#steam boiler thermax

Link

This year, the renewables industry increasingly relies on private investments to propel the sector. Traditional and rooftop solar power plant projects were either stopped or delayed in 2020 owing to strict constraints, increases in solar panel import prices, and changes in solar regulations, such as lowering the net metering maximum for rooftop solar projects.

#rooftop solar power plant#Rooftop Solar Power Plant by Thermax#steam boiler by Thermax#steam boiler thermax#Steam Boiler System

0 notes

Text

Enhancing Utility Engineering Solutions with Veda Engineering in Gujarat

Introduction:

In the dynamic landscape of utility engineering, finding a reliable partner who can deliver efficient, cost-effective solutions tailored to your needs is paramount. Veda Engineering stands out as a beacon of excellence in Gujarat, offering a comprehensive range of services spanning project execution, design, fabrication, audits, and consultancy. Let’s delve into how Veda Engineering is revolutionizing the industry.

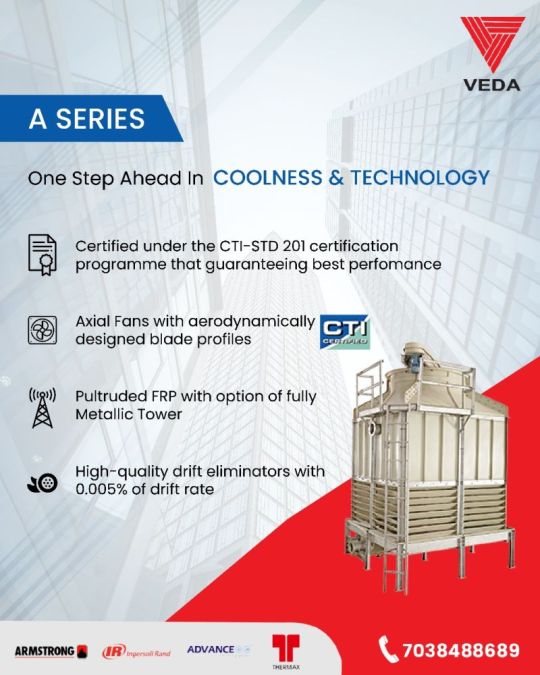

Cooling Tower Supplier/Manufacturer in Gujarat:

Cooling towers play a crucial role in maintaining optimal temperatures in industrial processes, requiring robust and efficient solutions. Veda Engineering stands out as a premier supplier and manufacturer of cooling towers in Gujarat, offering innovative designs and superior construction. With a focus on fast-track schedules and uncompromising quality, Veda Engineering ensures that clients receive cooling towers that meet their specific requirements.

Thermax Dealer in Gujarat:

Veda Engineering proudly serves as a trusted Thermax dealer in Gujarat, bringing cutting-edge solutions in heat engineering to the forefront. With a focus on high efficiency output and cost control, Veda Engineering ensures that clients receive top-notch products and services that meet their specific requirements. Whether it's steam boilers, thermic fluid heaters, hot water generators, or cooling towers, Veda Engineering has you covered.

Steam Boiler Supplier/Manufacturer in Gujarat:

As a leading steam boiler supplier and manufacturer in Gujarat, Veda Engineering understands the critical role of steam in various industrial processes. Leveraging expertise in mechanical design and fabrication, Veda Engineering delivers steam boilers that excel in efficiency, reliability, and performance. Clients can rely on Veda Engineering for customized solutions tailored to their operational needs.

Thermic Fluid Heater Supplier/Manufacturer in Gujarat:

Thermic fluid heaters play a vital role in numerous industrial applications, requiring precision engineering and top-notch quality. Veda Engineering emerges as a premier supplier and manufacturer of thermic fluid heaters in Gujarat, offering state-of-the-art solutions that ensure optimal heat transfer and energy efficiency. With a focus on thoroughness and quality, Veda Engineering guarantees unmatched performance and reliability.

Hot Water Generator Supplier/Manufacturer in Gujarat:

Hot water generators are essential for various industrial processes, demanding solutions that combine efficiency with durability. Veda Engineering, as a trusted hot water generators supplier and manufacturer in Gujarat, excels in delivering cost-effective and reliable solutions. With a commitment to high-quality fabrication and stringent quality control, Veda Engineering ensures that clients receive hot water generators that exceed expectations.

Conclusion:

In the realm of utility engineering, Veda Engineering emerges as a trusted partner, delivering highly efficient, cost-effective solutions tailored to clients' needs in Gujarat. Whether it's serving as a Thermax dealer, supplying steam boilers, thermic fluid heaters, hot water generators, or cooling towers, Veda Engineering remains committed to excellence, ensuring clients' success and growth in their endeavors. With Veda Engineering by their side, clients can confidently navigate the complexities of utility engineering with unparalleled expertise and support.

