Text

Exploring the Versatility: The Benefits of Aluminum Honeycomb Panels Across Industries

Innovation in construction materials has paved the way for revolutionary solutions in architecture, transportation, and various industrial sectors. One such advancement is the utilization of aluminum honeycomb panels. These lightweight yet sturdy structures offer a multitude of benefits across diverse applications, ranging from aerospace to interior design. In this blog, we delve into the advantages of aluminum honeycomb panels and their widespread applications in different sectors.

Lightweight Construction:

Aluminum honeycomb panels consist of a honeycomb core sandwiched between aluminum sheets. This design imparts exceptional strength while maintaining a lightweight profile. Compared to solid aluminum or steel structures, aluminum honeycomb panels offer significant weight savings, making them ideal for applications where weight reduction is critical. Industries such as aerospace, automotive, and marine benefit from this lightweight construction, enhancing fuel efficiency, maneuverability, and overall performance.

High Strength-to-Weight Ratio:

Despite their lightweight nature, aluminum honeycomb panels boast remarkable strength-to-weight ratios. The honeycomb core design distributes stress evenly across the panel, resulting in exceptional structural integrity. This characteristic makes them suitable for load-bearing applications in construction, such as building facades, cladding systems, and roofing. Additionally, their high strength-to-weight ratio allows for longer spans and greater design flexibility, reducing the need for additional support structures and simplifying installation.

Superior Thermal and Acoustic Insulation:

The honeycomb core structure of aluminum honeycomb panels acts as a barrier to heat transfer and sound transmission. This inherent thermal and acoustic insulation property makes them valuable in various sectors, including construction, transportation, and industrial applications. In buildings, aluminum honeycomb panels contribute to energy efficiency by minimizing heat loss or gain, thus reducing HVAC loads and operating costs. Similarly, in transportation vehicles, such as trains and buses, they provide a quieter and more comfortable interior environment for passengers.

Exceptional Flatness and Stability:

Aluminum honeycomb panels exhibit excellent flatness and dimensional stability, ensuring uniformity and consistency in their appearance and performance. This characteristic is particularly advantageous in architectural applications, where aesthetics play a crucial role. Whether used as exterior cladding, interior partitions, or decorative elements, these panels maintain their shape and surface quality over time, enhancing the visual appeal and longevity of structures.

Corrosion Resistance and Durability:

Aluminum is inherently resistant to corrosion, making aluminum honeycomb panels highly durable and long-lasting, even in harsh environmental conditions. This corrosion resistance makes them suitable for outdoor applications, such as building exteriors, signage, and marine vessels. Additionally, aluminum honeycomb panels are impervious to moisture, mold, and rot, further extending their lifespan and minimizing maintenance requirements.

Eco-Friendly and Recyclable:

As sustainability becomes a primary concern across industries, aluminum honeycomb panels offer an eco-friendly solution. Aluminum is fully recyclable, and the manufacturing process for honeycomb panels consumes less energy compared to other construction materials. Furthermore, the lightweight nature of these panels reduces transportation-related carbon emissions during installation and transportation, contributing to overall environmental conservation efforts.

Conclusion:

Aluminum honeycomb panels have emerged as a versatile and innovative construction material with numerous benefits across various sectors. From aerospace and automotive industries to architecture and interior design, their lightweight construction, high strength-to-weight ratio, thermal and acoustic insulation properties, and durability make them indispensable. As advancements in materials science continue, aluminum honeycomb panels are poised to play an increasingly prominent role in shaping the future of construction and industrial applications.

#eurobond acp#acp sheet#acp panels#building materials#eurobond honeycomb sheet#honeycomb sandwich panel#honeycomb panels#aluminium honeycomb sheet

1 note

·

View note

Text

Exploring the Versatility: The Benefits of Aluminum Honeycomb Panels Across Industries

Innovation in construction materials has paved the way for revolutionary solutions in architecture, transportation, and various industrial sectors. One such advancement is the utilization of aluminum honeycomb panels. These lightweight yet sturdy structures offer a multitude of benefits across diverse applications, ranging from aerospace to interior design. In this blog, we delve into the…

View On WordPress

#ACP panels#ACP sheet#Aluminium composite panels#Aluminium Honeycomb Panels#Eurobond#Eurobond ACP#Eurobond ACP panels#Honeycomb Sandwich Panel

