#acppanel

Text

A Comprehensive Guide: How to Choose the Right ACP Sheet Size for Your Next Project

In the realm of modern architecture and construction, Aluminum Composite Panels (ACPs) have emerged as a popular choice for cladding buildings due to their versatility, durability, and aesthetic appeal. However, selecting the right ACP sheet size for your project is crucial to ensure efficiency, cost-effectiveness, and a seamless installation process. In this guide, we’ll delve into the factors…

View On WordPress

#4mmacpsheet#6mmacpsheet#acppanel#acpsheet#eurobondacp#3mm acp sheet#ACP panels#ACP sheet#acp sheet size#Aluminium composite panels#Eurobond#Eurobond ACP

0 notes

Text

Get ACP Sheet at Affordable Price in India

ACP sheet is one of the latest cladding material used in various applications like front elevation (facade) of building, interior decoration, signage, modular kitchen, etc.

Get ACP Sheet Price

0 notes

Text

Aluminum composite panels (ACM) are a type of composite material made from two thin sheets of aluminum bonded to a polyethylene core. They are lightweight, durable, and easy to maintain. ACM panels are often used in exterior applications, such as cladding, roofing, and signage.

Here are some of the benefits of using ACM panels:

Lightweight. ACM panels are lightweight, which makes them easy to install and maintain.

Durable. ACM panels are durable and can withstand the elements.

Easy to maintain. ACM panels are easy to maintain and do not require regular cleaning or painting.

Versatile. ACM panels can be used in a variety of applications, including cladding, roofing, signage, and insulation.

Cost-effective. ACM panels are a cost-effective option for a variety of applications.

If you are looking for a material for an exterior application, ACM panels are a good option. They are lightweight, durable, easy to maintain, and versatile.

Please call or fill out our online form to request an estimate or ask general questions about our services. We are excited to serve you!

(718) 517-9178

https://www.skywindowsnj.com/

#aluminumcompositepanels#acppanels#compositepanels#aluminiumcompositepanels#exteriorpanels#cladding#roofing#signage#insulation#cost-effective#lightweight#contractor#brooklyn windows#window installation nyc#design#nyc windows#Aluminum composite panels

0 notes

Video

#acppanel Discover The Architectural Beauty With Our IDEABOND #Alucobond Composite Panel Project

Experience the epitome of architectural brilliance with IDEABOND! Our Alucobond Composite Panel Project showcases awe-inspiring beauty that will leave you breathless. Join us to explore a harmonious blend of innovation and design. #IDEABOND #Alucobond #ArchitecturalBeauty

0 notes

Photo

RMK Industries LLC is the Best Manufacturer for Aluminium Composite Panel used for constructions, buildings, signboard, walls and roofs. For more details, visit here: https://www.alcobond.com/

1 note

·

View note

Photo

Flexibond's Acrylic Solid Surface seams are glued and buffed for absolutely seamless walls, columns, display fixtures and other designs. And because the solid surface is nonporous, it is a replacement of stone where hygiene is essential for any application, such as health care and food service

#Flexibond#endlesscreations#reduceddeadweight#door#leadingACP#solid#wpc#frame#doorframes#wpcdoorframes#Inspiration#Innovation#flexibondindia#acppanel#flexibondpanel#Gujarat#aluminumcompositepanel#PVCfoamboard#WPCdoors#Acrylicsolidsurface#MakeInIndia#AnAttachment

1 note

·

View note

Video

Kompozit panel otomatik sürücü. Kompoziti otomatik olarak sürün. Yatara takın, kompoziti eliniz ile sürmeyin. Bu kadar rahatlık yok. Sizinde otomatik kompozit panel makineniz olsun. Kompoziti bir taraftan verin, diğer taraftan derzi açılmış halde ya da kesilmiş halde alın. #kompozitpanel #acppanel #kompozitkesim #kompozitebatlama #kompozitcephe #levhaisleme #levhaderz #levhayatar #yatarmakine #kompozitkesimbıçağı #kompozitcephekaplama (Aluminyum Cuyuz) https://www.instagram.com/p/CQ6hLg0Fxtt/?utm_medium=tumblr

#kompozitpanel#acppanel#kompozitkesim#kompozitebatlama#kompozitcephe#levhaisleme#levhaderz#levhayatar#yatarmakine#kompozitkesimbıçağı#kompozitcephekaplama

0 notes

Text

The Essential Guide to Aluminium Composite Panel Manufacturers In India 2021

Initially created in Europe, Aluminum Composite Panel (ACP) are acquiring prevalence past the Middle East. With the ascent of development work in the UAE, this has set off interest in India too for different outside and inner applications.