#Thermax dealer in Gujarat#Steam boiler supplier/manufacturer in Gujarat#Thermic fluid heater supplier/manufacturer in Gujarat#hot water generator supplier/manufacturer in Gujarat#Cooling tower supplier/manufacturer in Gujarat

0 notes

Text

STP Plant for Hotels/Hospitals and ETP Plant for Industrial Use

Welcome to Thermodynamic Services, your trusted partner for industrial air compressor solutions, air compressor installation services, Thermax products, industrial steam boilers, steam system engineering, hot water generators, STP plants for hotels and hospitals, ETP plants for industrial use, and RO plants for hotels and hospitals in Uttar Pradesh. We are your authorized dealer for top-notch Atlast Copco and Thermax products. Our commitment is to provide reliable and efficient solutions for your industrial needs.

Industrial Air Compressor and Installation Services:

At Thermodynamic Services, we offer a comprehensive range of industrial air compressors and professional installation services throughout Uttar Pradesh. Our team ensures that your air compressor system is installed efficiently, optimizing your production processes while reducing energy consumption.

Thermax Dealer in Varanasi and Lucknow:

As the authorized Thermax dealer in Varanasi and Lucknow, we bring you cutting-edge solutions for heating, cooling, and power generation. Our Thermax products are renowned for their quality and efficiency, ensuring that your industrial processes run smoothly.

Industrial Steam Boiler Manufacturer in Uttar Pradesh:

Our state-of-the-art industrial steam boilers are designed to meet the highest standards in performance and safety. We are the top industrial steam boiler manufacturer in Uttar Pradesh, offering tailored solutions for your specific requirements.

Steam System Engineering Services:

Thermodynamic Services specializes in steam system engineering services. Our team of experts will analyze, design, and implement the most efficient and cost-effective steam systems for your industrial operations in Uttar Pradesh.

Hot Water Generators for Hospitals & Hotels:

For hospitals and hotels in Uttar Pradesh, we provide high-quality hot water generators. These systems ensure a continuous and reliable supply of hot water, meeting the demands of your customers and patients.

STP Plant for Hotels/Hospitals and ETP Plant for Industrial Use:

We offer sustainable solutions for waste management with STP (Sewage Treatment Plant) and ETP (Effluent Treatment Plant) installations. Ensure your business is environmentally responsible and compliant with regulations.

RO Plant for Hotels and Hospitals:

Our RO (Reverse Osmosis) plants are ideal for hotels and hospitals, providing clean and safe drinking water. We prioritize the health and well-being of your guests and patients.

Conclusion:

Thermodynamic Services is your one-stop solution for all industrial needs in Uttar Pradesh. We pride ourselves on offering top-quality products and services that enhance your industrial operations. Partner with us to ensure efficiency, compliance, and sustainability. Contact us today for all your industrial requirements and enjoy the benefits of our trusted solutions.

conatct us on 91 78600 24711 or https://thermodynamic.co.in/

#Air Compressor Installation Services in Uttar Pradesh#Thermax Dealer in Varanasi#Thermax Dealer in Lucknow#Industrial Steam Boiler Manufacturer in Uttar Pradesh#Steam System Engineering Services in Uttar Pradesh#Hot Water Generator for Hospitals & Hotels#STP Plant for Hotels/Hospitals#ETP Plant for Industrial Use#RO Plant for Hotels and Hospitals

0 notes

Text

Industrial Boilers Market Forecast 2024-2033

Overview and Scope

Industrial boilers refer to the closed vessels that heat water or create steam for industrial heating and humidification purposes using a fuel source or electricity. It generates steam or heats water for space and process heating for the generation of mechanical power and electricity.

The industrial boilers market size is expected to see strong growth in the next few years. It will grow to $20 billion in 2028 at a compound annual growth rate (CAGR) of 6.8%. The growth in the forecast period can be attributed to increasing demand for power generation, stringent emission standards, renewable energy integration, globalization of industries, investments in infrastructure. Major trends in the forecast period include adoption of iot and automation, focus on energy efficiency, stringent emission regulations, shift towards biomass and renewable fuels, customization and modular designs.

Segmentation & Regional Insights

The industrial boilers market covered in this report is segmented –

1) By Boiler Type: Fire-Tube, Water-Tube

2) By Fuel: Natural Gas And Biomass, Coal, Oil, Other Fuels

3) By Boiler Horsepower: 10–150 BHP, 51–300 BHP, 301–600 BHP

4) By Applications: Chemicals And Petrochemicals, Paper And Pulp, Food And Beverages, Metals And Mining, Other Applications

North America was the largest region in the industrial boilers market in 2023. The regions covered in the industrial boilers market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa

Major Driver Impacting Market Growth

Increasing power generation is expected to drive the Industrial boilers market going forward. The market for industrial boilers is expanding primarily because of increased power generation and electricity for large-scale power plant installations of industrial burners in boilers. According to the report by world energy & climate statistics, an application that delivers data by region with updated statistics and related information, in 2022, in The BRICS countries, where electricity consumption increased noticeably, especially in China (+9.7%), India (+4.8%), Russia (+6.4%), and Brazil (+9.5%) were the driving force behind the growth in global power generation (+8.5% in 2021). In China, most of the increase in power generation came from coal, wind, and solar energy. Therefore, increasing power generation will stimulate the growth of the industrial boilers market in the forecasting period.

