Link

This year, the renewables industry increasingly relies on private investments to propel the sector. Traditional and rooftop solar power plant projects were either stopped or delayed in 2020 owing to strict constraints, increases in solar panel import prices, and changes in solar regulations, such as lowering the net metering maximum for rooftop solar projects.

#rooftop solar power plant#Rooftop Solar Power Plant by Thermax#steam boiler by Thermax#steam boiler thermax#Steam Boiler System

0 notes

Link

Steam boilers have existed in various versions since the 1700s. Similar to rooftop solar power plants, steam boilers are now used in various applications, from homes to industry. It is one of the considerate methods of assuring less impact on the already harmed environment.

0 notes

Text

Installing Solar Power Plant? Here is all you need to Know!

Introduction

A renewable energy source, solar power can be used to generate electricity. Solar power plants, called solar farms, are large-scale photovoltaic systems that convert sunlight into electrical energy. Industrial solar power plants are usually installed on rooftops or in open spaces. They are designed to supply electricity to factories, warehouses, and other commercial and industrial buildings.

Types of solar power plants

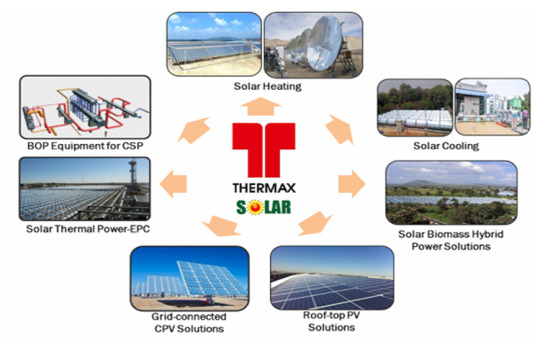

There are four primary solar power plants: Rooftop Solar Power Plant, photovoltaic (PV) plants, concentrated solar power (CSP) plants and solar water heaters.

Photovoltaic Plants: Photovoltaic plants convert sunlight into electricity. They are the most common type of solar power plant.

Concentrated Solar Power Plants: Concentrated solar power plants use lenses or mirrors to concentrate sunlight upon a small area. The concentrated light is then used to generate electricity.

Rooftop PV Systems: Rooftop Solar Power Plant are installed on the roofs of buildings. They are usually smaller than other types of solar power plants.

Solar Water Heaters: Solar water heaters use sunlight to heat water.

Considerations before installation

1. The first thing to consider is the amount of sunlight that hits the proposed solar panel site throughout the year. The more sun, the better, but even a moderate amount of sunlight can generate a significant amount of power if the system is designed correctly.

2. Another essential consideration is the orientation of the solar panels. They should be positioned to maximise exposure to sunlight.

3. The angle of inclination of the panels also affects performance; generally, it should be around 30 degrees from horizontal. It can be adjusted depending on latitude and time of year to optimise output.

4. The final primary consideration is shading from trees, buildings, or other objects. Of course, any shading will reduce power output, so it’s vital to ensure that the panels have unobstructed access to sunlight for most of the day.

Maintenance Of Solar Power Plant

Solar power plants require very little maintenance. Once they are installed, they can operate for decades with very little intervention. However, to keep your solar power plant running smoothly, you need to check the panels and clean them, if necessary, regularly.

You should also check the inverter and other electrical components regularly to ensure they are functioning properly. If any of the parts need to be replaced, you should hire a qualified technician to do the work.

If you follow these simple guidelines, your solar power plant will provide you with clean, renewable energy for many years to come.

Conclusion

Solar power is a renewable and sustainable source of energy that can be incorporated to generate electricity for industrial purposes. However, a few key points to consider before installing a solar power plant are the initial investment cost, the amount of land required, and the local climate conditions. Thermax also provides solutions for various small-scale industrial purposes. Machines like hot water generator from Thermax are also in high demand.

#Hot Water Generator from Thermax#rooftop solar power plant#Rooftop Solar Power Plants#Rooftop Solar Power Plant by Thermax#Nikhil TechnoChem

0 notes

Text

Benefits And Working Of Sewage Treatment Plant

Sewage treatment plants are used to remove impurities from water by using various physical, chemical, and biological processes. It is primarily used in industries where a large amount of wastewater is generated, like the textile industry, leather industry, food industry etc. Therefore, trusting highly ranked sewage treatment plant supplier like NTC is crucial.

Steps Of Sewage Treatment:

Screening: Screening is the first step of sewage treatment. It removes large objects like sticks and leaves from the sewage.