0 notes

Text

Ultimate Guide to Select the Right ACP Thickness for Building Exterior Wall Cladding

Aluminium Cladding Panels (ACPs) have become an increasingly popular choice for modern building facades due to their versatility, durability, and aesthetic appeal. Among the crucial decisions when selecting ACPs is choosing the right thickness for your project. In this guide, we’ll delve into the factors to consider and provide insights into selecting the optimal ACP sheet thickness for cladding,…

View On WordPress

#3mm acp sheet#4mm acp sheet#6mm acp sheet#ACP panels#ACP sheet#ACP sheet thickness#Aluminium composite panels#Eurobond ACP#Eurobond ACP panels

1 note

·

View note

Text

Ultimate Guide to Select the Right ACP Thickness for Building Exterior Wall Cladding

Aluminium Cladding Panels (ACPs) have become an increasingly popular choice for modern building facades due to their versatility, durability, and aesthetic appeal. Among the crucial decisions when selecting ACPs is choosing the right thickness for your project. In this guide, we'll delve into the factors to consider and provide insights into selecting the optimal ACP sheet thickness for cladding, with a focus on Eurobond ACPs.

Understanding ACP Sheet Thickness:

ACP sheet thickness typically ranges from 3mm to 6mm, with variations available to suit specific project requirements. The thickness directly impacts the panel's strength, rigidity, insulation properties, and suitability for various applications.

Factors to Consider:

Structural Requirements: Assess the structural demands of your building project. Higher wind loads, taller buildings, or areas prone to seismic activity may necessitate thicker ACPs for enhanced structural integrity.

Building Height: Taller buildings require ACPs with greater thickness to withstand wind pressures and maintain stability. For mid-rise to high-rise constructions, consider thicker panels to ensure long-term performance and safety.

Thermal Insulation: Thicker ACP sheets offer better thermal insulation, which is crucial for energy-efficient buildings. Evaluate the climate conditions and energy efficiency goals of your project to determine the appropriate thickness for optimal insulation performance.

Budgetary Constraints: While thicker ACP sheets offer enhanced performance, they also come at a higher cost. Balance performance requirements with budgetary constraints to select the most cost-effective thickness without compromising quality or safety.

Aesthetic Considerations: The thickness of ACP sheet’s can influence the appearance of the facade. Thicker panels may provide a more substantial and imposing look, whereas thinner panels can offer a sleeker and more minimalist aesthetic. Consider the desired visual impact when choosing the thickness.

Eurobond ACP Thickness Options:

Eurobond, a leading manufacturer of ACP sheets, offers a range of thickness options to cater to diverse project needs. Their product line typically includes 3mm, 4mm, and 6mm thickness variants, each with specific features and benefits.

3mm ACP sheet Thickness: Ideal for applications where weight is a concern or for projects requiring thinner profiles without compromising on performance. Suitable for low-rise buildings and interior cladding applications.

4mm ACP sheet Thickness: A versatile option suitable for a wide range of building types and applications. Offers a balance between strength, flexibility, and cost-effectiveness. Recommended for mid-rise buildings and general exterior cladding.

6mm ACP sheet Thickness: Designed for projects demanding superior strength, rigidity, and durability. Suitable for high-rise buildings, areas with high wind loads, and applications where maximum performance is required.

Selecting the Right Eurobond ACP Thickness:

Evaluate Structural Requirements: Assess the structural demands of your project, considering factors such as building height, wind loads, and seismic activity.

Consider Thermal Performance: Determine the desired level of thermal insulation based on climate conditions and energy efficiency goals.

Review Budgetary Constraints: Balance performance requirements with budget limitations to select the most cost-effective thickness option.

Assess Aesthetic Preferences: Consider the visual impact and design objectives when choosing the ACP thickness to achieve the desired architectural aesthetic.

Conclusion:

Selecting the right ACP sheet thickness is a critical decision in Aluminium cladding projects, influencing structural integrity, thermal performance, cost, and aesthetics. By carefully evaluating project requirements and considering factors such as building height, structural demands, thermal insulation, budget constraints, and aesthetic preferences, you can confidently choose the optimal Eurobond ACP sheet thickness for your project, ensuring both performance and visual appeal.