Key Industry Players

Major companies operating in the industrial boilers market report are Siemens AG, Thermax Limited, Harbin Electric Corporation, Bharat Heavy Electricals Limited, General Electric Company, Dongfang Electric Corporation Ltd., Babcock & Wilcox Enterprises Inc., IHI Corporation, Mitsubishi Heavy Industries Ltd., Cleaver-Brooks Inc., John Wood Group Plc., Doosan Heavy Industries & Construction Co. Ltd., Forbes Marshall Pvt. Ltd., Sofinter SPA, AC Boilers S.P.A, Alfa Laval AB, Bosch Industriekessel GmbH, Hurst Boiler & Welding Company Inc., Miura Co. Ltd., Zhengzhou Boiler (Group) Co. Ltd., Mitsui & Co Ltd., ABB Ltd., Viessmann Boilers, Harbin Electric Co. Ltd., Lennox, Baxi, Fulton, Worcester Bosch, Ideal Boilers, IBurnham Commercial .

The industrial boilers market report table of contents includes:

1. Executive Summary

2. Industrial Boilers Market Characteristics

3. Industrial Boilers Market Trends And Strategies

4. Industrial Boilers Market — Macro Economic Scenario

5. Global Industrial Boilers Market Size and Growth

.

.

.

31. Global Industrial Boilers Market Competitive Benchmarking

32. Global Industrial Boilers Market Competitive Dashboard

33. Key Mergers And Acquisitions In The Industrial Boilers Market

34. Industrial Boilers Market Future Outlook and Potential Analysis

35. Appendix

Explore the trending research reports from TBRC:

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

0 notes

Text

0 notes

Text

Waste to Energy Boiler Supplier in Singapore— Blissflowsystems

Introduction

In the ever-evolving world of industrial progress, the importance of sustainable practices and energy conservation cannot be understated. Waste Heat Recovery (WHR) technology has emerged as a game-changer, allowing industries to harness and utilize excess heat from various processes. This article delves into the significance of Waste Heat Recovery Boilers and introduces Bliss Flow, a leading supplier and distributor of these innovative solutions in Singapore and the UAE.

https://blissflowsystems.com/product/waste-heat-recovery-boiler/

1. What is Waste Heat Recovery?

Waste Heat Recovery (WHR) refers to the process of capturing and reusing heat that is generated as a byproduct of various industrial processes. Industries such as refineries, chemical plants, cement factories, and power plants produce substantial amounts of heat during their operations, which is often wasted in the atmosphere. Thermax manufactures hot water boilers in the range of 50,000 to 90,00,000 kcal per hour. The hot water boilers are designed to operate on various types of fuels such as heavy oil, light oil, gas, duel fuel, coal, husk, and other agro-waste fuels. The three types of hot water boilers, manufactured at our unit, are Aquamatic, Aquatherm, and Thermocontainers

2. The Need for Waste Heat Recovery Boilers

Traditional industrial practices often release a significant amount of heat into the environment, resulting in energy wastage and increased greenhouse gas emissions. By implementing Waste Heat Recovery Boilers, industries can reduce their carbon footprint, enhance energy efficiency, and achieve substantial cost savings in the long run.

3. Understanding Bliss Flows: A Trusted WHR Boiler Supplier

Bliss Flow has earned a reputation as a reliable and experienced supplier and distributor of Waste Heat Recovery Boilers. With a commitment to sustainability and innovation, Bliss Flow provides cutting-edge solutions to industries looking to optimize their energy usage and contribute to a greener tomorrow.

4. Advantages of Bliss Flow Waste Heat Recovery Boilers

Bliss Flow WHR Boilers offer numerous benefits to industries. Some of the key advantages include:

Enhanced Energy Efficiency: By harnessing waste heat, Bliss Flows' boilers increase overall energy efficiency, leading to reduced energy costs.

Reduced Environmental Impact: The utilization of waste heat decreases greenhouse gas emissions, making it an environmentally responsible choice.

Cost Savings: Industries can save significantly on fuel and electricity expenses by implementing WHR Boilers.

Enhanced Productivity: WHR technology can enhance process efficiency, leading to improved overall productivity.

5. Applications of Waste Heat Recovery Technology

Waste Heat Recovery finds applications in various industries, including:

Power Generation: WHR Boilers can recover heat from exhaust gases in power plants to generate additional electricity.

Chemical Industry: In the chemical sector, waste heat can be harnessed for preheating feedwater or air.

Refineries: Refineries can utilize waste heat to optimize various processes and reduce energy consumption.

Metal and Cement Industry: WHR technology can be employed to recover heat from high-temperature flue gases.

6. How Waste Heat Recovery Boilers Work

WHR Boilers employ advanced heat exchanger technology to capture and transfer waste heat from industrial processes to a heat medium. This medium is then used to generate steam or hot water, which can be utilized for different applications within the industry.

7. Key Components of Bliss Flows WHR Boilers

Bliss Flows' WHR Boilers consist of several vital components, including:

Heat Exchangers: These components facilitate the transfer of heat from exhaust gases to the heat medium.

Boiler Drum: The boiler drum stores and controls the generated steam.