Primary Treatment: Primary treatment removes floating material and settleable solids from the sewage. It is done by allowing the sewage to flow into a tank where the heavier solids settle to the bottom and the lighter materials floats to the top. The solids are then removed from the tank and disposed of properly.

Secondary Treatment: Secondary treatment removes dissolved and small suspended particles from the sewage. It is done by using bacteria to break down the organic matter in the sewage.

Tertiary Treatment: Tertiary treatment polishes the water by removing any remaining suspended particles. It can be done through various methods, including filtration, disinfection, and aeration.

What Are The Benefits Of A Sewage Treatment Plant?

There are many benefits of sewage treatment plants. They help to improve water quality by removing pollutants from wastewater. This, in turn, protects public health and the environment. Treatment plants also help to reduce odours from wastewater, making it more pleasant for nearby residents. Additionally, they can save money for municipalities by reducing the need for expensive clean-up operations after a sewage spill.

What Industries Use Sewage Treatment Plants?

The industries that use sewage treatment plants are many and varied. They include:

• Agriculture

• Manufacturing

• Pharmaceuticals

• Steel and paper mills

• Food and beverage processing plants

• Textiles

• Semiconductor plants

How Does A Sewage Treatment Plant Work?

A sewage treatment plant is a facility where sewage is treated to remove contaminants before it is released into the environment. Sewage treatment plants are used in municipal, commercial, and industrial industries to protect public health and the environment.

Sewage treatment plants remove pollutants from wastewater using a combination of physical, biological and chemical processes. Physical processes include screening, sedimentation, and flotation.

Chemical processes include aeration, coagulation, and chlorination. Biological methods include activated sludge, trickling filters, and lagoons.

Conclusion

A sewage treatment plant is a crucial piece of infrastructure for any community. It provides many benefits, including cleaner water and air and recycling nutrients back into the environment. It also helps reduce the spread of disease by treating wastewater before it is discharged into the environment. Thermax also provides solutions for various small-scale industrial purposes. Along with being one of the top screw air compressor supplier, Thermax is also in high demand for steam generators.

0 notes

Text

Benefits of Rooftop Solar Power Plant in the Manufacturing Industries

Introduction

Solar power is among the most promising renewable energy sources. It is a clean and inexhaustible source of energy. It is widely used to generate electricity, heat water or provide light. In India, the manufacturing industry is one of the most vital contributors to the economy. Therefore, the benefits of a rooftop solar power plant in the manufacturing industries in India are manifold.

Benefits Of Rooftop Solar Power Plants

By installing rooftop solar panels, a manufacturing company can take advantage of the sun's free and abundant energy. Solar power can help offset a portion of the company's electricity costs, leading to savings on the bottom line. In addition, using solar power can help a manufacturing company reduce its environmental impact. Being a clean and renewable source of energy, Solkar energy does not produce emissions or pollution.

Rooftop solar panels can also provide a new source of revenue for a manufacturing company. When the solar panels produce excess electricity, it can be sold back to the grid at market rates. This extra income can help improve the bottom line and make the investment in solar power more attractive.

The Economic Impact Of Rooftop Solar Power Plant

The economic impact of rooftop solar power plant has been positive in the manufacturing industries in India. There are many benefits for the industry, including the fact that it reduces the need for expensive and polluting grid-based electricity, provides a new source of revenue for the industry, and helps to create jobs in the solar installation and maintenance sector.

Rooftop solar power plants can also provide a new source of revenue for the manufacturing industry. Manufacturers can offset some of their energy costs by selling excess electricity generated by the plant back to the grid. In addition, the sale of carbon credits associated with reduced emissions can also provide another revenue stream.

Finally, rooftop solar power plants can help create jobs in the installation and maintenance sector. This can be a boon for local economies, as well as providing training and employment opportunities for people who are interested in this growing industry.

Conclusion

The benefits of rooftop solar power plants are many and varied, but finally it comes down to the fact that they provide a cleaner and more efficient source of energy. They also have the potential to save manufacturing industries in India a considerable amount of money on their energy bills.

With the right regulations in place, solar power could play a major role in helping India's manufacturing industries become more competitive and sustainable in the long term. NTC also provides solutions for various small-scale industrial purposes - Ranging from steam boiler Thermax to compressors and much more.