#eurobond acp#acp sheet#eurobond#acp panels#eurobondacp#acp cladding#ACP sheet thickness#3mm acp sheet#4mm acp sheet#6mm acp sheet#eurobond ACP

1 note

·

View note

Text

Exploring ACP Sheet Trends for 2024 with Eurobond ACP

In the ever-evolving world of architecture and construction, Aluminium Composite Panels (ACP) have emerged as a game-changer. These lightweight, durable, and versatile panels find extensive use in exterior cladding, interior design, and signage. As we step into 2024, let’s delve into the trends that will shape the ACP industry, with a spotlight on Eurobond ACP.

Eurobond ACP: Pioneering…

View On WordPress

1 note

·

View note

Text

Exploring ACP Sheet Trends for 2024 with Eurobond ACP

In the ever-evolving world of architecture and construction, Aluminium Composite Panels (ACP) have emerged as a game-changer. These lightweight, durable, and versatile panels find extensive use in exterior cladding, interior design, and signage. As we step into 2024, let’s delve into the trends that will shape the ACP industry, with a spotlight on Eurobond ACP.

Eurobond ACP: Pioneering Innovation

Eurobond, a leading manufacturer of ACP sheets in India, has consistently pushed the boundaries of design, quality, and sustainability. Here’s a closer look at the trends they’re championing:

1. Fire Resistance and Safety

Safety remains paramount in architectural materials. Eurobond ACP emphasizes fire resistance by rigorously testing their products for flame height, smoke generation, and toxicity levels. Architects and builders can confidently choose Eurobond ACP for projects where safety is non-negotiable.

2. Advanced Coating Technologies

Eurobond ACP invests in cutting-edge coating technologies. Their panels exhibit exceptional resistance to weathering, corrosion, and UV rays. Whether it’s a high-rise facade or an artistic installation, Eurobond ACP panels maintain their pristine appearance over time.

3. Innovative Materials and Composites

Eurobond explores novel materials and composites to enhance ACP performance:

High-Performance Cores: Mineral-filled or fire-resistant cores improve safety and durability.

Scratch and Stain Resistance: Eurobond ACP panels withstand daily wear and tear.

Eco-Friendly Options: Incorporating recycled materials aligns with sustainability goals.

4. Aesthetic Versatility

Design aesthetics evolve, and Eurobond ACP keeps pace. Their extensive color palette and finishes allow architects to unleash creativity. Whether it’s a minimalist facade or a bold statement piece, Eurobond ACP offers choices that resonate with diverse design sensibilities.

5. Global Impact

Eurobond ACP’s influence extends beyond India. Architects worldwide recognize the brand’s commitment to excellence. As ACP gains prominence globally, Eurobond remains at the forefront of innovation.

Conclusion

In 2024, Eurobond ACP sheet continues to redefine architectural possibilities. From futuristic skyscrapers to sustainable homes, their panels adorn structures that blend aesthetics with functionality. As we celebrate the fusion of art and engineering, Eurobond ACP stands tall—a testament to the future of ACP.

1 note

·

View note

Text

Eurobond ACP: The Ultimate Choice for Fire Retardant ACP Sheets

In the construction and architectural industry, the significance of fire safety cannot be overstated. With an increasing emphasis on building materials that offer robust fire retardant properties, the demand for reliable solutions has surged. Among the plethora of options available, Eurobond ACP emerges as a standout choice, renowned for its exceptional fire retardant capabilities and superior quality.