Steam Turbine: The steam turbine converts thermal energy into mechanical energy, which can be used for electricity generation.

Condenser: The condenser condenses the exhaust steam back into liquid form for reuse in the heat exchanger.

8. Factors to Consider When Choosing a WHR Boiler

When selecting a Waste Heat Recovery Boiler, industries should consider factors like:

Heat Source Temperature and Flow Rate: The temperature and volume of waste heat produced during industrial processes influence the type and size of the WHR Boiler required.

Type of Heat Medium: Different industries may require different heat mediums based on their specific needs.

Waste Heat Utilization: Understanding how the recovered heat will be utilized is crucial for selecting the most appropriate WHR Boiler.

9. Installing and Maintaining WHR Boilers

Proper installation and regular maintenance are essential to ensure the optimal performance and longevity of Waste Heat Recovery Boilers. Industries must work closely with experienced providers like Bliss Flow to ensure seamless installation and efficient operation.

10. Maximizing Efficiency with Bliss Flow Solutions

Bliss Flows offers customized solutions tailored to each industry's unique requirements, ensuring maximum efficiency and performance from their Waste Heat Recovery Boilers.

11. Economic Advantages for Industries

Apart from environmental benefits, implementing WHR technology can lead to significant economic advantages for industries, including reduced operational costs and improved competitiveness.

12. Waste Heat Recovery in Singapore: A Sustainable Approach

Singapore, known for its commitment to sustainability, has embraced Waste Heat Recovery technology to foster a more eco-friendly industrial landscape.

Conclusion

Bliss Flow Systems Waste Heat Recovery Boilers present a compelling solution for industries seeking to optimize energy usage, reduce their environmental impact, and achieve long-term cost savings. By harnessing waste heat and turning it into a valuable resource, these innovative boilers pave the way for a more sustainable future. Embracing Waste Heat Recovery technology is not only economically advantageous but also an ethical responsibility for industries looking to play their part in combatting climate change.

#Bliss Flow Systems#WasteHeatRecoveryBoiler#WasteHeatRecoveryBoilerSupplier#WasteHeatRecoveryBoilerDistributor

0 notes

Text

Waste Heat Recovery Boiler Supplier & Distributor in Singapore — Blissflowsystems

Introduction

In the ever-evolving world of industrial progress, the importance of sustainable practices and energy conservation cannot be understated. Waste Heat Recovery (WHR) technology has emerged as a game-changer, allowing industries to harness and utilize excess heat from various processes. This article delves into the significance of Waste Heat Recovery Boilers and introduces Bliss Flow, a leading supplier and distributor of these innovative solutions in Singapore and the UAE.

1. What is Waste Heat Recovery?

Waste Heat Recovery (WHR) refers to the process of capturing and reusing heat that is generated as a byproduct of various industrial processes. Industries such as refineries, chemical plants, cement factories, and power plants produce substantial amounts of heat during their operations, which is often wasted in the atmosphere. Thermax manufactures hot water boilers in the range of 50,000 to 90,00,000 kcal per hour. The hot water boilers are designed to operate on various types of fuels such as heavy oil, light oil, gas, duel fuel, coal, husk, and other agro-waste fuels. The three types of hot water boilers, manufactured at our unit, are Aquamatic, Aquatherm, and Thermocontainers

2. The Need for Waste Heat Recovery Boilers

Traditional industrial practices often release a significant amount of heat into the environment, resulting in energy wastage and increased greenhouse gas emissions. By implementing Waste Heat Recovery Boilers, industries can reduce their carbon footprint, enhance energy efficiency, and achieve substantial cost savings in the long run.

3. Understanding Bliss Flows: A Trusted WHR Boiler Supplier

Bliss Flow has earned a reputation as a reliable and experienced supplier and distributor of Waste Heat Recovery Boilers. With a commitment to sustainability and innovation, Bliss Flow provides cutting-edge solutions to industries looking to optimize their energy usage and contribute to a greener tomorrow.

4. Advantages of Bliss Flow Waste Heat Recovery Boilers

Bliss Flow WHR Boilers offer numerous benefits to industries. Some of the key advantages include:

Enhanced Energy Efficiency: By harnessing waste heat, Bliss Flows' boilers increase overall energy efficiency, leading to reduced energy costs.

Reduced Environmental Impact: The utilization of waste heat decreases greenhouse gas emissions, making it an environmentally responsible choice.

Cost Savings: Industries can save significantly on fuel and electricity expenses by implementing WHR Boilers.

Enhanced Productivity: WHR technology can enhance process efficiency, leading to improved overall productivity.

5. Applications of Waste Heat Recovery Technology

Waste Heat Recovery finds applications in various industries, including:

Power Generation: WHR Boilers can recover heat from exhaust gases in power plants to generate additional electricity.

Chemical Industry: In the chemical sector, waste heat can be harnessed for preheating feedwater or air.

Refineries: Refineries can utilize waste heat to optimize various processes and reduce energy consumption.

Metal and Cement Industry: WHR technology can be employed to recover heat from high-temperature flue gases.

