed version of the importance of bathroom waterproofing, do check out this blog.

We understand how tough it is to search for trustworthy contractors to complete this task. Hiring 20 MCC bathroom waterproofing services can save you a lot of time and effort and assure you of a long-lasting effect.

Source : https://www.20mcc.in/

#bathroom waterproofing#Chemical waterproofing#construction chemical#Construction chemical manufacturing company#waterproofing expert#waterproofing services#waterproofing solutions

0 notes

Text

Construction Chemicals Market 2022 – Key Regions, Company Profile, Opportunity Analysis, and Industry Forecast to 2026

The report titled Construction Chemicals Market offers detailed insights on the Construction Chemicals industry entailing key information on its different market segments. The report gives an industry overview from around the world and covers the latest trends, technology breakthroughs, market restraints, and investment opportunities, and conducts exclusive interviews of the Construction Chemicals industry leaders to contribute to the report’s findings. The report discusses the buyers’ requirements and suggests strategic actions & business changes accordingly to the market players. Moreover, the natural, internal, and external barriers to progress are given in the report. The wider business environment of the Construction Chemicals market and the industry challenges are included in the report.

Read Full Report at:

Growth prospects, leading trends, progress projections, key industries, and business innovations are the primary focus of the Construction Chemicals study. A comprehensive Construction Chemicals study is available for a number of key areas involved in the report. Furthermore, the Construction Chemicals study examines present and potential consumer positions in terms of sales based on market goods around the globe.

Key Players in the Construction Chemicals Technology market:

DowDuPont, Evonik, BASF, Rudolf, Choksey, Quicseal Construction Chemicals, DCP International, Build Core Chemicals, MC-Bauchemie Müller GmbH, ABE, Multi Construction Chemicals, Prine Eco Group, Hilti, Construction Chemicals Pty Ltd, Construction Chemical Corp, Mapei Construction Products, Jay Chemical Industries, Chenbond Chemicals, Commix, Euclid Chemical

Construction Chemicals Market Types:

Structure repair products

Concrete Admixtures

Protective Coatings

Construction Chemicals Market Applications:

The Way

Bridge

Others

Highlights of the Report:

The report gives information on all the active tenders in the Construction Chemicals industry across the globe based on different categories. The important government notifications and change in regulations according to the latest updates is provided in the report.

The market size and forecast estimates of the Construction Chemicals market is given in the report considering the economic, financial, and general business conditions prevailing in the Construction Chemicals market from 2022 to 2026.

The report demonstrates the contribution of each segment and sector in the improvement of Construction Chemicals market share, market size, and CAGR.

Request a sample report:

Regional Construction Chemicals Market (Regional Output, Demand & Forecast by Countries):

North America (United States, Canada, Mexico)

South America (Brazil, Argentina, Ecuador, Chile)

Asia Pacific (China, Japan, India, Korea)

Europe (Germany, UK, France, Italy)

Middle East Africa (Egypt, Turkey, Saudi Arabia, Iran) And more.

Why Purchase This Market Research Report:

Critical issues and challenges the Construction Chemicals market will be facing in the forecasted years are identified in the report to help market players align their business decisions and strategies accordingly.

The report identifies key trends facing the Construction Chemicals market.

Trends responsible for global and regional economic growth of the Construction Chemicals market are highlighted in the report to help market players in a critical understanding of the future of the Construction Chemicals market.

The report conducts an assessment of the production and operational practices taking place in the marketplace.

The report presents the challenges faced by the leading geographies and nations from the pandemic and their reorientation of policies to survive the market.

The Report Attempts to Answer the Following Questions:

What will be the financial performance of North America, APAC, Europe, and Africa in the Construction Chemicals market in 2022 and beyond?

Which companies are likely to succeed in the Construction Chemicals market with the help of foreign companies, mergers and acquisitions, new product launches, and technological innovation?

What are the strategy recommendation and business models for emerging market players?

Which are the Construction Chemicals market’s largest manufacturing firms and most competitive firms?

Thanks for showing interest in the Construction Chemicals Market research publication; you can also get individual chapter-wise sections or region / Country report versions like Germany, France, China, LATAM, GCC, North America, Europe, or Asia.

ABOUT US:

IndustryDataAnalytics is your single point market research source for all industries including pharmaceutical, chemicals and materials, energy resources, automobile, IT, technology and media, food and beverages, and consumer goods, among others.

CONTACT US:

Irfan Tamboli (Head of Sales) – Industry Data Analytics

+1 (704) 266-3234 | [email protected]

#Construction Chemicals Market#Construction Chemicals Market Analysis#Construction Chemicals Market Top Companies#Construction Chemicals Market Research#Construction Chemicals Market Trends

0 notes

Text

What Should be Done With All the Carbon Dioxide? - Technology Org

New Post has been published on https://thedigitalinsider.com/what-should-be-done-with-all-the-carbon-dioxide-technology-org/

What Should be Done With All the Carbon Dioxide? - Technology Org

Capturing carbon dioxide (CO2) from the atmosphere and storing it either in recycled concrete aggregate or in geological reservoirs in Iceland is technically feasible and has a positive carbon footprint. These are the findings of a pilot project led by ETH Zurich and commissioned by the Swiss Confederation.