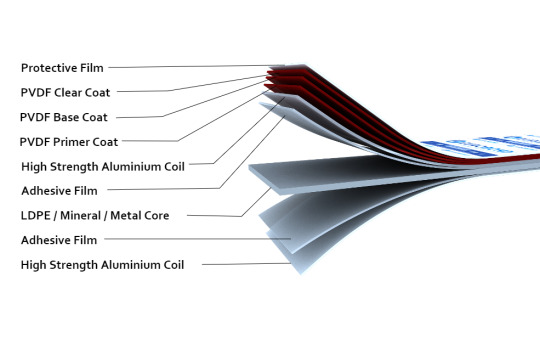

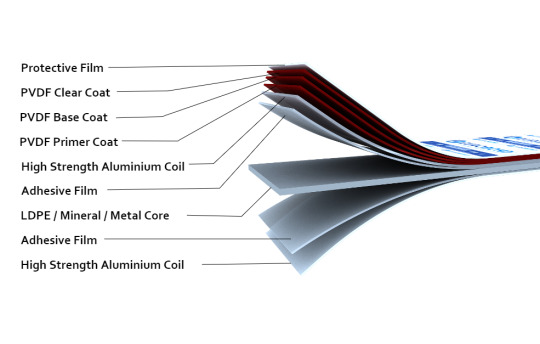

Eurobond ACP (Aluminum Composite Panel) is a versatile building material widely acclaimed for its durability, aesthetics, and most importantly, its ability to resist fire spread effectively. Comprising a core material sandwiched between two layers of aluminum, Eurobond ACP is engineered to deliver optimal performance under extreme conditions, making it an ideal choice for both interior and exterior applications.

One of the most compelling features of Eurobond ACP is its remarkable fire retardant properties. Equipped with a specially formulated mineral core, Eurobond ACP sheet is designed to inhibit the spread of flames, thereby significantly reducing the risk of fire-related damage. This inherent fire resistance makes Eurobond ACP an invaluable asset in enhancing the safety standards of residential, commercial, and industrial structures.

Eurobond ACP undergoes rigorous testing procedures to ensure compliance with international fire safety standards, including ASTM, EN, and BS. These stringent quality control measures guarantee that Eurobond ACP meets the highest industry benchmarks for fire retardancy, providing architects, builders, and property owners with peace of mind regarding the safety and longevity of their investments.

Moreover, Eurobond ACP offers a myriad of additional benefits beyond its fire retardant properties. Its lightweight nature facilitates easy handling and installation, resulting in cost savings and accelerated project timelines. The material's resistance to corrosion, weathering, and UV radiation further enhances its durability, ensuring long-term performance even in harsh environmental conditions.

Furthermore, Eurobond ACP is available in a diverse range of colors, finishes, and textures, allowing architects and designers unparalleled freedom to realize their creative visions. Whether it's a sleek modern facade or a vibrant interior accent, Eurobond ACP offers endless possibilities for architectural expression without compromising on safety or quality.

In conclusion, Eurobond ACP stands out as the epitome of excellence in fire retardant ACP sheets. Its proven track record of reliability, coupled with its superior performance in fire safety tests, makes it the preferred choice for discerning professionals across the globe. By investing in Eurobond ACP, stakeholders can uphold the highest standards of safety, sustainability, and aesthetics in their construction projects, ensuring a secure and visually stunning built environment for generations to come.

#eurobond acp#fireproof acp#fireproof acp sheet and acp panel#fire rated material#fire proof acp panel#fr acp sheet

1 note

·

View note

Text

ACP Louvers from Eurobond ACP Sheet: Transforming Architectural Spaces with Effortless Elegance

In the realm of contemporary architecture, the quest for innovation and aesthetics intertwines seamlessly. Architects and designers constantly seek materials that not only elevate the visual appeal of structures but also provide functionality and sustainability. Among these materials, Aluminum Composite Panels (ACPs) have emerged as a versatile choice, offering a plethora of design possibilities.…

View On WordPress

1 note

·

View note

Text

ACP Louvers from Eurobond ACP Sheet: Transforming Architectural Spaces with Effortless Elegance

In the realm of contemporary architecture, the quest for innovation and aesthetics intertwines seamlessly. Architects and designers constantly seek materials that not only elevate the visual appeal of structures but also provide functionality and sustainability. Among these materials, Aluminum Composite Panels (ACPs) have emerged as a versatile choice, offering a plethora of design possibilities. Eurobond, a frontrunner in the ACP industry, introduces an innovative addition to its repertoire: ACP Louvers. These louvers not only redefine architectural aesthetics but also enhance functionality with their transformative properties.

Elevating Aesthetics:

The integration of ACP Louvers from Eurobond introduces a new dimension of elegance to architectural spaces. Their sleek, modern design seamlessly blends with various architectural styles, whether it's contemporary, minimalist, or futuristic. The clean lines and crisp edges of ACP Louvers create visually striking facades, adding a touch of sophistication to any building exterior.