What is aluminium composite panel?

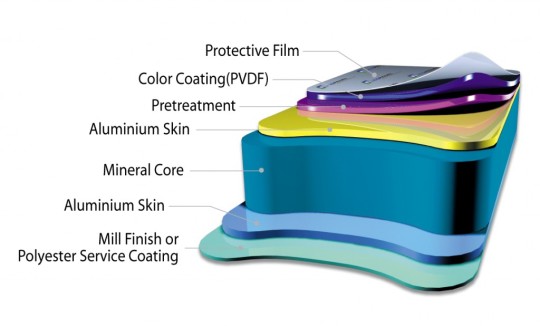

ACPs are likewise called Sandwich Panels. They have an Aluminum Composite sheet that has a polyethylene center. The ACP is made of three layers: a center that has low thickness, and a flimsy layer fortified from each side. The ACPs are utilized in application zones where there is a requirement for high underlying inflexibility but it must be low in weight. How about we consider further to be to why the ACPs are acquiring prevalence.

Characteristics of Aluminium Composite Panel(ACP Sheets)

The ACPs are a mix of polyethylene and polypropylene plastics that are reinforced so well in the assembling cycle that once handled it is hard to isolate the aluminum composite board sheets.

· Solidness: Since the ACPs are covered with Fluorocarbon they are impervious to tidy, climate, high temperature, mileage and contamination making them amazingly tough.

· Light weight: The primary inflexibility matches with the light weight of the ACPs making them much great for use in development. Because of its light weight it is likewise quicker to introduce subsequently quickening the development cycle.

· Imperviousness to fire: The external foil of aluminum forestalls the center inside from heat conduction during the underlying ignition measure. This trademark satisfies worldwide guidelines of security.

· Customization: The ACPs can be redone as per the size, shape and plan or example necessities. This causes clients to be more ready to adjust their current circumstance and change it according to the appropriateness of their necessities. Bendable element makes ACPs an unequaled top pick for development work.

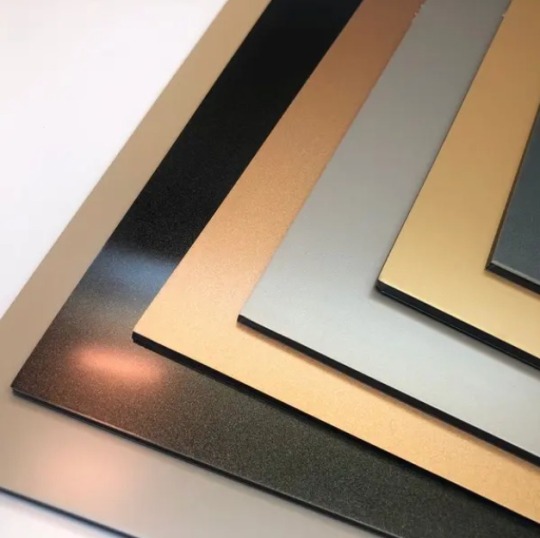

· Plan and Color: Any sort of plan or shading can be had for the ACPs making them appealing too. They can mix well with the climate and even improve its appearance because of their metallic completes and examples.

Types of Aluminum Composite Panel

To look into the application areas and various ways in which the ACPs can be used, let’s check the different types of ACPs. ACPs are of different types depending on the finishings given to them:

· matte finish that gives a rough touch

· plain finish that just blends with the environment

· wooden finish plays well with the natural look

· Stone finish provides a shine that outshines

· marble finish gives a durable and lasting impression

· These panels are used for different requirements and hence they differ in sizes too.