Carbon dioxide captured and liquefied in Switzerland is being injected underground for permanent mineralization at its existing wells by the geothermal power plant in Hellisheiði, Iceland. Image credit: Carbfix / ETH Zurich

Switzerland has set itself an ambitious goal: to reduce the country’s greenhouse gas emissions to net zero by 2050. But this will require more than just a massive expansion of renewable energies and saving measures.

The federal government assumes that hard-to-abate CO2 emissions, e.g. form incineration plants, will amount to 12 million tonnes a year. Some of the CO2 emitted therefore needs to be removed again from the atmosphere. The question is, how? – And what should be done with it?

Two different storage pathways explored

These questions were investigated as part of a pilot project led by ETH Zurich and funded and supported by the Swiss Federal Office of Energy (SFOE) and the Federal Office for the Environment (FOEN), which brought together a broad consortium of partners from science and industry.

The researchers explored two solutions for permanent storage of CO2: 1. Mineralisation in recycled demolition concrete manufactured in Switzerland and 2. Mineralisation in a geological reservoir in Iceland.

The diagram shows the process chain from CO2 capture in Switzerland to underground storage in Iceland or in concrete for construction. Image credit: DemoUpCARMA / ETH Zurich

The project used carbon dioxide emissions from a wastewater treatment plant in Bern. The researchers performed a life cycle analysis that covered the entire chain – from the capture and liquefaction of CO2 at the point of origin, to its transport and permanent storage.

They also calculated how much new CO2 is produced along the entire chain. In addition, different solutions were explored for carbon capture methods and technologies for a waste incineration plant and a cement manufacturing plant.

Already a positive carbon footprint

The project has demonstrated that both pathways are technically feasible and have a positive climate impact. In all the examples examined, the amount of CO2 stored exceeded the emissions produced along the transport chain.

When storing in recycled demolition concrete, the efficiency and thus the ratio between stored emissions and resulting new emissions is 90%; when transporting Swiss CO2 and then storing it in a geological reservoir in Iceland, it’s around 80%.

This efficiency should improve in future as most of the new emissions arise from transporting the containers by rail and ship, and some of these modes of transport still use energy from coal-fired power stations as well as fossil fuels. If in future CO2 is to be exported on a large scale, constructing a pipeline would be a potential solution.

One aspect that did surprise researchers, on the other hand, was the regulatory difficulties encountered when trying to transport CO2 through several countries to Iceland. This was the first instance of cross-border carbon dioxide transport for storage.

“A lot of CO2 is needed in the food production industry, and can be transported across borders without any problem, labelled as chemicals. But if the carbon dioxide is in the form of waste – as in our case – the regulatory environment is very unclear,” explains Marco Mazzotti, project coordinator and ETH professor.

The project team therefore came to the conclusion: if Switzerland wants to store CO2 on a large scale and create incentives for companies in future, it needs to work with its European neighbours to agree on clear regulations.

Many research questions still unanswered

Even though the technologies trialled in the project function correctly, much research is still needed in the area of CO2 management. It is also vital to make sure the technologies are worked up to a commercial scale.

In 2023 ETH Zurich, together with its partners in politics, science and industry, set up the “Coalition for Green Energy and Storage”, one of whose aims is to accelerate the adoption and roll-out on an industrial scale of existing technologies for capturing CO2, producing carbon-neutral gases and fossil fuels, and permanently storing CO2.

Another question ETH researchers are addressing is whether CO2 can also be stored underground closer to home, in Switzerland. A possible injection test in a borehole in Trüllikon no longer required by the National Cooperative for the Disposal of Radioactive Waste (NAGRA) could provide some initial answers.

Source: ETH Zurich

You can offer your link to a page which is relevant to the topic of this post.

#2023#Analysis#atmosphere#Capture#carbon#carbon capture#Carbon dioxide#carbon dioxide emissions#carbon footprint#cement#chemicals#Chemistry & materials science news#climate#CO2#coal#Companies#concrete#construction#Containers#efficiency#Emissions#energy#Energy & fuel news#Environment#ETH Zurich#Featured physics news#Featured technology news#Food#food production#form

1 note

·

View note

Text

One thing my brain keeps going back to about Pacific Rim (besides the rad giant robots) is the whole existence of kaiju organ harvesters and their implications.

Like, you have Hannibal Chau, a bizarre and interesting character, but we’re presented with a black market operation that seems mostly interested in the “alternative medicine” uses of kaiju parts.

But my brain demands to know: what does the corporate kaiju harvesting industry look like? Sure kaiju blood is toxic, but there are plenty of toxic materials that have useful applications. Are there chemical companies studying kaiju organs? Big-Pharma jumping on the kaiju bone-powder bandwagon? Are bio-tech firms studying kaiju hide to make tougher materials? Agribusinesses clamoring to acquire kaiju crap for fertilizer?