Effortless Integration:

One of the key advantages of ACP Louvers lies in their effortless integration into architectural designs. Available in a wide range of colors, finishes, and textures, these louvers offer designers the freedom to unleash their creativity. Whether used as sunshades, privacy screens, or decorative elements, ACP Louvers adapt seamlessly to diverse design requirements, enhancing the overall aesthetic appeal of buildings.

Functional Brilliance:

Beyond their aesthetic charm, ACP Louvers from Eurobond excel in functionality. Their lightweight yet durable construction ensures longevity and structural integrity, making them ideal for both interior and exterior applications. The inherent weather resistance and low maintenance requirements of ACP Louvers make them a practical choice for architectural projects in various climatic conditions.

Transformative Sustainability:

Eurobond's commitment to sustainability reflects in the manufacturing process of ACP Louvers. Crafted from high-quality aluminum and eco-friendly core materials, these louvers offer sustainable solutions for modern architectural needs. By incorporating ACP Louvers into building designs, architects contribute to sustainable practices without compromising on aesthetics or performance.

Enhanced Comfort:

The strategic placement of ACP Louvers serves more than just an aesthetic purpose; they also enhance occupant comfort. By regulating sunlight penetration and controlling glare, these louvers create a comfortable indoor environment while optimizing natural light utilization. Additionally, ACP Louvers contribute to energy efficiency by reducing the need for artificial lighting and cooling systems, thereby lowering operational costs.

Versatile Applications:

The versatility of ACP Louvers extends beyond traditional architectural elements. From commercial complexes and residential buildings to educational institutions and public spaces, these louvers find applications in diverse architectural projects. Whether used as façade accents, shading devices, or decorative features, ACP Louvers add a touch of contemporary elegance to any structure.

Conclusion:

Eurobond's ACP Louvers epitomize the fusion of form and function in modern architecture. With their effortless elegance, functional brilliance, and sustainable attributes, these louvers redefine architectural spaces, setting new standards for innovation and aesthetics. As architects and designers continue to push the boundaries of creativity, ACP Louvers emerge as a versatile solution, transforming buildings into timeless works of art. Embrace the elegance of ACP Louvers and embark on a journey of architectural excellence.

#eurobondacp#acp sheet#ACP Louvers#eurobond acp louvers#eurobond acp#acp panels#acp panel#building materials

0 notes

Text

A Comprehensive Guide: How to Choose the Right ACP Sheet Size for Your Next Project

In the realm of modern architecture and construction, Aluminum Composite Panels (ACPs) have emerged as a popular choice for cladding buildings due to their versatility, durability, and aesthetic appeal. However, selecting the right ACP sheet size for your project is crucial to ensure efficiency, cost-effectiveness, and a seamless installation process. In this guide, we’ll delve into the factors…

View On WordPress

#4mmacpsheet#6mmacpsheet#acppanel#acpsheet#eurobondacp#3mm acp sheet#ACP panels#ACP sheet#acp sheet size#Aluminium composite panels#Eurobond#Eurobond ACP

0 notes

Text

A Comprehensive Guide: How to Choose the Right ACP Sheet Size for Your Next Project

In the realm of modern architecture and construction, Aluminum Composite Panels (ACPs) have emerged as a popular choice for cladding buildings due to their versatility, durability, and aesthetic appeal. However, selecting the right ACP sheet size for your project is crucial to ensure efficiency, cost-effectiveness, and a seamless installation process. In this guide, we'll delve into the factors to consider and steps to follow when choosing the perfect 3mm, 4mm, or 6mm ACP sheet size for your next project.

Understand Your Project Requirements:

Before diving into ACP sheet sizes, it's essential to have a clear understanding of your project's requirements. Consider factors such as:

Building dimensions and surface area to be covered.

Architectural design and layout.

Environmental factors like wind load, temperature variations, and exposure to sunlight.

Budget constraints and material availability.

Assess Standard ACP Sheet Sizes:

ACP sheets come in various standard sizes, typically ranging from 1220mm to 2000mm in width and 2440mm to 6000mm in length. Familiarize yourself with these standard sizes and their availability from manufacturers and suppliers.

Measure Surface Area:

Calculate the total surface area to be clad with ACP sheets. Multiply the length and height of each wall or surface to get the square footage. This measurement will help you determine the quantity of ACP sheets required.