Uses of Aluminium Composite Panel

The aluminum composite board utilizes have extended throughout the long term. Prior they were considered to be utilized for simply dividing. Presently, they have a broad scope of utilizations inside and remotely because of their inborn qualities. Here and there they are utilized alongside different materials like glass in the structure.

Since the ACPs can be cut, fit, bowed, bored or punctured without it losing its construction, they are generally utilized for outside claddings, building exteriors, protection territories and signage.

With a wide scope of use territories, absolutely stunning qualities and highlights, wonderful scope of plan and tones, the ACPs are a help for the development business, inside planners and for building craftsmanships. They route forward for the ACP is accepted to be more conceivable because of logical achievements in development innovation that is accomplishing extraordinary steps ordinary.

At Envitect we have faith in the mixing of plan, innovation, use and client necessities to make the best items that guarantee more simplicity of living.

#aluminium panels#aluminium cladding#aluminum composite panels#acp sheet company#acpsheetsupplier#acppanel#ACPsheet

0 notes

Text

Why bother to build a case for aluminium composite panels?

Architecture defines a generation, and contemporary architecture is all about blending aesthetics with functionality, creating a space that is reflective of one’s persona, and upholding sustainability. Based on these three mantras many trends have come and gone, but one trend that stayed and grew with time is the use of aluminium composite panels for cladding. For buildings today, particularly the commercial ones, facade has become almost an integral feature. Whether for constructing a new building with a distinctive style or for giving an old building a face-lift nothing comes as useful and cost-effective as aluminium composite panels.

Unfortunately, this versatile building material has recently earned a bad name following a spate of fire incidents that took place in different parts of the world, the most recent being the Grenfell Tower fire in London. All these incidents were, in some way, linked to the use of aluminium composite panels (with flammable polyethylene cores) in cladding, by people from various sectors. While everyone including the fire safety professionals insisted for complete removal of aluminium cladding from the buildings or at least implementing a moratorium on aluminium composite construction, aluminium rolled product companies and ACP manufacturers continuously kept trying to put their best logic forward to prove their offerings guilt-free. What everyone missed out in the middle of the entire clamour was the non-compliance practised by even the best housing companies in the world.

But let us leave that issue for the compliance authorities to analyse while we concentrate on the benefits that ACPs offer as a futuristic building material.

1. Price advantage: No other cladding material can beat aluminium composite panels in cost terms. They are the most economical cladding material available in the market right now.

2. Design flexibility: Aluminium cladding comes in various shapes- from standard squares and rectangles to the unique curves and circles. Further, it can be shaped as per project specification using sophisticated CNC technology. Aluminium composite panel surface also allows for a wide-range of value addition in terms of colour-coating, polishing, texturing and sublimation printing.

3. Lightweight advantage: ACPs being lightweight can be easily transported, lifted to any height, and installed without having to worry about serious casualties at site. The panels are ideal for portable construction at any part of the world.

4. Durability: Like any other advanced aluminium flat rolled product, ACPs are rigid, durable and reasonably strong, and hence preferred by architects to prolong the building life.

5. Added advantages: ACPs have good heat insulation and sound reduction properties. These features make it ideal for creating spaces for modern living.

6. Low-cost maintenance: Superior stain and weather resistant properties make aluminium cladding low-maintenance and hence, worth investing in.

7. Recyclability: Choosing aluminium cladding is choosing sustainability. Aluminium is 100% recyclable and does not lose any of its quality in the down-gauging process. So, the metal from the cladding can be re-melted at any point of time and the process saves a significant amount of energy. This makes it possible to obtain the U.S. Green Building Council’s Leadership in Energy and Environmental Design (LEED) certification for modern “green” buildings.