I’m picturing something like the age of whaling, when humans hunted giant animals and carved them up to feed insatiable industries. Whale-oil lighting lanterns for entire cities, whale-bone being used in everything from knick-knacks, tools, umbrellas, and corsets. Ambergris alone was used in perfumes, medicines, cooking. It was even added to wine as an aphrodisiac.

We glimpsed how kaiju affected pop-culture. Now picture a kaiju smashing a city, but the stock market going up for construction companies (rebuilding the cities), vulture real estate (buying the destroyed land cheap), and all the other corporations that profit from the systematic dismantling of a kaiju corpse and making money off of its parts. Sure, a city was roughed up and who knows how many thousands are dead, but it’s a better windfall when a kaiju makes landfall. It’s always less profitable when jaegers kill them too quickly; sea-based extractions are so much more expensive.

Imagine entire industries, entire economies that don’t just make money from the devastation of kaiju attacks, but grow dependent on them. And then the laws, the squabbles over those valuable, resource-rich kaiju corpses. If a kaiju attacks one country but keeps rampaging and is killed in the country next door, who has claim over the body? The party who was damaged more by it or the country where the corpse physically is? Bidding wars over “cleanup” contracts that cut corners and are only interested in collecting those sweet, sweet, kaiju parts as fast as possible, even if their official mandate is supposed to be the safe removal and cleanup of a toxic substance.

Once jaegers started getting efficient at killing kaiju, the people with all the money became less interested in solving the problem of kaiju attacks and switched to merely managing the industries that kaiju-killing feeds.

What? You want to put more resources into R&D to try and close the Breach? Whatever for? The kaiju comes out, jaegers kill it, and the “host country” gets the proceeds from the kaiju’s body. It’s a win-win for everyone. Why waste time, money, and effort solving a problem that isn’t a problem anymore?

Everything is under control.

#Sorry Long Post#Nerd Rant#Pacific Rim#Kaiju#Hannibal Chau#Kaiju Harvesters#Worldbuilding#Capitalism#an entire kaiju-industrial complex#DARPA tech and military budgets build the jaegers#don't try to tell me that there isn't a entire cabal of corporations profiting off of kaijus beyond just simple toys and marketing#(though that also leads me to wonder WHO exactly has the patent on kaiju?#are they public domain or does the PPDC and the UN have an IP on the kaiju they identify and name???#there's nothing wrong with me I'm normal I swear

2K notes

·

View notes

Text

"Of South Korea’s countless kilograms of annual food scraps, very few will ever end up in a landfill. This is because of two reasons—the first is that it’s been illegal since 2005, and the second is because they have perhaps the world’s most sophisticated food waste disposal infrastructure.

While representing a significant burden on the economy, the food waste disposal nevertheless produces ample supplies of animal feed, fertilizer, and biogas that heats thousands of homes.

As the New York Times’ John Yoo and Chang Lee reported from Seoul, South Korean cuisine tends to lend itself to creating food scraps, since many staple dishes come with anywhere from a few to a few dozen sides.

With the culture erring on the side of abundance rather than restraint, many of these small dishes of tofu, kimchi, bean sprouts, and other bites would be tossed in the landfill if it wasn’t illegal to do so.

The government put the ban hammer on it because the mountainous terrain isn’t ideal for landfill construction.

Instead, restauranteurs and street hawkers pay the municipality for a sticker that goes on the outside of special bins. Once filled with food scraps, they are left on the road for collectors in the morning who take 90% of all such waste in the country to specialized collection facilities.

At apartments and among residential housing areas, hi-tech food waste disposal machines are operated by a keycard owned by residents under contract with the disposal companies.

Once taken to the recycling facilities, the food is sorted for any non-food waste that’s mixed in, drained of its moisture, and then dried and baked into a black dirt-like material that has a dirt-like smell but which is actually a protein and fiber-rich feed for monogastric animals like chickens or ducks.

This is just one of the ways in which the food scraps are processed. Another method uses giant anaerobic digestors, in which bacteria break down all the food while producing a mixture of CO2 and methane used to heat homes—3,000 in a Seoul suburb called Goyang, for example. All the water needed for this chemical process comes from the moisture separated from the food earlier.

The remaining material is shipped as fertilizer to any farms that need it.

All the water content is sent to purification facilities where it will eventually be discharged into water supplies or streams.

While one such plant was shut down from locals complaining about the unbearable smell, many plants are odorless, thanks to a system of pipes built into the walls that eliminate it via chemical reaction.

It’s the way South Korea does it. Sure, it costs them around $600 million annually, but they have many admirers, including New York City which hopes to implement similar infrastructure in the coming years."

-via Good News Network, June 15, 2023

#south korea#korean food#kimchi#bean sprouts#food waste#landfill#circular economy#sustainability#waste disposal#sanitation#good news#hope#hope posting#new york city#restaurants

540 notes

·

View notes