#steam boiler thermax#rooftop solar power plant#Rooftop Solar Power Plant by Thermax#steam boiler by Thermax#Steam Boiler System

0 notes

Text

Flaws of Rooftop Solar Power Plants

This year, the renewables industry increasingly relies on private investments to propel the sector. Traditional and rooftop solar power plant projects were either stopped or delayed in 2020 owing to strict constraints, increases in solar panel import prices, and changes in solar regulations, such as lowering the net metering maximum for rooftop solar projects.

Regardless of the challenges, the fast advancement of solar PV technology and energy storage will provide several investment possibilities in the solar rooftop sector. As a result, India's total installed capacity will increase by 10 Gigawatts (GW) by 2021. This has been the most significant 12-month capacity gain, with a roughly 200 percent year-on-year increase. As a result, as of February 28, 2022, India had 50 GW of cumulative installed solar power.

It is a crucial step toward India's aim of producing 500 GW of renewable energy by 2030, with solar power accounting for 300 GW of that total. With capacity additions of around 6.5 percent to the cumulative worldwide capacity of 709.68 GW, India ranks fifth in solar power deployment.

According to industry estimates, 35GW of rooftop solar power will require an expenditure of up to Rs 1.5 lakh crore. Most installations will come from the C&I sector, state and central government auctions, and the residential sector. However, policy changes have been a critical impediment to India's spread of solar rooftop installations.

Rooftop solar is viewed as a potential threat to DISCOMs' market predominance. Rooftop solar reduces DISCOM's billing produced by high-paying customers, which they want to retain. Credit should be encouraged in the rooftop solar market by the government. Banks currently do not offer rooftop solar financing.

These loans are only accessible if the planned solar rooftop property is utilised as collateral. In this instance, the OPEX model will be the most preferable type of funding. In addition, India's fast proliferation of rooftop solar power generation installations makes it an attractive investment market for energy storage.

Energy storage technologies are becoming more affordable. Increased technology adoption, fueled by stringent net metering regulations, will increase demand for energy storage solutions. In addition, given the rise in grid prices and the need for cost savings, many more C&I units will be forced to adopt rooftop solar.

The CAPEX model covers over half of the country's C&I rooftop installations. It is the first model created specifically for rooftop solar installations. Under the CAPEX model, the client makes the initial investment and owns the facility. The client's investment in the building is recovered over a 3-5 year period by the power provided by the plant.

O&M fees are the responsibility of the consumer. The deferred CAPEX model, in which a consumer makes a down payment for the installation and EMIs over a 3- to 7-year period, is another rising technique. This model is led by companies such as Nikhil TechnoChem. Its success has enabled such companies to expand into new markets offering high quality items such as hot water generator from Thermax.

#rooftop solar power plant#Hot Water Generator from Thermax#rooftop solar plant#Rooftop Solar Power Plants#Rooftop Solar Power Plant by Thermax#Nikhil TechnoChem#Nikhil TechnoChem for Solar Power Plant#Nikhiltechnochem

0 notes

Text

Explore The Environment-Friendly Steam Boilers

Steam boilers have existed in various versions since the 1700s. Similar to rooftop solar power plants, steam boilers are now used in various applications, from homes to industry. It is one of the considerate methods of assuring less impact on the already harmed environment.

Boilers typically have a minimum capacity of 10 litres and a maximum capacity of several thousand litres. Steam boilers provide thermal energy via steam and power the factory's operations. It is a cost-effective method of generating electricity as electric energy gets increasingly expensive.

Boilers come in various sizes to fit in smoothly with the current process, which explains their growing popularity. Steam boilers are used in almost every industry: Breweries, Food Industries, Chemical Industries, Textile Industries, Automotive Industries, and Commercial Laundry Industries.

Every industry uses boilers for various purposes, and the powerful equipment never disappoints. Regardless of size or design, boilers are often constructed with certain common elements. The fuel supply combustion air system, ventilation system, and feedwater system are all shared components. They are classified according to the type of fuel they utilise, the type of structure they have, their size, their function, and other factors.

While the industry is working hard to transition to a more sustainable and ecologically friendly manner of manufacturing, steam boilers remain critical. As a result, steam boilers manufacturers are introducing more inventive designs and more efficient boilers to provide enterprises with greater efficiency and efficiency.

Boilers are classified into water tube boilers and flame or smoke tube boilers, often known as shell boilers. Boilers have a lifespan of more than 30 years if properly maintained and cleaned at regular intervals.