Aluminium cladding and fire safety:

Now coming to the most crucial part, let’s face it that non-combustibility does not come as a default feature with all the varieties of aluminium composite panels. The sandwich panels behave differently to fire depending on the foam used, thickness of the metal, the coating, etc., and it is on the builder or the occupant to choose between the different sandwich panel types, depending on the budget and requirements. A study by the Association of British Insurers and the Building Research Establishment in the UK highlighted that “sandwich panels do not start a fire on their own, and where these systems have been implicated in fire spread, the fire has often started in high risk areas such as cooking areas, subsequently spreading as a result of poor fire risk management, prevention and containment measures.”

However, there are some technicalities that decide the combustibility of aluminium composite panels:

Design of the cavity between the panel and the exterior wall of a building if not optimized with precision may lead to secondary fire caused due to upward convection.

Use of polyethylene core as the outermost layer of the panel may often increase the possibility of fire, but then it depends on the application and the method of installation.

A mineral-filled core, like those used by the top aluminium composite panel manufacturers in the world, has been found to offer reasonable fire-safety assurance.

It is always advisable that the civic bodies quality-check these features before allowing a particular variety of aluminium composite panels in the market. Builders and consumers too should have a clear understanding of the important concepts like ‘fire rating’, ‘fire retardant’, and ‘fire resistant’ before zeroing on a product.

ACPs are the order of the future:

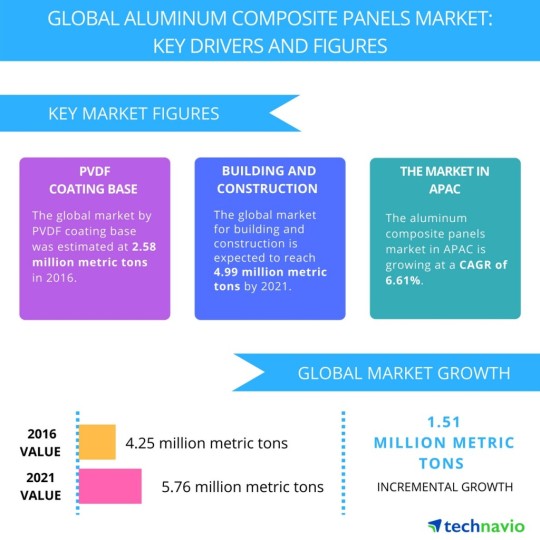

It is almost certain now that aluminium composite panels will rule the building and construction sector for the coming few decades. A half-an-hour walk through any of the world’s biggest cities would only reaffirm that trend. Globally, the ACP market is growing at a CAGR of 6.27% over 2017-2021, the latest Research and Markets report shows. With the number of residential and commercial building increasing and infrastructural projects getting sanctioned, the demand for aluminium composite panels will grow even more significantly.

So, it is pointless to refrain from using this cost-effective, versatile cladding material. Instead, vendors should invest more in developing new technologies and stay up-to-date with the global fire-safety standards that could improve the product line, because one thing is clear- only those aluminium composite panel brands are going to thrive that will offer the best fire-safety cladding solutions to the end users. Nothing more, nothing less.

0 notes

Link

Aluminium Composite Panel is the new age material used for buildings, constructing roofs, signage & interior applications. Get best ACP Sheet PriceQuote at Virgo.

1 note

·

View note

Text

A Comprehensive Guide: How to Choose the Right ACP Sheet Size for Your Next Project

In the realm of modern architecture and construction, Aluminum Composite Panels (ACPs) have emerged as a popular choice for cladding buildings due to their versatility, durability, and aesthetic appeal. However, selecting the right ACP sheet size for your project is crucial to ensure efficiency, cost-effectiveness, and a seamless installation process. In this guide, we'll delve into the factors to consider and steps to follow when choosing the perfect 3mm, 4mm, or 6mm ACP sheet size for your next project.

Understand Your Project Requirements:

Before diving into ACP sheet sizes, it's essential to have a clear understanding of your project's requirements. Consider factors such as:

Building dimensions and surface area to be covered.

Architectural design and layout.

Environmental factors like wind load, temperature variations, and exposure to sunlight.

Budget constraints and material availability.