6. How Waste Heat Recovery Boilers Work

WHR Boilers employ advanced heat exchanger technology to capture and transfer waste heat from industrial processes to a heat medium. This medium is then used to generate steam or hot water, which can be utilized for different applications within the industry.

7. Key Components of Bliss Flows WHR Boilers

Bliss Flows' WHR Boilers consist of several vital components, including:

Heat Exchangers: These components facilitate the transfer of heat from exhaust gases to the heat medium.

Boiler Drum: The boiler drum stores and controls the generated steam.

Steam Turbine: The steam turbine converts thermal energy into mechanical energy, which can be used for electricity generation.

Condenser: The condenser condenses the exhaust steam back into liquid form for reuse in the heat exchanger.

8. Factors to Consider When Choosing a WHR Boiler

When selecting a Waste Heat Recovery Boiler, industries should consider factors like:

Heat Source Temperature and Flow Rate: The temperature and volume of waste heat produced during industrial processes influence the type and size of the WHR Boiler required.

Type of Heat Medium: Different industries may require different heat mediums based on their specific needs.

Waste Heat Utilization: Understanding how the recovered heat will be utilized is crucial for selecting the most appropriate WHR Boiler.

9. Installing and Maintaining WHR Boilers

Proper installation and regular maintenance are essential to ensure the optimal performance and longevity of Waste Heat Recovery Boilers. Industries must work closely with experienced providers like Bliss Flow to ensure seamless installation and efficient operation.

10. Maximizing Efficiency with Bliss Flow Solutions

Bliss Flows offers customized solutions tailored to each industry's unique requirements, ensuring maximum efficiency and performance from their Waste Heat Recovery Boilers.

11. Economic Advantages for Industries

Apart from environmental benefits, implementing WHR technology can lead to significant economic advantages for industries, including reduced operational costs and improved competitiveness.

12. Waste Heat Recovery in Singapore: A Sustainable Approach

Singapore, known for its commitment to sustainability, has embraced Waste Heat Recovery technology to foster a more eco-friendly industrial landscape.

Conclusion

Bliss Flow Systems Waste Heat Recovery Boilers present a compelling solution for industries seeking to optimize energy usage, reduce their environmental impact, and achieve long-term cost savings. By harnessing waste heat and turning it into a valuable resource, these innovative boilers pave the way for a more sustainable future. Embracing Waste Heat Recovery technology is not only economically advantageous but also an ethical responsibility for industries looking to play their part in combatting climate change.

Inquire now: https://blissflowsystems.com/product/waste-heat-recovery-boiler/

aquamatic and aquathermbliss flow systemsequimentsoil and gassafety deviceswaste heat recovery boilerwaste heat recovery boilerswaste heat recovery boilers distributor

#Bliss Flow Systems#WasteHeatRecoveryBoiler#WasteHeatRecoveryBoilerSupplier#WasteHeatRecoveryBoilerDistributor

1 note

·

View note

Text

2 TON USED THERMAX BOILER

Thermax boiler is a type of industrial boiler that is widely used in various industries for generating steam. It is known for its high efficiency, reliable performance, and low operating costs. The boiler uses a variety of fuels such as coal, oil, gas, and biomass to produce steam.

Secondbuy is an online platform that provides an opportunity to purchase a 2-ton used Thermax boiler. The platform offers a convenient and affordable way to acquire industrial equipment without the need to go through the hassle of traditional procurement methods. By purchasing a used Thermax boiler from Secondbuy, businesses can reduce their capital expenditure and increase their operational efficiency.

0 notes

Photo

top steam boiler manufacturers in India

India has a significant presence in the steam boiler manufacturing industry, with several top manufacturers based in the country. One of the leading companies in this space is Thermax Limited, a prominent energy and environment solutions provider that offers a range of products, including boilers, heaters, chillers, and water treatment systems. Forbes Marshall is another large steam boiler manufacturer in India, specializing in steam engineering and control instrumentation solutions. For more information contact us at https://www.thermodyneboilers.com/gallery/

0 notes

Text

Thermax dealer in Maharashtra

Thermeon, the low-cost, reliable steam source, is suitable for coal, wood, and biomass briquettes, ensuring high reliability and performance at a small capacity.

The compact design results in a tiny footprint and saves installation space.

The low height of the boiler allows easy access to all parts and controls.

A boiler is supplied as a package along with assembled components, pre-insulated, and with a good sense of aesthetics.

Product Features are

- Completely Paneled and Ultra-compact – Best Aesthetics in range

- Integrated Heat Recovery Unit – High Fuel Efficiency

- Bigger Fire Door – Easy Fuel Feeding

- Centrifugal Pump – Highly Flexible and Continuous Operation

- FD & ID Fan – No Back Firing, Instant and Complete Combustion

- Automatic Pressure Switch – High Safety & Reliable Performance

.

.