Industrial machinery requires steam boilers. They are widely used to clean construction materials, efficiently remove dirt and stains, and eventually clean brewery barrels and bottles while the mash is boiling. A regular boiler inspection may help ensure that your boiler operates at maximum efficiency and delivers the most heat for the least amount of money.

State and local rules typically demand boiler inspections. Noncompliance may result in hefty penalties or other repercussions. An expensive piece of equipment that fails prematurely can cost a lot of money and ruin your budget. It is also crucial to recognise that power-generating equipment might be hazardous if not handled appropriately. As a result, a frequent boiler failure study is required.

If you need to know which boiler is best for your business, specialists and pioneers like Thermax, globally recognised for their designs and industrial solutions, can assist you. However, to grasp the job, guarantee correct boiler maintenance, and improve your final result, you must seek the assistance of an expert.

Nikhil TechnoChem will provide you with the highest quality steam boiler from Thermax, services and solutions that will alter your game for the better. If you are seeking a solution to your industrial demands, call NTC immediately and experience uninterrupted operation at all times!

0 notes

Text

Screw Air Compressors - What Are A Few Challenges

Rotary screw compressors are commonly used in businesses that require a large amount of compressed air, such as garages, workshops, and manufacturing facilities. So why not get good compressors from a leading screw air compressor supplier ?

They outperform reciprocating machines in terms of energy efficiency, air capacity for the size, and up-time. On the other hand, the truth about rotary screw compressors is not as rosy as the industry would have you believe.

These machines have unique design flaws that cause serious issues such as air leakage, oil carryover, overheating, maintenance demands, and durability issues. Compressed air systems can be complicated, with what appears to be thousands of moving parts.

How often do you discover that X is dependent on Y is dependent on Z or that your application is only highly efficient when a piece of equipment works precisely? It is most likely a fairly common occurrence. When something goes wrong, the frustration of dealing with the complexities of how your system works is often amplified.

Are you hearing unusual noises or noticing leaks that appear overnight? All of these, and more, are common signs that your compressed air system isn't working properly. It, combined with normal day-to-day operations, can quickly exacerbate the problem. A fundamental design flaw exists in rotary screw technology:

Screw rotors create "blow holes" as they revolve, which are gaps between the rotors and the cylinders that run the length of the rotors from suction to discharge. Because air is lighter than oil and screws use oil to seal the gap between the rotors and cylinder walls, the gas percolates up through the fluid and then recirculates from the high-pressure discharge end to the low-pressure suction end.

It causes continuous internal air leakage, resulting in unavoidable energy losses. To compensate for this flaw, rotors must run at high rotational speeds (rpm) to achieve the ideal high "tip speeds" for minimizing re-circulatory losses. You can perform the following steps/checks daily to ensure smooth operation:

Examine the cooling fan of the body's own cooling system to see if it is functioning normally.

Check that the cooler's air duct is not clogged with foreign matter. If a problem arises, it must be resolved as soon as possible.

Examine the lubricating oil quantity and specifications. You must add oil if the lubricating oil level falls below the red line to ensure the use of oil products.

Examine the air filter. Excessive impurities will also have an impact on exhaust gas temperature control. Generally, the frequency of dirty air and clogged oil filters is higher.

Examine the thermal control valve.

Examine the fine oil separator. When the fine oil separator fails, the oil content in the air rises, necessitating the replacement of the fine oil separator.

Check the exhaust pressure to ensure it is within the range specified.

These are common checks you can conduct on the floor directly. Alternatively you screw air compressor suppliers will often provide regular maintenance and servicing options through their experts. This will reduce your burden and allow you to focus on more important things.

Companies like Nikhil Techno-Chem are leading screw air, rooftop solar plant, hot water generator and sewage treatment plant suppliers.

0 notes

Text

Understanding the Growing Popularity of Solar

Solar power generates just as much attention as it does energy. Globally, headline-grabbing ideas and innovations have fueled the fast adoption of household solar systems, from big-tickets. Popularity of rooftop solar power plants is a way to look at interest in this sector as well.

Items like China's projected 36,000km-in-space solar power station or Tesla's game-changing

Gigafactory to solar-powered electric car charging stations (one in Tauranga) and the ongoing improvement of PV panels and battery storage technologies are leading the charge.

Even conventional fossil fuel behemoths recognize the global move toward renewables. BP declared this month in its annual energy forecast that wind, solar, and other renewable energy sources will be the world's primary source of electricity by 2040.

Given how swiftly this new technology has taken up, solar power would be the fastest-growing source of world energy. When comparing the time it took for gas to get from 1% to 10% of global energy generation, it took more than 50 years, oil over 45 years, and renewables less than 25 years.

