#Brazing Heat Sink

Text

Brazing Heat Sink

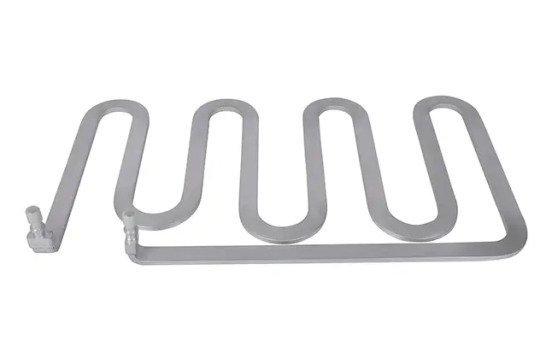

Brazing heat sink is one of the most effective heat transfer methods. It is composed of a set of corrugated pipe plates between the front and rear baffles. The baffle plate assembly is composed of a sealing plate, a sealing ring and a baffle plate. The interface type can be customized according to the specific requirements of the market and application fields. During the vacuum brazing process, a solder joint is formed at each contact point between the plate and the filler material (brazing material). Using this design method, a heat exchanger composed of two different channels or loops can be manufactured. The design purpose of the brazed fin heat sink is to provide unparalleled performance and the lowest life cycle cost. If brazing technology can be used in your next cooling project, it will surely bring you many benefits, including saving space, energy and maintenance costs.

1 note

·

View note

Text

China Aluminum Brazing Furnace: Enhancing Aluminum Welding Processes

China Aluminum Brazing Furnace: Enhancing Aluminum Welding Processes

Aluminum brazing furnaces play a crucial role in the welding process for various aluminum products. Specifically, these furnaces are essential for joining aluminum heat sinks and aluminum tube sheets. Let’s delve into the details:Get more news about China Aluminum Brazing Furnace,you can vist our website!

1. Purpose of Aluminum Brazing Furnaces

When using a vacuum brazing oven, aluminum heat sinks and aluminum tube sheets are placed on special supports inside the furnace. These components are heated to a high-temperature state, typically exceeding 620°C. The vacuum environment ensures that the brazing process occurs without oxidation, resulting in strong and reliable joints.

2. Applications of Aluminum Brazing Furnaces

The CAB (Condenser Aluminum Brazing) furnace is commonly used for brazing aluminum workpieces. Here are some key applications:

Radiator: Aluminum heat exchangers, including radiators, benefit from brazing using these furnaces.

Intercooler: Intercoolers, which cool compressed air in turbocharged engines, also undergo brazing.

Condenser: Aluminum condensers, used in air conditioning systems and refrigeration units, are brazed for optimal performance.

Evaporator: Evaporators, found in refrigerators and air conditioners, are another application.

Heater: Aluminum heaters, such as those used in industrial processes, can be brazed using these furnaces.

3. Protective Atmosphere and Flux

The CAB aluminum brazing furnace operates under a nitrogen protective atmosphere. This prevents oxidation during the brazing process. Additionally, non-erosive flux is used to facilitate the joining of aluminum components.

In summary, China’s aluminum brazing furnaces contribute significantly to the production of high-quality aluminum products. Their role in creating strong, leak-free joints ensures the reliability and efficiency of various heat exchangers and other aluminum-based systems.

0 notes

Text

Brazing Heat Sink: Revolutionizing Heat Transfer Efficiency

In the realm of heat transfer technology, brazing heat sinks stand out as one of the most effective methods, offering unparalleled performance and cost efficiency. Comprising a series of corrugated pipe plates sandwiched between front and rear baffles, these heat sinks are engineered to optimize heat dissipation in various applications.

The assembly of a brazing heat sink consists of a sealing plate, a sealing ring, and the crucial baffle plates. These components come together seamlessly during the vacuum brazing process, wherein solder joints are formed at each contact point between the plates and the filler material, also known as the brazing material. This meticulous design approach allows for the creation of a heat exchanger with distinct channels or loops, catering to diverse market requirements and application fields.

What sets brazed fin heat sinks apart is their ability to deliver exceptional performance while minimizing life cycle costs. By harnessing brazing technology, these heat sinks not only excel in heat dissipation but also offer numerous benefits to users. Among these advantages are space optimization, energy savings, and reduced maintenance expenses.

The compact design of brazing heat sinks enables them to effectively dissipate heat in confined spaces, making them ideal for applications where spatial constraints are a concern. Furthermore, their efficiency in transferring heat translates into significant energy savings, contributing to overall operational cost reduction. Moreover, the robust construction of brazed fin heat sinks minimizes the need for frequent maintenance, thereby further lowering the total cost of ownership over their lifespan.

For industries and projects seeking superior heat transfer solutions, brazing technology presents an enticing proposition. Whether it’s for electronics cooling, automotive applications, or industrial processes, brazed fin heat sinks offer a reliable and efficient means of managing thermal loads. Embracing brazing technology in cooling projects not only ensures optimal performance but also promises long-term benefits in terms of space utilization, energy conservation, and operational cost efficiency.

In conclusion, brazing heat sinks represent a paradigm shift in heat transfer technology, offering unmatched performance and cost-effectiveness. With their innovative design and advanced manufacturing processes, these heat sinks have become indispensable assets across various industries. By incorporating brazing technology into cooling projects, businesses can unlock a multitude of benefits, paving the way for enhanced efficiency and sustainability in thermal management solutions.

0 notes

Text

Plumbing and Sanitary Installation: A Comprehensive Guide

Plumbing and sanitary installation play a crucial role in maintaining the comfort and functionality of our homes and buildings. Whether you’re planning a new construction project, renovating an existing space, or simply need to fix a leaky faucet, understanding the basics of plumbing and sanitary systems is essential. In this blog, we’ll take you through the key aspects of plumbing and sanitary installation, from the fundamentals to some advanced tips.

Understanding Plumbing and Sanitary Systems

Plumbing and sanitary systems are very important for the health, hygiene and comfort of the people living in a building. They involve the design, installation and maintenance of pipes, fixtures and appliances that supply water and remove waste from a building. Plumbing and sanitary systems have many components and functions, such as:

· Water supply system: This system provides water for various purposes, such as drinking, cooking, washing, etc. The water supply system consists of water sources, storage tanks, pumps, pipes, valves, taps and meters. The water quality and pressure should be maintained according to the standards and regulations.

· Drainage system: This system collects and disposes the waste water from the sinks, toilets, showers, etc. The drainage system consists of traps, soil pipes, waste pipes, vent pipes, septic tanks and sewer lines. The drainage system should be designed to prevent clogging, leakage, backflow and odor.

· Sanitary fittings: These are the devices that are used to access or control the water supply and drainage system. They include hand wash basins, sinks, bathtubs, water closets, faucets, showers, etc. The sanitary fittings should be durable, easy to clean and aesthetically pleasing.

Tools and Materials For Plumbing and Sanitary works

Tools and materials are essential for plumbing and sanitary work. They help the plumber to perform various tasks such as cutting, bending, joining, sealing, and repairing pipes and fittings. Some of the common tools and materials used in plumbing and sanitary work are:

· Pipe cutter: A tool used to cut pipes of different materials and sizes. There are different types of pipe cutters, such as solid type, hook type, and chain type.

· Hacksaw: A tool used to cut metal pipes, nuts, bolts, screws, and other objects. It has a blade with fine teeth that can cut through hard materials.

· Hole saw: A tool used to cut circular holes in pipes, walls, floors, and other surfaces. It has a cylindrical blade with teeth that can drill through various materials.

· Pipe bender: A tool used to bend pipes into different shapes and angles. It can be manual or hydraulic. It has a curved form that can fit around the pipe and apply pressure to bend it.

· Wrenches: Tools used to tighten or loosen nuts, bolts, fittings, valves, and other objects. There are different types of wrenches, such as adjustable wrench, pipe wrench, basin wrench, faucet key, torque wrench, etc.