For more information about our products

Contact us at - 7875278724

Visit our website - www.vedaengg.com

#thermax#manufacturing#engineering#industries#manufacturer#capitalgoods#industrialutilitysupplier#consultant#vedaengg#utilitysuppliers#industrialutility#industriessupplier#boilersupplier#chemicalsupplier#coolingtowersupplier#pumpsupplier#APCsupplier

1 note

·

View note

Text

Oil and Gas Waste Heat Recovery Market | Size, Share, Industry Segments, Growth, Trends, Demand, Key Player profile and Regional Outlook by 2030

Oil & gas waste heat recovery is the process of extracting and reusing heat from the streams of large energy produced during the refining process in the oil & gas plant. The continuous evolution in industrialization across the globe has resulted in the generation of large waste energy as a by-product. Numerous large-scale methods are employed in the oil & gas sector to reduce overall energy consumption, operational cost, and greenhouse gas & carbon emissions. The large-scale implementation of waste heat recovery system in the oil & gas sector is expected to boost the industrial processes and substantially enhance their economic feasibility.

The impending factors for the growth of oil & gas waste heat recovery market are considered to be immense in the emerging economies of the Asia Pacific region. The dominant position of Asia Pacific is due to the rising need for energy by the highly urbanized and industrialized economies, such as China, India, and Japan. North America and Europe are also expected to witness a substantial growth over the forecast period, owing to increase in exploration and production activities in prominent oil & gas producing nations, such as the U.S., Canada, and Mexico in North America. The U.K, Norway, and Italy in the European region contributed the largest share for oil & gas waste heat recovery market evolution.

The global oil and gas waste heat recovery market are expected to witness ~ 7.5% CAGR during the forecast period.

Access Report Details @ https://www.marketresearchfuture.com/reports/oil-gas-waste-heat-recovery-market-5903

Key Players

The key players of global oil and gas waste heat recovery market are ABB Ltd. (Switzerland), Ormat Technologies (U.S.), General Electric Company (U.S.), China Energy Recovery (China), Bono Energia (Italy), HRS (U.K), Harbin Electric Company Limited (China), Dongfang Electric Corporation (China), Amec Foster Wheeler (U.K), Siemens AG (Germany), Mitsubishi Heavy Industries Ltd. (Japan), Echogen Power Systems Inc.(U.S.), Econotherm Ltd (U.K), Thermax Limited (U.K) and Cool Energy, Inc. (U.S.).

Market Research Analysis

Downstream by sector, thermal by application, heat exchanger by equipment, and residential by end-user are expected to hold the largest share and have the highest CAGR throughout the forecast period.

The global oil & gas waste heat recovery market has been segmented based on sector, application, equipment, end-user, and region. Based on sector, the market is segmented into upstream, midstream, and downstream. Among these, the downstream sector is projected to dominate the oil & gas waste heat recovery market until 2023. The downstream sector consists of refineries and petrochemical complexes, which generate a huge amount of waste energy during their operations, thus, having an extra advantage of utilizing waste energy. Based on application, the market is segmented into thermal, electricity power generation, and others. Thermal application dominated the market in 2016 and is projected to be the fastest-growing application segment for oil & gas waste heat recovery. Thermal waste heat recovery is highly efficient and vitally used for pre-heating and steam generation process. Based on equipment, the market is segmented into heat exchangers, boilers, heat recovery steam generators, turbines, and others. The wide application of heat exchangers, along all major end-users, is expected to drive the equipment segment in waste heat recovery market over the forecast period. Based on end-user, the market is segmented into commercial, residential, and others. Residential segment held the largest share in 2016 owing to the huge demand for energy.

Scope of the Report

This study provides an overview of the global oil & gas waste heat recovery market, tracking four market segments across four geographic regions. The report studies key players, providing a five-year annual trend analysis that highlights market size, volume, and share for North America, Europe, Asia Pacific (APAC) and Rest of the World (ROW). The report also provides a forecast, focusing on the market opportunities for the next five years for each region. The scope of the study segments the oil and gas waste heat recovery market by its sector, by application, by equipment, by end-user, and by region.

Get a FREE Sample@ https://www.marketresearchfuture.com/sample_request/5903

By Sector

Upstream

Midstream

Downstream

By Application

Thermal

Electricity Power Generation

Others

By Equipment

Heat Exchangers

Boilers

Heat Recovery Steam Generators

Others

By End-User

Commercial

Residential

Others

By Regions

North America

Asia Pacific

Europe

Rest of the World

0 notes

Link

Steam boilers have existed in various versions since the 1700s. Similar to rooftop solar power plants, steam boilers are now used in various applications, from homes to industry. It is one of the considerate methods of assuring less impact on the already harmed environment.

0 notes

Text

Industrial Steam Boiler Manufacturer in Uttar Pradesh

At Thermodynamic Services, we take pride in being a leading provider of innovative and eco-friendly solutions for a wide range of industries. With a commitment to excellence, we specialize in offering cutting-edge technologies that cater to the diverse needs of our clients.

Authorized Thermax Dealer in Varanasi and Lucknow

As an authorized dealer of Thermax, a globally renowned brand, we bring you the best in energy and environment solutions. Whether you're in Varanasi or Lucknow, we provide access to a comprehensive range of Thermax products, ensuring you receive top-notch quality and reliability for your industrial requirements.

Industrial Steam Boiler Manufacturer in Uttar Pradesh

Our dedication to engineering excellence makes us a trusted industrial steam boiler manufacturer in Uttar Pradesh. We design and manufacture boilers that meet the highest industry standards, providing efficient and sustainable solutions for your business operations.