Transpower's Te Mauri Hiko project, completed at the end of 2018, exemplifies the unavoidable conclusion of solar's growing popularity. It is estimated that roughly 25% of future electricity in New Zealand will be technology-based and generated on-site or nearby (i.e., solar panels on houses and commercial buildings).

The following are the causes behind solar's global expansion:

The cost of solar panels continues to fall.

The industry's response to rising demand for solar installation.

The increasing popularity of electric vehicles and the demand for battery storage.

People desire to lower their energy expenditures, contribute to climate change mitigation, and become more self-sufficient.

Solar has grown from a modest business that some felt was extremely sophisticated or out of their price range to one that dominates debate and commands headlines. The popularity has developed in tandem with a shift in consciousness. We've seen a significant increase in battery sales over the last year since most individuals considering solar are already familiar with the technology and want to learn more.

Companies like Tesla are generating attention with their new operating systems and high-end modern items. People are already considering what kind of system they need at home to power an electric vehicle. Solar has successfully translated technology into real-world success stories.

The need for renewable energy is increasing. Solar companies will continue to be inventive to meet client demand and bring new products to market. Solar cells are still being manufactured using cutting-edge technologies. New and improved materials were introduced by scientists for the creation of new solar products. The discoveries allow manufacturers to create a wide range of solar applications, which will be in high demand in 2022.

Solar carports, solar-powered roadways, floating solar farms, and other uses will be in high demand. It is a fantastic opportunity for the solar sector since it creates new markets and opportunities. Companies like Nikhil TechnoChem are prepared for the boom with modern technologies like hot water generators from Thermax that are modern and advanced.

0 notes

Text

Problems Presented By A Screw Air Compressor

When most people think of an air compressor, they imagine a piston air compressor, also known as a reciprocating air compressor. These devices have been around for quite some time. Rotary screw air compressors, on the other hand, are an improved sort of compressor that surpasses more traditional ones in many respects. Here's all you need to know about rotary screw air compressors, choosing the best screw air compressor supplier, and dealing with possible difficulties.

Compressed air is one of the most critical components in the industrial production process. For example, rotary screw air compressors have several power applications across the assembly line in auto-assembly plants and newspaper pressing machines. As a result, air compressors are widely used and must be serviced regularly.

Even a well-maintained air compressor might have difficulties with its many components, which could indicate a larger problem. Unfortunately, many compressor operators disregard these warning signs, owing to a lack of familiarity with the symptoms. Consequently, having an air compressor troubleshooting guide on hand is critical for understanding how to manage specific symptoms and a list of steps to do with each problem.

In addition, these compressors have complex parts that can fail in various ways. If these flaws are not addressed, a modest issue may escalate into a costly system breakdown, demanding a part replacement. As a result, understanding the sounds and visual indicators of a failing compressor is crucial.

Due to a variety of reasons, a rotary screw air compressor may fail far sooner than its entire life expectancy. Air leaks, filter obstructions, and inadequate lubrication are all signs of a failing system. While periodic compressor maintenance is usually recommended, problems associated with system failure can still occur if certain defects and their symptoms go undiscovered.

Suppose your compressor abruptly shuts off when it reaches a certain temperature. In that case, the problem is most likely due to an excessive ambient temperature, a poorly ventilated workstation, the incorrect oil type, a filthy oil cooler, a malfunctioning thermostatic valve, or a clogged/dirty oil line.

Overheating is the most common cause of compressor burnout, which can occur when too much humid air is trapped in the work area, especially on compressors with obstructed vents. If the unit is up against a wall and the vents lack breathing space, consider moving the compressor to a better-ventilated location.

Rotary screw models are employed in various assembly applications, with the end result becoming typical fixtures in modern life. Furthermore, in today's increasingly environmentally conscious world, compressed air is used as an alternative power source for a wide range of high-tech applications that would otherwise waste vast amounts of energy.

Screw compressors generate far better air quality than piston compressors. The most qualitative of the outlet air temperature and the quantity of oiled air in the outlet, which will be maintained by replacing the filters during good hours of air quality, will be maintained.

So, seek for the best screw air compressor provider, such as NTC, who is also a leading sewage treatment plant supplier, among other things, to guarantee you get the best service.