· Pliers: Tools used to grip, twist, cut, or bend wires, pipes, nuts, bolts, and other objects. They have two handles and two jaws that can be opened or closed by applying pressure.

· Plumber’s torch: A tool used to heat pipes and fittings for soldering or brazing. It has a flame that can melt metal and create a strong joint.

· Thread sealing tape: A material used to seal the threads of pipes and fittings to prevent leaks. It is also known as plumber’s tape or Teflon tape. It is wrapped around the threads before screwing them together.

· Pipes: Materials used to transport water or waste from one place to another. They can be made of metal, plastic, clay, concrete, or other materials. They have different sizes, shapes, and specifications depending on their use.

· Fittings: Materials used to connect pipes or change their direction, size, or shape. They can be elbows, tees, reducers, couplings, unions, valves, traps, etc. They have different types and standards depending on their use.

These are some of the tools and materials used in plumbing and sanitary work.

Planning Your Installation

· Creating a layout: A layout is a drawing that shows the location and connection of plumbing and sanitary fixtures, pipes, fittings, valves, etc. in your site. A layout helps you to visualize the design, estimate the materials and costs, and avoid conflicts and errors. To create a layout, you need to follow these steps:

o Measure the dimensions of your site and draw a floor plan to scale.

o Mark the location of plumbing and sanitary fixtures, such as sinks, toilets, showers, etc., on the floor plan. Make sure they are not too close together or too far from the water supply and drainage lines.

o Mark the drain lines and vents for the fixtures on the floor plan. The drain lines should be sloped at least 1/4 inch per foot to allow gravity to move the wastewater. The vents should be extended above the roof to prevent air locks and sewer gases.

o Add the supply lines for the fixtures on the floor plan. The supply lines should be sized according to the water demand and pressure of each fixture. You can use a water supply fixture unit (WSFU) table to calculate the required pipe sizes.

o Indicate the pipe sizes and the exact type of every fitting on the layout. You can use symbols or abbreviations to represent different types of pipes and fittings.

o Create riser drawings to show vertical pipe runs and connections between floors.

o Review your layout and check for any errors or inconsistencies. You may need to revise your layout according to the codes and standards, site conditions, or customer preferences.

· Determining pipe sizes: Pipe sizes are important for ensuring adequate water flow and pressure, preventing leaks and noises, and saving energy and water. Pipe sizes depend on various factors, such as water demand, pressure, length, material, etc. To determine pipe sizes, you need to follow these steps:

o Estimate the water demand of each fixture by using a WSFU table or a fixture flow rate table. The WSFU is a measure of how much water a fixture consumes per minute at peak demand. The fixture flow rate is the actual amount of water that flows through a fixture at a given pressure.

o Calculate the total WSFU or fixture flow rate for each branch or main line by adding up the values of all fixtures connected to that line.

o Find the appropriate pipe size for each branch or main line by using a pipe sizing chart or table. The pipe sizing chart or table shows the relationship between pipe size, water flow rate, water velocity, and pressure drop. You need to choose a pipe size that can deliver the required water flow rate without exceeding the maximum water velocity or pressure drop.

o Adjust the pipe size if necessary by considering other factors, such as friction loss, elevation change, fittings loss, etc. Friction loss is the loss of pressure due to the resistance of water flowing through pipes. Elevation change is the difference in height between two points in a pipe system. Fittings loss is the loss of pressure due to bends, elbows, tees, valves, etc. in pipes. You may need to increase or decrease the pipe size depending on these factors.

· Ensuring proper slope for drainage: Slope is the angle or gradient of a pipe that affects how fast or slow the wastewater flows through it. Slope is important for preventing clogging, backflow, siphoning, and odor in drainage pipes. Slope depends on various factors, such as pipe size, material, length, etc. To ensure proper slope for drainage, you need to follow these steps:

o Determine the minimum slope required for each drain pipe by using a slope chart or table. The slope chart or table shows the relationship between pipe size, slope

Installation Steps for Plumbing and Sanitary Works

Here are 3 installation steps for plumbing and sanitary works

· Underground rough-in phase: This is the first stage of plumbing installation, where the pipes and fittings are laid below the ground level, before the concrete slab is poured. This phase involves digging trenches, laying pipes, connecting fittings, installing traps, vents, cleanouts, etc., and testing the system for leaks and pressure. This phase requires careful planning and coordination with other trades, such as electrical, mechanical, etc., to avoid conflicts and damages.

· Aboveground rough-in phase: This is the second stage of plumbing installation, where the pipes and fittings are installed above the ground level, after the concrete slab is cured. This phase involves running pipes through walls, floors, ceilings, etc., connecting fixtures, installing valves, regulators, meters, etc., and testing the system for leaks and pressure. This phase requires accurate measurements and alignments, as well as proper supports and insulation for the pipes.

· Finishing phase: This is the final stage of plumbing installation, where the fixtures and appliances are installed and connected to the plumbing system. This phase involves mounting sinks, toilets, showers, faucets, etc., connecting water heaters, dishwashers, washing machines, etc., and testing the system for functionality and performance. This phase requires careful handling and installation of the fixtures and appliances, as well as aesthetic considerations.

Common Plumbing Issues and Solutions

Plumbing issues are common problems that can affect any household. They can range from minor annoyances to major emergencies, depending on the severity and location of the problem. Some of the most common plumbing issues and their solutions are:

Dripping faucets: This is a problem that can waste water and money, as well as cause annoying noises. The main cause of dripping faucets is usually a worn-out washer or O-ring that needs to be replaced. To fix this problem, you need to turn off the water supply to the faucet, unscrew the faucet head, remove the old washer or O-ring, and install a new one.

Leaking pipes: This is a problem that can damage your walls, floors, and furniture, as well as increase your water bill. The main causes of leaking pipes are corrosion, cracks, loose joints, or high water pressure. To fix this problem, you need to locate the source of the leak, turn off the water supply to the pipe, and either patch the leak with a repair clamp or tape, or replace the damaged section of the pipe.

Running toilets: This is a problem that can waste up to 200 gallons of water per day, as well as make annoying sounds. The main causes of running toilets are faulty flappers, fill valves, flush valves, or chains. To fix this problem, you need to open the tank lid, inspect the parts for wear and tear, and either adjust or replace them as needed.

Low water pressure: This is a problem that can make it hard to use your faucets, showers, and appliances. The main causes of low water pressure are clogged aerators, pipes, or valves, or faulty pressure regulators. To fix this problem, you need to clean or replace the aerators, pipes, or valves that are causing the blockage, or adjust or replace the pressure regulator that is malfunctioning.

Clogged drains: This is a problem that can prevent water from flowing freely through your sinks, tubs, or toilets. The main causes of clogged drains are hair, soap scum, grease, food particles, or foreign objects that accumulate in your pipes. To fix this problem, you need to use a plunger, a drain snake, or a chemical drain cleaner to dislodge or dissolve the clog.

These are some of the most common plumbing issues and their solutions.

Maintenance and Care

Maintenance and care for plumbing and sanitary work is an essential part of keeping your plumbing system in good condition and preventing costly repairs or damages. Plumbing and sanitary work involves the installation, repair, and maintenance of pipes, fittings, fixtures, and appliances that supply water and remove waste from a building. Some of the maintenance and care tips for plumbing and sanitary work are:

Check for leaks regularly: Leaks can waste water, increase your water bill, and cause damage to your walls, floors, furniture, etc. You can check for leaks by inspecting your pipes, faucets, toilets, showers, etc. for signs of dripping, wetness, corrosion, or mold. You can also use a water meter to monitor your water usage and detect any unusual changes. If you find any leaks, you should fix them as soon as possible or call a professional plumber to do it for you.