Consider Panel Thickness:

ACP sheets are available in different thicknesses, commonly ranging from 3mm to 6mm. Thicker panels offer increased rigidity and durability but may add to the overall weight and cost. Evaluate the structural requirements and aesthetic preferences of your project to choose the appropriate thickness.

Evaluate Installation Logistics:

Assess the logistics of ACP sheet installation, including transportation, handling, and fabrication. Consider factors such as:

Accessibility to the construction site.

Equipment and machinery required for cutting and shaping ACP sheets.

Installation method (mechanical fixing, adhesive bonding, etc.) and its compatibility with the selected sheet size.

Optimize Material Usage:

Minimize wastage and optimize material usage by selecting ACP sheet sizes that align with your project's dimensions. Consider cutting patterns and layouts to maximize efficiency and reduce scrap material.

Seek Professional Guidance:

Consult with architects, engineers, or construction professionals to validate your ACP sheet size selection. Their expertise can provide valuable insights into structural integrity, design aesthetics, and compliance with building codes and regulations.

Request Samples and Mock-ups:

Before finalizing your decision, request samples or mock-ups of the chosen ACP sheet size to assess its appearance, texture, and color under various lighting conditions. This step ensures that the selected size complements the overall design vision of your project.

Review Manufacturer Specifications:

Review the technical specifications provided by ACP manufacturers, including load-bearing capacity, fire resistance, weather durability, and warranty terms. Ensure that the chosen sheet size meets the performance requirements and quality standards for your project.

Factor in Future Maintenance:

Consider the long-term maintenance and upkeep of ACP-clad surfaces. Choose a size that facilitates ease of cleaning, inspection, and maintenance to preserve the appearance and performance of the building facade over time.

Conclusion:

Selecting the right ACP sheet size is a crucial decision that impacts the aesthetics, functionality, and durability of your building facade. By understanding your project requirements, assessing standard sizes, considering panel thickness, evaluating installation logistics, and seeking professional guidance, you can make an informed decision that ensures the success of your next construction project. Choose wisely, and let your building shine with the perfect 3mm, 4mm, or 6mm ACP cladding solution.

1 note

·

View note

Text

Elevate Your Building Facade with ACP Panels: A Fusion of Creativity and Durability

In the dynamic world of architecture, the facade of a building serves as its face, reflecting not only the aesthetic taste of its designer but also the practical considerations of durability and functionality. In recent years, Aluminum Composite Panels (ACPs) have emerged as a revolutionary choice in the building material industry, redefining the possibilities of facade design. Let’s delve into…

View On WordPress

#eurobondacp acpsheet acppanel buildingmaterial buildingfacade#ACP panels#ACP sheet#Eurobond#Eurobond ACP#Eurobondacp

1 note

·

View note

Text

Elevate Your Building Facade with ACP Panels: A Fusion of Creativity and Durability

In the dynamic world of architecture, the facade of a building serves as its face, reflecting not only the aesthetic taste of its designer but also the practical considerations of durability and functionality. In recent years, Aluminum Composite Panels (ACPs) have emerged as a revolutionary choice in the building material industry, redefining the possibilities of facade design. Let's delve into the world of ACP panels and explore how they're shaping the landscape of modern architecture.

Understanding ACP Panels:

Aluminum Composite Panels (ACPs) consist of two thin coil-coated aluminum sheets bonded to a non-aluminum core, typically made of polyethylene. This sandwich structure imparts exceptional rigidity, while remaining lightweight, making ACP panels an ideal choice for building facades. The versatility of ACP panels lies in their ability to be molded, bent, and cut into various shapes and sizes, allowing architects to unleash their creativity without compromising on structural integrity.

Benefits of ACP Panels:

1. Aesthetic Appeal: ACP panels offer a wide range of colors, finishes, and textures, providing architects with endless design possibilities. Whether it's a sleek, modern look or a rustic, textured facade, ACP panels can bring any architectural vision to life.

2. Durability: Despite their lightweight nature, ACP panels are incredibly durable and weather-resistant. They can withstand harsh environmental conditions such as extreme temperatures, UV radiation, and moisture, ensuring long-term performance and minimal maintenance requirements.