0 notes

Text

A Brief Comparison Between Steam And Thermal Boilers

When direct heating is impossible, a heat transfer medium is utilised in industrial operations. Steam was once the sole option because the water was inexpensive and had few environmental problems. Steam heat transfer employs latent heat, the heat necessary to transform a liquid to vapour without increasing its temperature.Steam boilers from Thermax are currently some of the best in the industry.

The vaporisation or saturation pressure determines the temperature at which heat transmission occurs. Greater steam system pressures are required for procedures that need higher temperatures. For example, a pressure of 2,610 psi / 180 bar is necessary to achieve 662 degrees F / 350 degrees C.

Because of the increased pressure requirements, the heat exchanger tubes used in steam lines must be thicker and particularly designed, and high-pressure pumps must be employed, resulting in greater construction and running expenses. One of the primary benefits of employing steam boilers is that they do not require any external energy sources to generate flow.

It means you won't need to invest in expensive pumps and regulators because steam allows it to produce flow organically, allowing it to reach all regions of your premises where it needs to be. Steam is extremely light, Rooftop Solar Power Plantand heated air rises. It implies that you may easily build flow to the higher portions of your property when employing a steam boiler.

It is especially beneficial in towering buildings where other heating techniques may struggle or be unsuccessful, making them suitable for more extensive settings that require a cost-effective heating solution. Thermal fluid heaters are known to be more efficient than traditional steam systems—Flash losses in a typical steam system range from 6% to 14%.

Add blowdown losses of up to 3% and de-aerator losses of 2%. The contrast in efficiency between the two systems is obvious since thermal fluid systems suffer none of these losses and can function up to 30% more efficiently. Corrosion is a common concern in steam systems. Metal corrosion is caused when hot water, air, and salt mix to form solids. Scale and other mineral deposits accumulate, accelerating corrosion.

Thermal fluids are non-corrosive and offer excellent metal surface protection. Although it is not essential, vessel and pipe designs for hot oil heating systems sometimes include a minimal corrosion allowance. Steam systems rely on pressure and temperature management. Still, as the system ages and corrosion takes its toll, it becomes more challenging to monitor and maintain the correct and steady temperature that all manufacturing operations require.

Thermal fluid systems are noted for their ability to deliver efficient and consistent heating as well as uniform cooling. The overall purchasing costs of steam systems are lower than those of thermal fluid systems.

Please contact them if you want to learn more about how NTC's staff can assist you with boiler installations, sales, maintenance, and repairs. Companies like Nikhil TechnoChem also offer some of the best steam boilers and services and setups.

0 notes

Text

Sewage Water Treatment - What It Looks Like In India

Almost 80% of the water supply is returned to the ecosystem as wastewater. If not properly managed, this can pose a serious environmental and health risk, but proper management can assist water managers in meeting the city's water demand. India has been growing in numbers with many industrial sewage treatment plant suppliers providing smart solutions.

According to the Central Pollution Control Board's 2015 report, India can treat approximately 37% of its wastewater, or 22,963 million litres per day (MLD), against a daily sewage generation of roughly 61,754 MLD. Furthermore, most sewage treatment plants do not operate at total capacity and do not meet the required standards.

In collaboration with the 2030 Water Resources Group, the Council on Energy, Environment, and Water (CEEW) completed an in-depth study on finding viable pathways for improved wastewater management in India. This study focuses on a framework of critical decision-making factors.

This research included a critical review of the literature, a comparative analysis of wastewater treatment technologies, an in-depth examination of 17 global case studies, expert interviews with wastewater treatment plant operators, academicians/researchers, urban planners/architects, and technical and financial experts.

The following eight factors were identified as the most important for making an informed decision:

Drivers of wastewater management implementation,

Policies and procedures,

Technology and financial access

Intervention scale,

Management strategy and organisational structure,

Public opinion,

Deployment phases and a framework for a participatory approach

These factors must be considered together; focusing on just one aspect, as often seen in interventions, may result in failure or under-performance. Water scarcity, for example, is the primary motivator for launching wastewater reuse initiatives worldwide; however, the enterprises must be supported by well-crafted policies and regulations, as well as access to technology and finance.

Many people are unaware that wastewater can be converted into reusable water. Toxins are removed during the treatment process, resulting in clean, safe water. Only about 3% of the water on the planet is drinkable. It is a renewable resource; however, evaporation and rain take a long time to remove toxins.

With wastewater treatment, the process is sped up and results in crystal clear, safe reusable water. A properly maintained and operated Industrial Wastewater Treatment system can also help you save money in the long run, as well as ensure compliance with regulations and legislation. The primary goal of water treatment is to remove harmful chemicals.