Clean your drains periodically: Drains can get clogged by hair, soap scum, grease, food particles, or foreign objects that accumulate in your pipes. Clogged drains can prevent water from flowing freely, cause backups, overflows, or odors. You can clean your drains by using a plunger, a drain snake, or a chemical drain cleaner to dislodge or dissolve the clog. You can also use baking soda and vinegar to create a natural drain cleaner that can remove minor clogs and freshen up your drains.

Replace your washers and O-rings occasionally: Washers and O-rings are rubber parts that seal the joints of pipes and fittings to prevent leaks. Over time, they can wear out, crack, or break due to constant use or exposure to water. You can replace your washers and O-rings by turning off the water supply to the faucet or valve, unscrewing the faucet head or valve body, removing the old washer or O-ring, and installing a new one.

Insulate your pipes properly: Pipes can freeze or burst in cold weather if they are not insulated properly. Frozen or burst pipes can cause water damage, flooding, or loss of water supply. You can insulate your pipes by wrapping them with foam pipe insulation, heat tape, or newspaper. You can also keep your faucets dripping slightly to prevent the water from freezing in the pipes.

Service your water-using appliances regularly: Water-using appliances such as water heaters, dishwashers, washing machines, etc., need regular servicing to ensure their efficiency and performance. You can service your water-using appliances by following the manufacturer’s instructions for cleaning

Advanced Plumbing Techniques

Advanced plumbing techniques are methods and technologies that can improve the efficiency, performance, and sustainability of plumbing systems. They can help plumbers and homeowners to save water, energy, and money, as well as prevent or solve common plumbing problems. Some examples of advanced plumbing techniques are:

Tankless water heaters: These are devices that heat water on demand, without storing it in a tank. They can save energy and space, as well as provide continuous hot water supply.

Hot water recirculation: This is a system that circulates hot water from the heater to the faucet, and back to the heater, using a pump and a loop of pipes. It can reduce water wastage and waiting time, as well as increase comfort and convenience.

Smart irrigation: This is a system that uses sensors and weather forecasts to control the watering of gardens and lawns. It can optimize water usage and plant health, as well as reduce runoff and erosion.

Leak detectors: These are devices that monitor the water pressure and flow in pipes, and alert the user if there is a leak. They can prevent water damage, flooding, and high water bills, as well as help locate the source of the leak.

Advanced touchless faucet: This is a faucet that uses motion sensors or voice commands to turn on and off the water flow. It can prevent cross-contamination, save water, and enhance hygiene and accessibility.

Hiring Professionals

When it comes to plumbing and sanitary installation, ensuring that the job is done right is paramount. At Alasafeer Contacting Co, we understand the importance of hiring qualified professionals who can deliver top-notch service. Our licensed and insured experts have years of experience in plumbing and sanitary installation, ensuring that your project adheres to the highest standards and local regulations. Whether it’s a repair, renovation, or new installation, we provide transparent quotes, clear communication, and a commitment to excellence. When you choose Alasafeer Contacting Co, you’re choosing reliability and peace of mind for your plumbing and sanitary needs.

0 notes

Text

What are the steps to replace the rubber parts of the plate heat exchanger?

The rubber seal is an aging part in the plate heat exchanger. The leakage of the plate heat exchanger means that the rubber seal of the heat exchanger should be replaced. Then the main replacement steps of the rubber parts are:

1. Inspection and testing of reuse performance. Inspect the wall thickness of the heat exchanger and piping when rust is suspected.

2. Remove the aged seals on the plate heat exchanger. According to different dirt, the acid-alkaline cleaning tank is used for chemical cleaning, and the surface of the cleaned parts will not be corroded by chemical media (such as gasoline).

3. After the plate heat exchanger is chemically cleaned. Use a high-pressure blow-off device to thoroughly remove the chemical medium remaining on the surface of the plate heat exchanger, etc.

4. Coat each heat exchanger plate with a fluorescent test agent, check whether there are small cracks and corrosion holes under the irradiation of ultraviolet light, and clean it again. In addition, the condition of the sealing groove should be checked and repaired if necessary.

5. For the adhesive gasket, the residual substances will be completely removed, and the re-adhesive adhesive will be used to re-bond the reassembled heat exchanger sheet group in a special fixture to cure the adhesive; In order to achieve the best bonding effect. For non-bonded gaskets, a different mechanism is used to secure the gasket in the heat sink.

6. Check the bonding position and bonding quality of each plate heat sink, classify them according to the installation order, and then carefully assemble the plate heat sink group.

The above is the introduction of the replacement steps for the rubber parts of the plate heat exchanger, and I hope it will be helpful to you. If you have any other questions or questions, please contact our online customer service.

Jiangsu Yuanzhuo Equipment Manufacturing Co., Ltd. is a professional manufacturer of plate heat exchangers. Plate heat exchangers are widely used. We have Brazed Plate Heat Exchangers and Gasketed Plate Heat Exchangers. If you are interested in plate heat exchangers, please feel free to contact us at 0086-510-86165907 or send an email to [email protected].

0 notes

Text

Principle And Characteristics of FSW

We have learned about the principle and characteristics of vacuum brazing before. In this article, let us understand the principle and characteristics of FSW, compare the difference between the two brazing technologies, and choose a more suitable brazing technology according to product needs in the future.

The principle of FSW(Friction stir welding)

The process of friction stir welding: a cylinder or other shape (such as a threaded cylinder) is inserted into the joint of the workpiece, and the high-speed rotation of the welding head causes it to rub against the material of the welding workpiece, thereby making the joint the temperature of the material rises and softens. Then makes it move with the welding heat along the welding interface. The transformative material deposit behind the welding head and become solid welding joint under the pressure of mould.

The advantages friction stir welding

1.Low welding temperature, small change in microstructure in heat affected zone ;the hardness of the cold plate will not change.

2.The operation process is convenient to realize mechanization, automation, low energy consumption, and low requirements on the working environment.

3.No need to add welding wire or remove oxide film before welding, no protective gas.

4.The welding process is safe, non-polluting, smokeless, etc.

5.Energy saving, environmental protection, low cost .

The disadvantages of friction stir welding

1.It can only weld the welding joint one by one, linear welding , so the welding speed is not fast;

2.The wear of the mixing head is fast .

3.High fixture requirements and high input costs .

4.At the end of the weld, there will be a process hole at the end of the weld, which requires complex design and processing of the process hole.

5.The amount of deformation of the product after welding is relatively high.

6.The design of the channel should be simplified, and the internal structure of the cavity cannot be complicatedly welded. When the heat dissipation requirement is difficult to meet it is necessary to increase the flow rate to make up for the requirements, which lead the cost increase.

Liquid cooled plate manufacturer recommendation

Aluminum vacuum brazing and friction stir welding (FSW) are widely used in two different welding processes in the field of cold plate (heat sink) products, each welding process has its own advantages, and there are certain differences and different priorities.

There is an excellent liquid cooled plate manufacturer, Sanqian Technology Co., Ltd., which sells high-quality water cooling plate. If you want to know more about it, or are interested in our products, you can visit the website of Sanqian Technology Co., Ltd.

0 notes

Text

Fic: Relief

Frankie “Catfish” Morales x female reader (cishet, no y/n, no kids, reader is on her period)

Warnings: Mutual hand jobs during period, blood is mentioned but not featured. Cramps described.

Summary: Frankie knows how to deal with cramps. Frankie's got you.

You exhale a sigh of relief when you step underneath the hot spray of water. Shuddering at the sudden heat of the shower, you tense up for a second before relaxing and turning your face up towards the stream. As you get used to the temperature, you turn up the heat a little more and carefully rub your lower back and stomach to spread out the warmth over the bloated, aching parts. You got your period this morning and have spent the day with a nagging ache radiating from your stupid fucking uterus. Towards the evening, the cramps worsened and you didn't eat much during dinner. Frankie had suggested you take a shower and an early night, let him worry about cleaning up, but you were loath to just let everything go because of something you've experienced once a month for over half your life. Besides, this wasn't even the worst your body could throw at you: you were still functioning. Uncomfortable, yes, but not bedridden and vomiting. After a few chores, however, you figured you had done enough for the day, and decided to take Frankie's advice.