3. Thermal Insulation: The insulating properties of the core material in ACP panels contribute to improved thermal efficiency, helping to regulate indoor temperatures and reduce energy consumption, thereby making them environmentally friendly.

4. Fire Resistance: ACP panels are available in fire-retardant variants, offering enhanced safety and peace of mind in case of fire outbreaks. These panels comply with stringent fire safety regulations, making them suitable for a wide range of applications, including high-rise buildings.

Applications of ACP Panels:

The versatility and practicality of ACP panels make them suitable for various architectural applications beyond building facades, including:

- Interior Decoration: ACP panels can be used to create stunning interior spaces, such as feature walls, partitions, and ceiling panels, adding a touch of elegance and sophistication to any environment.

- Signage and Branding: ACP panels serve as an excellent substrate for signage and branding elements, thanks to their smooth surface and ability to accommodate digital printing and vinyl graphics.

- Furniture Design: ACP panels can be used to manufacture durable and stylish furniture pieces, such as tables, chairs, and cabinets, blending seamlessly with any interior decor scheme.

Conclusion:

Innovation is the driving force behind the evolution of the building material industry, and ACP panels exemplify this spirit of innovation by offering a perfect balance of form and function. Whether it's enhancing the visual appeal of a building facade or revolutionizing interior design, ACP panels continue to inspire architects and designers worldwide with their limitless possibilities. As we embrace the future of architecture, let's remember that with ACP panels, the only limit is our imagination.

1 note

·

View note

Text

Your Guide to Effective Maintenance of Aluminum Composite Panels on Building Facades

Aluminum composite panels (ACPs) are a popular choice for building facades due to their durability, aesthetic appeal, and versatility. However, to ensure that your building maintains its visual appeal and structural integrity, regular maintenance of ACPs is essential. In this guide, we’ll walk you through the step-by-step process of effectively maintaining aluminum composite panels on your…

View On WordPress

1 note

·

View note

Text

Your Guide to Effective Maintenance of Aluminum Composite Panels on Building Facades

Aluminum composite panels (ACPs) are a popular choice for building facades due to their durability, aesthetic appeal, and versatility. However, to ensure that your building maintains its visual appeal and structural integrity, regular maintenance of ACPs is essential. In this guide, we'll walk you through the step-by-step process of effectively maintaining aluminum composite panels on your building facade.

Why Maintenance Matters:

Proper maintenance of aluminum composite panels not only preserves the aesthetic appeal of your building but also extends the lifespan of the panels. Regular upkeep helps prevent issues such as corrosion, staining, and structural damage, ensuring that your building maintains its value and attractiveness for years to come.

Step 1: Cleaning:

Start by cleaning the ACPs regularly to remove dirt, dust, and pollutants that accumulate on the surface. Use a mild detergent solution and a soft cloth or sponge to gently clean the panels. Avoid abrasive cleaners or brushes that can scratch the surface and opt for gentle, circular motions during cleaning.

Step 2: Avoid Harsh Chemicals:

When cleaning ACPs, steer clear of harsh chemicals or solvents that can damage the protective coatings on the panels. Stick to mild detergents or cleaners recommended by the manufacturer to ensure safe and effective cleaning without compromising the integrity of the panels.

Step 3: Rinse Thoroughly:

After cleaning, rinse the panels thoroughly with clean water to remove any residue from the detergent or cleaner. Ensure that no cleaning solution is left behind, as it can cause streaking or discoloration over time. Thorough rinsing is crucial to maintain the pristine appearance of your ACPs.

Step 4: Inspect for Damage:

Regularly inspect the ACPs for signs of damage, such as dents, scratches, or chipping of the paint or coating. Promptly address any damage to prevent it from worsening and compromising the integrity of the panels. Minor issues can often be repaired using touch-up paint or repair kits provided by the manufacturer.

Step 5: Preventive Measures:

Take preventive measures to protect the ACPs from potential sources of damage, such as falling objects or impact from machinery. Consider installing protective barriers or signage to prevent accidental damage to the panels and ensure their long-term durability.

Step 6: Professional Inspection:

Periodically schedule professional inspections of the ACP sheets, especially in high-rise or high-traffic areas, to identify any potential issues early and address them before they escalate. Professional inspection helps ensure that your building facade remains in top condition and complies with safety standards.