As a result, when it enters the ground, it will have no negative impact on the environment. If you're dealing with industrial waste, it could not be easy. An important investment is a high-quality wastewater treatment system. Industrial wastewater treatment is a method of reducing waste in the environment.

It not only saves money but also ensures that chemically treated water is removed in a safe and environmentally friendly manner. One thing to keep in mind is the importance of having a high-quality system in place. Therefore, it is critical to select a reputable company to handle the installation of your effluent treatment plant.

Examine online recommendations and choose a company with years of experience in the field that complies with discharge regulations. Companies like Nikhil TechnoChem are some of the best sewage treatment plant suppliers around.

0 notes

Text

Basic Steam Boiler Flaws And How You Can Easily Avoid Them

While boilers can have problems with their equipment, improperly balanced water is more likely to cause problems. Many boiler issues begin with poor water quality. Poor water quality can eventually cause damage to a good boiler's components, even a steam boiler from Thermax. Common boiler feed water issues or condensate return water problems can cause severe damage to the unit.

If you notice any equipment problems, consider all possible causes, including water chemistry issues that may necessitate treatment to rebalance it. Instead of waiting for a problem to arise, learn how the most common water quality issues arise and how to avoid them.

Water Spills/Leaks

Water leaks can occur throughout the steam system. Look for dripping around the tank or its pipes, but leaks can happen anywhere. Water can also exit the system via the air vents. These hidden leaks make it much more challenging to identify a problem. A water meter will tell you if a closed system is losing water, even if it is coming from a hidden hole. A water leak in a secure system will eventually reduce the available water level to the point where the system will shut down. If the water level does not drop significantly but the system leaks, it is possible that atmospheric moisture is entering the system. This untreated water in your tank can lead to premature wear.

Sludge in Greater Quantities Than Usual

Sludge is similar to more solid scale deposits but has a softer texture. Sludge is exposed to high temperatures when it reaches the boiler tank. However, it will typically harden only when the water level drops, such as when draining. The sludge hardens and forms a baked-on layer inside the boiler tank. This baked-on sludge can then cause scaling issues. Another issue with sludge is that it accumulates in areas with low water pressure or flow rates. Continued buildup without checking can raise the temperature inside the pipes by insulating that area of the boiler system. Water flow can be restricted by buildup anywhere in the boiler.

Issue With Scale Building Up

Poor water quality can cause significant damage to your boiler system. Minerals in the water, such as calcium and magnesium, can build up as scale deposits in the boiler and pipes. These deposits can either slow or completely block the steam passage through the system. Scale is the leading cause of efficiency loss in your steam boiler system. Scale buildup can reduce heat exchanger effectiveness and prevent hot water in the boiler from reaching the required temperature. As a result, removing and preventing scale buildup will restore your boiler's efficiency.

Many system problems, from minor to severe, can be avoided with boiler water treatment. In addition to filtering, monitoring water quality, and adding chemicals as needed to maintain balance, the initial treatment of the water is critical.

Connect with a good service provider of steam boilers like Nikhil TechnoChem who have experts that can easily smoothen your operations. They also are prominent screw air compressor suppliers.

0 notes

Text

4 Ways Solar Panel Efficiency Can Be Improved | Nikhil Technochem

Solar panels do not perform consistently in all situations, but you may take proactive actions to increase the efficiency and output of your solar system architecture or array. These simple steps will ensure you get the most out of your rooftop solar power plant.

From situating solar panels for the best power generation to qualifying for utility rebates and green energy subsidies, these four suggestions can help you optimize the output of your solar panels and save money on electricity.

Avoid Putting up Solar Panels in Shady Places

Because solar panels create energy from sunshine, it stands to reason that shadow reduces power output. Many individuals, however, are unaware of the impact of shade on a line of solar panels. Even if only one solar cell is shadowed, the energy generated by its neighboring cells might be affected. It is due to its function as a resistor. Tall trees and other structures are the two most common culprits for shadowing solar panels. Spend time throughout the planning phase analyzing a location to guarantee that shadow will not be an issue.

Purchase One of the More Energy-Efficient Solar Panel Models

Photovoltaic cells are used in solar panels to convert solar energy from sunshine into electricity. Although it would be fantastic, a solar panel cannot convert all the solar energy it absorbs into power. As a result, the efficiency of a panel is the percentage of energy that hits the panels that the solar cells convert into electricity. Despite the higher initial cost, purchasing one of the more efficient kinds of commercial solar panels is possibly the most crucial thing you can do if you want the greatest results.