Assess Standard ACP Sheet Sizes:

ACP sheets come in various standard sizes, typically ranging from 1220mm to 2000mm in width and 2440mm to 6000mm in length. Familiarize yourself with these standard sizes and their availability from manufacturers and suppliers.

Measure Surface Area:

Calculate the total surface area to be clad with ACP sheets. Multiply the length and height of each wall or surface to get the square footage. This measurement will help you determine the quantity of ACP sheets required.

Consider Panel Thickness:

ACP sheets are available in different thicknesses, commonly ranging from 3mm to 6mm. Thicker panels offer increased rigidity and durability but may add to the overall weight and cost. Evaluate the structural requirements and aesthetic preferences of your project to choose the appropriate thickness.

Evaluate Installation Logistics:

Assess the logistics of ACP sheet installation, including transportation, handling, and fabrication. Consider factors such as:

Accessibility to the construction site.

Equipment and machinery required for cutting and shaping ACP sheets.

Installation method (mechanical fixing, adhesive bonding, etc.) and its compatibility with the selected sheet size.

Optimize Material Usage:

Minimize wastage and optimize material usage by selecting ACP sheet sizes that align with your project's dimensions. Consider cutting patterns and layouts to maximize efficiency and reduce scrap material.

Seek Professional Guidance:

Consult with architects, engineers, or construction professionals to validate your ACP sheet size selection. Their expertise can provide valuable insights into structural integrity, design aesthetics, and compliance with building codes and regulations.

Request Samples and Mock-ups:

Before finalizing your decision, request samples or mock-ups of the chosen ACP sheet size to assess its appearance, texture, and color under various lighting conditions. This step ensures that the selected size complements the overall design vision of your project.

Review Manufacturer Specifications:

Review the technical specifications provided by ACP manufacturers, including load-bearing capacity, fire resistance, weather durability, and warranty terms. Ensure that the chosen sheet size meets the performance requirements and quality standards for your project.

Factor in Future Maintenance:

Consider the long-term maintenance and upkeep of ACP-clad surfaces. Choose a size that facilitates ease of cleaning, inspection, and maintenance to preserve the appearance and performance of the building facade over time.

Conclusion:

Selecting the right ACP sheet size is a crucial decision that impacts the aesthetics, functionality, and durability of your building facade. By understanding your project requirements, assessing standard sizes, considering panel thickness, evaluating installation logistics, and seeking professional guidance, you can make an informed decision that ensures the success of your next construction project. Choose wisely, and let your building shine with the perfect 3mm, 4mm, or 6mm ACP cladding solution.

1 note

·

View note

Text

ReynoArch Luxury panels are Aluminum based panels

Update your Home Decor with India's first luxury panel, ReynoArch Luxury panels are Aluminum based panels. They are robust, water and termite resistant and can be utilized for optimization of spaces in all domestic and commercial establishments like offices, hospital, shopping mall, etc.

For products & design related queries please visit our website https://bit.ly/3GD6Sfh Or Whatsapp at +91- 9810846953

#ReynoarchLuxuryPanels#LuxuryWallPanels#panels#aluminiumcompositepanel#aluminiumcomposite#aluminiumcompositepanels#ReynoArchACP#AcpPanels#reynobondacp

0 notes

Link

Not getting desired results from your current ACP panel? The quality of services vary with each service provider and it takes into consideration multiple factors. Switch to Alstrong UAE today and feel the difference in the services being rendered.

0 notes

Photo

ALCOBOND & CLADBOND ensures high level of security and fire protection for the architects and building owners to meet stringent regulations aimed at protecting inhabitants and visitors but also building structure and surrounding environment from re hazards,

0 notes

Photo

100% TERMITE PROOF

www.flexibond.com

#termiteproof#pcm#protect#fireresistant#wpcdoorframes#Inspiration#flexibondindia#acppanel#flexibondpanel#MakeInIndia#Gujarat

0 notes

Link

Viva is a premier manufacturer of Aluminium Composite Panel and its’ accessories in India. We are known for our manufacturing facilities which are equipped with state-of-the-art Korean machines with advance technology in order to ensure world class products.

0 notes