The hot water relaxes you and for a long while, you just stand underneath the stream, eyes closed and one palm resting on your lower abdomen, relieved that the shower is taking the edge of the pain, but you're still feeling swollen and sore. Finally opening your eyes, you reach for the shampoo just as the door opens and Frankie comes in. He’s wearing only a t-shirt and boxer briefs, and proceeds to shed these quickly before getting into the shower booth with you.

”How’s you, gorgeous?” he murmurs into your ear, slipping his arms around you from behind.

A little flutter in the pit of your stomach brings forth a smile on your lips, and you put the shampoo bottle away.

”Surviving.”

”I know you’re in pain but fuck, I love it when your tits and ass swell up like this.”

He moves his large hands to your ass cheeks and squeezes, before trailing his fingers lightly up your sides and to your front, covering your breasts. He’s a lot more careful with them than with your ass; experience has taught him that if he’s too rough when they’re tender, he’ll get punched in the face. (For real: you were once taken by surprise by his well-meaning but slightly too rough grip, the sudden pain making you startle in a perfect backwards headbutt. He got a nose bleed and you felt awful, but he felt worse, not from pain but for having hurt you.)

”It’s not as bad as it was two days ago. I wouldn’t even have let you touch them,” you let him know, the flutter in your stomach intensifying when Frankie brushes his fingers over your stiff nipples.

”I know, and it’s torture. They were bigger two days ago. But I just have to make do...”

He trails kisses down your shoulder, one hand staying on your breast and the other wandering down between your legs, finding your clit. You exhale in a soft sigh.

”I’m bleeding a lot," you warn him with a low moan. ”And I’m sore, Frankie, I... I don’t want you in me.” You feel awful for telling him this because you usually always want him in you, but right now, you would just be uncomfortable. It's not the blood, it's the overall uneasiness.

”Don’t worry baby, I know what you need,” he whispers in a low growl, his breath hot on your ear. You feel him grow hard against your butt, so your lean back, pressing yourself against his dick, just as he starts to rub your clit gently with two fingers. Sparks run up and down your body as you let out another sigh before turning your head so you can reach his mouth. You find it, but also get hit full on in the face by the shower, so you giggle and wipe at your eyes. Frankie chuckles as he redirects both you and the shower head before pressing his lips to yours, kissing you like only he can, lightly but with commitment. You've never been with anyone who could kiss like Francisco Morales. Then again, you've never loved anyone as much as you love him, never wanted anyone like you want him. Never been safe enough with anyone to want them so much, so bad, so fully.

He pinches your nipple a little too hard, and you bite his lip in return. You both grunt and fall back.

”Sorry,” he smiles. You smile back.

”No you’re not...”

You reach behind yourself, find his dick, and start to stroke it. Frankie leans his forehead to the back of your head, breathing audibly, his hand working faster between your legs. You moan and find the wall with your free hand to support yourself. The dull ache of your cramps is now shadowed by the escalating pull in your groin and despite the hot water, your skin prickles over for a moment, your arousal manifesting in goosebumps that quickly disappear in the stream of hot water.

Frankie's breathing is shallow against your ear, echoing your own, both of you breathing more audibly, exhales turning into small, short moans as you take each other closer to the edge. You're finding it difficult to work Frankie's hard dick with your hand awkwardly reaching behind yourself, but he doesn’t seem to have any complaints. You think dimly that if this doesn’t work out, you can suck him off once you're undone. He’d like that. Or...

”Wanna cum on my ass, baby?” you invite him in a breathless whisper. ”Wanna cum on my round, soft ass?”

”Fuck,” Frankie groans, flipping a couple of wet, heavy strands of hair out of the way before kissing your neck and sucking into the skin. You hiss and do your best to jerk him off faster, but your hand is no longer functioning optimally as you're closing in on your orgasm. You don't want to grab him too hard, so you let go of him and braze yourself with both hands against the tile wall. Panting, you bite down on your lower lip and hold your breath –

– and release a low keen, a tiny shudder traveling through your body as the orgasm relaxes and tenses you up, simultaneously, wonderfully. Frankie doesn't give your clit a rest when he grabs his cock, taking over where you left off.

”Cum on my ass, baby,” you beckon him, breathless and still riding the waves of your orgasm, ”that’s it, cum on my ass...” You tense up again, your fingers clawing helplessly on the walls without finding a grip, and your legs shake as you mewl your way through another release.

Despite the flowing water from the shower, you feel the hot spurts of cum on your ass cheeks. Frankie curses in a strangled voice and releases your burning bundle of nerves, slapping both hands to your hips and pulling you to him, pressing a gasping, open-mouth kiss to your shoulder. You feel him tremble about as much as you yourself are and very carefully, you take your hands off the wall and put them over his. You lean back and feel his chest heave against your back. He murmurs in appreciation at the contact.

”Damn, baby.”

”Uh-huh.”

You turn around and wrap your arms around his neck, gazing into those wonderful brown eyes of his.

”You’re so good to me,” you say sincerely. Frankie smiles softly, sliding his hands down to your ass.

”It’s because your ass is awesome,” he grins before dipping down to kiss you. ”And because I love you.”

He helps wash your hair, something he's done plenty of times before but still makes you purr with pleasure. You return the favor and it gives you the same kind of gratification to see how much he appreciates it as well.

After the shower, when you're dry, warm, and dressed in pj's, you go to the kitchen to put your rice heat pack in the microwave. Your cramps have subsided considerably, but you still want to keep your belly warm.

"You hungry?" Frankie asks, rummaging through the fridge. "You hardly ate anything."

"I'll have a cup of tea. Eating makes me so gassy," you grimace. It doesn't matter what you eat during your first two days on your period: your stomach turns upside down.

”Okay, baby." Frankie goes to the cupboard where the coffee and tea are stored. "The pink box?"

"Thanks, yeah, that's the one." You accept the box of tea from him, and your big teacup. Frankie fills the kettle with water and turns it on, before leaning against the sink.

"Wouldn’t want you to fart in your sleep all night,” he teases you with a little smirk. ”I’d send you to the couch immediately.”

”Here we go,” you sigh theatrically as you move into his embrace. ”Total asshole as soon as your dick’s back in your pants.” You kiss his nose before giving it a little nip.

”I was so good to you only thirty minutes ago," he reminds you, feigning offense. You scoff, but you also can't help smiling widely. He's always so good to you, every day. You can't believe your luck.

The microwave pings and you pick out the pad and grab your tea. On your way to the living-room for an uneventful rest of the night on the couch in front of the tv, Frankie catches you in his arms. Pressing his sharp nose to your neck, he inhales deeply and hums in approval.

”Feeling better?”

”If I say yes, are you gonna be a smug asswipe about it?”

”You bet.”

"Then no, I feel like shit." Sweetly, you bat your eyelashes at him. "You're going to have to make at least a bit of an effort."

"I like a challenge."

He follows you to the couch and not even half an episode of Parks and Recreation later, you're admitting that you feel a lot better. Another two episodes, and you're asleep against his side.

73 notes

·

View notes

Text

The Napolitalian summer heat burns in the night like Leonardo’s black mood.

“That’s the most stupid thing I’ve seen you do in my entire life”. Primo scoffs, derisive. “By far! You could have fucked it all to the ground, you know? You could have gotten yourself killed! You could have gotten us both killed!”. A beat. “Are you even listening?”. He aims to grab Primo’s shoulder and shake it, but Primo shoves him away.

Oh. Oh. That’s fucking rich.

“I’ve just gotten you out of the direction of Allegri’s fucking rifle!”