Keep Your Solar Panels Clean

Solar panels require extremely minimal maintenance since they have no moving parts. However, cleaning your solar panels regularly is essential since dust and debris can gather on the surface and reduce performance. The frequency with which you should clean your solar panels is determined by various factors, including how frequently it rains and how much it costs to get them cleaned. Dust and filth may only cause a 5% decrease in production over a year. However, if they get unclean — for example, in an area that does not receive regular rainfall - the production might drop by more than 20%. As a result, cleaning your solar panels once a year is a good idea.

Hire a Professional to Install Your Solar Panels

If solar panels are not correctly mounted, they will not get the maximum amount of sunshine and produce less power. When installing panels, the orientation and angle are two of the most critical factors. Solar panels should be installed at 18 to 36 degrees for excellent sunshine exposure. Temperature levels, strangely, affect solar panel efficiency. As the temperature rises, the efficiency of solar panels decreases. During installation, sufficient space should be allowed between the solar panels and the roof. It enables simple airflow and keeps your photovoltaic solar panels from overheating.

An expert from a company like Nikhil TechnoChem can help. They are the suppliers of rooftop solar panels for industrial applications. If you need other equipment like a hot water generator that Thermax manufactures, then connect with Nikhil TechnoChem.

0 notes

Text

Rooftop Solar Power Plant by Thermax | Nikhil Technochem

EPC and O and M services for rooftop solar power plants and solar photovoltaic off-grid and grid-connected power projects in Kanpur. Contact us!

0 notes

Text

Rooftop Solar Power Plant by Thermax | Nikhil Technochem

EPC and O and M services for rooftop solar power plants and solar photovoltaic off-grid and grid-connected power projects in Kanpur. Contact us!

0 notes

Text

The Internal Functionings of Screw Air Compressor | NTC

Indians have recently started seeking suitable screw air compressor suppliers for industrial applications. Knowing more about the equipment can help guide you in your pursuit. Air compressors function by blowing air into and pressurizing a container. The air is then driven through a hole in the tank, where pressure builds up.

Consider it an open balloon: once the compressed air is released, it may be used as energy. They are propelled by an engine, which converts electrical energy to kinetic energy. It functions similarly to a combustion engine, with a crankshaft, piston, valve, head, and connecting rod. The compressed air may then be utilized to power several pieces of equipment.

Nailers, impact wrenches, sanders, and paint sprayers are some common alternatives. In addition, there are several sorts of air compressors, each with its own expertise. Air compressors may be found in various settings, from corner gas stations to large manufacturing operations.

Air compressors are also increasingly being found in home workshops, basements, and garages. In addition, models suited to tackle every task, from inflating pool toys to powering equipment like nail guns, sanders, drills, impact wrenches, staplers, and spray guns, are now available in local home stores, tool dealers, and mail-order catalogs.

The main benefit of air power is that each tool does not require its own large engine. Instead, a single motor on the compressor converts the electrical energy into kinetic energy. This results in lightweight, compact, easy-to-handle instruments that run silently and have fewer wearable components.

Like a tiny internal combustion engine, a traditional piston compressor has a crankshaft, a connecting rod and piston, a cylinder, and a valve head. An electric motor or a gas engine powers the crankshaft. While tiny types only include the pump and motor, most compressors feature an air tank that holds a certain amount of air within a predefined pressure range.

The compressed air in the tank powers the air tools and the motorcycles on and off to maintain tank pressure automatically. A valve head at the top of the cylinder houses the intake and discharge valves. Both are little more than thin metal flaps. To meet the needs of the tools they power, standard compressors are available in 1- or 2-cylinder configurations.

On the homeowner/contractor level, most 2-cylinder machines work similarly to single-cylinder ones, except that there are two strokes every rotation rather than one. In addition, some commercial 2-cylinder compressors have two pistons that push air into a second cylinder, increasing pressure.

Compressors employ a pressure switch to shut off the motor when tank pressure exceeds a predetermined limit—about 125 psi for many single-stage models. However, most of the time, you don't need so much pressure. A diaphragm compressor can be helpful where air demand is low.

A membrane between the piston and the compression chamber shuts off the air and prevents leaking with this arrangement. Companies like Nikhil TechnoChem, who are experts in Rooftop Solar Power Plant, have also gained expertise in screw air compressors and have become its suppliers

0 notes