Steam System Engineering Services in Uttar Pradesh

Thermodynamic Services goes beyond just products; we offer comprehensive steam system engineering services in Uttar Pradesh. Our team of skilled professionals ensures that your steam systems are optimized for peak performance, enhancing efficiency and reducing operational costs.

Hot Water Generator for Hospitals & Hotels

For the healthcare and hospitality sectors, we provide advanced hot water generators designed to meet the specific needs of hospitals and hotels. Our solutions ensure a reliable and continuous supply of hot water, contributing to the comfort and well-being of your clients and patients.

STP Plant for Hotels/Hospitals and ETP Plant for Industrial Use

Thermodynamic Services is your trusted partner in wastewater management. We specialize in Sewage Treatment Plants (STP) for hotels and hospitals, as well as Effluent Treatment Plants (ETP) tailored for industrial use. Our environmentally conscious solutions help you meet regulatory standards while promoting sustainability.

RO Plant for Hotels and Hospitals

Our Reverse Osmosis (RO) plants are customized for the unique demands of hotels and hospitals. Providing clean and purified water, our RO systems ensure the highest quality standards for your guests and patients.

Conclusion

At Thermodynamic Services, we are more than just a provider of products and services – we are your strategic partner in achieving sustainability and efficiency. With a focus on quality, innovation, and environmental responsibility, we strive to exceed your expectations. Contact us today for all your energy and environment solution needs, and let Thermodynamic Services empower your success.

conatct us on 91 78600 24711 or https://thermodynamic.co.in/

#Industrial air compressor dealer in uttar pradesh#Air Compressor Installation Services in Uttarpradesh#Thermax Dealer in Varanasi#Thermax Dealer in Lucknow#Industrial Steam Boiler Manufacturer in Uttar Pradesh

0 notes

Text

Waste Heat Recovery Market Scope and Opportunities Analysis 2020 – 2030

Waste Heat Recovery Market: An Overview

New energy efficient equipment or waste heat recovery systems enable users to reduce energy losses and cater to the growing energy demands which drive waste heat recovery market. These systems can also be used to capture the heat generated in the course of several industrial processes and further use it for mechanical and electrical works, fulfilling the energy requirements by converting waste heat into a useful one.

Download PDF Brochure: https://www.tmrresearch.com/sample/sample?flag=B&rep_id=116

With rising energy demands, stringent environmental conditions, and the need to optimize or utilize the available resources in the best possible ways - waste heat recovery is the need of the hour. Presently, several companies have installed these systems for the purpose of energy generation as well as emission reduction.

Waste Heat Recovery Market: Key Segments

The waste heat recovery market can be broadly classified on the basis of source of waste heat, application, end-use industry, and the location of major areas employing waste to heat energy recovery systems for the purpose of converting the waste heat into a useful one. The major sources of waste heat are: ventilation system extracts, boiler flue gases, air compressors, refrigeration plants, turbines, power generation plants, process plants cooling systems, and others. The waste heat recovery systems can capture the heat generated from these systems to employ them for various other purposes.

The waste heat recovery system uses discarded heat and employs it to heat the water that creates steam, which is subsequently used for the purpose of running the turbines. The turbine movement thus converts the mechanical energy into an electrical one. The major applications of waste heat recovery systems include space heating, drying, power generation, pre-heating of combustion air for boilers, and fresh air for building ventilation and others. Key end-use industries for waste heat recovery units include petroleum and refining industries, pulp and paper industries, heavy metals reefing industries, chemical refining industries, and cement industries.

Waste Heat Recovery Market: Regional Analysis

The waste heat recovery market can be simply identified by the regions employing waste heat recovery technologies. The main regions are: the U.S., Canada, Germany, France, the U.K., Russia, China, India, Australia, Japan, Indonesia, Brazil, South Africa, and the Middle East countries.

The increasing fuel prices, supportive government policies, stringent environmental regulations, energy loss minimization, and the rise in the energy demands of individuals as well as industries are the major drivers for the waste heat recovery market. The additional costs involved in installation and longer payback periods act as obstacles for the waste heat recovery market. However, rapid industrialization, especially in Asia Pacific countries, has led to the increase in demand for energy. In addition, new, existing, and upcoming incentive schemes related to energy conservation and environmental protection can act as an opportunity to the waste heat recovery market.

Waste Heat Recovery Market: Key Market Players

The key players in the waste heat recovery market are: General Electric, Alstom SA, Siemens AG, Mitsubishi Heavy Industries Ltd, Thermax Ltd, and Foster Wheeler AG.

About Us:

TMR Research is a premier provider of customized market research and consulting services to business entities keen on succeeding in today’s supercharged economic climate. Armed with an experienced, dedicated, and dynamic team of analysts, we are redefining the way our clients’ conduct business by providing them with authoritative and trusted research studies in tune with the latest methodologies and market trends.