“You’re being so dramatic”, Primo grunts, trying to demonstratively ignore him as he continues cleaning up the cut on his nose over the sink of the bar’s bathroom and not quite achieving it. “Congratulations! Is that what you want to hear?”

A thanks would be nice. An oh, Leonardo, you were right. An oh my God, I was an idiot. A little bit of something.

“Good Lord, Primo”, he all but groans. “You see why Salvatore sent me?”, the words are out of his mouth before he thinks them through, and once he’s said them, well. He’s said them. He sees the hurt pass through Primo’s face before he schools his features into a carefully blank façade. He’ll poison himself, if he keeps on biting his tongue. Leonardo sighs, adds, still mad, but a touch softer: “Then you’ll go and keep on complaining”.

There’s a bruise darkening over Primo’s temple. Now that he’s paying attention, Leonardo sees Primo’s hand tremble a little, how he takes a breath as if brazing himself every time he wipes away the blood. He counts to ten and doesn’t even get through half of it before he’s grabbing Primo’s hand.

“I swear to God”, he curses, clutching Primo’s hand when he tries to shove him away again. “For my peace of mind”.

Primo stares at him and glares and makes a whole show of rolling his eyes, huffing and throwing out the paper towel he had been using as a wipe, all while Leonardo grabs another paper towel, damps it, and wrings it a little, completely ignoring his antics. There’s a trickle of blood at the side of Primo’s nose. He starts there. Leonardo can tell Primo’s fighting not to cross his arms when he rests his hands on the side of the other bathroom’s sink.

“Salvatore wanted to win more money, and now he’s winning more money”, Primo says after a while, breaking the room’s tense silence. He sounds defensive. Self-justifying. It makes Leonardo feel so tired. “My idea worked. You can stop fussing about it now”.

He tips Primo’s head slightly to the side before answering: “What Salvatore wanted was to pay less for the drugs”.

“He’ll be paying less for the drugs now”, Primo insists.

“You’ve single handedly gotten rid of our agreement with the Allegri family—”.

Primo’s tone is clipped when he answers: “They were skimming us off”.

“—That means we’ve lost our means of bringing the cigarettes back from Gioia Tauro from now on”, he explains, levelled. “Which means finding new drivers, and more cars, and a suitable new place to keep the cigarettes. Which means—”.

“It’s still less expensive in the long run”, Primo cuts him. He crunches his nose when Leonardo passes the towel over his upper lip. “And we get to control the whole process”.

Leonardo rumples the towel, grabs another one, damps it. He observes Primo, who looks serious, but not quite as tense. He takes a breath, brazing himself for the expected outburst when he says: “You know Salvatore is not going to see it that way”.

Automatically, Primo tenses up. And then he bottles it up, bites down whatever scathing answer was brewing in his lips and suggests, deliberately casual: “You can say it was my idea. That you tried to stop me”.

Pretending to be above everything, untouched and unaffected, didn’t work at all when Primo was fifteen. Leonardo hates so much that he’s still doing that now that he’s thirty.

“And why would I do that”. Primo shrugs, a little. It’s kind of awkward, given that Leonardo’s forcing his chin up to clean the cut. “You’re right. We’ll get more money in the end”.

It’s not until Leonardo’s following a trickle down Primo’s throat that he realizes that the other isn't moving a muscle. It must sting. He keeps his touches as light as he can.

“Wasn’t it a stupid idea?”, Primo says, as if in passing. “A very stupid idea. The most stupid idea ever”.

12 notes

·

View notes

Text

I’ll Miss You

Yeosang - Spanking - Fluff - Subby

“It’s a really long time to be away from you, Yeosang-ah…” I sniffled, my face pressed against my boyfriend’s black Nike sweatshirt breathing in the nutmeg and cinnamon cologne he wore. His arms squeezed me tightly, hands rubbing my back as I choked back my tears once more.

“Jagi, I know this is a lot to think about, so how about we just focus on the time we do have before the tour starts? There’s many things I have planned for us to do before we go.” I titled my face up to look at Yeosang, his perfect smile spreading across his face, those deep blue contacts staring me down. When did he become so ethereal?

“What kind of plans?” I finally asked, Yeosang leaning down to plant a warm kiss upon my lips.

“You’ll see.”

The restaurant was alive with the quiet humming of people eating dinner together, the smell of pork belly and white radish filling my senses gracefully. I grabbed onto Yeosang’s hand tighter tugging him down to hear my voice in his ear.

“Are you sure we can afford this place? It seems too fancy…” I gazed around the room noticing the slightly crowded restaurant filled with people, mostly couples, brazing their meats and grilling vegetables.

“Annyeong! How many today?” The hostess was tall, slender frame with blonde curls that flowed past her shoulders, eyes dark hazel focusing onto Yeosang’s. I could totally take her, I thought.

“Two please,” Yeosang squeezed my hand and dragged me behind him as the hostess led us to a table near the center of the restaurant surrounded by 3 more groups of people in tables within the same vicinity. The restaurant was dim-lit with dulled silver lights hanging over each table that gave off little reflective light against the dark red walls. Yeosang pulled out a chair for me to sit in, him pushing it gently under the table before taking his own seat beside me.

I lifted the menu and glanced at the prices, a churning in my stomach beginning. “Yeosang…”

“Hmm?” He acknowledged me without glancing up.

“How can we afford this…$30 for pork belly…I just don’t think –“

Yeosang’s hand was hot and heavy as he pressed it against my thigh, slowly sliding my dress up exposing my black tights. My cheeks flushed cerise as I caught his eyes in my irises. “For once in our relationship, let me be the one to worry about things, hm?” He removed his hand just as quickly as he had placed it onto my body, lifting up the menu once more just in time for the waiter to come to the table.

The blood in my ears echoed out at me, the feeling of his touch radiating through my body as his voice became muffled as he ordered our meal, the waiter walking off to gather our drinks. I looked down at my hands that cupped themselves together in my lap. Touch…touching was something so natural yet made me feel aflame with the heat of a thousand suns. The burning, the burning returned to my skin, my arm this time. I tilted my head up to look into Yeosang’s eyes, those blue contacts breaking my breathing. When did his chair get this close to me?

“Jagiya,” His voice was soft like crème, his breath brushing against my jawline as he leaned in closer, “tell me, what are thinking about right now?”

My heart pounded erratically as he spoke. My mind losing all train of thought I swallowed the lump sticking to my throat. He was so unfair to me and my feelings.

“Your pork belly, beef, and vegetables, sir.” The waiter returned finally, Yeosang leaning off of me enough to allow me to catch my breath, taking the items from the man as he named them. “Pickled white radish, kimchi, and finally the lettuce wraps. Is there anything else I can get you?”

“No, thank you, this is fine.” Yeosang cranked the grill heat up before placing the meat on the cast iron top the sizzle of the meat with mushrooms and onions parallel to them began our meal. I picked up the wooden chopsticks provided by the restaurant and slid some radish between my lips, my eyes widening at the flavor.

“Oh my--!” I put my hand over my lips surprised at the flavor that was spinning on my tastebuds.

“Good, huh?” Yeosang smiled at me as he flipped the meat on the grill top.

“It’s amazing!” I quickly slid two more pieces in my mouth before picking up a large piece and anchoring it to his mouth, his perfect pink lips opening enough to suck the radish from the wooden instruments my body quivering instantly, my thighs rubbing vigorously together. I couldn’t take this.

I laid my chopsticks on the table and stood up from my chair, “I think I am going to run to the restroom for a moment…” I quickly walked off and pushed into the single toilet restroom, leaning over the sink looking in the mirror. “You’re losing it, Y/N. You don’t need to touch yourself in a public place…you’re above that.” The pulsing between my folds radiated loudly, the heat needing cooled.

**KNOCK KNOCK**

My head shot up from the sink, “uh, occupied!”