Conclusion:

Proper maintenance of aluminum composite panels is essential for preserving the aesthetic appeal, functionality, and structural integrity of your building facade. By following these steps and implementing regular upkeep practices, you can ensure that your ACPs remain in excellent condition and contribute to the overall visual appeal and value of your property.

1 note

·

View note

Text

Conquer Cost with Eurobond ACP: Unveiling the Most Budget-Friendly Facade Solution

In today's construction landscape, striking a balance between aesthetics and affordability can be a daunting task. But fear not, budget-conscious architects and builders! Eurobond ACP sheets emerge as a game-changer, offering unparalleled cost-effectiveness compared to traditional building materials. Let's delve into the reasons why Eurobond ACP reigns supreme in the realm of value-driven facades:

1. Material Magic: Aluminum's Advantage

At the heart of Eurobond ACP lies a lightweight, yet robust, aluminum core. This translates to significant savings on structural support, transportation costs, and installation time. Unlike heavier materials like stone or concrete, Eurobond ACP panels are easier to handle and maneuver, reducing labor costs and expediting project timelines.

2. Durability that Defies Time (and Expense)

Eurobond ACP boasts exceptional weather resistance, standing tall against harsh sunlight, rain, and even fire (with fire-retardant options). This translates to minimal maintenance needs, saving you money on repairs and replacements down the line. Additionally, Eurobond ACP's longevity ensures your facade retains its pristine look for years to come, eliminating the need for frequent aesthetic upgrades.

3. Installation Efficiency: Less is More

Eurobond ACP sheets are known for their ease of installation. Their lightweight nature and readily available prefabricated options minimize the need for extensive on-site fabrication, saving time and labor costs. Additionally, the panels' simple click-lock system ensures a seamless and swift installation process, further reducing project timelines and associated expenses.

4. Maintenance Marvel: A Clean Sweep for Savings

Unlike other materials that require regular cleaning and upkeep, Eurobond ACP shines with its low-maintenance requirements. A simple wipe with mild detergent or water is often all it takes to keep your facade looking spotless. This translates to significant cost savings on professional cleaning services and specialized cleaning products over the lifespan of your building.

5. Energy Efficiency: Savings that Shine

Eurobond ACP's unique ventilated facade systems create an air gap between the panels and the building's wall. This air gap acts as a natural insulator, reducing heat transfer and lowering your energy consumption for cooling or heating. The resulting energy savings translate to lower utility bills and a more sustainable building, contributing to long-term cost benefits.

6. Design Versatility: Value Beyond Aesthetics

Eurobond ACP goes beyond mere cost-effectiveness; it empowers you to unleash your design vision without breaking the bank. With a vast array of colors, finishes, and textures available, you can create facades that are both stunning and budget-friendly. From sleek and modern to classic and timeless, Eurobond ACP caters to every design aesthetic, ensuring your building stands out without exceeding your budget.

7. Brand Trust: A Seal of Quality and Value

Eurobond ACP is renowned for its commitment to quality and innovation. Their dedication to using premium materials and stringent manufacturing processes ensures you receive a product that is not only cost-effective but also built to last. This peace of mind and assurance of quality further solidify Eurobond ACP's position as a leader in value-driven facade solutions.

In Conclusion:

Eurobond ACP sheets are more than just aesthetically pleasing; they are a strategic investment in your building's future. Their combination of affordability, durability, ease of installation, low maintenance, and energy efficiency make them the clear choice for budget-conscious builders and architects seeking to create stunning facades that stand the test of time. So, ditch the expensive, high-maintenance materials and embrace the cost-effective revolution with Eurobond ACP!

#ACP sheet#building material#cost-effective#Eurobond ACP#facade#aluminum composite panel#eurobond acp

1 note

·

View note

Text

Metal composite panels - Popular Facade Materials for high-rise buildings

Greetings, architecture aficionados and building enthusiasts! Today, let’s delve into the sleek and modern world of facade materials, specifically focusing on the rising stars of the high-rise building scene – metal composite panels, with a special spotlight on the versatile aluminum composite panels (ACPs).

In the ever-evolving landscape of architectural design, metal composite panels have…

View On WordPress

1 note

·

View note