Contact Us:

Rohit Bhisey

Head Internet Marketing

Tel: +1-415-520-1050

Website: https://www.tmrresearch.com/

0 notes

Text

0 notes

Text

Industrial Boiler Market Strategy, Status, Trend, Share, Analysis, Forecast up to 2027

Industrial Boiler Market Overview:

Stellar Market Research's study on the Industrial Boiler Market examines segments and sub-segments in global and regional markets in depth. In the medium and long term, the research focuses at how drivers, restraints, and macro variables affect global and regional Industrial Boiler markets. The study contains a comprehensive examination of the global Industrial Boiler market's trends, forecasts, and monetary values. According to the study, the global Industrial Boiler market is expected to develop at a considerable CAGR between 2021 and 2027.

Market Scope:

The research looks at demand projections, market trends, and micro and macro factors in depth. This research also identifies the factors that are driving and restricting the market's growth. The research's SMR Matrix provides existing and new market participants with information on potential investment opportunities. The research uses analytical methodologies such as Porter's five forces analysis and PESTLE of the Industrial Boiler market to provide market insights. Furthermore, the research examines current market trends as well as forecasts for the years 2021-2027. The analysis also identified key upcoming developments that will influence demand over the projected period.

Request for free sample: https://www.stellarmr.com/report/req_sample/Industrial-Boiler-Market/339

Segmentation:

The fire-tube boiler operates at a pressure of up to 20 bar. Because it requires more floor space and can't handle load fluctuations well, this type of industrial boiler is only employed in small power plants. Because short tubes can hold high pressure better and are less susceptible to fracturing and failure, the water-tube boiler portion is better suited to high-pressure steam generation. In 2020, the water-tube boiler sector had the largest market share of 60%. During the forecast period, this segment is expected to grow at a CAGR of 6.5 percent (2021-2027).

Get more Report Details: https://www.stellarmr.com/report/Industrial-Boiler-Market/339

Key Players:

Bharat Heavy Electricals

A.O. Smith

Parker

Cleaver-Brooks

Thermax

Weil-McLain

Fulton

General Electric

Babcock and Wilcox

Forbes Marshall

Burnham

Hurst Boiler and Welding

Cochran

DEC

John Wood Group PLC

IHI Corporation

Mitsubishi Hitachi Power Systems, Ltd.

ANDRITZ

ALFA LAVAL

Bryan Steam

Superior Boiler Works, Inc.

Vapor Power

Sofinter S.p.a, AB&CO GROUP

ZOZEN boiler Co., Ltd.

For the current forecast period, this study offers a complete analysis of every segment of the Industrial Boiler market. The leading players and current trends in the Industrial Boiler market are also examined in this analysis.

Regional Analysis:

The research paper delves into the Industrial Boiler market in depth, segmenting it into several regions. The study includes a review of regional market participants in the target industry as well as information pertinent to the market. On a regional and country-by-country basis, the study evaluates the market in North America, Latin America, Europe, Asia Pacific (APAC), Africa, and the Middle East. Each region's market is thoroughly researched, allowing for the discovery of regional market trends, constraints, and development potential.

Prime Reasons to purchase a Industrial Boiler Market research report:

The goal of this research report is to help consumers to gain a more information and clearer understanding of the industry. The global Industrial Boiler market growth analysis includes development trends, competitive landscape analysis, investment plan, business strategy, opportunity, and key regions development status for international markets.

The global Industrial Boiler market overview and the analysis of several affecting elements such as drivers, restraints, and opportunities.

Porter's Five Force Analysis and SWOT analysis are used to define, characterise, and analyse the market competition landscape, with a focus on global key players.

Extensive analysis into the global Industrial Boiler competitive landscape

Identification and analysis of micro and macro elements that influence and will influence market growth.

A comprehensive list of major market players in the global Industrial Boiler industry.

In the global Industrial Boiler market, it provides a descriptive study of demand-supply chaining.

Statistical study of certain key economic statistics

Figures, charts, graphs, and illustrations are used to clearly describe the market.

The Benefits of Purchasing This Report:

This report examines evolving competitive dynamics in depth, as well as the important variables that are driving or inhibiting market growth in the future.

It shows you a timeline of technological advancements to help you figure out how quickly your sector is changing.

It provides a seven-year prediction based on market growth expectations. It aids in the comprehension of significant product groupings and their future possibilities.

It gives consumers a complete picture of changing competitive dynamics and keeps them one step ahead of the competition.

It assists in making informed business decisions by providing comprehensive market insights and in-depth market segment analyses.

It includes eye-catching graphics as well as a thorough Porter's Five Point Analysis and PESTLE analysis of the major market segments.

About Us:

Established in 2018, Stellar Market Research is India Based consulting and advisory firm focused on helping clients to reach their business transformation objectives with advisory services and strategic business. The company’s vision is to be an integral part of the client’s business as a strategic knowledge partner. Stellar Market Research provides end-to-end solutions that go beyond key research technologies to help executives in any organization achieve their mission-critical goals.

Contact Us:

Address

S.NO.8, H.NO. 4-8 PL.7/4, KOTHRUD, PINNAC MEMORIES FL. NO. 3, KOTHRUD, PUNE, Pune, Maharashtra, 411029

Email

[email protected]

0 notes