**KNOCK KNOCK**

“SOMEONE’S IN HERE!” I started to become even more frustrated with this repeated knocking.

**KNOCK KNOCK KNOCK**

I yanked the door open, “I said someone is in here—ah, Yeosang, I –“ he pushed his way into the bathroom, our bodies taking up a lot of the smaller space.

“You left quite abruptly, I was concerned.”

“Ah…y-yes. I am sorry about that, I just needed a minute is all.”

Yeosang came dangerously close to my body, his heated hand sliding up my arm, along my shoulder, up my neck, his thumb rest against my throat as his lips stalled inches from mine. “Didn’t I tell you to let me worry about tonight and not you?”

I nodded not knowing what else to do.

“Alright, let’s go finish eating then, our meat must be burning.” Yeosang held open the door for me, “Ladies first.”

I began to walk past Yeosang when a quick sting hit me from behind, a moaning yelp leaving my throat as I tried to keep myself from stumbling forward. My cheeks burned with embarrassment. What did he just do?

“You sound so good when you make that sound, Jagi.” He purred out, his voice adding to his cocky demeanor.

I quickly pushed him back into the restroom locking the door behind us. “What are you trying to do, Yeosang?” I spoke almost infuriated at him, the teasing taking its toll on my body and mind.

“How do you mean?” He smiled half-heartedly, not seeming to care that he just made my core leak with arousal.

I smiled, “You’re not slick, Yeosang, in fact, I know exactly what you’re trying to do.”

“Do you?” His smile hung from the side of his face his smolder trying to stay hidden.

I moved in closer to him, his body backing up quickly until he hit the wall, finally he was the one in shock. I grabbed his collar and pulled his face down towards mine, my lips dangling in front of his now. “Take of your pants. Now.” He fumbled a moment, reaching for his belt and then his button on his pants. “Quickly.” He moved more quickly removing his pants, them crashing to the ground, the black clashing against the white tiles.

I pressed my body against his chest my hand grabbing his soft erection that hardened quickly in my touch. “You’re funny Yeosang.” I chuckled lightly, “You really wanted me to be begging for you to fuck me in this bathroom, but here you are about to cum with just my hand on your cock.” I squeezed his erection tightly feeling his pulse bounce against my skin. Yeosang’s head fell back, a gasp leaving his chest with a rise and fall in his lungs.

My hand released his erection before demanding him to get onto his knees his body reacting instantly to my demands. I cupped his face in my hands and then slapped him light against the cheek, his birthmark turning dark red from the mark. I leaned down to him burying my tongue between his lips. Our tongues massaging one another, twisting into a tangle of seduction. He tasted like the white radish, my taste buds remembering the look on his face as he sucked on the chopsticks. I groaned, reaching between my legs, sliding the tights that were now soaked away from my folds and sliding two fingers against my swollen nub.

I moaned against his mouth, echoing out my pleasure as I reached my high quickly from own touch. Yeosang gazed into my face as I came, my orgasm causing his cock to twitch out in front of me, him desperate for touch. “Jagiya…” his groaning like the sweetest rain falling from the sky, “Yes my love?” I rubbed his face with my wet hand, his tongue lapping at my arousal that moistened the tips. “Please?” He looked down at his pulsating cock before locking eyes with me once more.

I grabbed his erection, pumping it feverishly watching Yeosang mewl from my touch, the control I had over him giving me a different kind of high. I rubbed my thumb against his dripping tip, the redness like that of a raspberry, overly teased and ready to be released. I pumped quickly, my palm creating a sweet suction of pressure against his shaft. I moved quickly, Yeosang gasping for air, moments away from his orgasm when I released him from my grasp. He quivered, his body releasing quakes as his orgasm was being denied, he looked up at me, the blue in his contacts like an ocean.

“Touch yourself for me, Yeosang. Show me how much you’ll miss me when you leave.” I cooed out to him, Yeosang’s hand shaking as he grabbed his tender erection, palming it slowly, “Tell me how much you need me…” he heavily breathed out as he fucked himself in his hand, his fluid seeping out from his slit.

“I’m going to m-miss you, so so s-so much, baby,” Yeosang sucked air through his teeth, his high coming closer now, “I’m - - oh fuck…”

“Tell me baby,” I leaned against his ear whispering lightly as he pumped himself faster, “tell me how much you need me to touch you.”

“I…I need you so bad…please…”

I moved quickly to remove his hand from his cock and slip my lips around his dick. I pumped my mouth tightly over him for a short moment before his erection hit him like a freight train. He leaned back and his hips slid his dick deeper into my mouth as he came. His cum spurting into my mouth, back of my throat, and slid past my lips, down my chin. I swallowed his arousal, sitting up to look at him, his beautiful features resting against the dark blue wall of the bathroom.

“You know I’m going to miss you, right?” He spoke between heavy breaths.

“I know,” I smiled, grabbing his hand into my own, “me too.”

#yeosang#fluff#smut#subby#ateez#ateez x reader#ateez smut#ateez fluff#ateez x atiny#atiny#kpop reactions#kpop imagines#kpop smut#kpop#kpop fluff#kpop senarios#kpop scenarios#ateez x smut#ateez imagines#ateez scenarios#ateez reactions#ateez requests

96 notes

·

View notes

Note

*knock knock* “i need you to help me.” (that's it. that's the prompt. 👀)

i can work with that.

You nearly jumped out of your skin when you heard a knock on your window. Sure enough it was Peter. Only he would be at your window at this hour especially considering that you were on the fifth floor of your apartment building.

You opened the window and he was sticking to the side of the building in his spidey suit. You still didn’t understand how he did that.

“I need you to help me.” he said, his emotions hiding under the mask.

“Uh, sure Pete with what?”

“Help me inside.” he said.

You did and he cringed. He was hurt. “What happened?” you asked.

He slipped off his mask, his hair a curly sweaty mess. Cuts and bruises decorated his face. “I got shot. In the arm. Think I need stitches.”

“Peter.” you said in worry, inspecting his wounds. “Bathroom, now.” He slowly walked into the bathroom as you went to grab your first aid kit. This wasn’t the first time he came for help like this.

“What happened?” you asked as you got the supplies ready. Peter pressed the center logo, releasing the suit from his frame. He only wore his boxers underneath. He carefully laid his suit over the tub.

“Bad guys. That’s all you need to know.”

“Peter, I wish you would tell me more than that.” you said as you got a warm cloth to wipe his face with.

“I don’t want to worry you anymore than-ow!” he hissed as you gently brushed over a cut on his cheek.

“Sorry! Sorry!”

“-just a bank robbery. More guys than I anticipated. They surprised me.”

You cleaned up his face. “How bad is it?”

“Just a flesh wound but it hurts.”

You focused on his right shoulder where the would was. It was bleeding and you rinsed your rag to wash it away. “How’s it looking?” Peter asked.

“Not the worst I’ve seen. Five stitches at the most. You’re lucky I know what I’m doing.”

Peter chuckled.

“This is gonna hurt.” You tied the string around the needle then brazed it with heat. Peter bit his lip as he embraced for impact.He grunted in pain as you stuck the needle in his flesh.

“Don’t worry, after this I can give you ice cream.” you smiled.

Peter rolled his eyes. “I’m not a child.” He paused. “What kind of ice cream?”

“Cookie dough.”

“Figures.” he chuckles.

It was quiet as you finished stitching Peter’s wound. He was gripping the edge of the sink, careful not to break it with his strength. He let go when you were finished. You then moved to his smaller wounds, putting medicine on them and band aids. It was rare to see Peter without a band aid on him.

“Y/n?”

“Yeah?”

“You know I like you right?” he asked, biting his lower lip. Damn why was that so hot?

“Really? I had no idea.” you said sarcastically, blushing.

He wrapped his bare arms around you, pulling you close to him. “Pete.” you scolded.

“Please, don’t say anything. I just...want you close.” He nuzzled into your shoulder. You didn’t protest for you liked him too. You both knew for a while now but figured it was best not to say anything.

You gently massaged his messy curls with your fingers, his head against your chest. “It’s late you don’t know what your saying. You lost a lot of blood. You’re delirious.”

Peter laughed and it was such a joyous sound to hear. “Sure whatever you say. y/n.”

5 notes

·

View notes

Text

Optimizing Heat Sink Efficiency: The Role of Brazing Alloy Selection

Explore the crucial role of brazing alloy selection in enhancing heat sink efficiency in our latest article! Delve into the world of brazing processes and alloys, and uncover how they impact the performance and longevity of heat sinks. Learn about the factors affecting heat sink efficiency, such as thermal conductivity, mechanical strength, and corrosion resistance, and discover how the right brazing alloy can maximize heat dissipation.

Real-world case studies highlight the importance of tailored brazing techniques in industries like aerospace and electronics. Gain valuable insights into best practices and lessons learned for selecting brazing alloys that meet specific application requirements.

Don't miss out on this informative read for anyone interested in thermal management technologies. Check it out now on Tumblr!

1 note

·

View note

Text

What is heat insulation compound and how it works?

Heat insulation compound is a special chemical formulation which is made for decreasing the transfer of heat of massive extent, heat insulation compound is an insulation compound with sole heart absorbing properties which insulate against heat moving during soldering, welding, brazing or any other heat treatment.

The heat absorption properties shelter closely soldered parts, thin gauge metal, valve GASKETING and all other contents which could be harmed during installation and repair work. Heat insulation compound is used to protect plastic drain pipes in core proximity to metal pipes soldered or replaced. Heat insulation prevents distortion to plastic rubber, light gauge metals and plastic components and painted surfaces while brazing, welding or soldering.

This non-hazardous material might be formed around or on the surface of metal onto surfaces which may be damaged by heat flame during soldering or welding. It’s simply eliminated by wiping with running water or wet rags.

Clean surface to which heat insulation is to be applied, removing every dirt and grease. Apply a thick layer of Heat Sink totally surrounding the part to be soldered or welded.

Press tightly to eliminate air pockets and voids. Once the repair is done, eliminate heat insulation compound with running water or damp rag. This should leave no marks or stain and contains no toxic materials and is risk-free to the skin. Heat insulation compound is nonflammable and provides off no toxic fumes when exposed to heat.

Heat insulation compound is used in automotive, welding, plumbing, HVAC/R and shipyard industries, as-well-as other specialized industries. Heat insulation compound will:

· Protect against distortion of welded stainless

· Protect painted wiring, surfaces, tubing (rubber and plastic)

· Protect surrounding shells from flame

· Prevent surface staining of welded stainless

· Prevent harm to valves in close proximity to weld spot

· Prevent spatter from adhering to surrounding shells

· Prevent damage to adjoining valves and washers during sweating and soldering

· Protect surrounding surfaces from flame and heat

· Protect pipe insulation from flame and heat damage

· Protect valve gaskets all through plumbing repairs and many more.

· Protect cable from flame and heat during plumbing and welding repairs,

Use heat insulation compound where there’s a potential danger for Heat, solder in unwanted spots. Heat insulation compound is a heat absorbing paste that stops surface heat from adjoining spots. Protect again harm reasoned by excessive heat from soldering, welding, and all other heat-related treatment.

1 note

·

View note

Text

What symptoms can be seen that the oil radiator is broken

The oil radiator is a device that accelerates the heat dissipation of the lubricating oil to keep it at a lower temperature. In the enhanced engine with high performance and high power, the oil radiator must be installed due to the large heat load. The oil radiator is arranged in the lubricating oil circuit, and its working principle is the same as that of the cooler.

The easy failure of the oil radiator is caused by not letting off the cooling water inside the diesel engine body in winter. Generally, there will be copper pipe rupture and cracks in the front and rear covers.

The oil radiator is broken. The heat sink may be blocked, but it can still dissipate heat, but the airflow is relatively small. Just remove the back cover of the radiator, remove the radiator, and clean the hair and dust inside.

In addition, when there is a problem with the oil radiator, it depends on whether the CPU fan under the power supply is turned on and the motherboard indicator light is on or off. Under the condition that the circuit is energized. There may be a problem with the memory module. Pull out and wipe the gold finger part and try again. It is the fault of enumerating the memory module. There may also be other problems. This thing is broken simply because the oil temperature is too high. The oil may turn white due to internal leakage. It can also cause a lack of antifreeze in the tank. Poor heat dissipation of the engine oil results in engine oil failure and engine wear.

Maintenance method:

1. After draining the waste oil inside the radiator, remove the oil cooler. After laying down the removed cooler, fill the inside of the cooler with water through the water outlet of the oil cooler. During the test, the water inlet is blocked, and the other side uses a high-pressure air cylinder to pump air into the cooler. If water is found at the oil inlet and outlet of the oil radiator, it means that the inner core of the cooler or the sealing ring of the side cover is damaged.

2. Remove the front and rear covers of the oil radiator and take out the core. If the outer layer of the core is found to be damaged, it can be repaired by brazing. If the inner layer of the core is found to be damaged, a new core should be replaced or both ends of the same core should be blocked. When the side cover is cracked or broken, it can be used after welding with a cast iron electrode. If the gasket is damaged or aged, it should be replaced. When the copper pipe of the air-cooled oil radiator is unsoldered, it should be repaired by brazing.

Jiusheng Heat Exchanger Co., Ltd. is a professional manufacturer of compressed air cooling systems. We have advanced technology and excellent product quality. If you need a compressed air cooling system, please contact us.

0 notes

Text

Your Essential Plumbing Equipment Guide

Featured Image

Alt tag: A plumber repairing pipework

Plumbers, like every other tradesman, have specialised tools for their work. Each instrument has a distinct purpose. To begin, here's a list of the most popular plumbing items that any skilled Plumbers in Edgewood should have on hand.

Plumbing features a wide range of specialised equipment.

Typical plumbing issues include issues which can be handled by people utilising plumbing equipment on their own. Specific plumbing difficulties, including water heater malfunctions, can, however, be resolved by professional Edgewood Plumbers in the best manner .

A thorough understanding of your plumbing supplies can greatly affect a plumbing operation, so make sure to read further.

What is Plumbing?

Plumbing entails the usage of hydraulic fittings, tanks, and pipe fittings, among other things.

Plumbing is a framework that transports water for a variety of purposes, including sewage and wastewater disposal, heating systems, and the distribution of portable conduits.

What are the most commonly used plumbing equipment?

Some of the basic yet essential plumbing tools that you must know:

Pipe Cutter:

Caption: The pipe cutter is created particularly for cutting copper pipe

Alt tag: A pipe cutter

The pipe cutter is created particularly for cutting copper pipe. Pipe cutters can come in as numerous different models and dimensions as there are pipes. First and foremost, based on the diameter you are to remove, there are numerous dimensions to choose from. It's crucial to keep in mind that a pipe cutter must always be operated on the right kind of pipeline. It ensures a solid plumbing installation by providing a smooth, accurate, and burr-free cut (fittings, welds, etc.). Pipe cutters for metal pipe are also supplied. Because they don't distort the pipe and leave a completely spherical segment, they're far more practical than a hacksaw.

Plastic pipe shears:

These are basically a type of pipe cutting tool for PVC and PEX supplies. It resembles a pair of large garden clippers. This should not be used on copper piping (or vice versa with a pipe cutter).

Bung wrench:

Sink bungs are installed and removed with bung fasteners, and some forms of sink fittings are screwed in with bung wrenches. Shower bung attachment nozzles are also supplied.

Drain cleaner:

Caption: Drain cleaners are used to clear clogged pipelines or sinks.

Alt tag: A person using a Drain cleaner for sink.

Drain cleaners are used to clear clogged pipelines. Manual versions, usually known as ferrets, are available. They are often used for pipes with a relatively small size. For greater dimension pipes, water jet nozzles can create significantly higher pressure (particularly wastewater pipes). Suction-operated low - pressure machines are frequently used to unclog drains. Plungers may be used for minor blockage.

Lapping tool:

Lapping tools are required to fix the bottom of faucets that have started to leak due to the buildup of limescale over time.

Welding torch:

Torches are recommended for high-temperature soldering of steel and brazing of copper. Prudence: skillfully operating a welding torch necessitates a considerable level of expertise and precaution. Two gas cylinders make up the torch. one oxygen and one acetylene, pressure gauges to regulate the gas volumes, and a regulator to send the gas to the torch through a nozzle An ignition is required to activate the compressed gasses.

This was a simple guide to make you aware about the basic plumbing tools. Be sure to use the correct ones if you're going to accomplish a plumbing operation and make sure to contact professional plumbers for any severe damage or issues.

0 notes

Text

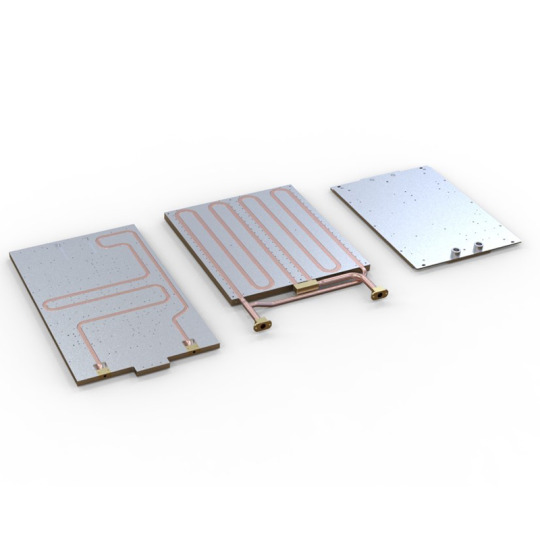

Principle And Characteristics of Vacuum Brazing

In the field of cold plate (heat sink) welding in the power electronics industry, aluminum vacuum brazing and friction stir welding (FSW) are widely used in two different welding processes in the field of cold plate (heat sink) products, each welding process has its own advantages, and there are certain differences and different priorities.

Principle and characteristics of vacuum brazing

1.Vacuum brazing is to heat the structural parts under vacuum,it is applied to high quality product and oxidizable material;

2.Vacuum brazing is solid phase connection,the base material will not melt when welding,as the melting temperature of solder is lower than the base material, the heat temperature is lower than the base material's solid line but higher than the solder's.

3.It heat the structural parts and the solder till melt at suitable temperature and time. The liquid solder will infiltrate the surface and gap of the base material, totally mix together with the base material.

4.Vacuum brazing removes oxide film with different mechanism of actions in vacuum environment. It improves the corrosion resistance as it doesn’t use flux.

5.The invasive and fluidity is very good, so it can weld relatively complex and narrow position, and it can improve the yield.

The advantages of vacuum brazing

1.It can weld several neighboring welding joint as a whole surface at one time,it can also superimposed loading, weld several components at the same time, improve the welding efficiency ;

2.All the welded products can bear 30bar internal pressure without deformation;

3.Universal tooling, one-time input cost;

4.The workpiece is heated evenly , small thermal stress . The amount of deformation can be controlled to the minimum, and a small margin can be achieved and processed easily;

5.The workpiece is under vacuum, no oxidation, carbonization, decarburization and pollution deterioration. Welding joints are beautiful and have no leaks ,not easy to corrode ;

6.Cold plate channel structure can be designed complexly according to parameters ,which can make the product achieve better performance and more stable heat dissipation characteristics

The disadvantages of vacuum brazing

1.The hardness of the cold plate will be lower after high temperature welding, so the cold plate need to do heat treatment again to improve the hardness which lead the cost increases.

2.The welding process requires high technological standard, which takes long time and high energy.

3.High cost of environmental protection.

Vacuum brazing of liquid cooled plate manufacturer recommended

Based on this principle, the vacuum brazing of liquid cooled plate realizes the connection of aluminum substrate, composite solder plate and aluminum cover plate. The engineer not only has rich experience in the design and Simulation of water-cooled panels, but also has a good grasp of all processes of production and processing. At the same time, he has very complete detection means, so as to ensure the reliability and quality of each set of Vacuum Brazed water-cooled panels in an all-round way.

There is an excellent vacuum brazing of liquid cooled plate manufacturer, Sanqian Technology Co., Ltd., which sells high-quality water cooling plate. If you want to know more about it, or are interested in our products, you can visit the website of Sanqian Technology Co., Ltd.

0 notes

Text

What Are The Types Of Liquid Cold Plates?

The increase in heat load of high-power electronic equipment and the requirements of product sealing performance have changed the traditional design thinking, and liquid cooling has become the mainstream trend. Compared with traditional air-cooled radiators, liquid cooling plates have significant performance advantages, especially in high-power equipment and high heat flux. Each product has its advantages, depending on the design of the liquid cold plate, the choice of coolant, the pressure drop requirements and the customer's budget.

Liquid cold plate is currently used in: renewable energy systems, medical equipment, IGBTs, lasers, data centers, industrial power supplies, defense systems, avionics, battery cooling, etc.

Buried cold plate

Buried pipe cold plate is the simplest form of cold plate, just embed the pipe in the base plate. According to the required thermal performance and coolant, copper or stainless steel tubes are generally used. Use CNC equipment to process pipe grooves on the substrate, embed the pipe into the substrate, and pour the epoxy resin pressure table, or weld in the appropriate position, which can maximize the service life and thermal performance.

Deep hole drilling cold plate

The deep hole drilling cold plate drills a series of holes on the aluminum plate to form multiple flow paths. First determine the inlet and outlet fluid paths, and then drill some holes perpendicular to the main fluid path, and then block some of the holes to form a continuous coolant path. The advantage of this kind of cold plate is that there is no thermal boundary in the manufacturing process, and the aluminum plate has no thermal stress, so it is easier to achieve flatness.

FSW friction stir welding cold plate

The FSW friction stir welding cold plate is constructed by a base plate and a cover plate. On the base plate, CNC is used to add a liquid flow path groove, and then the cover plate is placed in the groove above the flow path, and FSW (Friction Stir Welding) ). Finally, flatten the welding surface by flashing, and add inlet/outlet holes and component mounting holes.

Die-cast cold plate

Die-cast cold plate is a two-piece structure, suitable for complex large-capacity liquid cold plates. Multiple internal and external metal parts can be combined into two die casting tools. After casting, the two die-cast parts are bonded together by welding or using epoxy resin.

Brazing cold plate

Brazing cooling plates are usually used in designs that require low thermal resistance and high performance. This type of cold plate has great flexibility in design, such as thermal resistance, heat flow, pressure drop, fluid path, size, shape, material hardness, surface geometry, and installation of components on both sides of the plate. The interior can be completed by processing the deflector and heat sink from the base material, or by introducing high-performance corrugated aluminum fins, and then brazing these parts together.

Dip Soldering Cold Plate

The components are preheated in an air furnace to ensure that the temperature of all components is uniform, and then the parts are immersed in a molten salt bath. The molten flux is in contact with all inner and outer surfaces at the same time. This liquid is heated very quickly and evenly. The molten pool is a flux, so it can be completely bonded on an oxide-free surface. The immersion time is determined by the object to be heated, but the duration rarely exceeds two minutes.

Vacuum brazing cold plate

Brazing in a high-vacuum environment can control the brazing process to the greatest extent, and any oxidation or fouling phenomenon is the first choice for aerospace components, medical equipment and application equipment with high requirements on parts.

0 notes